Frame material

Unlike capital, heavy structures in the form of greenhouses, the design of a greenhouse made of arcs is as lightweight as possible. Its advantage is that installation takes little time. Even a child can handle the installation of such a greenhouse.

A greenhouse made of arcs can be installed anywhere on the site and moved, depending on what crop is supposed to be grown in it. This is very convenient from the point of view of observing crop rotation in the area.

The basis of this type of greenhouse is made of plastic or metal arcs. The main requirement for the material is its strength and at the same time flexibility. There are greenhouse arcs of the following types:

- — Arcs made of polyvinyl chloride. PVC is a thermoplastic material, resistant to aggressive acidic and alkaline environments, low-toxic. Such arcs are light and at the same time quite durable.

- — Metal arcs. They are made industrially from thin metal pipes or independently from thick wire.

- — Polypropylene arcs. For this purpose, a plastic pipe is used, cut into pieces of the required length. The main condition when choosing is the ability of the pipes to bend easily and take a rounded shape.

How is it different from a regular greenhouse?

Greenhouses made from arcs have their own characteristics:

- they are never heated, which does not make it possible to grow heat-loving plants and some berries in it throughout the year;

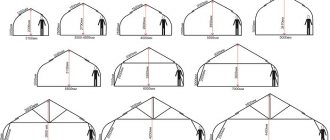

- the height cannot be sufficient to make it comfortable to walk in or plant tall plants, because the maximum value is 1.6 m. At the same time, a stationary structure can be made of any height (over 2.2 m);

- constructed only for the period of spring, summer and autumn;

- The minimum temperature from which an arched greenhouse can protect plants is -5°C.

Which to choose?

Ready-made arc greenhouses are currently widely available for sale. Each site owner makes his choice depending on the price and purpose of the structure. The most popular greenhouses are:

- "Dayas." A greenhouse based on polymer arcs with sewn-in covering material. The diameter of the pipes is 20 mm, length is 2 m. Fastening to the ground is carried out using legs. The number of pipes in the kit allows you to make a tunnel from 4 to 6 meters long. The width of the covering material is 2.1 m.

- "Snowdrop". The frame is made of PVC arches with a diameter of 20 mm. Covering – non-woven covering material with a density of 42 g/m2. Has different lengths (4,6,8 m). Supplied with feet for installation and clips for fastening.

- "Palisade". Steel arches are used as a frame. Height - 50 - 60 cm. Complete with covering material or polyethylene film, special plastic clips for fastening the covering.

- "Cucumber." Height 1 m, length 5 m. Frame – galvanized steel profile. Covering: polyethylene film with fastenings. It is equipped with slats for fixing the film in the open state. Assembly is carried out using screws and nuts that secure the arcs to the base of the boards. The covering is fixed with the cords included in the set, for which grooves are provided in the arcs.

In addition to ready-made kits, you can purchase separately arches and suitable covering material.

Comparison of indicators of greenhouses with different coatings

The comparison of indicators is shown in the table:

| Indicators | Coating material | ||

| Polyethylene film | Spunbond | Cellular polycarbonate | |

| The complexity of making a greenhouse | average | average | average |

| Labor costs for the construction of a greenhouse measuring 3x6 m, person*hour | 12…16 | 10…12 | 4…6 |

| Average cost per square meter of greenhouse, rub./sq.m | 400…600 | 300…500 | 1000…1300 |

| Effectiveness of maintaining a comfortable temperature for plants | average | above average | high |

| The need to remove the coating in winter | Yes | la | No |

| Average yield of determinate varieties of tomatoes, kg/sq.m | 4…6 | 5…8 | 6…8 |

| Average yield of indeterminate tomato varieties | 6…8 | 7…10 | 9…12 |

| Can be used for heated winter greenhouses | No | limited | Yes |

| Coating service life according to manufacturers | 1 | 3 | 20 |

| User rating on a five-point scale | 4,2 | 4,6 | 4,7 |

| Customer preferences when choosing material and design on a five-point scale | 3,2 | 3,5 | 4,3 |

Pros and cons of designs

Greenhouses made from arcs are convenient due to their mobility and ease of installation.

Installation does not require the construction of a foundation .

For the winter, such a greenhouse can be easily stored when folded, which means it saves storage space.

In addition, they are quite cheap compared to expensive stationary greenhouses.

However, the greenhouse also has a number of disadvantages:

- — The external insulating coating is not durable enough and requires regular updating.

- “For all the lightness of the structure, it can just as easily move under the influence of strong winds.

- — Additional heating cannot be installed in a greenhouse, as in a stationary greenhouse.

With your own hands

If it is not possible to purchase a ready-made greenhouse made of arcs with covering material, you can make it yourself. The greenhouse consists of a frame and cover. Let's consider options for making a greenhouse with your own hands.

The arcs that make up the frame are the main part that serves as the basis. Any covering material can be placed on this base, which can be replaced as necessary. There are several options for making arcs:

- — From a hose and wire (or willow twigs). An old hose that is not used for its intended purpose is cut into blanks into which metal wire or willow rods are inserted. Each piece is then given an arched shape. The arcs are stuck into the ground along the length of the bed at a distance of 50-60 cm from each other.

- — From plastic pipes. The basis for the arcs are metal pins stuck into the ground along the length of the bed. Bent pipes are put on them. The length of the pipe sections depends on the desired height of the greenhouse. But it is not recommended to make sections more than 3 m in length - a greenhouse of such a height will be unstable and it will be inconvenient to care for plants in it. To strengthen this design, you can screw an additional pipe on top using wire.

- — From PVC pipes. For such a greenhouse, it is necessary to make a frame from wooden boards, to which bent sections of pipes are attached. With this design, the pipe material does not stick into the ground and does not corrode.

- - Made of metal profile. Such a frame is strong and stable, but to manufacture it you will need special equipment - a pipe bender. Using this device, the pipes are given the desired shape. Since the greenhouse requires a small diameter pipe, a manual pipe bender can handle this task.

You can see several easy-to-assemble greenhouses made from arcs with covering material in this video:

You can see other greenhouses that you can also assemble or make with your own hands here: From polycarbonate, From window frames, For seedlings, From a profile pipe, From plastic bottles, For cucumbers, Under film, For the dacha, From PVC, Winter greenhouse, Wonderful dacha , Successful harvest, Snowdrop, Snail, Dayas

Types of designs

There are several design options for such structures, and they depend on the material from which the arcs are made:

- An arch made of dense and hard wire coated with a polyvinyl chloride (PVC) sheath that protects against rust and mechanical damage.

- An arch made of metal tubes with a diameter of 10–12 mm, which are also protected by a PVC sheath. These arches are characterized by increased rigidity and stability.

- Arch made of plastic pipes with a diameter of 20–30 mm. The disadvantage of the design is less reliability and durability, plus the risk of damage from strong winds.

Selection of covering material

For the successful cultivation of vegetables in a greenhouse, the choice of covering material is of no small importance. It must meet the following requirements:

- - It's good to let in the sun's rays.

- — Protect plants from cold air as much as possible.

- - Have sufficient strength for long-term use.

Two types of material have all these qualities:

1. Film.

There is a wide selection of films for greenhouses and greenhouses of different widths, prices and quality on sale. The cheapest option is regular polyethylene film. But its price is the only plus. It is quite thin and can only be used for one season, or at most two.

Reinforced or air-bubble film materials are more durable, although somewhat expensive.

REFERENCE! They are more expensive than regular film, but much more durable.

In addition, due to their thickness, such materials can withstand lower temperatures and better protect plants from adverse conditions.

2. Nonwovens.

They are very popular among vegetable growers.

Any brand of such material varies in thickness. The lightest material is the density of 17g/m2.

The densest thickness is 60 g/m2.

The optimal option for covering greenhouses, combining sufficient density and excellent breathability, is a density of 42g/m2..

ATTENTION! Experienced vegetable growers advise using two materials for arched greenhouses.

The frame is covered with film at the beginning of the season, before planting and when sowing seeds in the ground. The fact is that such a coating helps the soil to quickly warm up and retain maximum heat to improve seedlings.

Then, when the crops have sprouted or the seedlings are ready for planting in the greenhouse, the film covering is replaced with non-woven material. This coating allows the plant to breathe, which means it prevents the plants underneath from overheating. Replacement with non-woven material is carried out when heat sets in.

IMPORTANT! It is not recommended to cover a greenhouse made of arcs with a thin non-woven material, since under the influence of friction it will tear and is unlikely to serve you even until the end of one season.

Types of agrofibre

The general name “spunbond” combines several types of materials for attaching to a greenhouse with different characteristics. It is divided by color (mainly white and black), density, thickness.

White canvas is used to shelter seedlings from environmental influences. It scatters light well, ensuring rapid heating of the soil and creating an obstacle to the penetration of harmful UV radiation. White spunbond is attached to a greenhouse, creating a favorable microclimate for plants: moisture is passed through, the soil surface remains loose without crust, which ensures the supply of oxygen to the roots of the plants. Light stabilizers are usually added to the composition.

Black agrofibre is used to prevent soil erosion and keep fruits clean. Two-color spunbonds are used for the greenhouse. The upper white or foil side reflects light, accelerates the ripening of fruits, and the inner black side prevents weeds from germinating.

Colored dyes are added to the canvas. In this case, the material is used for decorative purposes: for sewing disposable clothing, for advertising and hygiene products. There are laminated spunbonds for greenhouses that have a polypropylene base. The material is of increased density with a smooth surface, air and moisture resistant.

The range of agrofibre is not limited to division by color; they can have different thicknesses, densities, and special additives (for example, a reinforcing layer).

Material Density

Spunbonds for greenhouses with different characteristics are on sale. When choosing, take into account its density. It is determined based on:

- the type of structure being built and its dimensions;

- time of planting seedlings under cover;

- possible height of seedlings in a greenhouse;

- the likelihood of cold snaps and frosts.

Spunbond No. 42 in a roll for greenhouses and greenhouses

There are canvases with low density (up to 20 g/m2), medium (20-45 g/m2) and high (more than 45 g/m2). Covering material of the first type is suitable if it is necessary to protect plants at low temperatures - down to -2°C. Spunbond for a greenhouse protects well from UV radiation because it contains light stabilizers, retains moisture in the top layer of soil, and protects from wind and insects. Its use is justified when growing early vegetables and other garden crops.

Spunbond with a density of 20-45 g/m2 is used to cover a greenhouse in which plants will be grown during possible frosts down to -5°C. It transmits sufficient light, retains excess moisture, and is suitable for plants whose fruits rot due to excessive watering. Covering material is used in warm winters and early spring; it can withstand layers of snow up to 5 cm. It can be used in the fall to prolong the growing season. When installing medium-density fabric, you should not use sharp pegs to prevent damage; it is better to use staples.

High-density spunbond creates a greenhouse effect and protects from cold temperatures down to -10°C. It provides rapid heating of the soil, allowing seedlings to be planted at the very beginning of spring. Agrofibre can withstand snow and gusty winds. The choice of covering material should be a dense product if the greenhouse is installed in climate zones with a cool climate.

Blade thickness

The thickness of spunbond for a greenhouse is measured in microns and depends on its density. The higher it is, the thicker the material turns out. The scope of application is determined by this property. The thickness of spunbond for a greenhouse depends on the raw materials used for its production. The technology is as follows:

Installation Rules

Prepare arcs, covering material and stones or bricks. The prepared area is dug to the required width. Depending on the design of the greenhouse, we install arcs, sticking them into the ground at a distance of 50-60 centimeters from each other, or screwing them to the prepared frame. We make additional fastenings with ropes. Wire, slats.

We cover the frame with the prepared covering material and secure it at the bottom with bricks or stones. If the design provides additional fastenings for covering material, we also install them.

Your greenhouse is installed in the right place and everything is ready for planting the intended garden crop. Now the plants are protected from possible frosts and the harvest is guaranteed.

Greenhouse “Breadbox” and “Butterfly” - photo

This design is called a “bread box” because it looks exactly like a plastic bread container. Its lid also rises upward, hiding behind the second half. If you look at the photo, you will understand everything.

You can weld such a greenhouse-breadbox with your own hands from a profile pipe

There are two types of such products: opening on one or both sides. If it is shallow, you can work with a lid that opens on one side. If the width is more than a meter, it will be easier to work if there is access from both sides. This design with two opening sides has its own name: “Snail”.

A film or spunbond is stretched over the manufactured frame, but polycarbonate is more popular for this design.

The second design differs in the type of door opening. Its vault is also made on arches, but opens on hinges upward (see picture).

Butterfly greenhouse: when open, the lids resemble wings

They can be installed directly on the ground or on a prepared foundation made of bricks or timber. In some cases, the lids do not open immediately from the ground, but there is a small side of 15-20 cm.