Every gardener is interested in getting the largest possible harvest of vegetables, and since a greenhouse plays an important role in this, its acquisition plays the main role. Today on the market you can see a huge number of models of greenhouse structures, each of which has its own characteristics and advantages. The Krepysh polycarbonate greenhouse also has them.

As is already clear from the name, this is a low but fairly reliable structure, the use of which will significantly increase the yield of grown vegetables, mushrooms, flowers or various garden crops.

Prices for greenhouses "Krepysh"

| Size | Frame price | Frame + polycarbonate Omsk density 0.52 4 mm | Frame + polycarbonate 4mm “Siberian Greenhouses” 0.62 10 years warranty. | Frame + polycarbonate 4mm Omsk density 0.8 "Kronos" | Installation | Beam processed for foundation 100*100/100*150 |

| 3*4 | 8200 | 13600 | 14200 | 16900 | 3000 | 2500/3000 |

| 3*6 | 9200 | 16400 | 17200 | 21700 | 4000 | 3000/3500 |

| 3*8 | 10200 | 19200 | 20200 | 24700 | 5000 | 4000/5000 |

| 3*10 | 11500 | 22300 | 23500 | 28900 | 6000 | 5000/6000 |

Installation Features

Due to the fact that the kit always includes detailed instructions, you can assemble the structure in just a couple of hours. Naturally, you can’t do it without tools. You will need:

- a screwdriver that can be replaced with an electric drill;

- crosshead screwdriver;

- wrench;

- construction knife;

- power extension cord.

In the case when the installation of the “Krepysh” greenhouse is not permanent and the greenhouse structure is planned to be moved in the future, there is no need to equip the foundation: in order to securely strengthen the frame in place, the greenhouses are equipped with T-shaped mortgages, which during assembly need to be deepened into the ground by 50 cm, and then thoroughly compact the soil around it.

But, if the structure is placed in a permanent place, the manufacturer recommends building a foundation: wet soil is not the best environment for metal: in late autumn or early spring, when the soil thaws at noon and freezes again in the evening, the moisture, turning into ice, will begin to destroy the material. At first, this will not be very noticeable, but over time, those parts of the frame that will come into contact with the soil will become unusable and the structure will become unusable.

Long service life and increased productivity of your plot

Its use in Krepysh greenhouses increases productivity by 30 - 60 percent compared to the use of glass or film. The reason is that light rays are scattered in all directions, not just from above. Thus, the plants inside the greenhouse receive maximum light, which reaches them with virtually no ultraviolet radiation.

Making greenhouses using cellular polycarbonate is advantageous, first of all, because the service life is approximately 15 years, which cannot be said about the same glass, and even more so about film. Polycarbonate is also not afraid of difficult climatic conditions and mechanical damage. Therefore, it is not afraid of snow cover, and the temperature range is from -10 to +120 degrees.

Greenhouse assembly

When ordering a Krepysh greenhouse in Yekaterinburg, the delivery package includes:

- cellular polycarbonate,

- prefabricated frame from individual integral parts,

- various accessories for installing a greenhouse.

The maximum installation time for a greenhouse is about eight hours, and this can be done either independently or with the help of our company’s employees. For self-installation, no specialized equipment is required, because for this you need: a Phillips screwdriver, a screwdriver, a construction knife and a wrench.

Assembly and installation of the Krepysh greenhouse

The kit includes a frame, arches, polycarbonate and fittings. The whole set weighs 160 kg. The base takes up to 2.5 m, polycarbonate 2.1x6 m. Assembly and installation of the Krepysh greenhouse must be carried out according to the attached instructions. The design parts are all-welded, so assembly is simplified as much as possible. You just need to connect a few elements, and the structure is ready.

The manufacturer offers the following step-by-step instructions:

- Prepare a gravel layer and level the soil.

- Install a foundation made of wooden beams 100x100 mm thick. A more reliable base is made of cement mortar using formwork.

- Deepen the reinforcing T-shaped embeds 500 mm into the ground and thoroughly compact the soil.

- Attach the frame to the foundation frame.

- Connect the arcs to the base using self-tapping screws.

- Install the end parts.

- Attach additional modules.

- Install doors and windows.

- Cover with polycarbonate.

Attention! The Krepysh greenhouse can be installed without a foundation. However, a small base will protect the metal from corrosion and extend its service life.

Required Tools

The greenhouse can be assembled with a small set of tools:

- construction knife;

- wrench;

- Phillips screwdriver;

- extension cord for connecting to the mains;

- drill or screwdriver.

Foundation

The manufacturer recommends making a foundation for installing the greenhouse. Corrosion occurs when metal and soil interact directly. The construction of the foundation significantly extends the life of the structure.

- The foundation is constructed from timber 100x100 mm wide. Wooden elements must be treated with primer and coated with paint. In the selected area, it is necessary to remove the top layer of soil level.

- Lay geotextiles and cover with a sand and gravel cushion. Install a timber frame to the size of the greenhouse.

- The concrete base increases the reliability of the structure. It is necessary to remove a layer of soil around the perimeter. Build the formwork and fill it with sand-cement mortar according to the level.

Installation of frame and ends

Installation is carried out in the following steps:

- The frame is attached to the erected base according to the instructions supplied with the greenhouse.

- The arcs are fastened sequentially with self-tapping screws in increments of 1 m.

- Then it is necessary to securely fasten the ends of the Krepysh structure. At this stage, it is necessary to strictly adhere to the level.

- Install doors, vents, and additional structural elements.

Sheathing

Cellular polycarbonate is durable. It does not form fragments under strong mechanical stress. Withstands the loads of long-term snow.

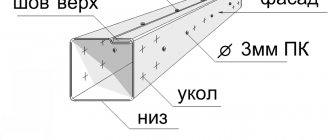

Advice! It is necessary to sheathe the greenhouse frame only across the polycarbonate stiffeners. Otherwise, the material will quickly become unusable.

Main characteristics and advantages of the Krepysh greenhouse

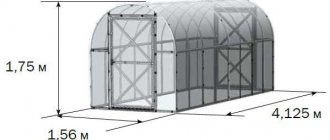

“Krepysh” polycarbonate greenhouses are sold in various sizes. The width and height of the greenhouse are 3 and 2 meters. The length can be 4, 6 and 8 meters. Depending on the length of the greenhouse, the number of frame arcs increases from 1 (for a length of 4 meters) to 3 (for a length of 8 meters). This is necessary in order to increase the strength of polycarbonate sheets and make the structure as safe and reliable as possible.

Unlike other types and types of greenhouses, polycarbonate fortress has the following features:

- First of all, the reliability of the structure is achieved by making a frame from steel pipes. The arched parts are represented by solid elements, without joints or additional connections.

- Secondly, to increase the service life, a special anti-corrosion layer is applied to the metal, which protects the surface of the frame from high humidity inside the greenhouse.

In addition, during the manufacture of greenhouses, customer wishes for additional ventilation windows in addition to the two standard ones are taken into account. Therefore, having decided on the dimensions of the “Strong”, contact our consultants, who will place your order, advise on the optimal options for locating openings for ventilation, etc.

Why is the Krepysh greenhouse so famous?

Here are the main advantages of the domestic greenhouse “Krepysh”:

- Factory welding from a 25x25 mm profile pipe with a cross-section of 1.5 mm.

- The wide door is almost a meter, which makes it easy to carry a motor cultivator into the greenhouse.

- Large windows do not have to be installed along the entire length of the greenhouse.

- All-welded end walls provide strength and greatly simplify assembly.

- Stability of the frame under any snow and wind loads.

- All-welded arcs every meter.

- Door and window at each end.

- Strong polycarbonate "Polyplast", which is well known for its quality.

But what pleasantly surprises buyers is that the greenhouse also comes with legs. There is one more bonus: each set of such a greenhouse comes with special fasteners for polycarbonate, which well protects the greenhouse itself from dirt, thereby extending the life of its coating.

Additional equipment

Residents of those regions where heavy snowfalls are not uncommon, in order to be on the safe side, can install arcs in increments of not 1 m, but 0.50 cm. To do this, it is simply enough to purchase additional arcs and T-shaped supports, which are placed under the arcs for the winter period. Then no snowfall will be scary - even if the greenhouse is completely covered with snow - it will still withstand the load and stand. This is especially important for those vegetable growers who grow vegetables in the country, but go to the city for the winter and do not have the opportunity to frequently check the condition of the greenhouse.

Note: In addition, you can also increase the number of vents that are installed on the roof.

This will make it possible to ventilate the “Krepysh” polycarbonate greenhouse more efficiently and then the plants will not “cook” on a summer afternoon from the very high temperatures inside the greenhouse. If you add an automatic watering system to your arsenal, caring for your plants will become even easier.

Advantages of our greenhouses:

1. The frame of our greenhouses is made of galvanized profile pipe. In order for the galvanized pipe to retain its properties longer, it is additionally treated with a preservative compound. 2. Our greenhouses are assembled using guides that allow the installation of arcs with longitudinal ties in one plane, thereby avoiding the gap between the polycarbonate and the greenhouse frame, increasing the service life of the polycarbonate and facilitating the assembly process.

Build process Build process

3. Our greenhouses do not require a foundation, which significantly allows you to save your money and time (included are embedded pipes 30*30, 0.5 m long for each arc), whereas most manufacturers do not include a foundation in the package of greenhouses . 4. The polycarbonate that we use for greenhouses is produced in Belgorod. He has U.F. protection both in the mass of the sheet and on one side additionally. Delivery of our greenhouses is free. 5. Payment for our greenhouses is made upon delivery or assembly, which saves your time and protects you from dishonest sellers. All these advantages guarantee you a reliable greenhouse and a high yield. We manufacture greenhouses according to individual projects.

To place an order, please call 8-903-840-24-03 or email [email protected]