Polyethylene and polypropylene are polymer materials that are used for industrial and household purposes. Situations arise when it is necessary to connect these materials or securely fasten them to the surface of wood, concrete, glass or metal.

Since polyethylene has a high degree of smoothness, it is quite difficult to glue such products together. To achieve good results, you can use various methods available even at home.

Why does polyethylene stick poorly?

Polyethylene is very popular and has a large number of useful properties. In most cases it is used for:

- insulation of crops;

- protection from excess moisture;

- packaging;

- electrical insulation.

The material is chemically resistant to most solvents. Sometimes this advantage acts as a disadvantage, since the question arises of how to glue the polyethylene. The bonding process involves two main areas of knowledge, such as chemistry and physics.

To connect the surfaces of different materials, it is necessary that the molecules of the substance of one element be attracted to the molecules of the substance of the second element. It follows from this that in order to glue polyethylene there must be an adhesive that will penetrate into it and, after hardening, continue to hold the parts being glued together.

It’s not easy to come up with such a composition. The problem is that the molecules of the substance that make up the structure of polyethylene are practically neutral, that is, they are not able to attract and repel. This is the reason for chemical resistance.

Science does not stand still and as a result of experiments, ways to connect parts of polyethylene were found. The most reliable of them are the following:

- welding;

- glue for foamed polyethylene;

- epoxy glue with oxidizing agent.

Application of bag sealers

Sealing bags is an important technological process. Not a single enterprise that produces products for sale can do without it. The device is used for packaging, packaging, storage, transportation, and sale of goods, such as:

- textile;

- cloth;

- linen;

- food products (in shops, canteens, catering establishments);

- medicines;

- accessories;

- Appliances;

- toys;

- disposable tableware;

- gifts, souvenirs;

- flowers;

- printing products.

The polyethylene sealer is widely used for domestic purposes.

Preparation for gluing

Before you begin gluing surfaces, you must carefully prepare them. Otherwise, the result will be negative and even the best glue will not hold parts of the whole. Preparation consists of several stages: cleaning, degreasing, surface activation.

Cleaning

Cleaning can be carried out with any detergents. Its essence is to get rid of severe contamination of the surface of the film or polyethylene. If the surface cannot be washed, then you can use physical cleaning with abrasive agents.

Degreasing

After the surface of the material has been completely cleaned of particles of dust and dirt, it must be degreased. The degreasing operation in most cases is carried out with water vapor, wiping the surface with a cloth that is pre-wetted with a solvent.

The process is repeated until the cloth remains clean after being passed over the surface of the material. The method of processing in solvent vapors is also effective.

Degreasing must be carried out in the most thorough manner; in any case, it would not be amiss to rinse, wash the surface with a fresh portion and leave it at that.

However, if more complex methods of surface preparation are used, degreasing in any case is a mandatory first stage of processing.

After degreasing by any means, cleaning compounds or detergent solutions must be used to remove dirt and other inorganic residues.

Surface activation by corona discharge

Surface activation

After degreasing has occurred, it is necessary to activate the surface. For this, it is recommended to use special epoxy compounds.

In some cases, activation is carried out using a gas-discharge lamp. The latter method is not so popular and requires additional equipment.

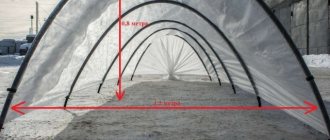

Characteristics of reinforced film for greenhouses

The indicators of the material are most often paid attention to by owners of country houses who want to purchase film and not be upset about the service life; how long the greenhouse will last directly depends on the choice of canvas. Experts advise looking at the following characteristics:

- Roll length.

- Width.

- Density per 1 cubic meter cm.

- Color design.

The polymer material must transmit at least 75% of sunlight so that the gardener can save on additional lighting. In bad weather, the frame can remain undamaged only if you buy the most durable film samples, and over time, the destructive effects of the environment will not affect the integrity of the canvas.

How to glue film using glue at home

Various situations arise when it is necessary to glue polyethylene or combine it with another material. This issue can be resolved at home. The gluing process itself depends on which surfaces need to be attached to each other.

In some cases, you can use simple soldering, in others it is necessary to use a complex chemical composition and maximum surface preparation. In any case, there must be a mandatory stage for removing contaminants and activation.

How does modern polyethylene adhesive work?

Modern compounds for gluing polyethylene are available in two varieties:

- one-component, is a ready-to-use product;

- two-component, which consists of two tubes, one of which contains the main composition, and the second contains the hardener, must be mixed immediately before starting work.

All adhesive compositions are divided into three groups:

- thermosetting (in order for them to start working they need to be exposed to high temperatures);

- cold exposure (begin to act at room temperature);

- mixed (harden in any case).

Basically, the adhesive composition contains substances that can dissolve polyethylene. At the moment when the polyethylene surfaces on both sides are dissolved, molecules of one can penetrate between the molecules of the other. After a moment, the active component evaporates and the seam site hardens.

Read also: How to remove superglue from clothes

Liquid tape

Liquid tape is a special type of mounting adhesive. It is characterized by a high degree of stickiness, which can persist for a long time. Its main feature is that with the help of this composition it is possible to glue together surfaces of various types. The tape does not contain plasticizers and is resistant to low temperatures.

Hot melt adhesive

Hot-melt adhesive differs from other compounds in that it is activated only under the influence of high temperatures. Gluing surfaces with this composition is not difficult.

Its distinctive feature is its almost instant hardening. You can start using the glued item almost immediately after application. To use this material, you must have a special gun, which heats the desired rod.

The thermal effect of the glue gun melts and deforms the thin polyethylene film. Recommended for use only for gluing thick-layer materials.

Double sided tape

The type of double-sided tape is selected depending on which surfaces need to be glued. The more uneven the surfaces to be glued are, the thicker the adhesive tape should be. The thickness of the double-sided tape allows you to smooth out the difference in the thickness of the surface of the glued material. By choosing the appropriate type of tape, you can achieve maximum coverage of the surfaces being joined.

The larger the surface that the tape covers, the more effective the gluing will be.

Bonding with epoxy glue

This type of gluing is the most affordable. However, this composition is not specifically intended for gluing polyethylene. But it is characterized by increased adhesion to the surface of polyethylene. To achieve a positive result, you must act according to a certain algorithm.

Time required: 15 minutes.

How to use two-component epoxy adhesive for bonding polyethylene:

- sand the surface using sandpaper

- degrease and dry

- Treat the bonded surfaces with a solution of thunderous anhydride at a concentration of 15-20% (you can use 20-30% potassium dichromate)

- carefully study the instructions and prepare the adhesive according to it

- Apply glue to both surfaces as thinly as possible

- join the gluing area

- keep the surfaces at a temperature of 30-45 degrees for several hours (it is better to keep for 24 hours)

Video review of adhesive options for gluing polyethylene film

How to glue PVC film

In order to glue PVC film, you can use two methods, namely, gluing the surfaces with glue or welding with hot air. In order to ensure the presence of hot air, it is necessary to have special devices. This type of equipment includes hot air guns, hot air welding machines of various kinds.

To join with glue, you need to purchase a special cream for PVC surfaces and get to work, having previously treated the surfaces to be glued.

Video on how to seal a plastic canister

In order to seal a polyethylene canister, you will need to try a little. Detailed instructions on how to do this are contained in the video.

PVC film soldering technology

When consulting beginners, specialists pay attention to two points, without which it is extremely difficult to achieve a positive result; the situation is like this:

- At the first stage, you need to thoroughly clean the soldering area and degrease the surfaces so that the canvas does not stick to the ink.

- When connecting, ensure reliable fixation of the material until complete hardening.

The resulting microscopic holes after making the main connection are simply covered with high-quality sealants; it is important to avoid the appearance of folds, such excesses are difficult to eliminate.

This method has become popular when creating three-dimensional banners; it is easy to make 20 by 30 meter specimens from several blanks, and craftsmen also use polyethylene glue to create reservoirs of up to 500 cubic meters.

Glue polyethylene by welding

Welding acts as one of the most reliable methods of joining polyethylene surfaces. But it must be done correctly. The problem is that the film is formed under high pressure and high temperature. When reheated, it tends to shrink.

If the welding is done incorrectly, you can simply ruin the material, which will not be able to return to its original state.

There are two types of surfaces that will need to be welded. This is a thin film and thick canisters or pipes.

The progress of the process depends on what materials we are welding. If it is a thin film, then you need to use a special apparatus for soldering such materials. If you have a denser specimen, you will need to use a gas portable burner.

Welding polyethylene with a hot object

This welding method is available for joining fairly thin surfaces. The hot object can be either a special unit or a regular iron. In the first case, it is enough to pass both pieces to be glued through a special hole in the device. In the second case, it is recommended to use paper that will protect the surface of the iron from polyethylene sticking.

Open flame welding of polyethylene

In this way, thicker surfaces, such as canisters, are connected to each other. In order for the process to be carried out professionally, it is necessary to follow a certain algorithm:

- treat and dry surfaces;

- prepare a seam filler made of polyethylene (you can take a piece of material that is soldered);

- heat the joint, melt it a little, but not much;

- introduce an additive to the thickness of the starting material;

- Allow the seam to cool to room temperature.

Video on how to seal a regular plastic bag at home

Sometimes situations arise when it is necessary to seal plastic bags to store certain products. Information about this is contained in the following video:

Alternative Methods

Other methods can be used to connect parts. An iron is a suitable option for gluing plastic film together. Perform the following steps:

- The appropriate heating temperature is selected through testing.

- The film parts are placed on top of each other to prevent sticking to the sole of the iron; paper is used.

- They run the device over the paper.

To prevent the paper from sticking to the sole, simply moisten it with a damp cloth.

An iron is a suitable option for gluing plastic film together.

Soldering iron, it is more convenient to use a special nozzle. Or a rod of aluminum is used as a sting; the contact area is 2 millimeters. The process includes:

- Degreasing the item.

- Securing sheets.

- The device is passed along the joint part.

If you need to solder a large surface, then a metal plate should be used as a tip; aluminum and copper are suitable.

Soldering iron, it is more convenient to use a special nozzle.

Flame method. Matches, candle, burner are suitable. By placing the flame along the seam, gluing is performed. Stages of work:

- Degreasing.

- The material is secured with bars.

- The place where the product will be welded is released to the edge by 4-5 millimeters.

- They walk through this part with flame.

- A seam is obtained in the form of a roller.

By placing the flame along the seam, gluing is performed.

Polyethylene adhesive is a reliable method of fastening polyethylene parts. The material itself has special properties that do not allow it to be bonded with conventional adhesive solutions; gluing it is a complex process, so the choice should be made in favor of high-quality products. It is easy to glue various objects with special solutions, but it is important to remember safety precautions when working with toxic substances; a person must protect himself by wearing protective clothing and gloves.

How to glue polyethylene foam to other surfaces

Foamed polyethylene is used to insulate buildings. It needs to be glued to the main surface. Depending on which surface acts as the base, the gluing method is also selected. In most cases, polyethylene foam glue is used, but sometimes welding should be used.

To metal

To glue foamed polyethylene to metal, follow the following algorithm:

- treat the metal surface with a special brush, then with sandpaper, degrease it;

- heat the metal with a lamp to a temperature of 110-150 degrees;

- Press the film against the metal and walk over it with a metal roller.

To concrete

To bond polyethylene to concrete, you need to do the following:

- clean the concrete, prime it;

- apply a layer of glue to the surface of the polyethylene from the side on which there is no foil;

- wait a few minutes until the material is saturated with glue;

- connect surfaces with light pressure.

Tools and devices

A strong connection of polyethylene film can be made with an iron, soldering iron, or special equipment.

Soldering with an iron

This is a fairly simple way to connect parts of fabrics, because household irons are found in almost every home.