Thanks to their high light transmittance, thermal insulation, lightness, flexibility and strength, modern polymer materials are widely used in everyday life. However, for one reason or another, they still get damaged. Let's consider. What adhesive for polycarbonate is the best in certain conditions, what adhesive compositions and materials are used and what are their main features, what types of polycarbonate are there, how and in what cases they need to be glued, what are the features of the procedure, what are the main mistakes that can be made admit.

Polycarbonate failure in a greenhouse Source wp.com

Bonding polycarbonate: adhesives, materials and their features

In everyday life, there are two main means of gluing polycarbonate - these are temporary materials with an adhesive base and specialized adhesives for major repairs. Let's look at their features in more detail.

Temporary methods

The following types of materials are used for temporary repair of polycarbonate:

- Insulating tape.

- Scotch.

- Liquid Nails.

- Adhesive tape.

Electrical tape and adhesive tape are most often used to temporarily repair polycarbonate surfaces. As a rule, these are cracks and crevices that occur due to seasonal changes in air temperature, and small punctures. The main disadvantage of this approach is its fragility. Because under the influence of dampness the patches will gradually peel off and lead to repeated even greater rupture.

Therefore, over time, an even larger area of the surface of the polymer material will have to be repaired. Liquid nails are a universal adhesive for quick repairs. With its help, not only holes are sealed, but also joints. In addition, the resulting connection becomes airtight and unaffected by moisture.

Small defect in polycarbonate Source ytimg.com

An alternative to the methods discussed is duct tape. It is flexible, versatility and durable. However, it does not at all have the properties characteristic of branded polycarbonate. Therefore, it is also used temporarily - until the damaged sector is replaced or major repairs are made using special adhesives.

Advice! To quickly fix polycarbonate sheets to each other or other material, double-sided adhesive tape based on acrylic is suitable. It can be either colored or colorless. High adhesive qualities make it universal in relation to any surface.

Glue for overhaul

The modern manufacturing industry produces adhesive compositions that differ in a number of characteristics:

- The material used.

- Mechanism and setting time.

- Composition.

- Application technologies.

- Light transmission capacity.

- Resistant to water, heating, cooling and mechanical stress.

- Degrees of fluidity.

Glue for repairing polycarbonate Source wp.com

Although there are no special adhesives for polycarbonate, nevertheless, for gluing this material, products used for plastics and polymers are used. Such one- or two-component mixtures are made based on the following compounds:

- Polyamides. Based on this substance, compositions are produced that exhibit good adhesive properties under heavy loads. Installation is carried out using hot air heating.

- Ethylene vinyl acetate. Another class of adhesive bases applied under heat. Despite their lower strength compared to other products, adhesives exhibit good elasticity and are resistant to water.

- Polyurethane. This is the most suitable adhesive for polycarbonate - transparent, durable and universal in relation to other materials: metals, wood, glass, plastic. The only negative is that application is only possible using a special device.

- Silicone. Available in tubes. It is easy to use and has good performance properties. However, it does not have a structure that transmits light. It mainly comes in matte white, black and gray shades.

Transparent adhesive for polycarbonate Source stroy-podskazka.ru

Note! Despite suitable performance characteristics, alkali- and solvent-based adhesives cannot be used with polycarbonate. Since the aggressive substances contained in their composition will destroy the material itself at the point of contact.

See also: Catalog of companies that specialize in paints and varnishes and related work

Adhesive tape

Special adhesive tapes are produced for repairing glass and plastic. They can be reinforced or completely transparent, which allows you to maintain the attractive appearance of the greenhouse. The standard width is 5 cm, the length in one roll is 10-20 m. Unlike stationery tape, construction adhesive tape is not afraid of rain, frost and scorching sun. It probably won't fall off for several years.

The tape is used to seal cracks in polycarbonate greenhouses in the same way as tape, but for best results it must be heated.

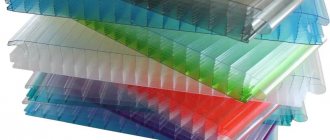

Types of carbonate and features of its gluing

The solution to the question of how to glue polycarbonate depends on the structure of the material itself. It can be cellular or monolithic. Each of them requires its own adhesive composition. Let's look at the features of selecting and using glue for each case.

Cellular

Polycarbonate with a cellular structure is used primarily for the construction of light, spacious buildings - greenhouses, greenhouses, greenhouses, gazebos, canopies, etc. The main feature of gluing them is to end up with a single, strong structure. Therefore, it is more practical and quick in this case to use one-component adhesives without specialized equipment - from a tube.

Compositions of this type provide the created compound with the following set of performance characteristics:

- Reliability and durability.

- Resistant to moisture and temperature changes.

- Constancy of properties under the influence of UV rays.

Polycarbonate of the cellular variety Source wp.com

This glue also allows you to perform small repairs efficiently. Before sealing a hole in the polycarbonate in a greenhouse, the product is applied along the previously protected surface of the entire perimeter, and then a polycarbonate patch is laid on top. Regardless of whether a local repair is made or the entire structure is mounted during installation, the fragments of material must be pressed against each other with force throughout the entire period of setting of the glue.

Video about the consequences of saving when purchasing polycarbonate material

The best time to carry out such work is a clear and sunny day without precipitation. This will protect parts and elements from unwanted moisture, which can lead to further failures.

The inspection will require careful examination of all structural elements of the greenhouse. First of all, you need to carefully examine the coating itself for the presence of clouding, swelling, cracks, dents or any other deformations.

Following the coating, the frame is inspected. It is necessary to check whether it was damaged during downtime, whether sediments have washed away the supports, and whether the frame products are installed evenly. Corrosion may have appeared on the parts, then they need to be cleaned and covered with a layer of paint.

When inspecting the frame, an ordinary level is useful. They can check the position of the building; it must be located strictly horizontally.

If no shortcomings were found, then you can start using it. Before this, you need to wash the greenhouse from the outside and inside.

Polycarbonate panels are cleaned with a sponge or cloth with warm water and detergents without alkalis or other aggressive substances. Afterwards, rinse everything with clean water.

Bonding options

There are several typical situations when you need to glue polycarbonate:

- Between themselves.

- In the greenhouse.

- On loaded and non-loaded structures.

Let us examine the features of each case more specifically.

Between themselves

In order for the structure being built to be strong, reliable and durable, it is important not only to know how to glue polycarbonate together, but also how to pre-prepare the surfaces. The general installation diagram for sheets is as follows:

- Contact surfaces are cleaned and degreased.

- The adhesive composition is applied in doses to the parts of the area to be glued.

- The sheets are placed on top of each other or to each other - depending on the chosen method - overlapping or end-to-end.

- For some time, a compressive load is applied to the contacting materials.

- Upon completion of the control time, the load is removed.

- The following structural elements are installed in the same way.

Good to know! For maximum convenience and dosing, the adhesive composition is applied to the surface of the polymer using a tube, gun, applicators or syringes.

Foundation

The basis of the structure - the foundation - plays an important role in maintaining heat inside.

Sellers of greenhouses made from polycarbonate greenhouses claim that they are lightweight and do not require a foundation - they can serve as timber or just soil. But if the owner wants his greenhouse to effectively retain heat, then a reliable insulated base is needed.

Base insulation

Insulating the base of a greenhouse consists of two points:

- warm foundation;

- soil thermal insulation.

If the greenhouse is located without a foundation - from below, a small distance is created between its covering and the soil, since it is impossible to perfectly level the site. The soil not only gives off heat during the day, but also takes it away at night - the structure cools down faster. A concrete or timber foundation will help prevent this. So, the most popular materials were:

- concrete - a strip of concrete is poured, which is lined with foam plastic on the bottom and sides;

- beam - the greenhouse is installed on beams with a large cross-section.

Main mistakes

Theoretically, knowledge of how to seal a hole in polycarbonate does not exclude the following series of practical errors:

- Poor cleaning and degreasing of surfaces.

- Insufficient elasticity of the seams formed.

- Destructive reaction of glued materials to the joint due to atmospheric factors or due to improper selection of components.

- Violation of technology.

Recommendation! Most often, silicone glue is used for gluing polycarbonate sheets. It does not violate the structure of the material, has sufficient strength and transparency. However, before applying it, thorough cleaning and degreasing of surfaces is required.

Hot gun

The next problem for owners of polycarbonate greenhouses is hail, which can leave microdents on the body or even pierce it. In the first case, you can resort to the already mentioned silicone sealant, and in the second it is better to use a hot gun. The heated glue reliably adheres to the polycarbonate, allowing you to seal a small hole hermetically.

The adhesive composition is generously applied to the cleaned damaged area, and when it sets slightly, the excess is carefully removed.

Briefly about the main thing

In order to solve the question of how to seal polycarbonate, it is necessary to take into account the type of material, type of construction, adhesive compositions and techniques used for this. For temporary repairs, the following are used: electrical tape, adhesive tape, adhesive tape, and liquid nails. For reliable restoration, adhesives based on the following bases are used:

- Polyamide.

- Polyurethane.

- Silicone.

- Ethylene vinyl acetate.

For gluing cellular polycarbonate, a one-component adhesive from a tube is most often used; for a monolithic one, a two-component adhesive is applied using a special device, and also in the form of rods that harden when heated. Polycarbonate is glued together in various variations - among themselves, in a greenhouse, in loaded and non-loaded structures. Each case has its own characteristics. During the gluing procedure, the main thing is not to violate the technology and not make obvious mistakes.

Rules for caring for a polycarbonate greenhouse

Most of the above cases of destruction or damage to the greenhouse are associated with an insufficient level of maintenance of the frame and covering elements. In order to avoid costly repairs, it is necessary to annually inspect the condition of the paintwork.

Old paint must be removed with a brush or chemical solutions. Each time before painting, the steel is stripped down to ferrous metal and primed. Particular attention must be paid to welding seams and places where screws are screwed in. When the first signs of rust appear, you should not wait for the greenhouse to be repaired, but rather open up the area of paint and apply a protective zinc-containing primer.

What else can sealant T be used for?

Sealant T has a semi-liquid consistency, so it can be used to seal small cracks that cannot be eliminated with a standard sticky mass. The composition is drawn into a syringe and injected into the crack with a thin needle. It spreads, penetrates into hard-to-reach places and seals them.

If some material remains after processing the assembly seams, close the container tightly, place it in a dark place and, if necessary, use it for minor repairs to metal or concrete structures.

Internal insulation work

Insulation and treatment of joints do not always solve the problem of heat preservation - the cold still penetrates through the greenhouse material itself, no matter how high-quality it is. Its windows must remain transparent, so coatings that transmit light well are used for internal insulation.

The standard method is to line the space from the inside of the structure with plastic film: a glass/air/film layer is formed that will prevent heat from escaping. Polyethylene is also used externally in the same way.

Installation of an additional layer

In addition to polyethylene, you can use another layer of polycarbonate; sheets of thinner thickness than those that make up the greenhouse are suitable. In this case, a three-layer coating is formed: two layers of material and a layer of air. The standard thickness of external sheets is 16 mm, internal - 4 mm.

You should know that simple polycarbonate does not hold heat well. For greenhouses, the ideal material would be cellular polycarbonate - it works much better as an insulator. Sheets of this material are easy to cut, drill, and are quite flexible.

A few nuances of installing an additional layer:

- the hole to be drilled must be at a distance of at least 40 mm from the edges of the sheet - this way the material will not crack;

- the hole should be 1-2 mm larger than the thickness of the screw;

- For fastening it is better to use a special thermal washer; you can make it yourself. It consists of a sealing washer (made of rubber material), a plastic washer, a self-tapping screw (sold separately), and a thermal washer cover.

In order for the design of a greenhouse or greenhouse building to be durable and reliable in operation, experts advise to analyze at the design stage how convenient it will be to repair a polycarbonate greenhouse. The lightweight openwork structure with polycarbonate cladding will theoretically last for a maximum of five to six years without periodic maintenance and repair work. In practice, polycarbonate repair in a greenhouse has to be resorted to much more often if owners want to prevent larger problems associated with a complete re-laying of the roofing material.

Correct design

A free-standing greenhouse requires a vestibule - this will protect the plants from sudden temperature changes. If the greenhouse is attached to the house and the entrance to it is located from it, then a vestibule is not needed. It is advisable to place the entrance even to a heated structure on the south side.

In addition, you can install racks for tools and equipment in the vestibule.

Sealing joints

Joints in the structure between polycarbonate sheets and the metal frame, between the structure and the foundation strip, are one of the main causes of heat loss. To reduce heat loss, roofing felt or waterproofing is placed on the base, but additional insulation of the greenhouse in these places will not hurt. This is also easy to do with your own hands.

To process joints use:

- sealants. The best ones are those that form flexible surfaces rather than hard ones. The latter react poorly to temperature changes and crumble. Various mastics performed well: thiokol, polysulfide;

- rubberized gaskets perfectly seal the gaps between the metal frame and the foundation.