New buildings, freshly finished with cellular polycarbonate, look very light and attractive. But after a short time they lose their appearance due to the contamination of numerous hollow channels into which dust gets, and small insects crawl in. This always happens when, during installation, care was not taken to seal the end sides of the sheets and remove condensation moisture from them. Therefore, you need to think in advance about how to cover the ends of polycarbonate in a greenhouse or other structure.

Sealing the ends will help preserve the integrity, beauty and cleanliness of the coating Source rus-stroitelstvo.ru

Why cover the ends?

Cross sections of cellular polycarbonate sheets represent a series of open cells with thin walls. To give rigidity to the walls and protect them from damage, as well as to close the cells from moisture and dirt getting into them, special end profiles are provided.

Such profiles perform not only a protective, but also a decorative function, framing the cut out element with a neat, even edge. Therefore, they are used not only on transverse sections, but also on longitudinal ones, which do not need to be reinforced or sealed. They are also suitable for decorating products made of monolithic polycarbonate.

Open cells at the ends of polycarbonate Source amazonaws.com

In addition to profiles, special adhesive tapes are also used to protect cuts. Since there is a difference in how to cover the bottom of a polycarbonate greenhouse and its top, such tapes, unlike profiles, are available in two types - sealing and perforated.

To understand why these materials are needed at all, you need to look at what happens to cellular polycarbonate during operation.

- Dirt, dust, and small debris enter the empty channels through open holes and remain there forever, gradually sticking to the inner walls, reducing the transparency of the material and spoiling the appearance.

- Moisture also penetrates into them. At the ends facing upwards there is rain and snow, at the bottom there is dirty water from melting snow and irrigation.

- Wet, warm mud becomes a suitable environment for the proliferation of microorganisms, and over time the material becomes covered with mold.

- When freezing in winter, water accumulated in the canals can tear or deform their walls.

- Insects crawling into the channels cannot turn around and crawl back out, so they also remain in them.

- Any accidental blow or stone flying from under your foot easily damages the unprotected edge of the polycarbonate.

This is what a coating with unprotected ends will look like over time. Source wp.com

Therefore, when installing the material, it is so important to think about how to cover the ends of the polycarbonate, and how to do it correctly. One end profile is not capable of ensuring tightness, so special tapes are glued under it to perform this task. Moreover, different types are used depending on the position of the cross section of cellular polycarbonate.

If it is facing upward, use a sealing tape that does not allow either dust or water to pass through. The lower ends are covered with perforated strips so that the condensate formed in the honeycombs and flowing down can freely flow out. Such tapes allow only water to pass through, serving as a reliable barrier to insects and dirt.

But such tapes do not have sufficient rigidity to protect the edges from mechanical damage. This function is performed by the end profile, which completely hides the edges of the sheets treated with not very attractive tapes.

Combined protection from sealing tape and profile Source legkovmeste.ru

Sealants

There are many different methods for sealing different materials at their joints. These include silicone sealant, which is used to seal polycarbonate products, as shown in the photo.

To seal the carbonate panels at the joints, and also to prevent them from moving out of place, silicone sealants are used. For example, they are used when assembling greenhouses from polycarbonate sheets, as shown in the photo.

Sealants have the following advantages:

- Elasticity. When the temperature changes, the material is able to compensate for any shifts in the joints to which it is applied;

- Tolerates any temperature during long-term use;

- Excellent adhesion to polycarbonate;

- Not exposed to various atmospheric influences, as well as mechanical damage.

What are the types of end profiles?

The end components for polycarbonate are made from the same plastic as the sheets themselves, and from aluminum. Both have an open U-shaped cross-section.

Plastic

The flexible plastic profile in cross-section is similar to the letter P with legs of different lengths directed inward. Its standard length is 210 cm, which is equal to the width of polycarbonate sheets. The wall thickness varies from 1.5 to 3 mm.

Before closing the ends of the polycarbonate with your own hands, you need to select an end strip that matches the thickness of the sheet - with a horizontal shelf of the same size. It comes in 4, 6, 8, 10 and 12 mm. There are plugs of larger sizes, but for home garden greenhouses they usually do not use cellular polycarbonate of such thickness.

The profile has standard dimensions, tied to the thickness of the polycarbonate sheets Source ruspolik.ru

See also: Catalog of companies that specialize in the design and installation of canopies, greenhouses and similar structures

A slight bend of the end profile legs towards each other allows them to fit tightly to the sheet on both sides. During installation, due to the flexibility of the material, they easily bend outward.

Since the plugs are made from the same material as polycarbonate, it has the same advantages:

- light weight;

- good strength;

- resistance to moisture and other atmospheric influences;

- resistance to low and high temperatures;

- ease of installation and operation;

- non-flammability.

If the greenhouse has a pitched roof, then the upper ends of the sheets that make up the roof are closed not with end profiles, but with ridge or corner profiles, which not only close the cavities, but also connect pairs of sheets into a single structure.

Ridge profile for polycarbonate Source portalfirma.ru

Aluminum

The cross-section of the aluminum profile is an even and symmetrical letter U with identical legs and a shelf of different lengths, selected according to the thickness of the sheets being finished. Unlike plastic, it is highly rigid and durable, so it better fixes sheets in a given position and protects the ends.

But it costs much more, so it is used mainly for critical structures made of thick polycarbonate - roofs, canopies, walls of various structures.

Restrictive protrusions on the inner walls of the profile prevent a tight fit of the ends of the polycarbonate to its bottom, forming a small gap necessary for the drainage of condensate from the honeycombs.

Aluminum end profiles Source teplica-exp.ru

How to quickly and easily repair a hole or crack in a polycarbonate greenhouse

To create greenhouses and canopies in garden plots, many use polycarbonate. This is a polymer plastic that transmits light perfectly, while it is much stronger than glass. The material is not afraid of hail, hurricanes and downpours.

The service life with proper care and installation is quite long. Unfortunately, there are cases when the mechanical impact on the surface is too great, as a result, cracks and even holes appear. To eliminate the defect, proven and effective recommendations will help.

Edge tapes

Self-adhesive edge tapes for the ends of cellular polycarbonate differ from adhesive tape and similar products in that they are permeable to air. This feature allows air to circulate quite freely in the honeycombs, which is important for structures such as greenhouses.

The tape covering the upper ends of the open channels completely protects them from moisture, debris, and insects. It comes in different lengths and widths. There is always information on the packaging about the thickness of the polycarbonate sheet such protection is intended for. The adhesive layer on the sides of the tape is covered with film or paper, which is removed during installation.

Sealing tape for polycarbonate 4-6 mm thick Source sdelai-lestnicu.ru

Hermetic tape (solid)

Hermetic tape is used to protect the upper part of the joint of carbonate sheets from precipitation. If the panel is mounted vertically, and the honeycombs are also in a vertical position, then the upper end of the panels must be completely sealed with polycarbonate tape, as shown in the photo. The solid tape is designed to prevent various types of wet precipitation (snow, rain, hail) from entering the hollow part of the honeycomb carbonate.

Finishing the ends of cellular polycarbonate

Profiles and tapes are mounted in the same way on any ends. If the greenhouse has an arched structure, it does not have open channels pointing upward, so you will only need perforated tape on both sides of the structure.

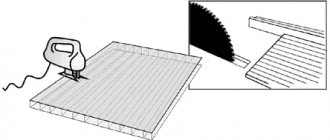

Before closing the bottom of the greenhouse, the ends must be unscrewed from the frame or loosened. It’s even better and more convenient to finish them immediately after cutting, before installing the sheets on the frame. The work gets done faster and more accurately.

Preparation for installation

The only tools you will need is a narrow spatula, with which it is convenient to push apart the profile shelves and tuck the sheet into it. It is better not to use a knife or other sharp tools to avoid scratching or perforating the material.

You also need to prepare a drill with a thin drill bit to make holes in the profile for water drainage. But it can easily be replaced by an ordinary nail heated over a fire.

To prepare the cut sheets for gluing the tape, the cuts need to be made smooth by removing all burrs and burrs using sandpaper. Before this, the edges of the sheet are freed from the protective film.

There is no need to completely remove the film in order to determine the outer and inner sides of the sheet during installation. Source krepezhinfo.ru

What may be needed to repair a greenhouse

Before sealing a hole in the polycarbonate of a greenhouse, you should collect all the necessary tools and materials. To repair damage you may need:

- scotch;

- liquid Nails;

- metal tape for fastening polycarbonate;

- rubber (silicone) adhesive sealant;

- small pieces of polycarbonate material;

- a small piece of greenhouse film;

- construction knife or scissors;

- construction hair dryer;

- glue for plastics.

Of course, repairing a hole in polycarbonate does not always require such an extensive set of tools and materials. Much depends on the nature of the damage and its area.

Video description

Watch the video that shows the installation of the perforated tape and the end profile:

To prevent moisture from accumulating in the profile, but flowing freely out of it, it does not need to be put on tightly until the bottom is connected to the end of the polycarbonate. It is necessary to leave a small gap between them. It is also needed to compensate for the thermal expansion of materials in extreme heat.

If, when choosing how to cover the bottom of a polycarbonate greenhouse, you chose an aluminum profile, all work on protecting the ends is performed in exactly the same way. Putting on the profile will require more effort, but it will last longer.

As for protecting the ends of the facade walls of arched greenhouses, it is enough to cover them with sealing tape, and when installing the side vaults, make a small release of polycarbonate.

Material advantages

Polycarbonate is a frequent guest at the dacha. It is used to install greenhouses because the material has many useful characteristics.

Peculiarities:

- Does not transmit ultraviolet rays. In its pure form, polycarbonate can be destroyed under the influence of ultraviolet radiation. To prevent this from happening, many manufacturers add a special protective composition during the production process, which helps combat the harmful effects of the sun.

- Flexible. Using honeycomb sheet in construction, it is easy to recreate a structure of any shape, build an arch or a dome.

- Resistant to fire . During a fire, it does not flare up, but dies out.

- Non-toxic.

- Temperature changes are not scary. Even in difficult weather conditions it retains its qualities.

- Due to its low weight, the material is easy to install.

It turns out that it’s not just that summer residents like this material. If the greenhouse is built of polycarbonate, then it looks more aesthetically pleasing than one covered with polyethylene.

Briefly about the main thing

To ensure that the polycarbonate in a greenhouse or other structure always remains clean and does not become a haven for microorganisms and insects, you need to securely close its ends, which provide access to the hollow honeycombs of the material. For this purpose, special profiles are used, under which protective tapes are glued. The upper sections are sealed to prevent moisture from entering them, and the lower sections are closed with a membrane that allows water to pass through, which condenses on the inner walls of the honeycomb when the air temperature changes. To ensure the integrity of the tapes and give the structure a beautiful finished look, special profiles are placed on the ends.

How to repair a greenhouse with your own hands?

Summer residents are in no hurry to seek the help of specialists. Many people are able to repair damaged areas on their own. Despite its high strength, the material can sag and crack if the thickness is incorrectly selected. If cracks and small holes appear, it is permissible to use silicone sealant. When a significant part of the structure is damaged, the sheet is replaced with a new one.

The first way to eliminate the defect will be to restore the greenhouse that has sagged under the influence of a layer of snow.

To do this you need to do the following:

- Raise the frame.

- Insert wooden supports under the resulting void.

- Use a jack to give the structure the desired shape.

- Metal plates with small diameter drilled holes.

- The old damaged sheet is dismantled and a new one is installed in its place. This is done using metal plates, bolts and connecting profiles.

The task is not that difficult. The material is easy to cut, takes the required shape, so it is pleasant to work with.