New buildings, freshly finished with cellular polycarbonate, look very light and attractive. But after a short time they lose their appearance due to the contamination of numerous hollow channels into which dust gets, and small insects crawl in. This always happens when, during installation, care was not taken to seal the end sides of the sheets and remove condensation moisture from them. Therefore, you need to think in advance about how to cover the ends of polycarbonate in a greenhouse or other structure.

Sealing the ends will help preserve the integrity, beauty and cleanliness of the coating Source rus-stroitelstvo.ru

Installation instructions for cellular polycarbonate

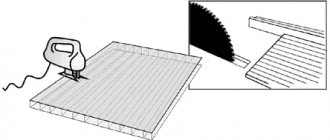

Panel cutting

Sheets of cellular polycarbonate and polycarbonate profiles are quite easy to cut. For better cutting, it is necessary to use high-speed circular saws with a stop . Blades for such saws must have small, unset teeth and be reinforced with hard alloys. When cutting polycarbonate panels, the profiles must be securely supported to avoid vibration. Cutting can also be done with a band saw.

After the panels are cut, shavings must be removed .

Drilling holes

Sealing the ends of a cellular polycarbonate panel

It is important to properly close the ends of the panels . When the sheets are inclined or vertical, the upper ends must be sealed with continuous aluminum self-adhesive tape. Cover the lower ends with a special perforated tape, which will prevent the penetration of dust and ensure condensate drainage. If the structure has an arched appearance, then both ends must be covered with perforated tape.

We strongly recommend using polycarbonate end profiles of similar color. They are quite aesthetic, reliable and very comfortable. The design of such profiles provides for fairly tight fixation at the ends of the panels and does not require additional fasteners.

To ensure condensate drainage, it is necessary to drill several holes in the end profile.

You cannot leave the ends of cellular polycarbonate open, seal them with regular tape, or hermetically seal the lower ends of the panels.

Orientation of polycarbonate panels during design and installation

In cellular polycarbonate, internal stiffeners are located along the length of the sheet (typical sizes are 3m, 6 or 12m). The panel must be oriented in such a way that the condensate that will form inside the panel can flow through its internal channels and be discharged outside.

If the glazing has a vertical orientation, then the stiffening ribs should be located vertically, in a pitched structure, respectively, along the slope. If the frame has an arched appearance, then the stiffening ribs should follow an arc and not parallel to the ground. These conditions must be taken into account at the design stage of the structure when calculating the number of sheets of cellular polycarbonate and their correct cutting.

For outdoor use, it is advisable to use cellular polycarbonate coated with a special protective UV-stabilizing layer , which is applied to the outer surface of the panel. On this side, the polycarbonate sheet has a protective film with special markings. We recommend installing the panels without removing this film, and doing this only after completion of the work.

You cannot bend panels to a smaller radius than that specified by the manufacturer for the specific thickness and structure of polycarbonate. Also, you cannot violate the rules of sheet orientation.

Point fastening of panels

Point fastening of cellular polycarbonate sheets to the frame is carried out using self-tapping screws and special thermal washers.

The thermal washer consists of a plastic washer with a leg, the height of which corresponds to the thickness of the panel, a sealing washer and a snap-on lid. This device allows you to reliably and hermetically fasten polycarbonate panels, as well as eliminate “cold bridges” created by self-tapping screws. In addition, the leg of the thermal washer will rest against the frame of the structure and thereby prevent the material from collapsing.

In order to compensate for the thermal expansion of cellular polycarbonate, the holes in the panels must be made 2-3 mm larger than the diameter of the thermal washer leg. And if the panel is long, then it is recommended to make the holes elongated along the sheet. The recommended point mounting spacing is 300-400 mm.

Profile fastening

These are special devices designed for fastening or joining polycarbonate sheets. The design of such profiles contains two elements – a base and a cover. With their help, double-sided clamping of the edges of the material is provided, which does not require drilling or direct twisting of the sheets. Only the base is fixed in the appropriate places where installation is planned. Such fastening of polycarbonate is advantageous, first of all, in terms of reliability and tightness, but in addition, the owner also receives an impeccable appearance of the coating. Since the profiles are usually made from the same polycarbonate, they visually merge with the main sheets. All you have to do is choose the elements that match the color.

There are also aluminum profiles with a similar design. They provide the same quality of connection as galvanized tape for fastening polycarbonate, but at the same time eliminate the disadvantages of the clamping method of installation. That is, it is not so easy to unscrew this system - the presence of self-tapping screws and strong clamping of the profiles make this task difficult for an attacker.

Sealants for effective sealing of joints

Durable and environmentally friendly polycarbonate is widely used in the construction and agricultural sectors to create greenhouses and canopies that perfectly transmit sunlight. Polycarbonate sheets are easy to cut, bend and can be drilled during installation.

A good owner will certainly have a question about whether it is necessary to seal the ends of polycarbonate. Which polycarbonate sealant should you choose when sealing joints in panels, since you can’t leave them untreated?

To protect the panels at the joints, silicone sealant for polycarbonate is used. It is convenient to use this tool when assembling a greenhouse.

It is necessary to choose the right sealant for polycarbonate, and which one is better for this or that design? Silicone has the ability to penetrate into all hard-to-reach places, so it can be used to cover internal seams in greenhouses. Special films are also used in special cases.

End Profile Installation Tools

No special tools are needed to thread the web into the end profile. To work, it is enough to use a metal spatula or a regular knife. The spatula can have any shape.

Tools must be blunt, without burrs or kinks. A sharp object can damage and ruin the polycarbonate sheet. It will be difficult to restore the tightness and integrity of the canvas.

Important! To drill holes in the profile mounted along the bottom edge of the canvas, you need an electric drill with wood drill bits. You can also use metal drills.

Protective tape

The excellent characteristics and undoubted advantages of polycarbonate have contributed to its popularity and wide distribution. However, structures made from this material are located in open space all year round, exposed to the destructive effects of the external environment. Fortunately, structures can be protected and their service life extended by sealing the ends of the polycarbonate.

For strength, layers of plastic in carbonate are connected to each other by thin bridges, which provide flexibility to the sheet. But water and unnecessary debris enter the open end cavities, facilitating the colonization of biological organisms.

The special self-adhesive tape has no expiration date, can withstand any temperature changes and absorbs movement of the material. A relatively constant microclimate is maintained in its cavities, and when assembling the structure, the adhesive tape does not allow the edging to wear off.

The tape serves to hermetically close the end of the polycarbonate and increase the service life of the structure. To reliably seal polycarbonate, two types of special tape are used:

- perforated – for the lower ends,

- continuous sealing – for the upper end profiles.

Manufacturers have specially developed these products to protect joints into which water and debris can get in. If assembly instructions are strictly followed, the structure will last for decades.

Advantages

The positive aspects of punched paper tape include:

- Possibility of use at high air humidity.

- Corrosion resistance.

- Ease and precision of use when assembling the structure.

- High tensile strength.

- Long service life.

- Wide range of applications.

- Equipped with a microfilter that protects polycarbonate honeycombs from water and dust.

- Withstands a wide temperature range.

- Resists profile friction along the edge.

- It is possible to re-glue the tape due to the special adhesion of the glue.

Ends

When erecting polycarbonate structures, you must definitely think about sealing the ends. To do this, you can use a special tape for this material. Currently, 2 types of such tapes are used:

These accessories are designed specifically to protect honeycomb carbonate from the penetration of debris and water. The service life of self-adhesive tape is unlimited. It withstands temperature changes and also follows the fluctuations of carbonate sheets. In addition, the tape maintains a relative microclimate in the cavity of the cellular polycarbonate. Also, the tape is able to withstand the friction of the edging when assembling the structure.

The product withstands temperature changes and high levels of humidity. The surface of the polycarbonate tape is coated with a special substance that prevents the appearance of various fungi. Its service life can last more than 10 years. The adhesive layer of the tape is quite reliable, but it has a property that allows it to be re-glued if necessary.

Thermal washer

Before the advent of thermal washer and galvanized tape, polycarbonate was secured with ordinary self-tapping screws. This is a simple and cheap method that ensures relative reliability of the design. The disadvantages of using such hardware are due to the physical and operational properties of polycarbonate, which make its structure changeable under temperature changes. The use of a thermal washer eliminates negative factors - the element naturally adapts to external conditions, evenly distributing the clamping force. Combined fastening of polycarbonate to metal is also practiced, in which self-tapping screws together with a thermal washer are screwed through a galvanized tape. This ensures maximum reliability of the metal frame sheathing and eliminates the disadvantages inherent in the single use of clamp bands. On the other hand, this is the most expensive and labor-intensive technology for installing polycarbonate, which in some cases does not justify itself.

Hermetic tape (solid)

Hermetic tape is used to protect the upper part of the joint of carbonate sheets from precipitation. If the panel is mounted vertically, and the honeycombs are also in a vertical position, then the upper end of the panels must be completely sealed with polycarbonate tape, as shown in the photo. The solid tape is designed to prevent various types of wet precipitation (snow, rain, hail) from entering the hollow part of the honeycomb carbonate.

Purpose of the end profile

To protect the edges of the canvas from natural factors and to impart rigidity, a special end profile is used.

Important! The edges of cellular polycarbonate must be protected with an end strip. The edges of monolithic slabs do not need protection; the end strips for such sheets play a decorative role.

The following can get inside a cellular sheet that is not protected by a profile:

Insects can settle in the honeycomb cavities, the appearance of which does not color the material in any way. Dusty, dirty, covered with mold inside and out, the material loses its transparency, and soon no trace remains of its former beauty. And the owners will have regrets about wasted money.

The end profile is placed on the edges of the canvases; it securely covers the honeycombs. For complete sealing, flexible tapes are glued under the profile strip. A completely sealed aluminum tape is glued to the part of the sheet that is located at the top on the sloping roof. It is sold in the same departments as polycarbonate sheets and the entire profile. A special perforated tape is glued to the lower (ground-oriented) part of the sheet.

Punched tape

This accessory is used to protect the lycarbonate connection from below, as shown in the photo. The perforated tape is equipped with an air filter, the pores of which have a size of 40 microns. They prevent various debris from getting into the hollow part of the material. In addition, the filter is capable of letting moisture out, which accumulates in the carbonate honeycombs. If the panel is installed vertically, and the honeycombs have the same direction, then this tape will protect its lower joint.

Depending on the type of structure, tapes have different purposes. Two inclined panels at the junction are covered with hermetic tape on top, and covered with perforated tape at the bottom. When constructing arched structures made of cellular carbonate, only punched tape is applied at both ends. At the same time, it is necessary to drill small holes at the end in increments of 25-35 centimeters so that condensation does not linger, as shown in the photo.

If moisture cannot escape from the honeycomb, where it always collects, the material will soon begin to deteriorate. In this case, you will have to spend a lot of money to repair the structure. And never use ordinary tape, as it is not able to protect the material from any damage.

Alternatives

Many gardeners are interested in whether it is possible to replace perforated tape with something. So, if it is not possible to purchase sealing tape, you can try using high-quality construction tape. However, you will have to spend a lot of time creating micropores. The holes must be microscopic, so you will have to work with a very thin needle. The process is so painstaking that it can take more than one hour.

According to experienced builders, there is currently no worthy alternative to punched paper tape.

Construction tape very quickly loses its quality and needs to be replaced.

Sealants

There are many different methods for sealing different materials at their joints. These include silicone sealant, which is used to seal polycarbonate products, as shown in the photo.

To seal the carbonate panels at the joints, and also to prevent them from moving out of place, silicone sealants are used. For example, they are used when assembling greenhouses from polycarbonate sheets, as shown in the photo.

Sealants have the following advantages:

- Elasticity. When the temperature changes, the material is able to compensate for any shifts in the joints to which it is applied;

- Tolerates any temperature during long-term use;

- Excellent adhesion to polycarbonate;

- Not exposed to various atmospheric influences, as well as mechanical damage.

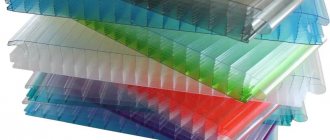

Types of end profile and its characteristics

The end profile is made of plastic (the same polycarbonate from which the sheets are made, monolithic or cellular) and aluminum.

Characteristics of plastic profile

The plastic profile for protecting the edges of the honeycomb plate is a strip curved in cross-section in the shape of the letter P, with one side longer than the other. The maximum length of a commercially available strip is 2.1 m. The cross-sectional thickness of the material is 1.5-3 mm. The plank should fit tightly to the sheet from below and above, so the long and short sides of the profile deviate slightly inside it, towards each other.

The main advantages of the plastic end profile include:

- light weight;

- flexibility;

- high strength;

- reliability in operation;

- ease of installation.

Plastic end profile is available for honeycomb slabs of standard thickness. In technical documentation, the material is marked with the Latin letters U, UP or Russian PT. The cross-sectional dimensions of the strip correspond to the parameters of the sheet.

Table. Standard sizes of plastic end profile.

Plastic strips are flexible enough to strengthen arched roof vaults. The material from which the sheets and profiles are made does not burn, but only melts in the fire. The planks do not soften at high air temperatures and do not break in the cold. No special skills, special tools or equipment are required to secure the planks. Polycarbonate has average resistance to scratches and impacts.

Important! On sale it is easy to find a profile of any color, including transparent, opal and bronze. The material is resistant to ultraviolet rays in the same way as sheet polycarbonate.

Aluminum end profile

An aluminum profile is much more expensive than a plastic one, but roofs, arches and walls of buildings fixed in such material to a metal frame can last ten years or more. This profile is most often used to fix and protect structures made of thick honeycomb carbonate (16, 20, 25 and 32 mm). But thin sheets (4, 6, 8, 10 mm) can also be attached to aluminum strips. The aluminum profile is symmetrical in cross-section and is shaped like the letter P.

Advantages of aluminum profile:

- corrosion resistance;

- long service life;

- high strength.

The structures assembled on an aluminum frame are very durable and have a beautiful appearance. The slats have restrictive grooves that prevent the cells from closing in polycarbonate sheets or special drainage grooves for water drainage.

An additional protective or decorative layer can be applied to the metal. Manufacturers anodize aluminum (coat it with a protective film of oxides) and paint it in different colors (bronze, turquoise, white, blue, yellow, green, gray, blue, orange, red). Manufacturers also, at the request of the customer, cover aluminum with a special film with a pattern of wild stone or wood. Decorative painting of aluminum can be beautifully combined with translucent polycarbonate fabric of the same or contrasting color.

Polycarbonate prices

What can I use to seal it?

Polycarbonate appeared relatively recently, but has already become popular due to its durability and resistance to different weather conditions. It transmits and disperses the sun's rays well and retains heat in a closed structure. Canopies and canopies for buildings are made from cellular polycarbonate, greenhouses and gazebos are erected. In this case, it is necessary to close the ends of the product so that it lasts a long time.

Some people try to do this with tape. Of course, such material will be cheap, but it will provide protection for a maximum of a year, then it will begin to tear. Therefore, you need to use materials specifically designed to seal open polycarbonate cells. There are different means to solve the problem.

For example, you can use a rubber end seal. It has a low price, is easy to use, and helps reduce vibration of polycarbonate in the wind.

However, over time, the rubber seal is subject to deformation, it is characterized by loss of elasticity, it becomes brittle, and it hardens in the cold.

You can glue the ends with special tapes. Their purpose is to protect cellular polycarbonate from factors that destroy it. The product has an almost unlimited service life; it is not afraid of mechanical damage, moisture, or temperature changes. The top layer of the tape plays a sealing role; the inner layer is coated with high-quality durable glue.

There are 2 types of tapes:

- perforated;

- continuous sealing.

When constructing a structure, both types will be needed, since they are used differently and have different functions. The sealing material is glued to those ends that are located at the top of the structure. It prevents debris, precipitation, and insects from entering the building material.

Perforated is applied to the lower ends, it has an air filter. The main task of such a tape is to remove moisture that accumulates in the honeycombs during the operation of polycarbonate.

Another effective way would be to use end profiles. They need to be put on the edge of the canvas. The end profile will reliably protect the honeycombs, create a frame for flexible polycarbonate sheets, and give a more aesthetic appearance to the structure.

To ensure the stability of the structure, you will need to seal the places where the polycarbonate panels are connected. This can be done with silicone sealant.

Recommendations

To ensure that the structure lasts for a long time, use the following recommendations.

- Before sealing the ends, be sure to remove any remaining protective film and glue from the polycarbonate sheet.

- When gluing the tape, do not allow it to fold or warp, and do not pull it too tightly. Use only punched paper tape if the structure is arched.

- For greater reliability, use end profiles over the tape. Match them to the color of the canvas.

- If you urgently need to seal the ends, but there is no tape, use construction tape. However, do not forget that it is only a temporary solution.

Source: https://stroy-podskazka.ru/polikarbonat/kak-zakryt-torcy/

Laying polycarbonate slabs

Installation of polycarbonate sheets on a frame made of metal corners is carried out in several stages:

- The sheets are cut into fragments of the required size.

Polycarbonate is cut to the required sizes before construction begins. - Each fragment is covered with sealing tape and punched paper tape according to the geometry of the future structure. It is advisable to degrease the surfaces before gluing.

- The surface of the corners is cleaned and then degreased.

- A sealant is applied to the metal from the inside.

- The fragment is applied to the cell and pressed down.

When using certain sealants, you do not have to resort to the services of a specialist. All the necessary work can be easily done with your own hands.

Source: https://polikarbonat.guru/montazh/germetik-dlya-polikarbonata.html

Termination diagram

It is quite possible to do the processing of the ends yourself. To seal the edges using tape yourself, you only need a tool for cutting the tape - a knife or scissors. It is also advisable to have a stitching roller on hand. You need to attach the tape correctly, so follow the step-by-step instructions.

- Prepare the end. Remove all burrs and dirt from it, it should be clean and dry. You also need to degrease the surface.

- Take measurements and cut the required length of tape. Remove the protective strip from it.

- Now you need to carefully apply the tape to the end. Make sure that the middle can then be laid on the end.

- Smooth the tape well so that there are no bubbles or uneven spots.

- Bend the tape and close the end of it with the middle, using ironing movements to secure it well.

- Fold the tape again and close the other side of the sheet. Iron it. Using a stitching roller, create a smooth and even attachment of the tape to the sheet.

Classification of sealing agents

You cannot start building long-term polycarbonate structures without a reliable sealant. To protect the ends and seams, two types of self-adhesive tapes are used:

- hermetic tape;

- punched paper tape

There are two types of self-adhesive tapes for protecting the ends of polycarbonate: hermetic tape and punched tape

In addition, silicone sealants are often used.

Each of them has its own advantages. Let's look at them in more detail.

Germolenta

It is recommended to use it to protect the upper areas of the connection of polycarbonate sheets from moisture penetration. Often the sheets are installed vertically, in which case the “honeycombs” are in the same position. To prevent precipitation from penetrating inside, the upper end of the sheet must be sealed, for which it is sealed with adhesive tape. The material has a solid structure, and therefore provides quite reliable protection from atmospheric phenomena such as rain and snow.

The sealant protects the polycarbonate from moisture getting into it

Punched tape

This material protects seams and joints on the lower sections of panels installed vertically. Structurally, punched paper tape is a porous filter that allows air to pass through. Each pore has a diameter of 40 microns. The resulting tape:

- protects building materials from penetration of dirt and dust from below during windy conditions;

- does not prevent moisture accumulating in the cavities of cellular polycarbonate from coming out.

In addition to installation strictly vertically, the panels are laid in a different way. Accordingly, tapes are used according to their characteristics:

- If the panels are connected at an angle, cover the joint at the top with hermetic tape and at the bottom with punched paper tape.

- When constructing arched canopies based on cellular polycarbonate, punched tape is used on both sides. In this case, small holes should be drilled at the ends at a distance of 25 cm from each other to allow the condensation to evaporate.

Silicone sealants

Although this composition is used to protect various building materials, it has proven itself equally well when constructing buildings based on polycarbonate.

Silicone sealants are well suited for the construction of any buildings

Silicone caulk can help hold sheets of material together, acting like glue. Both the adhesive and the sealant are durable and can withstand bad weather and strong winds. True, silicone is an opaque material; compositions are sold in white, gray and black. This should be taken into account when gluing and sealing structures that should have a beautiful appearance.

Silicone sealants are recommended for use when installing greenhouses assembled from polycarbonate sheets.

Main characteristics of the material:

- elasticity - possible shifts of the joints do not violate the integrity of the structure;

Silicone sealant is an elastic building material

- good adhesion to the surface;

- resistance to temperature fluctuations and mechanical stress.

Methods and preparation for operation

In short, in order to get a good heat retention rate, you need to perform a complex of the following work:

- choose a suitable location;

- insulate the foundation;

- treat joints, seams;

- improve the design (equip a vestibule);

- internal insulation works.