The reliability of greenhouses and other objects made of cellular polycarbonate is ensured not only by the correct construction technology and high-quality material, but also by protecting the latter from negative environmental factors. For this purpose, various components are used, including perforated tape for cellular polycarbonate.

Perforated tape for cellular polycarbonate

Application area

Punched paper tape is used when assembling suspended structures (drainage, etc.).

Also, similar strips are used during the installation of heated floors to fasten the cable that heats the floor. During the construction of polycarbonate buildings, punched tape plays the role of increasing the strength of the fastening units. In this case, plumbing tape or electrical tape is often used along with it.

The assembly of rafter systems is also not complete without punched tape. It is successfully used for vertical glazing, attached to the surface of the sheet and covered with a profile.

If the building structure has the shape of an arch, the sheets should be covered with punched tape on both sides.

This tape is also often used as a sealant. It allows you to protect the sheet from the influence of the external environment.

3 locations where this tape is most often used

- on elements of roofs and canopies. As well as other pitched structures;

- in the protection of greenhouses, greenhouses and winter gardens;

- in the cladding of other structures where polycarbonate cells are open.

Note. The sealing of the ends and seams of polycarbonate must, of course, be tight. This will preserve the aesthetics of the building. It will also protect it from the external environment and extend its service life. If you need a really high-quality installation of sealed tapes, then ANDRAUS will help you do it. Our craftsmen will come to your site tomorrow. And they equip polycarbonate according to all the rules.

Advantages

The positive aspects of punched paper tape include:

- Possibility of use at high air humidity.

- Corrosion resistance.

- Ease and precision of use when assembling the structure.

- High tensile strength.

- Long service life.

- Wide range of applications.

- Equipped with a microfilter that protects polycarbonate honeycombs from water and dust.

- Withstands a wide temperature range.

- Resists profile friction along the edge.

- It is possible to re-glue the tape due to the special adhesion of the glue.

What types of tapes are there?

For polycarbonate, two types of tapes are used:

- Perforated - having a special filter for water and dust due to the presence of tiny pores and allowing condensation to be easily removed outside. They are used in those places of the structure that require sufficient ventilation.

- Sealing solid - seals the opening of the edge well. They are often used for roof edging. There are no perforations in them, which means they do not let anything through, even condensation cannot pass through them. Therefore, such strips are more often used at the edges of the structure, where continuous sealing is required.

Kinds

Polycarbonate tapes are available in several types. The first one is perforated. The name itself denotes the structure of the material. Such tapes have tiny pores with a special filter that prevents moisture from penetrating while providing sufficient ventilation for the cellular polycarbonate tunnels. In addition, such tapes do not interfere with the removal of condensate.

The second type of sealing tape is a solid material that is good for use on exposed edges. For example, roof edging. Sealing tapes without perforation do not allow anything inside at all. But they also do not allow condensation to escape. In sunny weather, this can cause a “greenhouse effect” inside the leaf, which will promote the development of mold. Therefore, it is ideal to use both types of sealing tapes. For example, to treat edges that meet each other, it is better to use perforated adhesive tape, which will ensure sufficient ventilation of the tunnels, and continuous sealing tape along the edges.

Recommendations for gluing

- Sharp edges of the sheet must be removed.

- The ends of the sheet are cleaned, the protective film and any possible layer of glue remaining after it are removed. If this is done with a soap solution, the sheets should be dry afterwards.

- The sealing tape is applied without unnecessary effort and stretching so that it is in the center of the end, and is released from the backing. To do this, naturally, a size similar to the thickness of the sheet is selected.

- The tape takes root tightly, after which it is smoothed out with rubbing movements.

The result is an even, beautiful joint, with positive qualities for further use of the sheet. In the photo and in real life, the design with such decorated edges of the sheets looks complete and beautiful. Therefore, even for the aesthetic component, tapes will be needed. Such tapes are not used for monolithic polycarbonate, because its solid structure prevents any particles from getting into the material. The tape is needed exclusively for the honeycomb type of sheets.

What does perforated tape look like?

Perforated tape is an adhesive, flexible strip with a large number of small holes.

Condensation can escape from the material through these holes, but neither moisture nor dust can penetrate inside. Sometimes such tape is also called anti-dust and anti-condensation tape. Previously, perforated tape was made from aluminum foil, which acted as a base, and a perforated layer made of non-woven polypropylene. But such strips often did not release condensation or, on the contrary, allowed moisture to get inside. Aluminum foil also frequently tore, which significantly hampered the quality and speed of installation.

New models of perforated tape were produced taking into account all the negative aspects of the old ones. They use an elastic polymer as a base with a coefficient of linear expansion almost like that of polycarbonate. When the edge of the sheet narrows or expands, the strip does not tear; it is able to expand and contract along with the material. The perforated layer of modern tapes is made of water-repellent non-woven fabric. The pores of this layer are very small, from 40 to 45 microns, for this reason dust and moisture do not pass through them. But condensate in the form of steam can escape freely. That is, the tape plays the role of a one-way filter.

The punched tape is also designed to combat microorganisms. To do this, it is treated with a special substance that inhibits activity and kills bacteria.

Note: However, there are cases when using punched paper tape is not recommended. It is better to seal the areas where welding, cutting and grinding are carried out with continuous sealing strips.

Laying polycarbonate slabs

Installation of polycarbonate sheets on a frame made of metal corners is carried out in several stages:

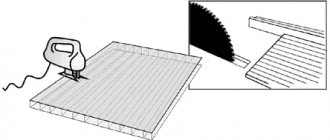

- The sheets are cut into fragments of the required size.

- Each fragment is covered with sealing tape and punched paper tape according to the geometry of the future structure. It is advisable to degrease the surfaces before gluing.

- The surface of the corners is cleaned and then degreased.

- A sealant is applied to the metal from the inside.

- The fragment is applied to the cell and pressed down.

When using certain sealants, you do not have to resort to the services of a specialist. All the necessary work can be easily done with your own hands.

Purposes of material sealing

Various structures are erected from cellular polycarbonate, including sheds and greenhouses. The structure of such a material is represented by several parallel layers with cell patterns between them. This material is waterproof, but the edges of the sheets during transportation and storage can absorb moisture, as well as dirt and dust.

Blowing and washing the honeycombs in this case is a very difficult process; if you do not dismantle it, it is almost impossible.

Moisture that gets into the honeycomb of the polycarbonate sheet can play a negative role, accumulating on the walls of the building in the form of condensation. For this reason, the light transmission of the plates is greatly reduced. If the material is used for the construction of greenhouses, this is a huge disadvantage that will significantly reduce productivity.

In addition, the condensate located in the honeycombs has high thermal conductivity. Therefore, frosts can cause rapid freezing of the greenhouse, the lining of which contains condensate. And this can be destructive for plants.

Debris and dust trapped in the cells of the material will also not lead to anything good. When they combine with condensate, dark dirt appears, causing dark spots on the structure’s skin and its clouding. Externally, a building made of such material will look very unattractive.

But the harmful effects of dirt and dust do not end there, because along with them fungal spores and bacteria often penetrate into the material. Such polycarbonate can not only become cloudy, but also “bloom”. The appearance of the material, light transmission and thermal conductivity further reduce the positive characteristics. In addition, microorganisms will gradually destroy the structure.

Cleaning such a sheet is an almost impossible task. It's better to replace it with a new one.

Perforated tape allows you to protect the edges of the material from external influences, and the finished building from troubles and unwanted costs associated with replacing unsuitable sheets.

Why do you need punched paper tape?

Choosing a greenhouse made of cellular polycarbonate: types of structures, frame, pros and cons, photos

Thanks to many positive qualities, polycarbonate cladding has found its application in various fields of activity, including agriculture. Cellular polycarbonate is a hollow sheet of plastic with thin crosspieces inside.

Moisture that gets inside the hollow cells of cellular polymer plastic settles in the form of condensation, resulting in the appearance of mold. The accumulation of dust and dirt leads to the loss of the original physical properties and qualities of the material. However, there is a solution to this problem - we are talking about punched paper tape.

Punched paper tape helps protect polycarbonate from moisture

Perforated tape, often called adhesive-based anti-dust or anti-condensation film, is made of an elastic polymer.

The advantages of punched paper tape include:

- strength, elasticity and high wear resistance;

- protection against penetration of dust, small debris and insects;

- excellent moisture resistance;

- ensuring air circulation and, accordingly, eliminating condensation;

- the presence of an antibacterial protective coating;

- ease of installation and further maintenance;

- resistance to atmospheric conditions and temperature changes.

Punched paper tape has a high linear expansion coefficient. Thus, with slight deformation of the panels and connecting seams, the perforated tape can expand by 10–15%.

Dimensions

Perforated tape is available in different widths depending on the thickness of the sheet of material on which it will be used.

Polycarbonate plates up to 6 mm thick are covered with tape 12 mm wide.

If the plate thickness is 8-10 mm, the tape width should be 38 mm.

Sheets 32-40 mm thick are covered with 50 mm tape.

Rolls of regular punched paper tape usually hold 33 meters of its length. As for the sealing tape, it is produced in rolls of 50 meters.

How do you seal the ends of cellular polycarbonate with punched tape?

Let's look at the procedure for using the tape step by step:

- The protective film is removed from the polycarbonate.

- A construction knife is used to process the edge of the sheet, level it, and remove defects and burrs, if any.

- Inspect the sheet for contamination (both dust and glue remaining from the protective film).

- A sponge soaked in a soap solution removes dirt and degreases the end.

- Dry the end of the plate; for this you can use a regular vacuum cleaner.

- The sheet is placed in the desired place and secured with clamps.

- Using a tape measure, measure the end and cut the desired size of the tape with a knife.

- The protective paper strip is removed very carefully.

- The tape is applied to the edge of the sheet so that when it is subsequently folded, its middle ends up on the end part of the plate.

- The part of the tape that was glued to the end of the sheet is ironed, irregularities and bubbles are removed.

- The tape is folded so that the middle covers the end of the plate. Iron this area well.

- Bend the tape again to cover it with the end of the second edge of the plate. Iron again and release air.

- To ensure that the tape is perfectly connected to the material, you can use a stitching roller.

- After the end is completely sealed, proceed with the installation of the appropriate profile.

How to choose?

Installation of polycarbonate on a metal frame

The choice of tape for polycarbonate should be approached as carefully and responsibly as possible. In this case, experts advise taking into account several key parameters.

- Purpose. Initially, you need to figure out for what purposes you will use the tape. This decision will determine what type and size of material you choose. Accordingly, you must make this choice before purchasing the material.

- Manufacturer. Preference should be given only to those goods that are produced by manufacturers who enjoy the trust of consumers. This is due to the fact that only such a tape will meet all the necessary requirements, and its production will comply with generally accepted (national and international) standards.

- Place of purchase. You should buy tape for polycarbonate only in specialized construction stores, where you can get qualified advice from salespeople and managers.

- Reviews. Before purchasing a tape, you need to carefully study user reviews and comments. In this case, you will be confident that the qualities declared by the manufacturer will fully correspond to the real state of affairs. Considering these characteristics, you can purchase a tape that will 100% meet your needs and perform its functions well.

Using galvanized strip

Galvanized tape is different from those used for sealing and protection purposes. It is used when installing polycarbonate plates based on the structure. To secure the material, its sheets must be pressed to the frame with galvanized steel tape. Zinc-coated steel will not be subject to rapid corrosion, which makes the life of the belt longer.

The advantage of fastening polycarbonate with galvanized tape is the high speed of installation and dismantling. In addition, there is no need to drill the material, which means it can be reused.

As for the disadvantages of such fastening, they can be called the simplicity and speed of dismantling the structure, due to which it can be stolen. In addition, the strength and rigidity of the structure in this case is reduced due to the reduction of attachment points. Also, such a design will have sharp edges resulting from the clamping angles, which increases the risk of accidental injury.

Using tape as a sealant

Polycarbonate sealing tape, as its name suggests, is used to seal seams and joints of polycarbonate sheets, protecting them from unwanted external influences. The main task of this type of tape is to prevent moisture, dust and other unwanted debris from entering the honeycombs (cells) of the polycarbonate sheet.

This material is made of durable plastic on the outside, acting as a sealant. On the inside of the tape there is a layer of durable adhesive that provides excellent adhesion to the sheet.

Due to its good flexibility, sealing tape can be used to seal surfaces of any complex shape. As a result of its use, it becomes impossible for debris to enter the sheet tunnels, which, in turn, maintains high transparency of the structure for a long time.

Alternative option

There are situations when installation is urgently needed, but perforated tape could not be purchased. Is it possible to replace it with something? Yes, it is possible, but this will require considerable desire and diligence.

You can use ordinary construction tape as the basis for a homemade analogue of punched paper tape. It is more difficult to create pores. This can be done with the finest needle or a tool that can make tiny holes.

You need to understand that such a product may be temporary, since its characteristics are significantly inferior to factory punched tape. Next, if possible, you should dismantle and replace the tape with a magazine one.

How to use?

Of particular importance is not only the choice of the appropriate type of polycarbonate tape (in terms of type and size), but also the correct use of the material. Experienced builders recommend following simple instructions when using the material and be sure to follow the recommendations of specialists.

First of all, you need to prepare the polycarbonate panels. They need to be cut to size (which is relevant in a particular case), then holes specially designed for thermal washers must be made. After this, it is necessary to begin the process of purging the honeycombs. Only after these processes are completed can you begin to directly apply the tape.

Before gluing the tape, you need to carefully treat the polycarbonate

It is important to remove existing bumps, scratches and any other defects. This will allow you to stick the tape onto the surface as accurately as possible, and accordingly, the tape will effectively perform its tasks

In those areas where the tape will be glued in the future, you need to remove the protective film from the polycarbonate.

At this stage, you can begin directly applying the tape to the ends of the polycarbonate

In this case, it is important to pay attention to the fact that the edges of the tape are neatly and evenly distributed over the polycarbonate. To ensure this effect, during the application of the tape you need to tighten it (however, this must be done in such a way as not to tear the material). In addition, during the process of gluing the tape, you need to pay attention to ensure that folds do not appear on the surface of the material.

In addition, when gluing the tape, you need to pay attention to ensure that no folds appear on the surface of the material.

Once you have applied the tape, press the edges of the tape using a soft felt cloth. At the same time, you should not put excessive pressure on the material so as not to spoil or destroy it. After completing the above steps, the end profiles should be installed on top of the material. At the same time, you must remember to leave a small gap (2-3mm). Such a gap is a drainage gap, since it is used to remove condensate.

Thus, we can conclude that polycarbonate tape, despite the fact that it is an auxiliary building element, plays a very important role. Its use will significantly increase the strength and reliability of the structure. At the same time, you should carefully approach the choice of material and take into account all its characteristics, so as not to regret your purchase in the future.

To learn how to seal the ends of polycarbonate with different types of tapes, see the following video.