Almost throughout the entire territory of Russia it is impossible to grow a decent harvest without the use of covering material. But if previously only greenhouse film was used for these purposes, now the choice amounts to dozens of items.

Covering material for beds and greenhouses, when chosen correctly, can solve a lot of problems. It will protect against weeds, soil drying out, frosts, temperature changes and other “disasters” that accompany farming. However, you need to understand what exactly you are buying and be well versed in new products, because even materials that are similar to each other can have diametrically opposed properties.

Specifics of using covering materials and main varieties

Initially, before the advent of non-woven fabric, polyethylene film was widely used as a covering material for constructing greenhouses and greenhouses. Depending on the region, such agricultural technology either made it possible to obtain early harvests, or was the only possible way to grow garden crops (cold climate). With the advent of non-woven polypropylene fabrics, not only frames and arches with covering material became available, but also other possibilities.

- Protection from pests (insects, birds).

- UV protection.

- Plant protection in winter.

- Protection against return or early frosts.

- Weed protection.

- Increasing crop yields.

- Creation of optimal moisture balance.

- Reduce watering.

By choosing the right material, you can significantly reduce labor and time costs, and even reap an excellent harvest.

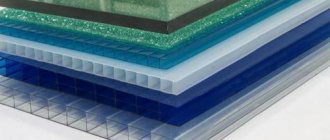

Once upon a time in villages, seedlings planted in open ground were covered with large burdock leaves, changing them as they dried. Fortunately, now, instead of the “handicraft” method, there is a large selection of specialized artificial protective materials. It is not advisable to consider cellular polycarbonate within the framework of this review, since although it belongs to covering materials, it is still more of a facing material and is used for permanent greenhouses. And all the varieties of universal covering materials available on the market can be divided into two main categories.

- Polyethylene film.

- Non-woven covering materials.

Until recently, polyethylene film was poorly represented and there was little choice, but now it is a broad category that unites several types. Like non-woven covering fabric, it is divided into a large number of subcategories with their own characteristics and specific application.

Spunbond

One of the popular materials for greenhouses is spunbond. This is a non-woven fabric consisting of polymer extruded fibers. It is ideal for covering greenhouses. Transmits light and provides free access of air, uniform distribution of both moisture and heat. Helps maintain a stable microclimate. Characterized by optimal thermal insulation properties. Practical and durable. Resistant to frost, chemicals and the influence of bacteria and mold. Safe for plants. Can be used all year round.

This material comes in three types:

- for open ground;

- for covering greenhouses or greenhouses;

- for mulching the soil.

The first two types are white, the last is black. Spunbond for covering greenhouses has a density of 30-60 g/sq. m.

Polyethylene films

A true “classic of the genre”, which once simply had no equal in demand in country life and the gardening sector. Before the advent of such modern polymers as cellular and monolithic polycarbonate, simpler greenhouses were covered with polyethylene in one or several layers; permanent greenhouses were glassed mainly with old windows. Despite the advent of non-woven fabric and SPC, even today the lion's share of greenhouses and greenhouses remains under film, which is not least due to its availability, significant improvement in characteristics and the emergence of specialized types. Even the most ordinary film perfectly protected from frost and wind and maintained the temperature inside the greenhouse.

But she also had plenty of shortcomings.

- Airtightness - because of this, the temperature in the greenhouse could rise to critical, so the arcs with film covering material had to be opened periodically.

- Formation of condensation - this disadvantage “flows” from the air tightness, condensing on the inside, moisture falls abundantly on the plants, which for many crops is fraught with diseases and a decrease in yield.

- Short service life - the shelter was enough for one season, since under the influence of the wind the material was worn on the arcs, and due to sunlight the polymer became brittle. In the spring, the film had to be changed, which is especially inconvenient and unprofitable in large greenhouses.

However, the latest generation of polyethylene is free from extreme disadvantages, and, depending on the subspecies, it can even be left for the winter.

CofessorFORUMHOUSE Member

Modern films also last for several years. The problem here is the mounting method that allows you to remove the film. The most convenient one is the Zigzag fastening. Although copolymer films do not need to be removed for the winter, they last up to 7 years without losing their transparency. Their transparency, by the way, is phenomenal. But in the design it is necessary to provide something like a corset that does not allow water, snow and ice to accumulate in winter, and the wind to fray the film. A base is also desirable, otherwise the snow will press down and may break through the shelter below.

Films have also appeared that are intended not only for greenhouses and greenhouses on arcs or frames, but also for beds.

Light-stabilized films - special substances have been added to the polymer composition to prevent the destruction of the material under the influence of ultraviolet radiation. This type of covering material is used not only for greenhouses and greenhouses, but also as a ground cover when planting garden crops. The black film attracts the sun's rays, creating a greenhouse effect between the rows; particularly stubborn weeds that manage to break through without solar feed literally “boil in their own juice.” But since the heating is local, it does not threaten the root system of cultivated plants planted in the slots. Not only can the beds not be weeded, and this is the procedure that takes up the lion’s share of gardeners’ time, but they can also be watered less often. The moisture from under the film practically does not evaporate and is not consumed by weeds.

Cellular polycarbonate

It is advisable to build medium- and large-area greenhouses from polycarbonate. It lasts up to 10 years or longer, withstands wind and snow loads, is not damaged by hail and does not deteriorate due to temperature changes. Plastic is inert; microbes and fungal spores do not multiply on it. Other advantages of the material:

- good light transmittance;

- no odor;

- ease;

- plastic;

- heat resistance.

If the material is heated, it can be bent to give the desired shape, but even with a strong increase in temperature, it does not spread combustion, but only melts. The structure of polycarbonate is formed by many small cells - honeycombs, thanks to which low thermal conductivity is achieved. Light transmission is 92-93%. Sheets are available with or without the addition of a UV stabilizer; you need to pay attention to this when purchasing.

Non-woven polypropylene fiber

Otherwise called agrofibre or agrotextile, since this is their direct scope of application and they “went” to the private sector from industrial greenhouse complexes. In this segment, the domestic manufacturer did not disappoint, and nonwoven materials are represented by both ours and foreign brands that have become household names - Lutrasil, Agrospan, and other brands. The technology itself for producing non-woven fabric from a melt of polymers is called spunbond, by analogy, all non-woven fabric as such is also spunbond, no matter who and wherever the material is produced, but today it is also one of the most popular brands. But in fact, there are no fundamental differences between different brands and all these are non-woven agrotextile materials, within the type differing only in density, color and specialization. That is, it is not so important whether it is spunbond or a covering material from another manufacturer; it is much more important to follow the rules of application related to the quality parameters of the fabric. The most important of them is density, which varies over a wide range.

- Light: 17-30 g/m² - the thinnest “web” with increased permeability, but quite capable of protecting plants from pests (try piercing a sunflower in gauze, and this is even cooler), and from summer fire, and from small ones (up to - 2 ˚С) return frosts. The canvas in this density range is light but durable; it is used to cover shrubs; it is used to make shelter for vegetable and berry crops by simply throwing it over plantings and securing it from the wind. But it is not intended as a covering material for arcs, and it is not capable of protecting beds from weeds, and this is not required of it.

- Medium: 42 g/m² - a universal group of materials intended both for constructing greenhouses on metal or composite arcs, and for protecting plants in winter. In a greenhouse with medium-density covering material, plants will be reliably protected from frost down to -6 °C, which allows you to get the earliest harvests of not only green vegetables, but also other garden crops. Seedlings, shrubs, perennial flowers that need shelter and other species are also wrapped in canvas. A greenhouse with covering material reliably protects against freezing and external influences, but allows light and air to pass through well.

- Dense: 60 g/m² - not only dense, but also quite weighty non-woven covering materials, intended primarily for mulching and covering heat-loving crops in winter. The canvas will keep you warm inside even at -10 ˚С, which is especially important in cold regions. Due to the weight, simply wrapping the plants is not an option; you will need a wooden or metal frame. This category is also actively used to cover greenhouses and greenhouses, including by participants of our portal.

Tatyana331 FORUMHOUSE participant

Our greenhouse is covered with agrospan 60. It’s quite good, the material hasn’t suffered during the year, I think it’ll be enough for a few more seasons. In the spring, they additionally covered the arcs with a layer of agrospan, but in the summer the plants did not overheat as in a glass greenhouse. But it lets water through.

Which is quite natural, since a non-woven covering material, even in arcs or on a frame, is still not a film and is not intended to create a sealed contour; it has a lot of other advantages.

meloman54FORUMHOUSE member

My neighbor installed Agrospan 60 on his homemade arched greenhouse, attaching it to the frame with narrow wooden slats. The end planes are decorated with polycarbonate. The material is dense enough to protect plants from sudden spring cold snaps, but it “breathes”, there is no danger of overheating in the heat, and there is no need for shading. The fact that water passes through is just normal and even desirable. Watering yourself can be problematic, especially if the owners come only on weekends.

And one more thing: the density of the material did not allow the holes from the nails under the slats to crawl into holes. The cover was removed for the winter, now, in the spring, it was put back on again, nailed down in the “traces” of last year’s holes. Choose dense agrospan; it will last for more than one season, even with such fasteners. Clips are a more gentle method of fastening, but also more expensive and scarce.

In addition to density, agrotextiles also differ in color; there are two main categories.

- White covering material can be light, medium or dense, and is used for its intended purpose based on density, with the difference that white spunbond or agrospan, even 60 g/m², is not used for mulching. But it feels great on permanent greenhouses and frames for winter shelters. And for mobile greenhouses on arcs, 42 densities are sufficient; such material will be cheaper, there will be no special load on squat structures and it will last for several seasons.

- Black covering material is only dense, as it was originally intended for mulching and creating conditions unsuitable for weeds due to its harsh greenhouse effect. Also, black agrotextiles (polyethylene) are used to “warm” the soil before planting crops, for which purpose a fabric of the desired size is pulled over the cultivated (dug up) area or directly onto the beds and tightly fixed at the edges. The material attracts the sun's rays during the day and prevents heat from escaping at night, resulting in intense heating of the soil. As soon as the air temperature reaches the desired values, you can begin sowing, rather than waiting another week or more until the ground also warms up enough. If such preparation is redundant for the southern regions, then for Moscow and similar climatic zones it is just in order.

Recently, two-layer nonwoven materials, both black and white and in other variations, have appeared on sale, but it does not make much sense to consider this covering material separately, since ordinary white and black nonwovens are sufficient to obtain the desired effect. Green non-woven fabric, intended for decorating and protecting tree trunks and flower beds, is also not the most popular product.

Reviews from summer residents

I want to warn gardeners against making mistakes. I bought black non-woven material so that the air in the greenhouse would not become waterlogged. I thought it was a great success, because we rarely have it on sale. I spread it out as indicated in the instructions, made slits for the seedlings, but it turned out that the material allowed moisture to pass through. The greenhouse was not ventilated, so dampness developed and the seedlings became sick. Now I will use all new products carefully.

Tamara Ivanovna, Omsk

In the summer we always use Lutrasil and Acrylic, or Ogril, I don’t know exactly what they call it, my husband buys everything. In winter for roses - Obernite. Our neighbor leaves reinforced film on the greenhouse for the winter and says that it is durable and does not deteriorate. This year we also decided to do the same, and the result was a lot of snow, and our covering material was torn. It's a shame, but now we'll be smarter.

Valentina Galichenko, Torez

We have been using spunbond at our dacha for 4 years now.

We cover the strawberries and vegetable beds after sowing, then the plants lift the canvas with their leaves. We take pictures when the weather gets warm. It is very convenient: the soil under the agrofibre breathes, but does not dry out, and there is no need to mulch. The downside: when it rains, you need to cover the beds with film, because the spunbond gets wet and becomes heavy, and all the water seeps through it. Svetlana, Balakhna

Features of application

The main specifics, rules and features of the use of covering materials depend on the method of use (arches, direct covering, greenhouses, greenhouses) and the density described above, but there are also some nuances.

- It is undesirable to connect tightly in width, this impairs uniformity and reduces the performance characteristics of the greenhouse or shelter. Manufacturers offer rolls and cuts of various sizes; you can choose the optimal ones, taking into account the characteristics of fixation. If this is a ground shelter, then it should extend beyond the garden bed by at least 10 cm on each side.

- This is not an immutable rule, but rather a piece of advice - in cold regions, for greenhouses on arcs, it is worth using films as a covering material, especially at the beginning of the season; they hold the temperature better and are not blown out. In areas where the sun poses a greater danger, non-woven fabric of suitable density is more relevant. Alternatively, combine these types throughout the season.

- Mulching strawberries with black non-woven fabric allows you not only to get rid of weeds and minimize care and watering, but also to speed up the ripening time. For this berry, not only humidity is important, but also warmth, and black intensely attracts the sun's rays, locally increasing the temperature. This feature is important when summer is not too sunny.

- For winter greenhouses, which is rare, but still found not only among farmers, but also among private owners, even the densest agrotextiles, even in several layers, are not an option. This is the prerogative of either reinforced or copolymer films, or cellular polycarbonate, or glass.

Shading nets

This material is not exactly covering material, but it is widely used by gardeners and gardeners, so it deserves attention.

The shading net performs the only function - it protects the plantings from the scorching rays of the sun. It can be placed on top of potatoes, cabbage, tomatoes, cucumbers, young seedlings, currant bushes, raspberries and gooseberries. In fact, the net is suitable for any plants. When working for a long time in a raspberry or other berry garden, the gardener himself can hide from the sun under the net.

The basis for the manufacture of shading fabric is polypropylene film. It contains a UV stabilizer, which achieves a scattering effect. White and green nets are produced, but upon request, manufacturers produce canvases of any colors. The length is not limited, the width is 3 m.

These are the main materials used to cover soil and plants in open and closed ground. What to choose is up to the gardener to decide, and he must take into account the purpose, service life and price, which differs significantly from different manufacturers.

Conclusion

Modern covering materials, both specialized films and non-woven varieties, are an excellent help for gardeners. It allows you to get a harvest earlier, spending less effort, and also provides reliable protection from pests and natural phenomena. And thanks to the large selection, you can find a suitable option in terms of price, quality and characteristics. When used for their intended purpose, either film or non-fabric lasts for several seasons, during which they will fully pay for themselves.

In our previous publications you can learn more about cellular polycarbonate and the nuances of its choice for greenhouses. And also about the nuances of construction and operation of winter greenhouses. The video is about an insulated greenhouse in harsh conditions.

Subscribe to our Telegram channelExclusive posts every week

Tips for choosing material

Before purchasing a covering material, you should take into account all the nuances of the canvas and ask which material is best suited for certain conditions. The following factors need to be considered:

- shelter area;

- climatic conditions of the area in which the greenhouse will be located;

- period of operation of the structure;

- crops that will be grown in the structure;

- the amount of money allocated for the arrangement of the greenhouse;

- purpose of use of the structure;

- complexity of installation.

When choosing a greenhouse, a gardener can rely on other factors that are important to him.

Video description

Find out what is the best way to cover a greenhouse in the following video:

Cellular polycarbonate

A significant part of the finished greenhouses offered on the market is made of cellular polycarbonate, a material that looks like two-layer plastic sheets connected by jumpers. For self-production, this covering material is also used; In a greenhouse made of polycarbonate, the following advantages are manifested:

- Light and fairly durable two-layer plastic produces greenhouses with excellent heat-insulating properties.

- Light transmission reaches 84%, greenhouses are fully illuminated.

- Long (15-20 years) service life.

- The flexibility of polycarbonate allows the production of radius-shaped greenhouses.

The following features are considered to be the disadvantages of using polycarbonate:

- Experience is required to work with this covering material. Polycarbonate deforms when heated (for example, a sheet 6 m long can increase the length by 5 cm), which must be taken into account during installation.

- Greenhouses require polycarbonate that is UV resistant (regular varieties become cloudy over time), but it is more expensive.

Polycarbonate provides good thermal insulation Source o-dveryah.ru

Manufacturers and retail price

The leading brands of nonwoven material for agriculture are Lutrasil (Freudenberg, Germany), Agril (Avintiv, France), Agrotex (Geksa Group, Russia), Agrin (Unispan, Ukraine) and Plant-Protex (Poland). On the Russian market you can buy spunbond from any manufacturer from official representatives and regional managers or in gardening stores.

For farms, covering material is sold in rolls of 100 m or more, the most popular width is 160 or 320 cm. When ordering products to order, dimensions may vary. For the needs of summer residents, manufacturers produce canvas 10 m long.

On the Internet you can find specialized stores offering spunbond at manufacturer’s prices, with additional discounts for wholesale. However, for a private country house, even retail will be quite acceptable. The price per meter is determined by the density of the material and the type of spunbond.

For wholesalers, the average price of spunbond with a density of up to 42 g/m2 is 3-6 rubles/m2, a density of 60-80 g/m2 will cost 7-12 rubles/m2. The average retail price (for 2016) for a package of 10 m of canvas will range from 170 (width 320 cm, density 17 g/m2) to 550 rubles. (width 320 cm, density 60 g/m2).