The frame of garden greenhouses and greenhouses is most often covered with inexpensive film material. Polyethylene retains heat well and does not allow precious moisture to escape. However, this material, unfortunately, is not very durable and strong. For many manufacturers, this has become an incentive to develop new high-quality films for greenhouses and greenhouses with improved performance characteristics. One of the most popular perennial covering materials among our gardeners has become the Svetlitsa film. The reviews about it online are simply excellent. At the moment, varieties of material of this brand are produced, intended not only for covering greenhouses, but also for mulching the soil, laying the bottom of reservoirs, etc.

Manufacturer

The film "Svetlitsa" was developed by specialists of the LLC "Shar" company. This domestic company was organized more than 20 years ago - in 1991 in St. Petersburg. Its main activity is the development of composite materials with a set of specified properties according to customer specifications, as well as the development of technologies for their production.

Shar LLC specialists conduct various types of research to significantly extend the service life of films under a variety of extreme conditions: elevated temperatures, intense UV radiation, high humidity, etc.

No. 6. Polyethylene films with special additives

If you introduce specific substances into polyethylene, you can slightly improve its performance. Depending on the additives, the following types of material are distinguished:

- Stabilized film is produced with the addition of substances that increase resistance to sunlight . The service life increases by 2-3 times, and the price also increases. The material may have an orange or pinkish tint, but this is not necessary. Externally, stabilized and regular polyethylene films are the same, so you need to carefully look at the packaging and labeling;

- light converting film “knows how” to convert hard ultraviolet radiation, harmful to plants, into infrared and red radiation, which increase productivity. All this is possible thanks to the phosphor additive, but in order for the material to last for a long time, it is necessary that the composition also contains stabilizing substances. To make sure that you really have a light-converting film in front of you, you need to shine it with an ultraviolet lamp, and the light from the lamp should change to red;

- heat retaining film has a matte whitish tint. It weakly transmits thermal radiation, so the temperature in the greenhouse will be 1-30C higher than in similar other types of film. Due to this, early harvests can be increased by 10-30%, saving on heating costs. The service life of the film is about 9 months, the material has antistatic and hydrophilic properties;

- stabilized hydrophilic film allows you to solve the “drop” problem characteristic of other types of material. Flat-drip condensate forms on this film in the form of a continuous layer, so there is no negative effect on plants. Light transmission is high, the ability to transmit thermal radiation is 30-35%, so it will be warm in such greenhouses;

- bubble wrap strongly resembles the one used to package fragile goods. It has good light transmission, and the level of thermal insulation is comparable to polycarbonate. The strength is low, with the exception of special types of film, but the material is suitable for growing early crops in a small greenhouse;

- foamed film consists of a monolithic and foamed layer of polyethylene, transmits 70% of light, retains heat well, and is suitable for the construction of greenhouses intended for vegetative propagation of plants;

- copolymer ethylene vinyl acetate has a decent level of strength, retains heat well, it is resistant to punctures, wind loads, frost, and hydrophilic. High light transmittance (up to 92%) can cause overheating on hot summer days. Durability – up to 3 years;

- Photodestructible film is destroyed after a certain period of time (20, 45 and 60 days). Used for frameless shelters and mulching.

Despite the stated service life, some experts recommend changing the film every three years, as it still becomes cloudy. If the material has retained its integrity, it can be used for other purposes.

You can also find films in the production of which several additives were used at once - this is the best option. But often, ordinary polyethylene films are issued under the guise of special films, so it doesn’t hurt to look at the certificates and markings.

According to GOST 10354-82, stabilized film for greenhouses and hotbeds is marked ST, stabilized light-converting film – SIC. You can also use film for greenhouses, which is marked with the letter H: this is a stabilized or unstabilized film for the manufacture of household products.

Varieties

The Svetlitsa film, the reviews of which from domestic consumers are simply excellent, is thus distinguished by truly remarkable qualities. At the moment, several varieties of this material are produced:

- Designed for mulching. Such films can have a variety of colors (green, yellow, black, etc.).

- Hothouse. Can transmit rays of different spectrums.

- For thermal curtains.

- For packing hay. A very durable and elastic variety. It is almost impossible to puncture such a film.

- Waterproofing films. Used as a protective agent in the construction of buildings, construction of reservoirs and sedimentation tanks, etc.

- For steaming the soil.

- Photodestructible films are used in operations such as tree grafting, vineyard mulching, etc.

Advantages of Svetlitsa film

The most important advantage of Svetlitsa film is durability. With proper installation, greenhouses made from Svetlitsa film will last more than 5 years. According to the manufacturers, the minimum service life is 7 years without the need for dismantling for the winter. And although the cost of this canvas is higher than that of conventional greenhouse polyethylene film, the latter option only works for one season. And this, in turn, requires the annual purchase of a new covering polymer, which of course is not profitable.

| The main problem with ordinary film after the summer heat in the cold is that it cracks. If it is not removed at the end of autumn, after winter it becomes completely unusable. |

A long-term operational period is not the only advantage of films for the Svetlitsa greenhouse.

Practical polyethylene Svetlitsa can be used as a material for greenhouse shelters located in different climatic regions of the country. So, even in constant use (when the film is not removed for the winter) in the northern zones, the canvas lasts for seven years. Svetlitsa film is equally good both in the south and in the north.

Advantages of greenhouse film

This variety is most widespread on the domestic market. The manufacturer lists the main advantages of such material as Svetlitsa greenhouse film:

- Durability. This material can last at least 7 years without being removed from the frame.

- Presence of a hydrophilic surface. Water drains from a structure covered with this material much easier than from a polyethylene one.

- High heat-retaining qualities. At night, under such a film, the air cools much less. Its average temperature is about 4 degrees higher than in a greenhouse covered with polyethylene.

- Ability to stick together under slight pressure. In places where there is an overlap, this film sticks together over time, making the entire structure completely airtight.

- Ability to transmit sunlight perfectly. The illumination of plants under such a film is 20% higher than under polyethylene.

- Flexibility. Thanks to this feature, the film for the Svetlitsa greenhouse is easily stretched onto the frame.

- Frost and hail resistance

Main characteristics and comparison of material

| Film SVETLITSA, sleeve 1.5 and 2 m, 200 microns | Differences between SVETLITSA film and polyethylene films: |

| Transparent sunny yellow film. | More transparent (20% more illumination) |

| Service life more than 7 years without removal | 3 times stronger, 1.5 times more elastic |

| Film thickness 120, 150 and 200 microns. | 5 times more resistant to wind loads |

| Rubber-like | 3 times more resistant to hail |

| Hydrophilic surface (no drops in the greenhouse) | Resistance to cracking is 16 times higher |

| Heat retention effect | Puncture resistance is 2 times higher |

| Frost resistance - minus 80'С | At night and during frosts, it is 2 -4'C warmer underneath |

| Productivity increases by 30% or more | |

In terms of external characteristics, the Svetlitsa film for greenhouses and greenhouses is almost no different from the classic polyethylene-based polymer canvas, with the exception of color. It is bright yellow, which makes it stand out among similar ones in the assortment. Reviews about the Svetlitsa film are only positive. Why do many summer residents and landowners prefer this particular polymer fabric? Everything is very simple: with a relatively small difference in price, this greenhouse material has improved performance characteristics

Transparent "Svetlitsa"

This film is yellow in color and is mainly used in the construction of greenhouses in the regions of central Russia. Its advantages, among other things, include the fact that it is practically dust-free. Microcracks appear on the surface of ordinary polyethylene within the next year after the start of use, into which dirt gets packed. As a result, the material loses its ability to transmit sunlight. “Svetlitsa” is a film for greenhouses that retains its transparency until the very end of its service life.

Improved characteristics of Svetlitsa film

Strength

Thanks to mechanical strength and high elasticity, the film base of this category is able to withstand strong and gusty winds of up to 28 m/s. In addition, such special properties help it cope with snow loads and other negatively affecting weather conditions, such as hail, snowfall, etc. And given that this polyethylene has high strength characteristics, you can freely clean the roof of the structure from snow mounds without fear that the fabric will tear or be damaged.

Thermal stability

Film for greenhouses Svetlitsa is highly resistant to temperature peaks, extreme heat and exposure to sunlight. These properties are invaluable for landowners and summer residents who grow seedlings and other cultivated vegetation in indoor gardens.

No tearing due to UV rays

Separately, I would like to note the presence of light-stabilizing additives in the composition of the fabric. Thanks to them, it is possible to avoid the destruction of polyethylene fabric under the influence of ultraviolet radiation, as always happens with samples made of classic polyethylene. In addition, the presence of such substances in the polymer prevents the formation of cracks, which reduce its mechanical strength properties.

Hydrophilicity - the ability to absorb water well

Good water absorption is another unique property of Svetlitsa film. This feature is determined by the ability of the fabric to prevent the formation of condensation in the form of droplets on the surface. The latter, dripping onto plants, contribute to their destruction and inhibition of development, which does not have a very good effect on yield. Of course, we are not talking about the complete absence of condensation. It is simply distributed over the fiber in an even layer and, if there is an excess, flows down in a stream down the fabric.

Some crops, tomatoes, nightshades, etc., do not tolerate even drops of water getting on their flowers. It is when growing such plants that it is recommended to use a greenhouse or polycarbonate.

Features of using greenhouse transparent films

It is better to arrange a frame of a light shade under the yellow covering material. The fact is that dark metal or plastic gets very hot in the sun. Therefore, in places adjacent to such frame structures, the Svetlitsa greenhouse film experiences extreme temperature loads. And this somewhat shortens its service life. Therefore, all dark elements of the frame should be painted white. Before you start stretching the film, you need to dry it thoroughly. Exposure to chemicals can also damage the covering material and shorten its lifespan.

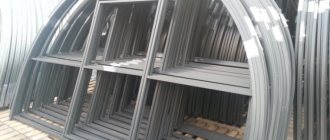

Reinforced fabrics

In the production of reinforced covering materials, light-stabilized polyethylene is used as a basis, and it is additionally reinforced with propylene threads. It is possible to obtain a material that is good for covering large areas with a minimal frame.

This type of film is not widely used due to its controversial properties. On the one hand, it is indispensable for wind loads. Tall and long greenhouses with a light frame are the main area of application, especially in regions of risky farming. But reinforced material also breaks easily from mechanical stress and requires careful fastening with special clamps. At the same time, the light transmittance coefficient due to the addition of polypropylene increases by at least 20 percent. The decomposition period in the natural environment also increases significantly, so you cannot simply throw it away; it must be recycled.

On a note! Such a film can easily be broken with a sharp object, so it still requires care during installation and further maintenance.

When choosing a perennial reinforced film, you need to pay special attention to the density of propylene threads. The higher it is, the stronger the canvas, the less light and air it lets through. You can also find products with special ventilation holes, but they are much more expensive. In some cases, reinforcement is carried out using glass fibers. Such materials will be unsuitable for use in agriculture if they are not made in accordance with the standards. Fibers can contaminate soil and water if they break through to the surface, so a composition with polypropylene is considered safe.

Opaque "Svetlitsa"

A distinctive feature of this type of film is its ability to reflect excess ultraviolet radiation. The color "Svetlitsa" - an opaque film for greenhouses - is white. This option is very good for constructing structures on a frame in hot regions of the country, as well as for constructing greenhouses for seedlings of crops that do not tolerate overheating very well. An opaque film is also used to shade plants that need it.

Mulch film

This material is used to protect plants from weeds and also to prevent the soil from drying out. In addition to strength and elasticity, the Svetlitsa mulching film, reviews of which allow us to judge it as very high quality, is also distinguished by its durability. It can remain in the garden bed for at least 5 years without the need for replacement. Films of this type are used for both open and closed soils. This covering material is especially often used for mulching strawberries. However, you can use it to protect against weeds and any other garden crops.

Unstabilized species

Plain polyethylene film, which has not undergone stabilization, was the first to come into use in private households. This is the thinnest fabric with minimal strength and durability. It is used as a shelter for one season, and it is better to use it for greenhouses and greenhouses, which are planted from mid-spring to mid-autumn. The material transmits up to 90 percent of radiation, so the plants will receive maximum ultraviolet radiation, but the air inside also cools down quite quickly.

On a note! During spring frosts, it is important not to maintain the temperature inside, but not to allow the cold fog to settle on the plants and soil, so even a thin film is effective.

The service life of such canvases is one season. They are most often sold in pure form, that is, containing only low- and high-density polyethylene, without copolymer additives. If there is more LDPE in the composite, the stretch effect will be clearly pronounced, but the service life and strength will be even lower. The more HDPE in the composition, the thicker the canvas, the more resistant it is to mechanical stress, but the less elastic. PVC film is also offered in an unstabilized form. Its use and even production are prohibited in many EU countries due to the high level of toxicity of the material itself. Products made from polyethylene are absolutely safe, so it is recommended to buy them.

When installing, you must be careful and follow the advice:

- Excessive stretching should not be allowed; it is permissible to lay the canvas in two layers to increase strength and thermal insulation.

- It is better to use smooth PP pipes of small diameter as a frame.

- Many site owners burn such film after one season; this is acceptable if the area of the canvas is small, but it would be more correct to hand it over to recycling points.

- When purchasing, you need to pay attention to the environmental class. Manufacturers can use those substances that are recognized as relatively safe. For example, clarity additives are toxic when burned or exposed to extreme heat.

Material "Water"

The rubber-like film “Svetlitsa” is mostly used when constructing ponds. Thanks to its elasticity, it is puncture resistant. Also, the advantages of this material include frost resistance and durability. Ordinary polyethylene film, when used to lay the bottom of a reservoir, lasts no more than 2-3 years. “Svetlitsa” doesn’t have to be changed for all ten. This wonderful material can easily be installed on any, even the most complex, terrain. It is not damaged by plant roots.

If desired, you can choose a transparent film for ponds with a beautiful blue tint, through which the bottom is clearly visible. A very popular option is black material. This film makes ponds visually deeper.

No. 4. Reinforced film

Reinforced film differs from ordinary polyethylene film by the presence of a unique frame made of fiberglass, pressed, twisted or stretched polyethylene or polypropylene, the thickness of the frame threads is 0.29-0.32 mm. Polyethylene, as a rule, is used more durable, sometimes with additives for greater resistance to sunlight. The main load is borne by the frame, so a greenhouse with such a coating becomes resistant to wind, snow and even hail. The film can protect seedlings even in frosts down to -50C.

The material will last in the greenhouse for more than a year, usually it lasts for three seasons , but some manufacturers talk about a service life of 5 or even 7 years, but much depends on the characteristics of the film and the climatic conditions of the region. Reinforced film is more repairable : holes can be sealed with tape, they do not tend to spread to the entire canvas. The main characteristic of the material is not thickness, but density. The most common material is considered to be with a density of 120-200 g/m2. There is a film on sale with holes in the cells, which provides the greenhouse with proper tightness, but does not allow the air to be “preserved” in it.

The durability and strength of reinforced film comes at a higher price . In addition, the light transmission of this material is slightly lower than that of a conventional stabilized film, and dust is very difficult to wash off due to the relief, which also harms transparency.

Film from Dirs Stroy LLC

produces and sells reinforced and polyethylene films of different densities and sizes. All standards are observed in production, strict quality control is carried out, and high-quality and safe raw materials are used. All products are accompanied by quality certificates, and since production is located in the Moscow region, product prices are more favorable than those of many competitors. You can get acquainted with the products and terms of purchase on the company’s website.

Film for greenhouses “Svetlitsa”: reviews

The owners of suburban areas, who have already tried this material, praise it very much. This is especially true for greenhouse varieties of film. Due to the hydrophobicity of the material, drops do not appear on the walls of the frame structure from the inside. Thanks to this, plants get sick less. As a result, productivity increases. Russian gardeners also consider it very convenient that greenhouses covered with this material are not damaged even by large hail. And, of course, the most important advantage of this film is its ability to last for several years without loss of light transmittance.

There are also very good reviews on the Internet about the material intended for mulching beds. Thanks to the variety of colors, you can choose the option most suitable for creating a particular soil temperature regime.

No. 8. Film color

It is better to choose a transparent film - it lets in more light. To obtain material of different shades, food coloring is usually added to the composition, which tends to fade under the rays of the sun, so there is no point in it. If the paint is persistent, then less light will penetrate into the greenhouse, which will lead to a decrease in yields and the need to use additional lighting.

approximate cost

The price of a linear meter of Svetlitsa film can vary quite widely depending on the type and thickness. This material is supplied in rolls, usually in the form of a sleeve 1.5-2 m wide. The thickness of the greenhouse version can be 100-200 microns. A roll costs about 7000-11500 rubles. Of course, you can buy Svetlitsa film by linear meters. The cost of one is 90-220 rubles.

In general, the material is not bad - Svetlitsa film. Reviews from owners of suburban areas speak about this more than eloquently. It costs, of course, more than polyethylene. However, in the end, its purchase is justified due to its long service life.

Heat-retaining polyethylene

A number of materials have similar properties. First of all, these are the already mentioned air bubble sheets. In them, the temperature is maintained due to the presence of insulated chambers and the large thickness of the covering material. Another design is matte polyethylene films, which have special heat generation properties due to the conversion of ultraviolet rays. Manufacturers achieve this effect by creating complex polymers with many additives. The basis is the same - polyethylene in various combinations, the opacity of the film is given by polypropylene, which has minimal heat transmission capacity.

Advantages and disadvantages:

- Such covering materials have a very short service life at a high price. This is the main disadvantage.

- They are not used for more than one season, but if the greenhouse is year-round, replacement may be required after 7 or 8 months.

- In terms of its strength, it is almost a reinforcing film for large greenhouses; it is quite difficult to tear a thick layer of material. Therefore, installation is not difficult.

- When installing a greenhouse, you need to choose the most sunny place so that the heating will be optimal and the illumination will be optimal. In such greenhouses, the crop ripens approximately 15-20 percent faster, which is why they are often used for industrial purposes.

From an environmental point of view, such durable films for greenhouses are not the most dangerous. They are completely harmless to the environment and decompose faster than many of their analogues, especially in the presence of sunlight. But the material cannot be burned due to the large number of additives, nor can it be buried in the ground.

On a note! Polyethylene is safe from a fire point of view. It instantly melts without supporting combustion, so it can be used even near the house.

Materials of this type are best suited for year-round greenhouses in which crops are planted in both winter and summer. However, when constructing the frame, it is necessary to provide for the possibility of opening and frequent ventilation. Since the heat does not escape anywhere from the internal space, a ripening effect may occur, which is dangerous for plants.

These properties are directly related to frost resistance. Such films are well suited for covering permanent greenhouses that are not removed for the winter, especially in northern climates. At temperatures down to minus 80 degrees, the film does not “tan” or crack. It loses a little elasticity, so during this period it is better not to perform any manipulations with it, but to wait for at least a little warming up.