Svetlitsa film for greenhouses differs from other types of covering materials in a number of properties.

Thanks to new technologies, modern covering materials have emerged that are characterized by high strength characteristics. Svetlitsa film is among the most affordable and optimal for covering greenhouse frames. It's inexpensive and easy to work with.

Main characteristics and comparison of material

| Film SVETLITSA, sleeve 1.5 and 2 m, 200 microns | Differences between SVETLITSA film and polyethylene films: |

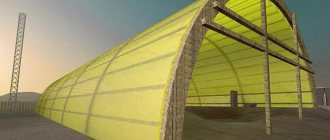

| Transparent sunny yellow film. | More transparent (20% more illumination) |

| Service life more than 7 years without removal | 3 times stronger, 1.5 times more elastic |

| Film thickness 120, 150 and 200 microns. | 5 times more resistant to wind loads |

| Rubber-like | 3 times more resistant to hail |

| Hydrophilic surface (no drops in the greenhouse) | Resistance to cracking is 16 times higher |

| Heat retention effect | Puncture resistance is 2 times higher |

| Frost resistance - minus 80'С | At night and during frosts, it is 2 -4'C warmer underneath |

| Productivity increases by 30% or more | |

In terms of external characteristics, the Svetlitsa film for greenhouses and greenhouses is almost no different from the classic polyethylene-based polymer canvas, with the exception of color. It is bright yellow, which makes it stand out among similar ones in the assortment. Reviews about the Svetlitsa film are only positive. Why do many summer residents and landowners prefer this particular polymer fabric? Everything is very simple: with a relatively small difference in price, this greenhouse material has improved performance characteristics

Advantages of Svetlitsa film

The most important advantage of Svetlitsa film is durability. With proper installation, greenhouses made from Svetlitsa film will last more than 5 years. According to the manufacturers, the minimum service life is 7 years without the need for dismantling for the winter. And although the cost of this canvas is higher than that of conventional greenhouse polyethylene film, the latter option only works for one season. And this, in turn, requires the annual purchase of a new covering polymer, which of course is not profitable.

| The main problem with ordinary film after the summer heat in the cold is that it cracks. If it is not removed at the end of autumn, after winter it becomes completely unusable. |

A long-term operational period is not the only advantage of films for the Svetlitsa greenhouse.

Practical polyethylene Svetlitsa can be used as a material for greenhouse shelters located in different climatic regions of the country. So, even in constant use (when the film is not removed for the winter) in the northern zones, the canvas lasts for seven years. Svetlitsa film is equally good both in the south and in the north.

Introduction:

To be honest, a greenhouse has never been a priority for us, and the cultivation of the main vegetable crops (cucumbers, tomatoes) on our plot was carried out in open ground, using the simplest greenhouses made of covering material in the early stages of plant growth. The harvest was always quite satisfactory for a small family; there was always enough for a daily fresh summer salad. And all this was fine until we had to deal with the complete loss of the tomato crop (blackening) and the unsatisfactory quality of the “cucumber” products due to very unstable weather last summer. It becomes a pity to spend time and labor on preparing the soil, planting seedlings, watering, caring - and as a result you end up with a pile of tops that is unsuitable even for a composter. In this regard, it was decided to build a full-fledged greenhouse, with high beds, where there would be no restrictions on the types of crops grown (due to small greenhouses, it was necessary to choose low-growing varieties, and the peppers did not have time to ripen at all). The greenhouse design according to Mittleider was chosen. This design worked successfully for gardeners I knew. The frame of the greenhouse was designed from pine lumber with the bottom frame supported by concrete pillars. A simple greenhouse project was developed in SketchUp. The dimensions of the greenhouse in plan are 8000 mm x 3400 mm. The height from the base (ground) to the lower chord of the truss is 1800 mm, you can move freely to your full height. The greenhouse was planned to be divided into two sections, for different vegetable crops. By the way, the project is missing a very important detail; more on that later).

Properties of the polymer film Svetlitsa

Such performance characteristics are largely due to the unique structure of the fabric, thanks to which other properties are achieved:

- mechanical tensile strength in comparison with the classic sample, this figure is three times higher

- Resistance to punching and puncture is three times higher than that of ordinary polyethylene

- high elasticity

- Impact resistance is five times higher than that of classic polyethylene film

- good heat retention properties due to low transparency for thermal infrared radiation

| The brightness film is not electrified and, accordingly, does not attract dust particles. Even after a season, you don’t have to clean it, which can’t be said about regular film, from which you have to wash off the dirt and dust that has stuck on at least once a week. |

In addition, the film manufacturer Svetlitsa guarantees high frost resistance. Thus, the film base of this category can withstand even temperatures of -80°C

This material is produced in rolls, the width of which can be 1.5 m, 2 or 3 meters. The thickness of the Svetlitsa film is 0.12 or 0.15 mm. As for the length of the roll itself, the footage largely depends on the manufacturer and on the seller, who can form rolls according to individual orders

Video: Choosing a film to cover a greenhouse

Helpful Tips for Durability

It wouldn't hurt to follow a few simple but very useful tips. So, when installing the greenhouse itself, it should be positioned so that the impact of wind and light falls predominantly on the end block.

It is also worth remembering that the largest gap between the frame racks, provided that a film with a thickness of 120 microns is used, should not exceed 1 m.

It is also important to take care in advance of strengthening the frame, the lack of strength of which can lead to very unpredictable, but at the same time unpleasant consequences. Don’t forget about periodically cleaning the surface from fallen snow, especially after heavy snowfalls or blizzards.

It should also be taken into account that this light-stabilized film produced in the form of a sleeve also has a vulnerable spot, which occurs at the bend. It is for this reason that during the installation process it is imperative to reliably strengthen the structural element on which this bend will fall. This is often the strong point of a greenhouse.

Optimal color scheme for the base

The choice of color for the frame also deserves attention. Practice shows that dark paint negatively affects the integrity of the coating and leads to its premature aging - during the hot period, the heating temperature of such a frame reaches +70°C. It is for this reason that experts advise painting the structure exclusively white.

Such a solution will almost halve the heating temperature of the base, and will have an exclusively positive effect on the illumination inside the greenhouse, increasing this indicator by approximately 5-10%.

Improved characteristics of Svetlitsa film

Strength

Thanks to mechanical strength and high elasticity, the film base of this category is able to withstand strong and gusty winds of up to 28 m/s. In addition, such special properties help it cope with snow loads and other negatively affecting weather conditions, such as hail, snowfall, etc. And given that this polyethylene has high strength characteristics, you can freely clean the roof of the structure from snow mounds without fear that the fabric will tear or be damaged.

Thermal stability

Film for greenhouses Svetlitsa is highly resistant to temperature peaks, extreme heat and exposure to sunlight. These properties are invaluable for landowners and summer residents who grow seedlings and other cultivated vegetation in indoor gardens.

No tearing due to UV rays

Separately, I would like to note the presence of light-stabilizing additives in the composition of the fabric. Thanks to them, it is possible to avoid the destruction of polyethylene fabric under the influence of ultraviolet radiation, as always happens with samples made of classic polyethylene. In addition, the presence of such substances in the polymer prevents the formation of cracks, which reduce its mechanical strength properties.

Hydrophilicity - the ability to absorb water well

Good water absorption is another unique property of Svetlitsa film. This feature is determined by the ability of the fabric to prevent the formation of condensation in the form of droplets on the surface. The latter, dripping onto plants, contribute to their destruction and inhibition of development, which does not have a very good effect on yield. Of course, we are not talking about the complete absence of condensation. It is simply distributed over the fiber in an even layer and, if there is an excess, flows down in a stream down the fabric.

Some crops, tomatoes, nightshades, etc., do not tolerate even drops of water getting on their flowers. It is when growing such plants that it is recommended to use a greenhouse or polycarbonate.

Other features of Svetlitsa film

It is highly elastic, durable, resistant to wind, frost, punctures, pressure, does not crack, is not afraid of hail, and does not allow the earth to overheat. Holds well and retains the heat accumulated during the day longer.

With the help of such a film you can create additional lighting in more shaded areas of the greenhouse or vegetable garden. Drops of moisture formed on the inside flow down the walls without hitting the plant. Due to the unique combination of high strength and elasticity, it lasts up to 7 years.

Several types of such film are produced. White light-diffusing “svetlitsa” protects plants from overheating. It is very convenient, especially in the south, when growing seedlings and coniferous plants (used for shading). The reflective “svetlitsa” (it is black on one side and white on the other) is intended for mulching the soil in greenhouses and open areas.

Provides additional lighting and retains heat accumulated during the day, preventing overheating. Adheres tightly to the soil, suppressing the growth of weeds. The soil underneath is always warm, loose and moist. By covering the lower part of the greenhouse with this film, you can give the plants additional lighting.

| If there is a need to dismantle the coating, then you should not resort to radical methods. Sticky edges are easily separated, while maintaining their performance properties |

All these features make it possible to create an optimal microclimate in greenhouses and greenhouses, thereby accelerating ripening time and increasing yield.

Construction of the greenhouse frame:

A columnar foundation was chosen for the greenhouse. I made wells with a 100mm hand drill, inserted a 110mm sewer pipe, and filled it with self-mixed concrete. M12 embedded studs were made in each post to secure the lower frame of the greenhouse.

It was decided to take the material for part of the greenhouse structures from the existing remains after the construction of the house (sections from floor beams 100mm x 200mm), and to dismantle the beams a serious saw was required. Therefore, the “beast” Makita 5008MG was purchased to help. The most positive impressions.

So, long-awaited sections of 100x200 beams were selected, which needed to be cut into two parts of 100x100:

To saw the beams, I quickly made an improvised sawing base:

To be honest, it’s not the best solution; the disc bites when it meets the unevenness of the beam and the parallel stop. But in the end I sawed through.

To splice and fasten the resulting beams on the posts, I chose quarters at the ends, 100x50 in cross-section. Used a miter saw. I made several cross cuts and knocked out the resulting sectors with a hammer:

Next, I cleaned the surface by longitudinally moving the timber under the working saw blade.

To fasten the beams to the posts on studs with M12 nuts, I made recesses for the washer and nut with a Forstner drill:

The shank of the 13 mm drill I purchased turned out to be too large for my screwdrivers, so I came up with a kind of adapter:

I secured the strapping bars to the posts:

To make the vertical posts of the greenhouse frame, I prepared the next beams for sawing. Each beam should make 4 racks. This time I decided to simply mark the cutting lines with a pencil and saw the timber on both sides. This happened much faster, the saw goes through the entire depth of the cut like clockwork, without even choking, its capabilities really amazed me, a very powerful device:

The resulting racks had to be planed, so an additional electric planer was purchased to help, another addition to the fleet of useful power tools:

Ready racks:

Prime and coat with water-based paint:

At this point, the supply of old lumber of the required length ran out, so the next structural elements were made from purchased timber with a section of 100x50.

Assembling the first side wall:

To obtain a length of 8 m, we connect 6 m and 2 m bars with quarters using PVA glue and self-tapping screws:

Add posts and diagonal struts, one on each side:

We assemble the end walls in place, after lifting the side walls of the greenhouse. If you noticed, another pillar appeared, the trim was cut, and finally a door appeared, which somehow miraculously was not designed earlier.

We begin to assemble farms. We fasten all elements with galvanized self-tapping screws:

After painting the trusses, add overlays to the truss nodes and add a pack of screws, and finish painting:

We cover the upper planes of the trusses with foamed cushioning material (shoot with a stapler) to avoid unnecessary contact between the film and the wood:

We install the trusses and connect everything with a front board:

We add internal struts, which also serve as a common wall for the two sections of the greenhouse:

We make the covering of the greenhouse base from cut-up DSP boards, painted with rubber paint (we will also make beds from them). The DSP strips were attached to the bottom trim with roofing screws that remained from the roof of the house.

At this stage, it is necessary to proceed to the construction of beds inside the greenhouse in order to complete all the basic work before the process of covering the greenhouse with film.

The frame of the beds was welded from a steel profile 20x20x1.5

We saw pre-prepared 10mm thick and 300mm high CBPB plates to size (we bought whole CBPB sheets, sawed the plates with a circular saw and painted them with rubber paint) and fastened the plates to the frame of the beds with galvanized self-tapping screws with a press washer:

We lay the bottom of the beds with old boards, fill them with a variety of greens and rotted “goodies” - used straw cassettes for growing oyster mushrooms, which a local enterprise distributes to everyone:

Fill the beds to the top with soil:

We make greenhouse windows from 30x30 bars, paint them, install hinges, 3 pcs. on one 4-meter window:

We also prepare 30x10 overlay strips for attaching the film to the greenhouse structures, paint it with paint and nail the foamed “buffer” material

Attention! The photo above shows a very dangerous position of the saw. The saw is at a very low level, which makes it possible to move above it, and this is simply very dangerous! This arrangement of the saw led to the fact that, moving behind the block, essentially over the sawing table, I waved my hand over the saw blade, and the saw, without thinking at all, snatched off part of the nail phalanx of my right finger. The bone was not affected, and now everything has healed, the finger is like new, but the recovery process is very long. It's good that it is!

Always think about safety! As practice shows, the more work experience, the less you think about safety, you already know and can do a lot, the feeling of fear and caution dulls, and at the most unexpected moment such unpleasant things come out.

Application of Svetlitsa film

| When choosing such a product, you need to not only ask yourself how much Svetlitsa film costs, but also take into account its purpose. This is what determines the service life and suitability of the product for the purpose of a particular structure. |

Based on the scope of application of Svetlitsa film, we highlight the main ones:

- bases for mulching - laying the canvas on the ground to protect seedlings from weeds and improve the properties of the soil;

- the greenhouse option provides good light transmission and protects vegetation from the harmful solar spectrum;

- models for arranging thermal curtains;

- packaging polyethylene for hay film Svetlitsa, thickness over 150 microns, practically does not tear and is not pierced by sharp objects;

- high quality waterproofing sheets allow them to be used as a protective layer during the construction of structures, construction of artificial reservoirs, settling tanks, etc.;

- for steaming soil;

- photo-destructive polymers are used during grafting of seedlings, mulching of vineyards and other identical processes

A favorable climate for plants is formed under the Svetlitsa film. The productivity of tomatoes increases by 20%, cucumbers by 30%

Manufacturer

The film "Svetlitsa" was developed by specialists of the LLC "Shar" company. This domestic company was organized more than 20 years ago - in 1991 in St. Petersburg. Its main activity is the development of composite materials with a set of specified properties according to customer specifications, as well as the development of technologies for their production.

Shar LLC specialists conduct various types of research to significantly extend the service life of films under a variety of extreme conditions: elevated temperatures, intense UV radiation, high humidity, etc.