No. 1. Advantages and disadvantages of greenhouse film

Previously, only plastic film was used to cover greenhouses. At the moment, summer residents are offered more advanced analogues, in which some of the disadvantages are less pronounced. In general, all types of films that are used to equip greenhouses and greenhouses are characterized by common pros and cons.

Main advantages:

- low price. There are price differences between different types of film, but compared to glass and polycarbonate it is still a budget option;

- high elasticity and plasticity, so with the help of film you can equip a greenhouse of any shape;

- moisture resistance;

- high level of light transmission and ability to diffuse sunlight;

- low weight and easy installation.

Main disadvantages:

- low durability. When choosing plastic film, you should be prepared that it will need to be changed next season. More expensive analogues will have to be replaced after 2-3 seasons;

- low resistance to sunlight, which leads to rapid destruction of the material, but in some films this disadvantage is not so pronounced;

- Condensation accumulates on the surface of the film, which is harmful to most crops grown in the heifer. This drawback was avoided by hydrophilic films, in the production of which special additives are used;

- accumulation of electrostatic charge, which helps attract dust, and this, in turn, reduces transparency. Manufacturers are also trying to combat this disadvantage by introducing special additives.

Many summer residents also complain that the film stretches and sag, so they have to constantly tighten it. But the presence of so many significant disadvantages still does not make the material less popular, because this is the cheapest way to equip a greenhouse in the country, and many believe that it is more profitable to change the coating once a year than to immediately spend money on buying expensive polycarbonate.

Types and characteristics

Regular greenhouse film can be one of several types:

- Polyethylene film is usually produced thin, unstabilized. The service life of this material does not exceed a year, since direct sunlight destroys the polyethylene layer;

- . The coating of this film will not allow moisture to accumulate on the surface of the material, and therefore in the greenhouse the microclimate created inside the greenhouse is more favorable for delicate garden crops. In addition, such a film deteriorates much more slowly under direct sunlight;

- Greenhouse heat-retaining film intended for use in cold regions. It retains 10-15% more heat, which can become critical in autumn or spring;

- . The three-layer material, reinforced with a thin reinforcing mesh, has a large margin of strength and lasts many times longer.

In addition, it is very important to choose a covering material of the correct thickness, since both the thermal insulation properties and service life depend on its density. But the density of polyethylene also affects its cost, so a dense film, which can be used for gardening for more than one season, will cost more than a thin, annual one.

As a rule, for light greenhouses a thin material is used that does not have high heat-insulating properties, but for permanent greenhouses, on the contrary, a dense, heavy film is used that retains heat on the cold days of the year. The density of polyethylene affects the weight of the roll.

Based on this data, when purchasing, you can identify dishonest sellers who pass off a thin coating as a dense one. But it should be remembered that the weight largely depends on the width of the roll, and it, in turn, can be different.

No. 3. Polyethylene film

The main advantage is low cost . The film transmits about 80% of thermal radiation, so daytime heat is poorly retained at night. Properly installed high-quality polyethylene film will last no more than a season , and is unlikely to survive the winter, since temperature changes, wind and snow will destroy the material. Even the thickest films are not particularly durable.

Polyethylene film is very delicate , so it must be transported and installed very carefully. Even the smallest cut will soon “grow”, which will negate all efforts to arrange the greenhouse.

The material is sold in rolls 1.2-3 m wide; it can be a single-layer fabric or a sleeve. In the second case, the material can be cut along the seam and a wider sheet can be obtained, or you can cover the greenhouse with a sleeve, although you should not count on a significant increase in durability. The bend of the sleeve is considered the weakest point and is destroyed first, so it is better to immediately strengthen it with tape.

How to cover a greenhouse with film

You need to know how to cover a greenhouse with a film with a wooden or metal frame. Work should be performed at a temperature of 10-15°C, at which the film web is stretched without overhanging or tension. To prevent rubbing, the skates and protruding corners are pre-glued with transparent tape.

The canvas is attached to the frame with self-tapping screws or nails with a wide head; the limiter can be a rubber washer, a strip or strip made of wood, polymer, or durable tape. The overlaps at the junction of the strips must be at least 15 cm; such a connection is glued with tape.

Before covering the greenhouse with film, the following frame elements must be processed:

- There should be no burrs, irregularities or sharp edges on wooden parts. Defects are processed with sandpaper.

- There is no rust on metal rods and welding areas.

The choice of which film is best to cover the greenhouse depends on climatic and operating conditions and the characteristics of the covering material.

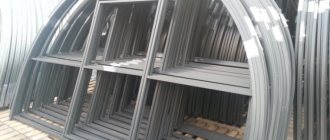

No. 4. Reinforced film

Reinforced film differs from ordinary polyethylene film by the presence of a unique frame made of fiberglass, pressed, twisted or stretched polyethylene or polypropylene, the thickness of the frame threads is 0.29-0.32 mm. Polyethylene, as a rule, is used more durable, sometimes with additives for greater resistance to sunlight. The main load is borne by the frame, so a greenhouse with such a coating becomes resistant to wind, snow and even hail. The film can protect seedlings even in frosts down to -50C.

The material will last in the greenhouse for more than a year, usually it lasts for three seasons , but some manufacturers talk about a service life of 5 or even 7 years, but much depends on the characteristics of the film and the climatic conditions of the region. Reinforced film is more repairable : holes can be sealed with tape, they do not tend to spread to the entire canvas. The main characteristic of the material is not thickness, but density. The most common material is considered to be with a density of 120-200 g/m2. There is a film on sale with holes in the cells, which provides the greenhouse with proper tightness, but does not allow the air to be “preserved” in it.

The durability and strength of reinforced film comes at a higher price . In addition, the light transmission of this material is slightly lower than that of a conventional stabilized film, and dust is very difficult to wash off due to the relief, which also harms transparency.

Film from Dirs Stroy LLC

produces and sells reinforced and polyethylene films of different densities and sizes. All standards are observed in production, strict quality control is carried out, and high-quality and safe raw materials are used. All products are accompanied by quality certificates, and since production is located in the Moscow region, product prices are more favorable than those of many competitors. You can get acquainted with the products and terms of purchase on the company’s website.

How to extend the life of film

To increase their service life, even durable covering materials require proper installation and careful handling. In addition, you need to know that you need to remove the film from the greenhouse for the winter. There are several reasons:

- If the canvas is thin, then under the pressure of snow it will sag and may tear from strong winds.

- High-strength canvas is resistant to negative influences, but there is a high probability that the wooden frame will not withstand the load created by snow.

If it is possible to take care of and remove snow in a timely manner during the winter, then the stronger and more durable canvas can not be removed from the frame, but only free the upper part so that the snow can get inside.

No. 5. PVC films for greenhouses

Polyvinyl chloride films are one of the best options for arranging greenhouses. This is an elastic and durable material that can last from 2-3 seasons to 6-7 depending on operating conditions, care and climate. As a rule, light-converting and stabilizing additives are added to the composition.

The material transmits up to 90% of light, 80% of ultraviolet radiation and blocks up to 95% of infrared radiation, which means that at night and during frosts the greenhouse will be warmer than in the same one made of plastic film. This is a very significant advantage of the material.

The disadvantage of the material is the price, which is 2-3 times higher than the cost of the polyethylene analogue, but taking into account the fact that there is no need to buy a new film and install it every season, this disadvantage cannot be called too significant. Another nuance - polyvinyl chloride strongly attracts dust , but it is also easy to wash off. The frost resistance of the material is low; at temperatures below -150C the film becomes too fragile, so heating will be mandatory for winter greenhouses.

How to glue?

Sometimes the size of a sleeve, even a wide one, is not enough to completely cover a greenhouse or greenhouse. And then gardeners and summer residents have to look for a way to place the greenhouse frame under a small film.

Greenhouse polyethylene film, even made from dense material or reinforced, is not at all resistant to high temperatures. Therefore, to glue the coating, you need to use one of the devices:

- Iron. Even an ordinary household iron can melt polyethylene and weld the pieces to each other. But you must remember that it can also remain on the sole of the iron, and therefore you should definitely put fabric or paper on the layer of covering material. The iron glues the layers of coating together quite slowly, but reliably;

- Construction hairdryer. A faster way to glue parts of the coating, but also more dangerous. Since a construction hair dryer heats up to a high temperature even when operating at low speeds, the polyethylene greenhouse film can melt or stick together unevenly. After the layer of polyethylene has melted, it is necessary to iron it with a smooth, dense roller to press the layers together;

- A special device that will provide both the required temperature and the required pressure. The device is quite expensive, but the quality of the seam is noticeably higher than with homemade gluing. Some stores or manufacturers that sell greenhouse film can cut and glue the material at the request of customers.

Greenhouse polyethylene film is glued quite simply, but it is a long and painstaking job that one person cannot handle. As a rule, to glue a sleeve of even a small width with a hairdryer or iron, you need at least two assistants, one of whom will iron the material with a roller, and the second -.

To glue the greenhouse film correctly and to ensure that the seam is reliable, it is recommended to make a large overlap. Experienced gardeners and manufacturers recommend leaving at least 25-30 cm on each side of the sleeve for gluing. When processed in this way, the seam will be strong enough to withstand rain, hail and gusts of wind, and the service life of the greenhouse will not depend on natural disasters.

No. 6. Polyethylene films with special additives

If you introduce specific substances into polyethylene, you can slightly improve its performance. Depending on the additives, the following types of material are distinguished:

- Stabilized film is produced with the addition of substances that increase resistance to sunlight . The service life increases by 2-3 times, and the price also increases. The material may have an orange or pinkish tint, but this is not necessary. Externally, stabilized and regular polyethylene films are the same, so you need to carefully look at the packaging and labeling;

- light converting film “knows how” to convert hard ultraviolet radiation, harmful to plants, into infrared and red radiation, which increase productivity. All this is possible thanks to the phosphor additive, but in order for the material to last for a long time, it is necessary that the composition also contains stabilizing substances. To make sure that you really have a light-converting film in front of you, you need to shine it with an ultraviolet lamp, and the light from the lamp should change to red;

- heat retaining film has a matte whitish tint. It weakly transmits thermal radiation, so the temperature in the greenhouse will be 1-30C higher than in similar other types of film. Due to this, early harvests can be increased by 10-30%, saving on heating costs. The service life of the film is about 9 months, the material has antistatic and hydrophilic properties;

- stabilized hydrophilic film allows you to solve the “drop” problem characteristic of other types of material. Flat-drip condensate forms on this film in the form of a continuous layer, so there is no negative effect on plants. Light transmission is high, the ability to transmit thermal radiation is 30-35%, so it will be warm in such greenhouses;

- bubble wrap strongly resembles the one used to package fragile goods. It has good light transmission, and the level of thermal insulation is comparable to polycarbonate. The strength is low, with the exception of special types of film, but the material is suitable for growing early crops in a small greenhouse;

- foamed film consists of a monolithic and foamed layer of polyethylene, transmits 70% of light, retains heat well, and is suitable for the construction of greenhouses intended for vegetative propagation of plants;

- copolymer ethylene vinyl acetate has a decent level of strength, retains heat well, it is resistant to punctures, wind loads, frost, and hydrophilic. High light transmittance (up to 92%) can cause overheating on hot summer days. Durability – up to 3 years;

- Photodestructible film is destroyed after a certain period of time (20, 45 and 60 days). Used for frameless shelters and mulching.

Despite the stated service life, some experts recommend changing the film every three years, as it still becomes cloudy. If the material has retained its integrity, it can be used for other purposes.

You can also find films in the production of which several additives were used at once - this is the best option. But often, ordinary polyethylene films are issued under the guise of special films, so it doesn’t hurt to look at the certificates and markings.

According to GOST 10354-82, stabilized film for greenhouses and hotbeds is marked ST, stabilized light-converting film – SIC. You can also use film for greenhouses, which is marked with the letter H: this is a stabilized or unstabilized film for the manufacture of household products.

Types of greenhouse film

Today, the market offers a wide range of films that can fully satisfy all the requirements placed on them.

Polyethylene unstabilized

The most common economical option is considered to be ordinary polyethylene (PE) unstabilized film.

- Its advantages are as follows:

- affordable price;

- good wind protection;

- excellent light transmission qualities.

This covering material does not retain heat well at night, forms condensation, which promotes the development of fungi and mold, and has a short service life - a maximum of 7-9 months.

This coating is suitable for use only for one season. Unstabilized film is usually sold in the form of rolls 1–3 m wide or in the form of a sleeve. Important! Film of various thicknesses is available on the market. But this indicator will not in any way affect the service life of the coating, therefore, when choosing between films of different thicknesses, preference should be given to the less expensive ones.

Polyethylene stabilized hydrophilic

By using various additives, manufacturers were able to produce a stabilized hydrophilic PE coating with excellent ability to absorb sunlight, reflect heat and not form condensation on the surface of the greenhouse. In addition, the composition of the material was supplemented with antistatic components, which prevent the accumulation of dust and allow the film to remain transparent throughout the entire period of operation.

At night, heat is retained much better in a greenhouse made of hydrophilic polyethylene. Daily temperature fluctuations are almost imperceptible, which has a positive effect on the condition of the plants inside the greenhouse. Excellent technical and operational characteristics contribute to a fairly long period of use of the material, which is 3-4 seasons.

Important! Greenhouse film is characterized by a long service life, but in terms of frost resistance, manufacturers only provide a 3-year warranty.

Heat retaining

A heat-retaining coating is an ideal option for those who are trying to save on heating costs in the winter. The matte-whitish material has excellent heat-saving function, increased ability to absorb thermal radiation, antifog (anti-fogging effect), antistatic and hydrophilic qualities. In the middle of the greenhouse, covered with a heat-retaining film, temperatures are always 2-3 degrees higher than in others.

Due to its quality, such material is recommended for use in regions with unstable climatic conditions, where large differences in night and day temperatures often occur. Among the disadvantages of this coating, experts note low strength and insufficient elasticity. The service life of the film is approximately 2 seasons.

Important! The width of the covering fabric should coincide as much as possible with the dimensions of the greenhouse frame.

PVC

Of all types, polyvinyl chloride film is the most durable, practical and elastic. According to the manufacturers, its service life is 8 years. It is intended for use in regions with a large number of sunny days per year.

- In addition, PVC boasts the following properties:

- excellent light transmittance - up to 90% light and 80% ultraviolet;

- high strength and elasticity;

- heat-saving functions;

- excellent frost resistance and moisture resistance;

- ability to block over 95% of infrared radiation.

PVC coating is subject to sagging and stretching, which is why its installation should be done with special care.

Another disadvantage of this material is its rather high cost compared to other types. Did you know? Many people mistakenly believe that a greenhouse and a greenhouse are the same thing. Although the structures are designed for the same purposes, the main difference is the method of servicing the plants. In greenhouses, crops are cared for from the outside, and in greenhouses - from the inside.

Reinforced

Reinforced polyethylene film is made on the basis of conventional stabilized covering material with additional reinforcement with strong PE threads, 0.29–0.32 mm thick. Since the threads used for reinforcement have high strength, the final product - the film - also receives increased strength properties, thanks to which it can last at least 2 years. The main disadvantage of reinforced coating is considered to be a low degree of light transmission, which is explained by densely installed reinforced threads, which reduce throughput.

Copolymer reflective

To organize greenhouses in regions with the harshest climates, experts advise using copolymer reflective film, which is highly resistant to cracking and frost resistance. Thanks to its high strength, it can withstand high loads and withstand strong winds.

The material has good hydrophilicity, due to which moisture in the form of drops is evenly distributed over the surface of the entire greenhouse. The copolymer coating has high light transmission, which is considered its main disadvantage, since on bright days vegetables grown in a greenhouse run the risk of overheating.

Find out more about how to properly stretch the film onto a greenhouse.

Acrylic

A special feature of acrylic greenhouse film is its ability to “breathe”. It perfectly allows air to pass through, prevents the formation of condensation, and maintains stable temperatures inside the greenhouse. In addition, it has good light transmittance, which varies between 82–85%. The service life of acrylic material, in the absence of heavy winds and large hail, reaches 3 years. Among the negative qualities of the coating are low strength and elasticity.

No. 7. Film density and thickness

The denser and thicker the film, the better it will cope with negative environmental factors. In the case of conventional polyethylene film, thickness has little effect on durability, but when it comes to stabilized materials, this factor is more important.

Externally, it is impossible to distinguish between films with a thickness of 200 and 100 microns , which is what unscrupulous sellers take advantage of. To protect yourself from a bad purchase, it is worth remembering that a thicker film weighs more: a linear meter of 200 micron film weighs 530 g , 150 microns - 400 g, 120 microns - 320 g, 100 microns - 260 g and 80 microns - 210 g. For greenhouses, it is better to choose a film with a thickness of 150-200 microns.

Lenght and width

When choosing film for greenhouses, it is necessary to take into account parameters such as the size and thickness of the film, as well as the dimensions of the packaging.

This will allow you to plan transport to transport the material to the installation site.

Film for greenhouses is available in rolls of standard sizes:

- roll length is from 1.5 to 3 m (the film is folded in half, the width of the material when unfolded is from 3 to 12 m);

- film length per roll from 25 to 100 m;

- film thickness from 30 to 200 microns (for greenhouses we recommend using a film with a thickness of 145 microns.).

No. 8. Film color

It is better to choose a transparent film - it lets in more light. To obtain material of different shades, food coloring is usually added to the composition, which tends to fade under the rays of the sun, so there is no point in it. If the paint is persistent, then less light will penetrate into the greenhouse, which will lead to a decrease in yields and the need to use additional lighting.

Construction

Typically, greenhouses for film have non-standard sizes or intricate shapes, which preclude the use of other materials. But even a simple square frame with a pitched roof must be properly covered with polyethylene so that the fallen layer of precipitation does not tear the material and destroy the greenhouse.

The key to the strength of a greenhouse is proper calculation of the material. When calculating how much greenhouse film is needed, it is necessary not only to measure and calculate the area, but also to add at least 10% to the resulting number. This is necessary in order to properly isolate the joints and leave a small margin in case of incorrect calculations or an uneven frame. In addition, cutting the material in advance is not recommended. It is much better to cut the sleeve along its entire length and throw it over the greenhouse frame. After this, you need to add a few tens of centimeters on each side, glue the canvases together and cover the greenhouse with one large piece of covering material.

At cold air temperatures, slight shrinkage of the material occurs, so it is recommended to cover greenhouses in warm, but not hot, weather. If it was cold during construction, the temperature was below +5 degrees Celsius, then when it warms up the material will sag.

They begin to pull from the largest area of the part. To prevent polyethylene from tearing and retain its properties longer, nails for fastening are driven not into the film, but into a more durable material. You can attach polyethylene to a wooden frame using:

- Thin wooden slats;

- Plastic packaging tape;

- ;

- Thin strips of linoleum;

- Meshes with large cells.

For a small, low greenhouse with plastic arches, you can use small clips instead of permanent fastenings. Modern greenhouse models have special fastenings for easy winding of covering material. With this type of greenhouse design, the film can be quickly removed on a hot day and thrown over the frame during bad weather and frosts. To ensure that the covering material lasts as long as possible, it is attached to the frame not with self-tapping screws, but with thin nails or furniture staples using a stapler.

Film greenhouses are one of the most popular in summer cottages. They have a light but durable frame, can be assembled with your own hands without any problems and just as easily disassembled for the winter. Cheap but durable modern film will make it possible to operate greenhouses from early spring to late autumn, and some models of covering material can even be used for several years in a row. If you choose the right type, density and width of the covering material, then all heat-loving crops in the greenhouse will grow well from early spring to late autumn.