Today we will talk about the criteria by which greenhouse film is selected. What you need to pay attention to first. How much does film cost per meter of roll length? What dimensional parameters should you pay attention to in order to reduce material costs?

The greenhouse is covered with plastic film Source obyava.ua

Properties of film coatings

Polyethylene film is used not only in agriculture, but also in construction, as well as for packaging various goods. However, not every roll film is suitable for covering greenhouses. Types of film made from low-density polyethylene have low strength and do not tolerate temperature changes and solar radiation. Such a film becomes deformed and breaks within 2-3 months in summer, and cracks when the temperature drops below -10°C in winter.

Professional greenhouses under film

There are several types of film for greenhouses:

- made of high-density polyethylene;

- light-stabilized polyethylene;

- light-transforming, heat-retaining film;

- ethylene vinyl acetate copolymer film “Svetlitsa”;

- PVC film;

- reinforced polyethylene;

- air bubble, thickness from 4 to 10 mm.

Films for covering greenhouses, regardless of type, have general advantages and disadvantages.

Features of film coverings for greenhouses:

- simple installation, repair or replacement of film;

- light weight and low load on the frame;

- large selection of thickness, width and types of film.

Greenhouse with film

Prices for PVC film

PVC film

To improve the characteristics of the film, various components are added to the polymer, giving it special properties.

- Light stabilizers are components built into the polymer chains of a material and reduce the harmful effects of solar radiation on the structure. Film with light stabilizers does not deteriorate after several months of use, even under the bright spring and summer sun. In addition, light-stabilized film has greater elasticity and frost resistance; it does not have to be removed for the winter.

Light stabilizers or UV stabilizers

- Thermal stabilizers increase the film's resistance to elevated temperatures, which is important when using the coating on a metal frame.

- Antistatic additives prevent the formation of a static charge on the surface of the film, so it does not attract dust and contaminants that impair its transparency. The light transmittance of such a film practically does not decrease over the entire period of use.

- Anti-blocking components prevent sticking of film layers - this property is important for long-term storage of covering material.

- Hydrophobic additives prevent the formation of large drops of condensation that can cause burns to plants. Moisture on such a film is distributed in a thin layer and flows down, practically without impairing the light transmission of the coating. In the film characteristics they are also called antifog.

- Sliding additives improve the plasticity and smoothness of the film surface, making it more pleasant to use.

- Phosphors are components that help convert ultraviolet light waves that are useless for plants into the visible part of the spectrum. This increases plant illumination and accelerates photosynthesis and growth. Another feature of light-transforming films is the weak transmission of infrared rays to the outside, due to which the greenhouse releases heat more slowly at night.

Adding just 1% antistatic agent 104355-E is enough to prevent dust accumulation on the surface of EVA films

The effect of using chalk additive F-2 in LDPE film of various thicknesses

The influence of a combined additive (sliding + antistatic agent) on the technical parameters of a film produced by blowing a high-density polyethylene sleeve

Comparative results of phosphor service life in film

Note! Identifying film with phosphors is quite simple: you need to shine an ultraviolet lamp or blue LEDs through it. The light passing through the film should turn red.

Where is it used?

Types of covering polyethylene films differ in their areas of application. For storing building materials or protecting furniture, there are no special requirements for film, choosing an inexpensive option.

If the area of use involves wind, snow loads or certain properties, the material is selected based on performance indicators, comparing price and quality characteristics.

We recommend: Pros and cons of building a house from wood concrete

Construction

The material is widely used in construction due to its waterproofing properties and high tensile strength.

Light-stabilized and black polyethylenes protect foundations, floors, tunnels, underground pedestrian crossings, and ceilings from moisture . The bottom of oil and fuel tanks is lined with black geomembranes. In roofing pie and walls of frame-type houses, films are used for waterproofing.

Storage of building materials in the open air cannot be done without a transparent coating; scaffolding and temporary structures are covered with polyethylene in bad weather.

Important! If it is not possible to use a seamless fabric, all film joints are sealed with special tape or glue.

The reinforced fabric creates a good microclimate, allowing you to work inside the dome.

The material is used to temporarily cover the roof truss system, isolate door and window openings , continuing work inside the building in the absence of roofing and filling of openings.

The membrane protects the structure from atmospheric moisture and maintains the required temperature in adverse weather conditions.

Repair

In the renovation of premises, polyethylene protects walls, floors and furniture from moisture and dust during dismantling of structures, plastering and painting work. When pouring floor screed, polyethylene sheeting is used as waterproofing.

Agriculture

In plant growing, greenhouses and greenhouses are covered with hydrophilic, light-stabilized films. The hydrophilic membrane retains heat at night, which is very important for increasing yield. Polyethylene is useful for constructing silage pits, germinating seeds, and packaging agricultural products .

The black membrane is valued for its light resistance. The mulch planting method involves growing seedlings through holes in a membrane spread over the beds. All plants under the cover die without light; there is no need to treat the soil with weed poisons. The fertile soil layer is preserved, herbicides do not penetrate into crop plants.

Landscape design

The bottom of pools and decorative ponds is lined with black or dark green film, giving visual depth and a reflective surface to the artificial reservoir. The geomembrane easily takes on its intended shape, which can be changed at will, and is repairable if damaged.

We recommend reading: Which polypropylene pipes are best for the home?

Ordinary polyethylene film

The cheapest type of film, its service life is only a few months. This film is used for greenhouses and greenhouses, from which the cover is removed for the winter. Change annually or every two years.

Polyethylene film

The film is produced in rolls 50 or 100 m long in the form of a sleeve; its width according to GOST is 1.5 m, 2 m or 3 m. The thickness of the film can vary from 40 to 200 microns. A thin film (up to 100 microns) is suitable for temporary greenhouses; a more durable film can be used for greenhouses with a large area of walls and roof.

Advantages of ordinary polyethylene film:

Flaws:

- low strength, the film can be easily damaged with a sharp tool;

- easily sag, stretch and tear from rain, snow and wind;

- has a tendency to form condensation and dew drops;

- accumulates a static charge and attracts dust, quickly becoming dirty;

- polyethylene is susceptible to UV radiation, under its influence the polymer chains are destructured, and the film becomes brittle;

- the air in a greenhouse covered with ordinary film cools quickly at night.

PET film

It is advisable to use such a film if the design of your greenhouse involves dismantling it for the winter. In this case, the cost of purchasing a covering material will be low, and the film will not have time to lose its performance characteristics.

Note! For greenhouses and hotbeds, it is recommended to use grade 1 film labeled LDPE. Grade 2 film (HDPE) does not have the required strength and elasticity and quickly breaks and deforms.

Main characteristics

Classification

Polyethylene films are produced in rolls up to 3 meters wide in the form of a sheet or sleeve. They are classified according to the following parameters:

- Depending on the raw materials used in their production - LDPE, HDPE films, LLDPE linear polyethylene films and others;

- From the possibility of contact with food products: food and technical;

- According to the design of the material itself: Single-layer and multi-layer,

- Plain and foamed

- Coated with other materials (foil, etc.),

- Stretchable,

- Skin films with hot melt adhesive,

Heat shrink for maximum fit of objects,- Photodestructible,

- Reinforced,

- Air bubbles, etc.

Light-stabilized hydrophilic film

Thanks to the introduction of various additives into the polyethylene structure, stabilized films have improved characteristics and a long service life - up to 6 seasons. You can leave it on the frame for the winter - thanks to the UV blocker and plasticizer, the film is not destroyed by frost and aggressive spring sun.

Light stabilized film

In addition, UV filters prevent the penetration of ultraviolet radiation into the greenhouse, which inhibits the activity of pathogenic microorganisms and pests - thrips and whiteflies without UV rays lose orientation in space and die. Hydrophilic additives prevent the appearance of drops and the accumulation of dust on the surface of the film, so the film does not lose transparency for a long time.

The film is produced in rolls of standard sizes: length 50 or 100 m, sleeve width 1.5, 2 or 3 m. The thickness of the stabilized film can be from 100 to 200 microns. Film with stabilizers can be transparent with a slight blue tint or colored. Over time, the pigment may partially fade, but this does not affect the properties of the film.

Greenhouse light-stabilized film, 150 microns, 6 m width

Advantages of stabilized polyethylene film compared to conventional polyethylene:

- extended service life - up to 6 seasons or 3 years without removing the coating;

- increased strength and elasticity;

- increased heat capacity;

- absence of condensation and dew;

- good light transmission for a long time;

- inhibition of viruses, bacteria and fungi, as well as pests.

The disadvantages include a higher price, but the costs are recouped over several years of using the film. It is advisable to install them on non-demountable greenhouses, including those for winter use - they often suffer from whitefly attacks.

Note! In southern regions with hot daytime sun, you can use colored light-stabilized film - it transmits less light, so the plants will not overheat.

Prices for light-stabilized film

light stabilized film

Which film to choose for a greenhouse

Each gardener decides for himself which film is best for a greenhouse. It is selected according to different criteria, and in different cases something specific is needed. For example, for a test, for people who want to try out a greenhouse on their site for the first time, a simple plastic film for one season will be enough. But if coverage is needed for a long time, then choose something else. So, what you should pay attention to when choosing greenhouse film:

- Price . The price must be reasonable.

- Durability . It makes no sense to take a thin film for a greenhouse, since the crops will easily pierce it. So it is better to choose models in the range of 150-200 microns. In addition, the film must be flexible so that it is easy to work with.

- Transparency . If there is no additional lighting in the greenhouse, only transparent film is selected. The matte option is suitable for rooms where additional lighting lamps will be installed.

- Additional characteristics . In certain cases, it is important that the film retains heat or transmits a lot of light, converts it into infrared, etc. All these features are always indicated in the characteristics of the material.

By correctly choosing and fixing the film on the greenhouse frame, you can get a good room for growing a wide variety of crops. Throughout the warm season, it will reliably protect plants from the influence of the external environment. The only thing that may be required of the gardener is to wash it as needed so that it does not become dirty. It is recommended to remove the greenhouse film for the winter, then it will last much longer.

Heat-retaining film with phosphor

This film contains components that convert the ultraviolet component of sunlight into infrared, and also prevent thermal radiation from escaping outside. Film with a phosphor has a scattering effect, creates even light throughout the entire greenhouse, and prevents leaf burns. The spectrum of sunlight is adjusted, the plants receive maximum beneficial rays.

Scheme of action of light-converting film

Maximum film width is 6 m, roll length is 100 m. Film thickness is 100-200 microns. Color – transparent or with added dyes.

Advantages of light transforming film:

- long service life - up to 5 seasons;

- increased thermal insulation properties;

- adjustment of the color component of the spectrum, increasing the number of blue and red waves by 40-60%;

- inhibition of pathogenic microorganisms and pests;

- accelerated growth and high yield of cultivated crops;

- allows you to grow capricious heat-loving plants in any region.

Heat-retaining film

Among the disadvantages, it is worth noting a small range of widths and a higher price. Film with phosphor is recommended for use in regions where cloudy and cool weather prevails. The temperature in a greenhouse covered with a light-transforming film is always 3-4 degrees higher than with a conventional covering, and the daily temperature difference is not so pronounced.

Light-converting film “Urozhay” with UV protection

Note! Well-known brands of films with phosphors: “Polysvetan”, “Redlight”, “Urozhay”, “Anti-mold”, “Biosvet”.

Film "Svetlitsa"

A film based on polyolefins with a long service life and excellent performance characteristics: increased strength and elasticity, high light transmittance, heat-retaining properties. The standard hose width is 1.5 or 2 m, thickness is from 120 to 200 microns. The color of the film is transparent with a slight yellow tint.

Film "Svetlitsa"

Advantages of the film “Svetlitsa”:

- durable, stretches well, is not afraid of punctures;

- frost resistance up to -80°C;

- high wind resistance - up to 18 m/sec, as well as the ability to withstand hail and heavy precipitation;

- light transmittance – up to 95% in the visible spectrum and up to 80% in the UV radiation spectrum;

- good heat-retaining properties;

- hydrophilic effect - condensate settles on the film in small drops and flows evenly down the walls without causing dripping;

- the joints of the film stick together, ensuring the tightness of the coating; when dismantling, they are easy to separate;

- service life without removal from the greenhouse is at least 7 years.

The film has practically no disadvantages, except for the high price. The film has several modifications for different regions. For northern latitudes, a transparent film is used; for southern regions with active sun, a matte film is used. The light transmission of the latter is lower than that of transparent film, which allows you to avoid burns during the daytime. In the evening, the matte film slowly releases heat, eliminating temperature changes.

Greenhouse under matte film “Svetlitsa”

Note! Due to its high frost resistance, in winter the film does not lose elasticity, does not tan or crack when clearing snow.

Prices for Svetlitsa film

film room

PVC film

PVC film is similar in characteristics to light-stabilized polyethylene, but at the same time has increased elasticity and strength. You can distinguish PVC film from polyethylene by its absolute transparency without a bluish matte tint. Due to its resistance to cracking, the transparency of the film is maintained throughout its entire service life. The light transmittance of PVC film is close to 90%.

PVC film

The film is sold in rolls with a length of 50 to 150 m and a web width of 1.4-1.5 m. The thickness of PVC film is 150 microns. The surface texture is smooth and sliding, which ensures poor wettability - water drops simply bounce off the material.

Advantages of PVC film:

- high degree of protection against UV radiation - it is converted into blue and cyan wavelengths useful for plants;

- the ability to retain heat well inside the greenhouse due to poor transmission of infrared radiation;

- the breathability of the material allows plants to breathe and improves thermoregulation;

- high hydrophilic properties;

- the film is not prone to cracking and contamination;

- antistatic properties prevent dust settling and film clouding;

- high elasticity eliminates ruptures and damage due to careless handling, hail and wind;

- The service life of PVC film is at least 4 years without removal from the frame for the winter period.

Flaws:

- higher price than polyethylene;

- Proper disposal is required.

Greenhouse covered with PVC film

The elasticity of PVC film allows it to be stretched 1.5-1.7 times without damage, after which it will return to its original shape. This property is useful for greenhouses and greenhouses with a low roof slope, when water can accumulate in the film cover. In this case, polyethylene breaks.

Note! When PVC film is burned, a poisonous gas is formed that paralyzes the respiratory system. You cannot burn it along with garden waste!

A little about film and greenhouses

It should be noted that polyethylene film, used by many summer residents as a covering for greenhouses, is a cheap material. But its popularity ends there; this polymer product has never aroused much respect or trust. It's all about its shortcomings, of which there are not so few:

- transparency deteriorates over time;

- at low temperatures compression occurs, at high temperatures sagging occurs;

- low mechanical strength;

- condensation forms on the inner surface;

- under the influence of natural loads it quickly fails.

Today, manufacturers have refocused film production on greenhouses. They began to offer completely unique varieties of material with higher technical and performance characteristics. For example, increased frost resistance, elasticity and strength, the ability to pass fresh air through the greenhouse and remove carbon dioxide back, a high level of transparency and the ability to better diffuse light.

It must be admitted that there are more than a dozen new types of film for laying on greenhouses. This is not to mention the experimental models that sometimes appear on the market. All of them are many times better than ordinary polyethylene. But in terms of price, availability, and ease of use, this is the most ideal option.

Condensation on the film from inside the greenhouse Source kupolvz.ru

Reinforced polyethylene film

One of the most durable types of film coatings is reinforced polyethylene. It is a mesh made of twisted polyethylene, polypropylene thread or fiberglass, sealed between two layers of light-stabilized polyethylene. Thanks to the reinforcing frame, the strength of the film is much higher than that of conventional polyethylene or PVC.

Reinforced film

The film is produced in rolls 15 or 20 m long, 2 to 6 m wide. The thickness of the film is not uniform, so to describe its strength, a characteristic such as density is used - it can be from 80 to 200 g/m2. There are also denser films, but they are not used for greenhouses. The color of the film is transparent, matte white, green or blue. Yellowing indicates poor quality or improper storage of the material.

Advantages of reinforced film:

- increased strength, resistance to wind and precipitation;

- simple repair - the reinforcing mesh keeps the material from spreading when punctured;

- resistance to UV radiation, light stability;

- long service life - up to 6 years.

Flaws:

- reduced light transmittance - no more than 80%;

- an uneven surface contributes to dust and contamination;

- quite high price.

Transparent reinforced PVC film for greenhouses and greenhouses

Reinforced film is used on permanent greenhouses made of wood or metal in areas with strong winds and precipitation - it is able to withstand them. Also, convenient covers for greenhouses and greenhouses are made from reinforced film.

Greenhouse with reinforced film cover

Note! The film for the cover can be sewn together in the usual way or through a sealing tape, and also zippers, Velcro and other fasteners can be sewn to it.

Prices for reinforced film

reinforced film

Methods for producing polymer films

In the industrial production of film polymer material, two main methods of plastic processing are used, the choice of which depends on the areas of application of the resulting product and on the polymers used:

- Extrusion. Applicable in most cases.

- Calendering. Also includes polymer pre-extrusion.

Extrusion is one of the most common technologies for the production of plastic products. The extrusion process in its simplest form involves squeezing out a molten polymer mass through a special molding tool (extrusion head). From the point of view of film production, the forming head must be slotted or annular, that is, suitable for forming a thin polymer strip of finite width or a film sleeve. The extrusion method is indispensable for the production of multilayer polymer films. In this case, several extruders loaded with different types of raw materials work in one complex head, which usually produces an odd (from 3 to 11) number of layers with different properties.

The main types of extruders are:

- single-worm (single-screw);

- multi-worm (multi-screw);

- disk;

- piston.

In modern industrial production, single-screw extruders are used in the vast majority of cases. Twin screw machines, due to their special powder processing properties, are often used only for PVC production.

Fig.1. Co-extrusion extruder

The calendering method is used much less frequently than extrusion. It is less productive, but is capable of producing a polymer film with more accurate dimensional characteristics, as well as applying the desired texture. The main type of equipment used is a calender, consisting of 3-6 thermostatically controlled rolls. The film web is formed in the gaps between the rotating rollers of the calender.

Calendering technology is used mainly for the manufacture of film products from polyvinyl chloride compositions. The PVC composition is prepared in special mixers for powdered materials and is sent for preliminary homogenization to rollers or an extruder. Then the resulting melt of the polymer composition enters the gap between the first and second rollers of the calender and moves further, taking on the desired shape and texture.

Fig.2. Calender

Air bubble film

Three-layer polyethylene film: the top and bottom layers are smooth, and the inner one forms bubbles filled with dry air. Thanks to this structure, the thermal insulation properties of the film can be compared with polycarbonate and significantly exceed ordinary polyethylene.

Three-layer bubble film

The film contains light-stabilizing and light-converting additives - phosphors. The spectrum inside the greenhouse is close to optimal, which increases the rate of growth and ripening of the crop by 10-15%. Hydrophobic additives prevent the appearance of water droplets.

The roll length is 25 or 50 m, the width is 1.2 or 1.6 m. The thickness of the bubble film can be 4, 6, 8 or 10 mm.

Bubble wrap

Advantages of bubble film:

- excellent thermal insulation;

- sufficient mechanical strength;

- damage to one air chamber does not affect adjacent and general thermal insulation properties;

- the closed structure prevents dust, water and insects from entering the cavity;

- does not form drops of condensation;

- allows you to create diffused light of the optimal spectrum in the greenhouse;

- light stabilizers and UV filters extend the service life of the film to 3-5 years without removal from the frame;

Flaws:

- small standard width; gluing of the material may be necessary during installation;

- quite high price.

It is advisable to use air bubble film in spring or year-round greenhouses with heating; due to its good thermal insulation properties, heating costs are reduced by 35-45%.

Bubble film on a greenhouse

Note! It is not recommended to use double-layer packaging bubble film for greenhouses - the uneven surface contributes to the accumulation of dust and dirt, in addition, the material does not contain special additives.

What is the difference between construction films?

Of course, these materials differ in composition and the components from which they are made. Films are mainly made from polyethylene, but sometimes from other materials.

In addition, construction films differ in their thickness, diffusion resistance coefficient, water vapor, reaction to high temperatures, strength, and durability.

How to extend the life of film

Even durable types of films for greenhouses require proper installation and careful handling, otherwise the service life may end earlier than predicted. The table contains expert advice on the use of greenhouse films.

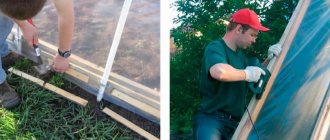

Table. Step-by-step instructions for installing and operating film greenhouses.

| Action, photo | Description |

| Preparing the wooden frame | All parts of the wooden frame in contact with the film must be sanded with fine sandpaper. Burrs, sharp edges and irregularities will lead to punctures and tears. The fasteners are embedded flush into the wood. The wood is coated with an antiseptic or paint and dried well - the solvent contained in it can destroy the film. |

| Preparing the metal frame | The metal frame must be sanded to remove rust, and the welding areas must be cleaned with a grinder. The fasteners are positioned so that their protruding parts do not come into contact with the film; if this is not possible, gaskets made of foamed polyethylene are provided. The frame is coated with a primer and then with light-colored paint - dark metal in the sun heats up to 70-80 degrees, which will damage the film. |

| Optimal temperature for installation | It is best to stretch the film onto the frame at an ambient temperature of 10-15°C. At the same time, the film has average linear dimensions, which will allow it to be stretched well without sagging, but at the same time without excessive stress. It is better to do this in cloudy weather or in the evening - in the daytime sun the film glares, so the creases on it are difficult to see. |

| Reinforcing the ridge and corners | The film is most often wiped on the ridge of pitched greenhouses or on the corners - where it fits most tightly to the frame. It is recommended to pre-glue these places with transparent tape on both sides. They also tape the bend of the film sleeve with tape - due to the nature of the technology, in this place it is most vulnerable. |

| Attaching the film to the frame | The film is attached to the frame using self-tapping screws or nails with a wide head and a rubber washer, or through a strip. The plank can be a wooden strip, strips of rubber or polymer material, or a strong tape. The film overlaps at the junction of the strips are made at least 15 cm and taped for reinforcement. |

| Sagging protection | On pitched roofs with a slight angle of inclination, water can accumulate in the film. To strengthen the structure and avoid damage to the film, you can stretch the insulated wire parallel to the rafters or crosswise. The ends of the wire are carefully insulated so that they do not pierce the film. You can also install additional rafters from the slats. |

| Caring for film in summer | Dust and dirt, for example from splashes during heavy rain or intensive watering, are washed off the film with a weak stream of water. If necessary, you can use a soft sponge and a solution of laundry soap or dishwashing detergent - they do not have a harmful effect on the film. |

| Film repair | Punctures and small tears in the film can be sealed with ordinary transparent tape on both sides in one or two layers. Before this, the film must be washed to remove dirt, wiped or dried. It is usually useless to repair large damages and breaks in the film. It's easier to change a separate sector. For dense options, it is better to use a special film device. |

| Preparing for winter | Non-removable film greenhouses must be washed and dried in the fall at above-zero temperatures, and all damage must be repaired. The greenhouse frame is reinforced with supports if it is not strong enough. Snow is removed from the film regularly using a soft brush, avoiding sagging. It is better to remove the film from a roof with a small angle of inclination for the winter. |

Adhesive double-sided tape Fixit M-2 for fastening and repairing film for greenhouses and greenhouses

Hot air gun 8018LCD

Greenhouse film

There are more than a dozen new varieties of film on the domestic/foreign market, not counting experimental ones. They are strikingly different from simple polyethylene film in their qualities. Moreover, in terms of price, availability, wealth of choice and ease of handling. Read more here.