Despite the abundance of existing types of greenhouses, the choice of greenhouse should be approached with special care, because even the slightest violation in the design features can have an extremely negative impact on its thermal insulation properties.

Any structure of this kind must meet quality requirements and be made only from approved materials. One of the highest quality and most noteworthy types of greenhouse structures is the “Droplet” - a reinforced greenhouse that can withstand any weather conditions.

Description and characteristics

The main design features of “Kaplya” greenhouses are as follows.

- teardrop shape

This design solution does not allow snow to accumulate on the surface of the greenhouse, and also increases the stability of the structure even with very strong gusts of wind.

- Reinforced frame design

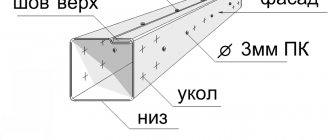

The frame is formed by profiled pipes with a rectangular cross-section of 20x40 or 20x20 mm and a wall thickness of 2 mm. All arcs are fastened with reinforced transverse elements, which allows the greenhouse to withstand significant loads.

- Anti-corrosion coating of main parts and fasteners

Coating the frame with a special composition guarantees protection against rust formation and significantly extends the service life of the structure.

- Complete with high quality polycarbonate sheets

This material is protected from the destructive effects of UV rays and does not form fragments even when the strength threshold is exceeded. In this case, the entire greenhouse is covered with polycarbonate, due to which every centimeter of usable area inside the greenhouse receives the required amount of light.

Galvanized or painted

The frame material is key when choosing a greenhouse. The duration of operation of the greenhouse and the ease of care for it depend on its quality. To create the base, various materials are used, ranging from traditional wood or metal to PVC pipes. Each of the options listed above has its own advantages and disadvantages.

PVC pipes have become an effective solution for DIYers. They bend perfectly and are easy to drill. Even a novice craftsman can create a plastic frame. However, you will have to find an assistant for the work, since it will not be possible to bend the pipe, hold the edges and control the correctness of the resulting arc at the same time. Plastic tolerates temperature changes well, is not afraid of humidity and pests, so it will serve for many years without requiring constant maintenance or repair.

The classic solution for creating a greenhouse is wood. This is an environmentally friendly material, which is important for obtaining a “clean” harvest. Wood is relatively inexpensive, which allows you to build a decent-sized greenhouse without capital investment; it retains heat well.

When considering the disadvantages, it is worth considering the susceptibility of wood to rot in conditions of high humidity. To reduce the destructive effects of water, you will need to periodically generously treat the frame with drying oil and paint. Wood is not resistant to mechanical stress. A strong impact, a large amount of wet snow, rodents - all these factors can lead to the destruction of the structure.

Most rodents do not respond to specialized impregnations. Despite their use, animals continue to damage the base of the greenhouse. The use of toxic compounds in such a situation is not recommended, since they will have a negative effect on growing vegetables.

The metal frame can be galvanized or painted. Despite its strength, metal, like wood, needs protection from negative atmospheric influences. When choosing aluminum alloys to create a greenhouse, you need to build a good foundation. The advantages of aluminum include ease of fastening, low weight, and affordable cost.

A steel frame will help create a greenhouse that will last for decades. This is the most expensive material, but also the most durable. High-quality galvanized steel is not afraid of any weather conditions. The high strength of the metal allows you to attach the heaviest covering material to it, including cellular polycarbonate, since such a frame can easily cope with any load.

Advantages and disadvantages

Which polycarbonate greenhouse is better: “Droplet” or arched?

Compared to other types of greenhouses, “Kaplya” has the following advantages:

- pointed shape that prevents snow from lingering on the structure;

- impressive dimensions allowing you to carry out work in comfort;

- long service life (from 5 years even in harsh climatic conditions);

- the possibility of increasing the length of the greenhouse through the use of special inserts.

In addition, “Kapelka” retains heat well, and the presence of doors and windows has a beneficial effect on ensuring proper air exchange and, as a result, creating a microclimate suitable for plants.

The drop shape allows you to increase the height of the greenhouse to 2.39 meters, which provides additional free space under the ceiling for hot air in hot weather. At the same time, the tallest arched greenhouse can only reach 2.1 meters.

The higher the distance between the roof and the top of the shoot (the so-called buffer zone), the more favorable the thermal regime for plants.

The disadvantages include:

- installation is quite difficult, but you can still assemble such a greenhouse yourself, without turning to specialists for help;

- high cost, so prices for such greenhouses are slightly higher than for arched ones;

- the need to plant tall crops closer to the center.

It should also be noted that there is a weak spot – the ridge. If it is not covered with a galvanized profile, then rainwater will fall directly into the polycarbonate honeycomb.

Other types of greenhouse structures

On private plots, so-called droplet greenhouses are also used. They have sloping sides like arched buildings. Only the top is pointed like that of a house. With a high-quality polycarbonate coating, the greenhouse can withstand a snow mass of up to 290 kg/sq. m. but it is difficult to assemble such a “hat” on the roof - it easily slides off on its own.

The greenhouse has a high ceiling. Farmers use this feature to plant determinate crops. The width of the building is also spacious. It is not easy to construct a “droplet” on your own, and factory samples are not cheap. The kit will necessarily contain a large number of disassembled load-bearing elements, components, and fittings.

A cone-shaped greenhouse is also suitable for planting tall vegetable crops. It is a structure of two sloping side walls with a connection at the top in the form of a ridge roof joint. Cucumber vines, determinate tomatoes, and melons feel great in such a greenhouse. The owner does not have to provide access inside through the doors. The structures are equipped with rising side doors. Watering and other plant care occurs through them.

Snow does not stay on this greenhouse. Its installation is simple. Coverage - any available. The main difficulty is to ensure the tightness of the joints.

These types of greenhouses are most in demand among the people. All have been tested by many years of field experience and have the right to exist. Your choice should be based on how fully you can use the advantages of a particular design in the conditions of a particular site.

Installation features

Each product must be accompanied by instructions for assembling the “Droplet” greenhouse from the factory (manufacturer). Typically, the sequence of actions is as follows.

- Construction of the foundation.

- Make a marking, remove the top part of the soil along it, compact the soil at the location of the greenhouse. Lay a layer of geotextile and create a sand and gravel cushion.

- Install a foundation in the form of a frame using 10x10 cm timber. If it is necessary to obtain a more reliable foundation, pour concrete using formwork.

- Assembling the frame in accordance with the included instructions.

- Using self-tapping screws, fasten all the arcs and parts of the end module to the door. Attach it to the foundation frame.

- Assemble additional modules with a window and attach them one by one to the base.

- Assemble and install the last end module and also attach it to the foundation.

- Fasten all parts of the frame together.

- Laying polycarbonate . Lay the sheets in a vertical direction, bending them if necessary at the locations of the stiffeners. Apply special tape to the panel ends and cover with a profile.

You can follow the following videos for instructions on assembling a “Droplet” greenhouse made of polycarbonate with your own hands.

A little about the manufacturers

And in conclusion, a few more words about greenhouse manufacturers. In principle, I have already said a lot, but I would like to summarize and generalize the information. So…

- ready-made greenhouses can be factory-produced, or they are custom-made by a local company - a manufacturer of metal structures;

- factory greenhouses are usually represented by a whole line of different models, while a small manufacturer, most often, offers standard products with minor differences in configuration options; on the other hand, if you need a greenhouse according to individual parameters, it is better (and easier) to manufacture it on site;

- factory greenhouses, as a rule, are available in specialized retail outlets; Locally produced greenhouses are often made to order (this means additional waiting time).

Everyone decides who to trust for themselves, and manufacturers in different regions may be different, so there is hardly any point in dwelling on this issue in more detail. But I hope that the results of my little “research” will be useful to you.

And one more thing - I would like to know the opinions of those who chose and bought a ready-made greenhouse: what did you encounter? Have there been any problems or difficulties? Which criteria did you consider important for yourself, and which were insignificant, secondary? Share your impressions and observations!

Source: 7dach.ru

Greenhouse care

Caring for “Droplet” does not take much time and effort.

Shading should be done by spraying the surfaces of the greenhouse with ordinary chalk.

In autumn from the greenhouse you need:

- remove plant debris;

- carry out soil treatment;

- disinfect the structure;

- preserve the greenhouse for the winter.

Thanks to the pointed shape of the “Drops”, there is no need to clear snow from it in winter - it will roll off the surface without loading the structure with its own weight.

Alternative models

Before making a choice, many gardeners consider several greenhouse design options. In addition to the popular arches and “house”, these are:

- Single-pitch. Attached to the wall, saving materials.

- Lancet (drop-shaped). It somewhat resembles an arched one, but has a connecting seam at the top.

- In the shape of a pyramid. Such a greenhouse requires scrupulous calculations and the participation of specialists.

- Trapezoidal or polygonal. It is a unique combination of arched and gable. The walls are also often made at an angle.

- According to Mittleider. Similar to straight-walled, but with a special roof design for better ventilation, etc.

Purchasing a greenhouse is a responsible and troublesome task. Experienced summer residents are sure that shape does not play a special role. After all, each variety has its own pros and cons, and therefore deserves attention. It is more important to focus on quality material and conscientious installation. It is these two components that are the key to the strength and reliability of any greenhouse.

Customer Reviews

Judging by customer reviews, the Droplet greenhouse has a number of undeniable structural advantages. At the same time, experienced gardeners recommend installing the frame on a prepared foundation, and the wooden beam is subject to destruction, so it is best to make the foundation from concrete or brickwork.

Greenhouses of this type are most popular in regions subject to heavy snowfalls. According to them, “Kaplya” withstands the tests not only of snow, but also of strong gusts of wind.

Thus, “Kapelka” polycarbonate greenhouses are an excellent option for those who value functionality and reliability in greenhouse structures.

Triangular greenhouse made of boards

This greenhouse is good for seedlings, but you can make it for peppers and eggplants. A stand is nailed in the middle of the base. There are two inclined boards attached to it. The cross section results in a triangle. If you need a long greenhouse, the same structure is installed approximately every meter. All tops are connected with a long bar or pipe. This greenhouse has a simple and convenient design.

Cucumbers are grown with it only until they begin to curl. Under the cucumbers, the covering material is removed, posts are nailed (screwed) to the sides, and twine is pulled between them.

Triangular greenhouse made of boards

Here's how to remake such a greenhouse for cucumbers

Let's delve into the details: which greenhouse is better, a droplet or an arched one?

There is ambiguity in terms of assessing the performance characteristics of greenhouses when it comes to “Kapelka”. For its manufacture, pipes are used, the cross-sectional size of which ranges from 20 to 25 mm.

All elements are fastened together by welding, which eliminates the need to seal the seams. This type of structure can be used year-round.

The information provided allows us to make an unambiguous conclusion that the “Drop” greenhouse is not mobile.

The following facts will help you get a more detailed understanding of the comparative characteristics of the two models:

- Volume of sunlight - “Drop” is suitable for moderately lit areas, and for other options only an arched shape is chosen.

- Structural reinforcements - in the first case, it is enough to correctly place the arches of the greenhouse, and in the second, the use of reinforcement is mandatory.

- Coating – arched structures allow the use of film coating, but “drop” structures do not. In the second case we are talking about double-glazed windows.

By shape

Manufacturers offer greenhouses of various shapes, so summer residents have a legitimate question - what to choose. To make an effective decision, you should carefully study the features of the various options.

Arched or gable

The arched greenhouse reaches a height of no more than 2 meters, its length has no restrictions. The summer resident decides which sizes are suitable for his needs.

- ease of assembly, ability to carry out work independently;

- no need for a foundation;

- affordable cost of the finished structure;

- easy to disassemble, change the covering or move to another place;

- you can change the length of the structure without major alterations;

- high resistance to snow load.

Among the disadvantages are instability to gusts of wind and limited height.

Choosing a “house”, i.e. gable greenhouse, the summer resident receives:

- high variability of sizes (it is easy to create a structure of any height, width);

- wind resistance;

- the ability to do without a foundation;

- possibility of making vents on the roof.

The high reliability of such greenhouses is guaranteed only if there is a foundation, which means that moving it will not be easy. It will require more material, thicker polycarbonate is needed for the coating.