Despite the emergence of ever new, more advanced and modernized models, everyone’s favorite greenhouse “Urozhay” has not lost its position for several years now. This is a fairly durable and warm structure with an arched shape (“Harvest Elite”) or a “house” shape (Urozhai Classic greenhouse, the very first option). Its frame is made of galvanized steel pipe 25x25 mm and 0.9 mm thick. The height of the greenhouse is 2.2 m, the width is 2.5 m and any length that can be a multiple of 2 meters. The greenhouse has 2 windows and 2 doors at the ends, the distance between the arches is 1 meter. The covering for the greenhouses of the "Harvest" series is either polycarbonate or white agrotex - here it is optional. The frame of the Harvest greenhouse is made of galvanized metal, and cellular polycarbonate is used as a covering. The Harvest greenhouse can stand without a foundation, and if necessary, it can be easily moved from place to place, especially since even one person can lift it into the air.

One of the latest Harvest models is the Harvest Elite greenhouse. Its assembly is already much more difficult, but thanks to the improved design its strength has become much greater, which is especially important for the harsh Russian winter. But the Harvest Economy greenhouse is no less popular today - compact and inexpensive. There are two options - 1.5x1.8x4 m, with both doors at the ends, and 2x2x4 m with one door with a window and just a window at the opposite end.

Advantages of a greenhouse

The very first and main indicator is that the structure can withstand snowfalls of any intensity and even stormy winds, therefore it is recommended for use in the northern regions. In addition, the greenhouse:

- Differs in multi-purpose purpose.

- It has increased strength: engineering calculations for all loads far exceed GOST standards.

- Installed by digging T-shaped ends into the ground. It is necessary to deepen to the bottom trim. You can remove the ends and install the structure on a foundation made of boards, timber, or metal corners.

- Easy to assemble and transport.

- Quite durable: service life - from 20 years.

The main purpose of a greenhouse is not just to create the most favorable microclimate for cultivating various crops, but also to provide the opportunity to carry out this process all year round. All that remains is to maintain the temperature required for the plants inside the structure.

How to make a good foundation for this greenhouse?

It is best to make a foundation for such a greenhouse - the galvanizing of a profile dug directly into the ground can simply come off, and the frame will simply begin to rust. So, experienced builders advise making the following foundation for this greenhouse: sand cushion + posts + timber. To do this, it is best to purchase ordinary concrete cubes in advance, 10 pieces - 4 pieces will be on one side and one at the ends. You will also need a sand machine. But it will only take a day to make the foundation.

So, you need to dig 10 holes 60 cm deep and 50x50 cm wide. Gradually, the holes need to be filled with sand and compacted well with your own weight. After which you can start laying the treated timber - it is best to order it from a store, 6 meters long, and have it processed there (but sawn in half will be worse in terms of the strength of the entire structure). The most important thing when laying timber is to place the entire perimeter in a perfectly horizontal plane, for which sand can be added under some cubes and removed from under others. And as soon as the building level shows the norm, the wooden foundation for the Harvest greenhouse can be considered ready.

All that remains is to seal the gaps that have arisen between the greenhouse and the resulting foundation. And this is not much, not little - 15 cm from the timber to the lower profile. And better material. Which is not afraid of either water or frost, like linoleum, in this regard, one cannot imagine.

Design Features

To produce the base for polycarbonate sheets, the manufacturer uses a galvanized closed pipe. Thanks to this, the frame is not subject to corrosion damage.

Note: Since the frame parts do not need painting, they do not harm the environmental situation inside the greenhouse: paint is a chemical substance, therefore, when heated in the sun, it can release toxins.

In addition, a closed pipe is a very durable material, so it is ideal for creating a frame for a greenhouse made of Harvest Classic polycarbonate. And if we add to this that the frame is made carefully, the holes are made very precisely and all the parts fit neatly, then it becomes clear why the base is strong and reliable.

"Harvest PCT"

Like the previously discussed models, the “Harvest PKT” is an arched greenhouse. The frame of the greenhouse is made of Larsen tongue and groove, which is a special Ω-shaped galvanized profile. Another feature of the model is that the gap between the trusses is 67 cm, which means that the number of arcs is greater and the strength of the structure is higher.

The four-meter greenhouse has 7 arcs. Thanks to these features, “Urozhay PKT” is considered one of the most load-resistant models in the “Urozhay” series.

Specifications

The basic model weighs 50 kg. When packaged (for this purpose it is placed in a box), the product has dimensions of 18.5×210×11 cm. If the product is purchased with an extension, then the dimensions of the latter are 11×9.5×210 cm and weighs 25 kg. At the same time, you can purchase not one extension, but several - to install a structure of the desired length. The height and width of the structure are fixed values - 2.2 and 2.5 m. The greenhouse can be any length, starting from two meters.

The basic kit contains:

- fastening - 4x25 and 4x4 screws. But you can buy a kit with 4.2×25 and 4.2×16 screws. Galvanized washers are also sold with them. But, these fasteners are designed for polycarbonate with a thickness of 4 mm, so when choosing a material of a different thickness you need to pay attention to this;

- the basic package includes 2 doors and the same number of transoms, but if necessary, side windows can be purchased;

- polycarbonate 2.1x6 m - 2 sheets: one for the tunnel, the other for the ends. But this is for a basic two-meter model. For a four-meter greenhouse, for example, 3 sheets are needed.

INSTRUCTIONS FOR ASSEMBLYING THE GREENHOUSE “Harvest Classic-T”

Thank you for purchasing our product. Our company's many years of experience in the production of greenhouses and various improvements have made our products one of the most reliable assistants for those who use greenhouses in their amateur or professional activities.

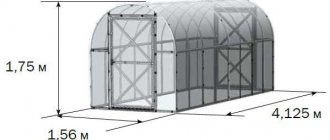

Taking into account the wishes of gardeners, in the traditional production of greenhouses with a house, our company has released a new series of pipe greenhouses “Harvest Classic-T”.

We wish you good harvests and hope that our products will fully satisfy your expectations.

BASIC TECHNICAL DATA.

The greenhouse "Harvest Classic-T" is manufactured according to TU5262-001-61188124-2011 and is designed to create a microclimate favorable for growing garden crops in summer cottages and garden plots in the spring-summer-autumn period. In winter, it is allowed to operate the greenhouse with constant maintenance of a positive temperature inside.

The supporting frame of the greenhouse is made of galvanized closed profile pipe of square section, and the auxiliary parts are made of U-shaped profile. Assembly is carried out using 4.2x16 self-tapping screws, screws (m4x14) and nuts.

Covering: cellular polycarbonate. Attention! The greenhouse cover is not included in the delivery package, must be purchased separately

. For a greenhouse 4 m long, three sheets of cellular polycarbonate measuring 2.1 x 6 m are required, for a greenhouse 6 m long, four sheets measuring 2.1 x 6 m, and for a greenhouse 8 m long, five sheets measuring 2.1 x 6 m.

Cellular polycarbonate is installed with a strictly defined side outward, which has a protective layer against ultraviolet radiation. The packaging film from the covering must be removed and the honeycombs protected from dirt before installation on the frame. The covering on the greenhouse frame is secured with 4.2x16 self-tapping screws with galvanized washers. Attention! The fasteners for fastening polycarbonate are designed for a coating thickness of 4mm.

The four-meter (basic) greenhouse "Harvest Classic-T" is equipped with parts of two ends with opening doors with windows and a four-meter tunnel. The delivery set of the basic greenhouse “Harvest Classic-T” consists of two packages. Package No. 1 contains greenhouse pipe parts, package No. 2 contains U-shaped profile parts.

The six-meter greenhouse "Harvest Classic-T" consists of a set of basic greenhouse and one set of extension 2m "Harvest Classic-T". An eight-meter greenhouse consists of a set of basic greenhouse and two sets of 2m extensions, etc.

To fix the greenhouse in the ground, the ends of posts No. 2 and No. 12 with supports No. 30 are buried in the ground up to the lower stringer No. 14n and No. 15n, and the lower end trim No. 3 and No. 4, which prevents the greenhouse from moving under the influence of the wind.

Also, if desired, you can additionally install an opening window to ventilate the greenhouse tunnel. The window is installed in any convenient place for the consumer on the roof or on the side of the greenhouse.

Attention! The window is not included in the delivery set. Sold separately

.

Attention!

The manufacturer reserves the right to make changes to the design of the greenhouse without notifying the consumer.

EQUIPMENT OF THE GREENHOUSE “Harvest Classic-T”.

| No. Parts | Name | Length mm | Qty |

| Rafters | |||

| 2l | Left stand | ||

| 2pr | Right pillar | ||

| Bottom end trim left | |||

| Bottom end trim, right | |||

| Doorway post | |||

| Middle end cross member | |||

| Doorway lintel | |||

| End jib | |||

| Screed | |||

| Strut | |||

| Extension rafters | |||

| Extension stand | |||

| Kerchief | — | ||

| 14n | Lower end stringer | ||

| End stringer | |||

| 15n | Lower end stringer | ||

| End stringer | |||

| Extension stringer | — | ||

| Horse | |||

| Door pillar | |||

| Door cross member | |||

| Door jib | |||

| Window stand | |||

| Window cross member | |||

| Window jib | |||

| Tunnel jib | |||

| Corner end stringer | |||

| Corner extension stringer | — | ||

| Overlay | — | ||

| A loop | — | ||

| Angle 90° | — | ||

| Support | |||

| Corner | — | ||

| Pinwheel | |||

| Hook | |||

| Self-tapping screw 4.2x16 (652+126t+132b) | — | ||

| Screw m4x14 | — | ||

| Nut m4 | — | ||

| Galvanized washer | — |

General instructions for assembly.

1. Carefully read the greenhouse assembly sequence indicated in the instructions.

2. Unpack the greenhouse parts and arrange them by number. Check the availability of parts as specified in the instructions.

3. The item number indicated in the package corresponds to the part number in the pictures and is indicated by the corresponding markings on the parts in the packaging.

4. The parts are connected using gussets No. 13, overlays No. 27 and corners 90̊ No. 29, as well as by installing the crimped end of the part or installing the part into the extended end of the part and fastening them with self-tapping screws.

5. In some parts there are free holes, which is not a defect, but a consequence of the unification of parts.

6. When assembling, be careful not to damage the parts, since they do not have sufficient rigidity until final assembly. Before attaching the part, in the places indicated by the injection, first make a puncture with a self-tapping screw. Using a screwdriver, screw in the self-tapping screw until the self-tapping screw begins to twist along the thread.

Attention! When tightening, do not allow the screw to turn. Drilling connecting holes in the supporting structure is strictly prohibited!

7. When assembling, be careful and attentive. Do not confuse the right part with the left part, the top with the bottom, or the end part with the extension.

Example

Fig. 1 - The end part of the greenhouse No. 1 has punctures on the front side for attaching polycarbonate (PC).

8. To assemble the greenhouse you will need: a Phillips or flat screwdriver with a Ø4mm rod, depending on the configuration with screws and an M7 key for attaching the hinges, a cordless screwdriver with replaceable bits for self-tapping screws, pliers, a 3m tape measure, a marker, a metal ruler 1m or 2m rule for cutting PC (polycarbonate), stepladder, sharp knife with replaceable blades, transparent tape, four boards 25x200x3000 and two bars 50x50x3000 for cutting PC and covering the greenhouse roof with polycarbonate.

9. Attention! When attaching the covering to the roof , be extremely careful and use support boards . The weight of a person when working on the roof should not exceed 80 kg.

"Harvest Economy 2"

This model is a structure consisting of vertical walls and an arched roof. The frame for the material is made of steel V-shaped profile.

Polycarbonate sheets are secured using external ties. This model is available in a single size of 400x200x200 cm. The basic set contains 2 end doors and vents. The Harvest Economy 2 model is designed for heat-loving plants grown in spring and summer in a temperate climate zone.

In general, the “Harvest” series of greenhouses is easy to use; thanks to their sufficient height, they can be used with shelving. The durable frame eliminates the need to remove the greenhouse for the winter. Certain shortcomings that we mentioned above can be easily eliminated with a small amount of time and effort. What are your impressions of using these greenhouses?