Has a greenhouse fallen? We'll tell you why and what to do

8; 8 495 225-44-73

Attention! Greenhouses that collapsed due to snow in the winter of 2022 more details...

Options for durable greenhouses on summer cottages can be considered in detail in the photo reviews section for more details...

The winter of 2022 - 2019 was, according to the Roshydrometcenter, moderately snowy. However, many greenhouses were destroyed by snow this winter . Most of the crushed greenhouses are made from square pipe. This happened because the previous six winters were snowless, and during this time a large number of “disposable” greenhouses with a low snow load were sold. Next we will tell you what a durable greenhouse .

What kind of greenhouse can be considered a durable, reinforced and strong greenhouse for the Moscow region? So that you don’t have to buy a new greenhouse after every moderately snowy or snowy winter.

Agroparnik organization has been involved in greenhouses for more than 25 years. An analysis of the winters that have passed during this time in the Moscow region and neighboring regions allowed us to draw a number of conclusions about the cyclical nature of snowy winters in the central region. What, besides direct snow loads, affects the stability of greenhouses? What structures can be considered truly durable, reinforced and strong for greenhouses? Cooperation with specialized research institutes, in particular with GIPRONIISELPROM (state research institute for the creation of greenhouses and greenhouse equipment. City of Orel) allowed us to find out the basic requirements for greenhouses. This specialized institute issued SNiP “Greenhouses and Greenhouses” in 1985. The appendix to this SNiP “Greenhouses for individual use” provides a number of characteristics necessary for the competent design of greenhouses. For the production of strong, reinforced and strong greenhouses. And studying the data of the Roshydrometcenter over the past 25 years made it possible to take into account snow loads in the Moscow region by year. Observations by the Hydrometeorological Center of Russia make it possible to draw conclusions about which greenhouses can be considered durable, reinforced and strong for the Moscow region. Let's consider this issue more carefully.

Reinforced polycarbonate greenhouse.

For the Moscow region, according to twenty-five years of observations, a greenhouse with a snow load of at least 90 kg/m2 is required . Since in the winters of 2001, 2010, 2011, 2012, greenhouses with a strength of up to 90 kg2 were destroyed. Taking these observations into account, a greenhouse with a snow load of 180 kg/m2 has a double safety margin and can be considered a reinforced polycarbonate greenhouse.

SNiP 2.01.07-85* “Loads and impacts” speaks about this. According to this SNiP, the Moscow region belongs to climate zone III with a snow load of 180 kg/m2. This load is given for all permanent buildings (apartment buildings with a flat extended roof). In the case of sloping roofs, a reduction factor is introduced depending on the angle of inclination. For greenhouses according to SNiP, a coefficient of 0.5 (90 kg/m2) is suitable. This again suggests that a greenhouse with a snow load of 180 kg/m2 for the Moscow region can be considered a reinforced polycarbonate greenhouse.

- a leading company in the Russian market for the production of greenhouses (with twenty-five years of experience), after the snowy winters of 2010, 2011, 2012, strengthened its main greenhouse (at that time) - “Dachnaya-2DUM” from 60 kg/m2 to 150 kg/m2 and classifies this greenhouse as “ guaranteed strength ”. This means that he considers it a reinforced polycarbonate greenhouse for the Moscow region.

How to choose the right greenhouse

A greenhouse is an excellent helper for any gardener. Thanks to it, you can get the first harvest of vegetables and herbs early enough, and if you have heating, you can generally grow plants all year round and always have vegetables from your own garden on the table. But to fully meet these expectations, it is very important to choose the right greenhouse. How to choose it correctly?

First of all, think about what functions it will perform and how it will be used. Some people plant plants in it only in the summer, while others need a product that allows them to grow vegetables all year round. Evaluate the structure itself: is there a need to disassemble it for the winter or is it easier to install a monolithic version. And, of course, it is important to decide what crops you plan to grow - at a minimum, decide whether these will be low-growing varieties or tall varieties.

Based on all this, you will have to choose a greenhouse, looking at its design features, dimensions, thickness of metal and polycarbonate and other factors.

Important! Take into account your region of residence. In areas where snowfalls are frequent and there are strong winds, you need to install a durable, or better yet, reinforced structure. Lightweight options will last at most 1-2 years in such conditions.

The material from which the greenhouse elements are made is also important. This is the frame and covering. Let's figure out what they are made of and which option would be preferable.

Covering material

The covering material protects the plants from rain and wind, and also helps retain solar heat inside the greenhouse, creating an optimal microclimate for growing. The classic option is regular polyethylene film (there is also reinforced film). This is a cheap material that retains heat well and allows the sun's rays to pass through. Installation is very simple and quick. However, the film is short-lived and breaks quickly - in a couple of years, at best, it will have to be completely replaced. Also, in some cases, when heated strongly, the film begins to release harmful substances into the atmosphere.

Previously, glass was also used, especially in industrial greenhouses. It is environmentally friendly, quite durable, and lasts longer than film. But glazing a greenhouse is not easy, and it is quite easy to break it.

The optimal and modern solution is cellular polycarbonate, something between film and glass in its properties. This synthetic material can withstand fairly heavy loads, is durable and does not lose its properties for many years. The material is very simple to install, lightweight and relatively inexpensive. We recommend choosing polycarbonate.

On a note! Monolithic polycarbonate is also available for sale. This is not the best option for a greenhouse. It is heavy and does not retain heat well.

If we talk about polycarbonate, it is important to choose its thickness correctly - the light transmittance and strength of the greenhouse depend on it. The best option is carbonate within 4-10 mm thickness. The thicker the sheet, the better the heat will be retained inside the greenhouse, and the stronger the greenhouse itself will be. And yes, be sure to take into account the presence of a UV-protective layer during installation - that side has a special marking. Without such a layer, polycarbonate quickly deteriorates.

What material should you not buy:

- with low density up to 0.65 kilograms per square meter;

- with a short warranty period;

- made from recycled materials.

A good polycarbonate sheet weighs between 7-10 kg, is made from primary raw materials, and is protected from UV rays.

Greenhouse frame

The second main element of the greenhouse is its frame. It can be created from plastic, aluminum or steel profile.

Table. Types of greenhouse frame.

| Type of material | Description |

| Plastic | This is the cheapest option. Plastic pipes are lightweight, easy to install, and do not rust. But a greenhouse based on them will not be durable and is unlikely to survive even the first winter if there is heavy snowfall. |

| Aluminum | Stainless steel frame, lightweight and easy to transport, quite easy to install. A fairly reliable option, but it is recommended to fix the arches in the foundation and remember that under heavy snow load it can bend and collapse. |

| Steel | Galvanized steel profile is the most durable and reliable option. Durable, does not rust if treated with anti-corrosion treatment, but is heavy. It is advisable to buy a greenhouse with solid arcs without welds. |

On a note! Previously, many people made a greenhouse based on a wooden frame. Nowadays such options are almost never found. Wood is a good material, but it rots quickly and, moreover, often becomes a breeding ground for parasites that destroy plants.

If we talk about a metal frame, then which option should you not buy:

- with metal that is too thin, less than 1 mm;

- with collapsible arches (depending on the region and climate);

- with a frame that requires more than 50 bolts to assemble;

- without anti-corrosion treatment;

- with very low weight.

What else needs to be considered

And finally, we’ll outline a few more points that need to be taken into account. So, a very important aspect is the shape of the greenhouse. This is especially important for regions where there is heavy snowfall in winter. Due to the heavy snow load, polycarbonate, and even the frame of the greenhouse, can easily break.

The traditional arched model of polycarbonate construction provides a lot of free space inside, but due to its fairly gentle slope, it requires regular cleaning of the roof in winter. The exception is very durable, reinforced greenhouses. An arched model, even the simplest one, is very wind-resistant.

Equal-wall structures with gable roofs also provide a lot of free space inside and can be very high. But they are usually difficult to install. As for the snow, it does not linger on such roofs, and this is already a big plus.

The third option is conical droplet greenhouses. They are optimal for those who grow tall plants. The snow comes off them without much difficulty on their own. But in most cases, this option requires additional sealing of the ridge part.

What else you need to look at:

- the distance between the arcs - the smaller it is, the stronger the greenhouse roof;

- presence of seals included;

- how many doors and windows are there;

- completeness of the set.

Which greenhouse is stronger?

When purchasing a greenhouse, the buyer inevitably faces the question: which greenhouse is stronger? This is actually not a simple question because there is a huge selection of different greenhouses on the greenhouse market. The first question that arises is, which profile is the stronger for the greenhouse? This is not the right question. Greenhouses made from both an open profile and a square pipe can be durable. It all depends on the design of the greenhouse. Namely, on the frequency of the arcs, the presence of arc amplifiers, their number and the design of the amplifiers themselves. As a result, it is very difficult for a buyer, even with a higher technical education, to understand which greenhouse is stronger. This requires special calculations and tests. So it is absolutely impossible to determine “by eye” which greenhouse is stronger. Many unscrupulous greenhouse sellers take advantage of this. Offering greenhouses that are profitable for the seller (cheap to purchase), and not for the buyer. But the buyer has a very simple way to determine which greenhouse is stronger. We need to ask the question: what strength does the greenhouse have according to its passport ? No manufacturer will ever put the strength higher than it actually is. Since in the very first snowy winter this will become clear, and the manufacturer will incur losses to reimburse the buyer for the cost of the greenhouse crushed by snow, if the strength of the greenhouse in the passport was overestimated.

If there is no strength in the passport, then this means that, firstly, it is too small to show. Secondly, the manufacturer and seller will not be held liable if the greenhouse is destroyed by snow. See the example here - https://otzovik.com/review_6095107.html

For example, this is what the passport for our greenhouse Dachny Ideal – Domik looks like

Conclusion: Do not pay attention to advertising gimmicks (various videos and photographs), but ask about the strength of the greenhouse according to the passport .

Strong greenhouse. For a long time.

What does "strong greenhouse" mean? Above we wrote how to determine a reinforced (strong) greenhouse - according to the passport . But the concept of a “strong greenhouse” may change over time. What affects the change in the strength of a greenhouse over time? That is, what is needed for the greenhouse to be strong for a long time.

In order for the greenhouse to remain strong for a long time, reliable protection of the steel frame from corrosion is necessary. The best protection for steel is a hot-dip galvanized coating (like roofing steel). This coating lasts more than 40 years .

Electro galvanized (galvanic) coating is not an independent coating. It is the basis for further painting. And if the electro-galvanized frame is not painted, then the greenhouse will remain strong for a very short time. Especially considering the warm and humid microclimate inside the greenhouse.

The most short-lived protection is painting. The paint is scratched during transportation and assembly. Also, the paint bursts due to temperature changes in the greenhouse.

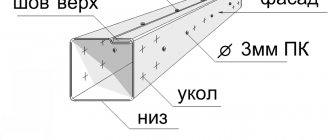

Does the shape of the profile affect how strong the greenhouse remains for a long time?

In the appendix to SNiP “Greenhouses and Greenhouses” of 1985 (greenhouses for individual use) it is written that a closed profile, i.e. a square pipe, is not suitable for greenhouses. Since the inside of a closed (square) profile cannot be painted. Also, a closed profile (square pipe) cannot be coated with zinc using the galvanic method (electrogalvanizing). Since the electric current flows in a straight line (the shortest path) and according to the laws of physics, it is impossible to galvanize the pipe inside. That is why steel pipes for heating are galvanically coated with zinc only on the outside. In a humid and warm climate in a greenhouse, water quickly penetrates the tube and never leaves. And the corrosion of the square pipe inside continues throughout the year. As a result of corrosion, the strength of a square pipe decreases by 10-12% per year. Therefore, a greenhouse made from a square pipe remains strong for a very short time.

Another thing is the open “greenhouse” profile. This profile is equally protected from corrosion on all sides. Made from an open profile, the greenhouse remains strong for a long time. For many decades.

Conclusion: a greenhouse can remain strong for a long time if it is made from an open (greenhouse) profile, and the profile protection is made by hot-dip galvanizing.

Covering for greenhouses

A wide range of structures designed for growing flowers, herbs and vegetables allows you to choose the most suitable option for each individual case. One of the important selection factors is the covering material. The most commonly used coatings are:

- cellular polycarbonate;

- polyethylene film;

- reinforced polyethylene film;

- spunbond;

- glass.

Each of these options has certain pros and cons.

Cellular polycarbonate

This material has been used in this area for a relatively short time. Its popularity is due to its increased strength, which is approximately two hundred times higher than glass. Therefore, structures can easily withstand heavy rains, hail, and strong gusts of wind. Another advantage is the long service life, during which the transparency of polycarbonate does not deteriorate.

Greenhouse made of cellular polycarbonate Source bloomhuff.com

Polyethylene film

The most affordable coating is polyethylene film, which is also used very often. It has several significant advantages:

- Easy to mount on any greenhouse, regardless of its shape.

- It transmits ultraviolet rays well, which are required for the full development of all plants.

- Provides reliable protection against light frosts.

- Good density.

Greenhouse made of polyethylene film Source 9dach.ru

Among the disadvantages, fragility should be noted, because, for example, large hail can tear the film, especially in a place where it is tightly stretched.

Reinforced polyethylene film

The advantages of the material are exactly the same as those of conventional polyethylene film, but it has a special reinforced mesh that increases strength - the product can withstand both hail and strong gusts of wind. This option will cost more, but precipitation will no longer be so dangerous.

Greenhouse made of reinforced polyethylene film Source goza.havezuny.ru.net

Spunbond

In recent years, greenhouse manufacturers have increasingly used spunbond covering material to cover structures. It is a durable non-woven fabric, white in color. It is characterized by resistance to rain, wind, hail and birds. With its help you can protect plants from frosts reaching -7 °C. In addition, spunbond can be used for five seasons - during this period of time it does not lose its original properties.

Greenhouse made of spunbond Source polikplast.ru

Glass

Quite widely in the production of greenhouses for summer cottages, glass is used as a covering material - a traditional option, which is characterized by excellent thermal insulation properties, as well as light transmittance.

Economy greenhouse - from teplici-lux Source teplici-lux

But when choosing it, you should not neglect the fact that it has a number of disadvantages:

- The construction of the structure requires a lot of time and effort, because glass is quite heavy and fragile. Its installation and fastening must be carried out carefully and in several pairs of hands.

- For reliability, the preliminary creation of a strong frame is required, the construction of which requires a large sum of money.

- Inside a greenhouse covered with glass sheets, the air heats up in a short period of time, which negatively affects the development of plants.

- As a result of one awkward movement, the sheet can be broken or its integrity can be seriously damaged, after which it will become unsuitable for arranging the structure.

Reinforced greenhouse. Myths and reality

Above we wrote how to choose a reinforced greenhouse - according to your passport . But which greenhouses are reinforced, and which ones only emit it?

Let’s take for example the Strelka greenhouse from the most famous greenhouse on the market. This reinforced greenhouse has a strength according to the passport - 360 kg/m2. This strength is achieved by using a powerful profile with a section of 60x21 mm. Also, to achieve such strength, a special design with a large number of reinforcements and the original shape of the greenhouse are used. But many buyers have the impression that it’s all about the shape of the greenhouse. Unscrupulous greenhouse manufacturers take advantage of this by repeating the shape of the greenhouse. In this case, a cheaper and weaker square profile is used. Amplifiers are not used at all. As a result, these low-quality repetitions (usually called “Droplets”) have extremely low strength as a result of the greatly reduced cost of the greenhouse. Such low-quality repetitions cannot be reinforced greenhouses. This is confirmed by the drops in such repetitions during this moderately snowy winter.

Conclusion: To be sure that a particular greenhouse is truly

a reinforced greenhouse , it is not enough that it externally replicates a well-known reinforced greenhouse from a serious greenhouse manufacturer.

There is also a whole family of greenhouses made of square pipes with double welded arcs, having the same design and different names: “Novator”, “Tsarskaya”, “Kremlevskaya”, “Rublevskaya”, etc. These greenhouses are made according to the example of structures for canopies, hangars, sheds, where it is dry inside. And in such a microclimate, these structures will last a long time - 10-15 years. But the disadvantage of these structures is that they cannot be protected in any way from corrosion inside the pipe itself. And if such structures are used for greenhouses, where there is a humid and warm microclimate inside, the square pipe, unprotected by anything inside, begins to corrode intensively, and the initially reinforced greenhouse quickly loses its strength. Also in such greenhouses, the distance between the arcs is, as a rule, 1 meter. On such a span, even with 9 longitudinal parts, the polycarbonate inevitably sags under the weight of snow, and so-called “snow bags” are formed, preventing the snow from moving off the greenhouses and thereby further loading them.

The best cone greenhouses

1№ 1 – Hacienda-4 Standard

A Russian-made greenhouse with a durable galvanized frame. The cross-section of the pipes is 2.5x2.5 cm, and the thickness of the metal is 1.2 mm. The step between the solid arcs is small, only 65 cm, which suggests an increase in the strength of the product. And the polycarbonate with which the greenhouse is closed has a thickness of 4 mm, there are two options - standard and nano. The width of the structure will allow you to arrange three beds inside. The height is 2.3 m and is suitable for growing tall crops. The greenhouse is easy to assemble. It is suitable for those regions where snowfalls and strong winds are frequent.

pros

- very durable

- wide

- thick metal arcs

- solid arches

- optimal ratio of cost and quality

Minuses

- not detected

2№ 2 – Orange Droplet

This drop greenhouse is an excellent solution for growing tall crops. It has two variations, differing in width - 2.4 and 3 m. The frame has additional strength due to the presence of 8 stringers. In general, the greenhouse has two doors on the end sides and a pair of vents for ventilation. It is very durable and practical, has a simple design, is assembled fairly quickly and can last for a very long time. The only obvious drawback is the need to seal the gaps after assembly that form in the area of the doors and the ridge part.

pros

- very durable

- two width options

- nice appearance

- galvanized frame

- light

- nice price

Minuses

- additional sealing required

Video - Assembling the Orange Drop greenhouse

3№ 3 – Innovator Droplet

Greenhouse designed for installation in northern regions. It is very durable and can easily withstand a large load of snow, which, however, almost does not linger on the roof due to its teardrop-shaped shape. The distance between the frame arcs is 66 cm. The frame itself is made of metal with corrosion protection, the profile has a cross-section of 2x2 cm. This greenhouse is very easy to assemble, since all its parts are informatively marked, and it is difficult to confuse them during installation. The manufacturer also provides a 10-year warranty on polycarbonate.

pros

- 10 years warranty

- durable and reliable

- anti-corrosion treatment

- roof vent and plastic barrel included

Minuses

- Expensive

4№ 4 – Dachnaya Strelka

A tall and comfortable greenhouse that rightfully occupies a leading position in various ratings. Its height is 2.4 m, and its pointed shape allows you to pay less attention to clearing snow from the roof in winter. And the frame itself is very durable and is designed for a snow load of up to 360 kg per square of roof. The width of the structure is 3 m and it is suitable for most areas. The greenhouse can be placed on a soil foundation without a foundation; it is fixed securely thanks to specially shaped pins. The frame can be disassembled, which allows the product to be transported even in a passenger car.

pros

- easy to transport

- durable and reliable

- installed without foundation

- high

- good ventilation

Minuses

- thin metal frame

Video - Assembling a greenhouse Dachnaya Strelka

5№ 5 – Kremlin Strelka

Stable, durable and reliable greenhouse with a pointed roof. It is based on a metal frame made of a 2x2 cm profile and galvanized metal 1 mm thick. The height at the highest point of the roof is 2.45 m - the greenhouse is suitable for growing tall crops. Snow load is almost 300 kg per square meter. There are a pair of doors at the end and a pair of windows. The main disadvantage is the small width of 2.7 m, which is why it will not be possible to place many plants inside. In addition, among the disadvantages there is also a long and complex assembly. But the greenhouse will last for many years without complaints.

pros

- durable

- durable

- stainless steel frame

- high

Minuses

- difficulty of assembly

- narrow

Conclusion. To buy a durable, reinforced greenhouse, and for it to last for a long time, you need:

- Find out the strength of the greenhouse from the passport .

- It is necessary that the profile of the greenhouse be protected from corrosion on all sides and it is desirable that it be open and not closed .

- The most durable protection of steel against corrosion is hot-dip galvanized coating .

- The distance between the arcs in arched greenhouses should be less than a meter .

- If you cannot see the technical data sheet for a greenhouse on the website, this may mean that the sellers are trying to hide something (it is better to refuse to purchase such a greenhouse).

- External repetition of a durable, reinforced and strong greenhouse from a well-known manufacturer does not at all mean the strength of this greenhouse .

Rating of the best greenhouses

| Photo | Name | Rating | Price | |||

| The best arched greenhouses | ||||||

| #1 | Volya Dacha Optima | ⭐ 4.95 / 5 2 - votes | More details | |||

| #2 | Bastion Premium | ⭐ 4.9 / 5 5 — votes | More details | |||

| #3 | Kremlin Suite | ⭐ 4.85 / 5 1 - voice | More details | |||

| #4 | Will Yota | ⭐ 4.8 / 5 1 - voice | More details | |||

| #5 | Uralochka | ⭐ 4.75 / 5 1 - voice | More details | |||

| The best cone greenhouses | ||||||

| #1 | Hacienda-4 Standard | ⭐ 4.95 / 5 2 - votes | More details | |||

| #2 | Orange Droplet | ⭐ 4.9 / 5 1 - voice | More details | |||

| #3 | Innovator Droplet | ⭐ 4.85 / 5 1 - voice | More details | |||

| #4 | Dachna Strelka | ⭐ 4.8 / 5 | More details | |||

| #5 | Kremlin Arrow | ⭐ 4.75 / 5 | More details | |||

Which greenhouse would you choose or recommend?

Take the survey