Summer residents know that it is better to grow tomatoes, cucumbers and peppers in a greenhouse. We will tell you below how to build a greenhouse with your own hands from film.

Depending on the season, greenhouses are divided into winter and summer. Their fundamental difference is that a winter greenhouse must be heated, and therefore requires additional difficulties in construction. A summer greenhouse can be built in one weekend.

Film is the most popular covering material for greenhouses and greenhouses in the summer. From this we will make our greenhouse.

The difference between a greenhouse and a greenhouse is that the first can only accommodate a plant, while the second can house a person.

What types of greenhouses are there?

When choosing a greenhouse design, you need to decide what you will use the greenhouse for.

By purpose

greenhouses are divided into seedling and vegetable greenhouses and vegetable greenhouses.

By period of operation

greenhouses are divided into spring greenhouses - which are used from spring to autumn; and winter ones - which are used throughout the year. Winter greenhouses come with a polymer and glazed coating, while spring greenhouses come with film.

By growing method

There are soil types - plants are grown in soil mixtures, and soilless - plants are grown using aeroponic and hydroponic methods.

By type of supporting structures

Greenhouses are divided into frame and frameless. Frame greenhouses are most widespread.

According to fencing material

, are divided into plastic - various polymer films, plastics and glazed - profile and sheet glass.

Video - How to make a greenhouse

Common types of greenhouses

The most convenient and often chosen types of greenhouses by gardeners are arched, lean-to and gable.

Arched greenhouses

The best in terms of wind resistance, reliability and ease of use is the arched greenhouse. Thanks to the arcuate surface, plants receive more light and the sun's rays are scattered across the surface.

If the foundation is made well and the frame is strengthened, then in winter you are not afraid of snow, it does not accumulate on the arched roof.

Installation

The period of its use and the quality of the harvest depend on the correct installation of the greenhouse. It must create optimal conditions for plant growth and fruit ripening. It should be well lit and protected from the wind.

Choosing a place to build a greenhouse

To install the greenhouse you will need to choose a location. You can focus on the cardinal directions: the sides are turned to the north and south, and the facades are turned to the east and west, or vice versa. The first option is more acceptable; all seedlings will be exposed to full daylight. The peak of photosynthesis will occur before lunch, and the plants will receive the maximum amount of sunlight. If the specifics of growing seedlings do not require this or placing them on plots in this way is not possible, you can choose the second option.

In a situation where the greenhouse will be installed in early spring, it is better to choose a place where the snow melts faster. The shadow of a house or tree should not fall on it; it must also be taken into account that snowdrifts from the roof do not fall onto the building. If the dacha plot is located in a shady area, on a slope or in a depression, or the soil on it is infertile, the instructions for installing a greenhouse must be strictly followed. When the site meets the required conditions, detailed planning of the greenhouse can begin.

Preparatory actions

You will need to clear the area for installation - remove debris, level the surface, there should be no slopes or holes. Places where moisture collects are not suitable, as this disrupts the air exchange in the roots of the seedlings. It is desirable that the soil for seedlings be of the same composition. In places where power structures are installed, it is necessary to compact the soil; it is allowed to create a foundation with concrete or blocks.

If it is planned to install heating for year-round operation of the greenhouse, it should be done before installing the structure. The wooden parts used for installation are treated with an antiseptic to extend service life and reduce the likelihood of rotting.

DIY installation of a greenhouse made of reinforced film

Lean greenhouses

Usually such a greenhouse is built adjacent to one of the walls of a country house, for example, to the southern part of a country house. Such a greenhouse requires heating, and if the country house is heated, you will spend less effort on heating.

This type of greenhouse saves space and is very budget-friendly. One minus is that in winter it is necessary to clear the snow from the roof; it does not roll off on its own.

Selecting a base

The frame is the basis of a country house; the type of fastening of the covering film and the resistance of the structure to gusts of wind and precipitation will depend on it. It must be reliable and strong.

You can build the base of a greenhouse from the following materials:

- wood - characterized by low price and ease of installation. However, it absorbs moisture, can rot, requires constant care, and does not last long;

- metal - it makes strong and durable greenhouses. Construction is expensive. Additionally, to cover with film, it is necessary to perform welding or buy special fasteners. Installation takes a long time, and the base itself is susceptible to corrosion;

- aluminum - models for covering plants made from it are expensive. Such a greenhouse is light in weight, durable, resistant and rusts in conditions of high humidity;

- plastic is not the most reliable material for construction. At the same time, it is inexpensive, light in weight and installation.

In addition to the greenhouse frame, it is necessary to select a covering sheet. Summer residents share positive reviews about reinforced film. It can withstand wind gusts of up to 34 km/h, has light transmittance sufficient for plants at 77%, is durable, and stable over a wide temperature range: from -50 to +60 °C. Due to the reinforcing layer, the service life is extended. The structure is covered with canvases with various additives, glass, agrofibre, and cellular polycarbonate.

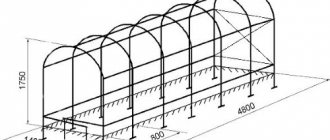

Frame design for a greenhouse made of reinforced film

Winter greenhouse-thermos

A variant of a winter greenhouse sunk 2 m into the ground. Such greenhouses are very expensive. A deep pit is made under the greenhouse with reinforced walls.

The walls are insulated with special heat-insulating panels, and attention is paid to the strength of the roof materials to prevent destruction from large amounts of snow. Such a greenhouse will require additional lighting and the installation of a heating stove.

Choosing material for the frame

The frame is of key importance in the structure of the greenhouse, as it ensures its resistance to strong gusts of wind and temperature changes. That is why the frame, first of all, must be reliable .

- Wooden frames . They are most popular because they are inexpensive and easy to install. The disadvantages include a short service life and the need for regular maintenance.

- Steel frames . They guarantee the strength and durability of the structure (for decades). As for the disadvantages, such a greenhouse will cost much more. Moreover, the metal frame under the film is assembled using special corner fasteners or welding, which complicates the task and increases the amount of upcoming expenses.

- Aluminum frames . They are more expensive than the above models, but are distinguished by high strength, low weight and resistance to corrosion.

- Plastic frames . Easy to assemble, lightweight, inexpensive. But in terms of durability, they leave much to be desired.

Summer greenhouses

Such greenhouses are easy to manufacture, the cheapest and can be built quite quickly. A summer greenhouse is usually made of thick polyethylene film stretched over a frame made of wire, wood or PVC pipes.

With careful use, such a greenhouse will last for several seasons.

A summer greenhouse can be made more durable:

- using reinforced film for coating; - using such methods of attaching the film to the frame so that you can easily remove the film for the winter or replace the damaged area; — use of a collapsible frame for dismantling for the winter.

Building a summer greenhouse, even for novice summer residents, will not be difficult. Using modern PVC pipes for the frame, you can build a film greenhouse in 2-3 days.

Operating rules

The service life of a film cover will depend not only on the technical parameters of the material itself, but also on its operating conditions. During use, it is recommended to regularly care for the film, clean it from dirt and dust, and wipe with a damp sponge if necessary.

When using reinforced material in a greenhouse, it is allowed not to be removed for the winter, since it has a relatively high resistance to surface loads.

In other cases, it is better to take care of removing the coating to avoid damage:

- After all vegetation has been removed, the film cover is washed directly on the frame.

- After the film has completely dried, it is carefully removed: starting with the material located at the ends.

- The ends of the film are thrown onto the roof from the ends and left in this position for some time. Such measures will allow for ventilation of the room and ensure drying of condensation on the inside of the panel.

- After airing, the film is wrapped in a roll, tied with elastic material or twine, and placed for storage in a dry, ventilated place, protected from sunlight until the next season.

Did you know? According to scientists, recycling 1 ton of polyethylene products makes it possible to save more than 1.5 tons of coal.

Every summer resident with basic skills and knowledge in the field of construction can install a functional, practical and reliable greenhouse with his own hands. The main thing is to decide on the type of structure, its main purpose and, taking this into account, select a durable, wear-resistant covering material.

How to build a film greenhouse from PVC pipes with your own hands

Using an example, we will consider the construction of a greenhouse with a frame made of PVC pipes, which will be covered with plastic film.

Application of PVC pipes

- an advantageous solution, they are not afraid of moisture, unlike wooden materials, and do not corrode like metal profiles. To begin with, we advise you to draw up a plan for the greenhouse, calculate the quantity and cost of the material.

Once you have decided on the location of the greenhouse, you will need the following materials:

- timber and boards must first be soaked with an antiseptic 2-3 times, this will prevent rotting; — PVC (polyvinyl chloride) pipes and fastening elements; - thick polyethylene film; — fittings, rods 1 m long and 14 mm in diameter; - screws and nails; — clips for fastening the polyethylene covering; — hinges, locks, handles for doors and windows.

Step-by-step description of the construction of an arched greenhouse

1. Before starting construction, it is necessary to level the area for the greenhouse.

Along the perimeter, knock down a box of 30x200 mm wooden boards, which will be reinforced at the corners with reinforcement.

2. Drive reinforcement rods, 1 meter long, along the perimeter of the foundation, at a distance of 50-80 cm from each other. The closer they are located, the more stable the structure will be.

Drive the rods into the ground to a depth of at least 40 cm (to be safe, it is enough for 50-60 cm to peek out of the ground). They should also be located opposite each other on both sides.

3. Place PVC pipes onto the reinforcement bars (usually pipes with a diameter of 25 mm are used, and the length is chosen in accordance with the size of the greenhouse). The greenhouse calculation can be done using the building materials calculator https://www.zhitov.ru/glasshouse2/.

4. Secure all pipes to a wooden frame.

5. In the corners, for reliability and stability, strengthen the frame with additional timber.

6. After installing all the arcs, horizontal pipes are secured along the length of the structure in several places (3-5 supports) using fastening elements.

7. The frame is ready, it’s time to cover it with plastic film, which is secured with special clips. It is better to perform this work at a temperature of 16-18 degrees to avoid sagging of the material. The film can be buried near the ground with earth or pressed down with bricks or boards.

Choose reinforced film if you want it to last longer.

8. In those places where the doorway is planned, fold the film into the inside of the greenhouse.

9. Measure the dimensions of the doorway and knock down the timber to size, then secure the film. Using hinges, attach the door to the greenhouse frame. Make vents for ventilation in the same way.

Now the greenhouse is completely ready, all that remains is to arrange the beds inside, fill the shelves with fertile soil and plant seedlings of your favorite vegetables. This summer greenhouse made of PVC pipes does not require heating.

Advantages and types of film

There are several reasons why film is used to cover a greenhouse. Let's highlight the most significant :

- the material is very light , accordingly, the process of installation and installation of the structure is greatly simplified;

- such a greenhouse allows air and sunlight , providing optimal conditions for growing plants;

- the film is light in weight , but is highly wear-resistant and reliable.

Among the minuses , we can name only one, but a very significant one - the film is afraid of cuts .

As for the assortment, the following subtypes of material can be distinguished:

- Hydrophilic stabilized film: eliminates the formation of condensation on the walls of the structure, which, by the way, can harm plants. The moisture is distributed evenly and trickles down the walls, but does not drip.

- Ethylene vinyl acetate copolymer. It is characterized by high strength, hydrophilicity, and transparency (up to 92%). Resistant to strong gusts of wind and temperature changes.

- Light stabilized fabric. It contains special light-stabilizing components, so it easily prevents the destructive power of UV rays.

- Film with additives. Significantly increases the strength of the structure, is characterized by an antistatic effect, can be hydrophilic, and repel parasites.

- Reinforced film. Very durable: the thickness of its threads is up to 0.3 millimeters, due to this it can withstand heavy loads. But it is characterized by low light transmittance.

- Material "Svetlitsa". It has a yellowish tint and is optimally suited for use in different climatic zones. The strength indicator is 3 times higher than that of similar products in this product range.

- Heat-saving film. Reliably protects both the structure frame and the plants inside from sudden temperature changes.

Covering nonwoven materials

should be placed in a separate category . They are increasingly used for arranging greenhouses and greenhouses. There is a wide range of products on the market; you can choose, for example, spunbond , agropan , agrotex and others.

Distinctive advantages of nonwoven materials:

- they transmit UV rays and moisture well, but are characterized by the presence of a stabilizer, which completely eliminates the harmful effects of sunlight on grown plants;

- non-woven materials guarantee the maintenance of an optimal microclimate because they do not absorb excess moisture. The soil also does not dry out;

- the greenhouse itself heats up quickly and cools down slowly;

- Caring for such a surface is as simple as possible.

Gardeners often wonder: is it possible to use ordinary cling film as a covering material for a greenhouse? The answer will be clear: no . The fact is that these products are made from high-density polyethylene. Due to this, it does not have high strength.