Greenhouse growing of vegetables and fruits on the site has undeniable advantages over growing in open ground.

The advantages of a metal corner are its size, ease of installation, strength.

You can start planting seedlings earlier than it gets warmer outside, and extend the growing time of plants until the start of the cold period, which increases productivity. A greenhouse from a corner, assembled with your own hands, is undoubtedly a double win, since it is assembled to the individual needs of the site while saving money.

Since there is diversity in the choice of materials, there is no point in describing them all in one article, since each material has its own qualitative differences, including design capabilities.

In this article we will talk about the design of a metal corner. Metal corner as a material has many remarkable aspects, such as:

- strength (the corner frame can withstand up to 240 kg of snow per square meter);

- size (corner greenhouses can be large in size and serve for industrial purposes);

- ease of installation (the structure is easy to install and dismantle).

In this case, it is possible to choose not just a metal corner, but a perforated one, with holes pre-drilled along its entire length. This corner is more versatile, it simplifies the assembly work.

Homemade greenhouses

The frame of the greenhouse can be rounded or rectangular, gable.

A hot summer awaits us ahead, which we already miss. And we must carry it out with maximum efficiency and benefit for ourselves and our children. In order to be less at the mercy of nature’s tricks and to grow beautiful flowers in our garden plot or to get a wonderful harvest of vegetables, we simply cannot do without a greenhouse.

I think that many of you can make a homemade greenhouse with the help of a chisel, a hammer and some mother (just kidding). Particularly golden hands are not needed here.

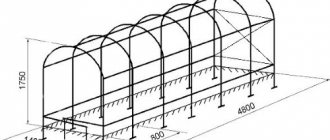

A greenhouse with dimensions of 6.0 by 2.5 m, made in the form of a metal glazed (or film) frame and built on a plinth made of concrete blocks - this is what we need to get a good harvest for the winter.

Conclusion

It is worth approaching construction with full responsibility. Otherwise, instead of a good-quality greenhouse, you will get a shaky and unreliable structure. Of course, metal is considered to be the best material. But you can very successfully combine it with wood or plastic.

Wood has a low price, but without treatment with an antiseptic it will quickly become unusable. In the same way, you shouldn’t skimp on coverage; by purchasing film, you risk, at a minimum, rapid depressurization of the room. Spend a little more on quality material, especially if you live in an area with an unstable or cold climate.

If you want more visual information, watch the video in this article!

The base is an important part of the greenhouse

The frame of the greenhouse is made of metal corners, resting on a strip foundation.

The base of the plinth will be a strip concrete foundation of shallow depth MZFL (since the greenhouse is light). a columnar foundation would be quite suitable , but as usual.

It should be cast directly into the trench (with formwork installed above it), correctly laid in it and tied with reinforcement wire.

The ratio of cement and sand in the solution is 3 to 1 or 4 to 1 by volume. The formwork above the ground does not have to be made high - 20-30 cm is quite enough, and the rest of the base can be made from a block (but again ask yourself the question - do you need a high base?).

Pouring the greenhouse foundation into formwork and trench (directly into the ground)

After the mortar has completely hardened, we lay out the first row of blocks (piping) along the perimeter of the foundation. Starting the next row, in one of any walls of the greenhouse, leave an opening for the door . During laying, it is necessary to constantly check the correctness and verticality of the corners .

To securely fasten the corners of the trim into the base, we embed pins or plates. We level the surface of the base with a layer of mortar, creating a slope to the outside to drain the water.

Some people place greenhouses directly on the ground, without any foundation - this may be relevant for lightweight arc structures covered with film. But personally, I am a supporter of permanent structures, and not “cardboard houses” ready to collapse at the first strong gusts of wind. In addition, the option under consideration can be adapted for winter. To make the greenhouse winter-proof, you need to install thicker double-glazed windows/polycarbonate, and of course add heating, you can even use a biogas plant. The soil must warm up in winter, because our winters are harsh.

Types of profiles

Strictly speaking, a profile greenhouse is a collective concept. It denotes structures that are noticeably different from each other and are built from many types of metal (and not only) profiles. Some of the profiles were originally manufactured for other purposes, while others were created specifically for the construction of greenhouses. The most popular of them are shown in the table below.

Table. Types of profiles suitable for building greenhouses.

U-shaped or U-shaped profile

| Title, photo | Description |

| Many subtypes of U-shaped profiles, differing in width, wall height and metal thickness. They are used for the construction of various structures, including greenhouses. To combat corrosion, depending on the material, it is galvanized (for steel) or anodized (for aluminum). | |

| Metal profile of V-shaped section with “shelves” for fastening in the lower part and on the edges. A cheap and easy-to-use product, but inferior in strength to some U-profile options. Created specifically for the construction of greenhouses. Reinforced options may be called W-profiles. | |

| Galvanized steel pipe of rectangular or square section. High levels of strength and reliability. To combat corrosion, it is galvanized or powder coated. | |

| CD profile for drywall | Load-bearing ceiling profile (PP) for plasterboard. It has a U-shaped section, bends at the ends. Equipped with corrugations that increase the strength of the product. |

| UD profile for drywall | Guide profile for drywall. It has a U-shaped cross-section and is used to form a frame plane from a CD profile and attach the latter to a wall, floor or ceiling. |

| Profiles made of polyvinyl chloride of U-shaped, square and other sections. It differs from metal analogues in greater flexibility and low cost with less resistance to loads. |

There are several ways to fasten profile elements to each other.

- Bolts and nuts with washers - well suited for profiled pipe, V-shaped and U-shaped structures. They provide ease of subsequent dismantling and reassembly of the greenhouse, but at the same time require preliminary drilling of holes in the profile and careful monitoring of the reliability of the connections.

- Self-tapping screws - used in working with all types of metal profiles, especially CD and UD. For a greenhouse, it is justified to use not “bugs”, but self-tapping screws with a press washer - a thin head will not interfere with the installation of the sheathing. Some of the screws come with drill bits on the ends to facilitate entry into the metal.

- Welding is a reliable and durable permanent fastening. Use only if subsequent dismantling of the greenhouse is not planned. Welding seams require additional protection against corrosion.

- Connectors - a variety of designs used to connect PVC profiles to each other.

Advice! When choosing a profile for a greenhouse, pay attention to the quality of the anti-corrosion coating, especially on the corners and bends - there it should not have abrasions, stains, foreign inclusions or other defects. Otherwise, the service life of the frame may be significantly reduced due to the gradual destruction of elements affected by corrosion.

Greenhouse metal frame

the greenhouse frame from metal bars and corners. It consists of wall frames, which must be reinforced with intermediate struts and racks. The gable roof is based on rafters and a ridge corner. The rigidity of a greenhouse on a metal frame is provided by ceiling braces and wind braces.

Greenhouse frame drawings:

An example of a greenhouse frame drawing (dimensions can be changed)

A simplified version of the greenhouse frame with a stretched fishing line between the posts

Greenhouse frame drawing with explanations

Note: you don’t have to draw the greenhouse in all its details yourself (it’s still not a house). If there is a photo that at least approximately matches your greenhouse parameters, we will use them. You just need to make your notes regarding the size, desired material and nature of the homemade heating system, if provided. If you want to “go crazy” and draw a frame in all the details, it will be easier for a beginner to use the free Google program sketchup.com (there are good tutorials on the Internet on how to use it).

Drawings and diagrams

Fastening polycarbonate to steel pipes

Installation of sheets

Types of greenhouses with single-pitched, gable and multi-pitched roofs

Drawing of a table from a profile on an elevated foundation

Greenhouse assembled using a metal profile

Drawing of a greenhouse made from a profile pipe

How to make ventilation

The gables are equipped with slightly opening window frames for ventilation of the metal greenhouse. The same role is played by a double-leaf door - with lower and upper leaves that open independently. The frame of each sash is welded from 35 by 35 mm corners. I fix the position of the open window frame with a screw, clamping the rod in the bushing of the locking mechanism.

As an option, here the greenhouse frame is assembled from light galvanized metal profiles

Construction technology

Drawing of the greenhouse

There must be ventilation openings in the form of window and door openings. The roof should be made in the shape of an arch, thereby increasing the volume of air in the structure. The built-in lever system will allow you to open the windows built into such a roof.

The size of the window must be at least ¼ of the entire roof surface. Additional air circulation will be provided by doors located in the end or side walls of the structure.

To pave the paths, choose paving slabs, and enclose the ridges with high borders, which will greatly facilitate the process of caring for the plantings. Under the ceiling space, secure the rods that will be needed to secure some plants.

Glazing or cellular polycarbonate

Glazing of a metal greenhouse is done using rubber seals, window putty or sealant. The internal dimensions of metal frames made from corners should be 5-8 mm larger than the linear dimensions of the glass. Additionally, you can fix the glass in the frames with pieces of corners with a rubber insert using screws screwed to the frame.

However, glass has a drawback - they break. Many began to use a more modern material - cellular polycarbonate, which transmits light no worse than glass. It is also fragile, but if damaged it does not splinter and is easy to repair/replace. In addition, it is cheaper than double-glazed glass.

This greenhouse is “glazed” entirely with cellular polycarbonate

That’s basically all I wanted to tell you about a metal greenhouse, which is not so difficult to make with your own hands. If you liked the article, share it. In the next article we will arrange our greenhouse. After all, in order for it to give us a good harvest, we also need to properly design the beds and passages inside. All the best, and low regards to those who shared the article.

UPD: If you are a widow, this video with step-by-step instructions for installing a greenhouse made of wood may be useful. Who knows, for some this option will be easier and more profitable, although wood, of course, has its well-known disadvantages.

Let's find out everything about sizes

The dimensions of the greenhouse are calculated based on your own wishes and compliance with the standard dimensions of the profile pipe with polycarbonate. This is done to eliminate waste of materials, unnecessary scraps and unnecessary work that can be associated with arranging these scraps in an attempt to save money. The latter is absolutely not worth doing.

To make arches, it is best to take a metal profile 6 meters long. One whip will make an arc 2.2 meters high and 3 meters wide. This width is suitable for placing two beds and a path between them.

The standard dimensions of polycarbonate are 6x2.1 m. When covering the frame, you will not need to cut its sheets.

The height can be increased artificially: using a strip foundation. Another advantage of such a foundation is protection from the penetration of rodents or other pests.

The distance between each arch is set to 1 meter. That is, for every three arches - one sheet of polycarbonate (6x2.1 m). If, for example, you are planning a six-meter-long greenhouse, then you will need 7 profile rods for the main arcs and 3 polycarbonate sheets.

The optimal section of the corrugated pipe for the arches and the lower support frame: 25x25x2 mm. For lintels and vents, a section of 20x20x1.5 mm is suitable. For the door frame – 25x25 mm.

If you need a greenhouse more than 6 m in length, also focus on the standard parameters of polycarbonate to avoid overspending. For example, 8-10-12 m.

If you have a greenhouse that is larger in all dimensions, then for the base of the frame, take a profile pipe with a cross-section from 30x30 to 40x40 mm.

Advice: purchase material in reserve in order to avoid unforeseen situations with its shortage.

Make the entrance to the greenhouse at least 0.7-0.8 m, this will ensure the convenience of bringing in seedlings and tools, and there will be enough space for a regular garden wheelbarrow to enter.

If the greenhouse will be used during the cold season, make a small vestibule. It will protect against drafts when entering and exiting. It is also practical to store gardening tools.

Thickness of polycarbonate for greenhouse

For an arched shape, 4-6 mm is enough, but it is better to take 6 mm polycarbonate, the roof will be stronger and more stable. But 4 mm may not survive the winter, depending on what the weather is like. If you live on your property all year round, you will be able to control the snow load, clearing away the accumulated snow if necessary.

If the greenhouse is sheathed with 4 mm polycarbonate, the distance between the arcs is reduced so as not to lose load. But saving in this way, you still spend more on metal profiles. And it’s not a fact that the reliability of the roof will increase from this.

And with polycarbonate 6-8 mm thick in winter there is much more guarantee that the sheets will not bend under the weight of snow.

Manufacturing of metal products to order

Projects of any complexity

5 year warranty on all products

More than 300 satisfied clients

Reliable metal structure (greenhouse) made from a steel angle

There are a huge number of options for constructing a greenhouse, and one of the most economical and reliable is a greenhouse made from a steel equal-angle angle. At the same time, you can focus on other options: for example, take not an equal-flanged corner, but a different-flanged one, not hot-rolled, but bent, not steel, but aluminum - it all depends only on the availability of materials and the imagination of the builder.

Strengths

If you choose the right steel corner of the right size, then the greenhouse made from it will be durable, strong, but at the same time light and inexpensive. In winter, it can withstand heavy snow loads.

Greenhouses made from metal corners are easy to assemble even by non-professionals and just as easy to dismantle and move (if there is no foundation under them).

To make the angle steel frame last even longer, you need to treat it with an anti-corrosion compound. In this case, it would be preferable not just anti-corrosion impregnation, but paint containing zinc or polymer, which will protect the structure from bad weather.

Instructions

Such a metal structure does not necessarily require a foundation, however, if desired, it can be equipped. The greenhouse can be covered with film, glass or polycarbonate.

To assemble the frame, you must first make a drawing. There are many design options, and one of the most optimal is the shape of a house with a gable roof so that precipitation and snow roll off it.

For such a greenhouse, you need to cut blanks from the corner - 4 equal to the length and 4 equal to the width. Then you need to make lower and upper frames out of them, connecting the corners with ends cut at an angle of 45 degrees and connected at right angles.

Then blanks for the roof are cut out and welded in the form of two triangles and a number of rectangles. To strengthen the roof, which will take on the pressure of snow and wind, it is advisable to weld a jumper from a steel strip somewhere at half the height of the triangle.

Lastly, vertical racks are prepared according to the number of rectangles. Rectangles and triangles are attached to the top frame, and racks to the bottom. Then both “halves” are connected. Welding will be the most reliable fastening for such a greenhouse.

To finish, weld the ridge element onto the tops of the rectangles from the steel corner, reinforce all structural components by welding, strengthening them additionally if necessary. The frame is ready. You additionally need to make a door and, if necessary, a window onto it, and then stretch the covering material. We follow all the news in the field of metal structures and will keep you informed.