When we talk about a nurse’s greenhouse, we obviously mean a specific greenhouse design developed by Novosibirsk. It was she who, after the first reviews of her customers, received the name “Nurse”. After this, this name became a household name, and people began to call it all greenhouses of this type.

The design of the structure turned out to be not only simple, quite suitable for making with your own hands, but also quite durable.

With proper assembly and additional reinforcing elements, it can easily withstand both strong winds and heavy snow cover, which most regions of our country are not deprived of.

Design features of the nurse's greenhouse

The main design solutions of this greenhouse are its arched shape, which promotes the best distribution of loads from wind and snow, and polycarbonate as a covering. Its cellular structure allows you to most effectively create a microclimate inside the greenhouse.

At the same time, the material, with a thickness of 4 mm, is easy to process, attached to the body without preliminary preparation and is relatively durable.

Most greenhouses bearing this promising name have similar technical characteristics, but still differ from each other.

1. The “Nurse” greenhouse has the appearance shown in the photo above. It can have dimensions from 3.0x4.0x2.1 m to 3.0x10.0x2.1 m. Such greenhouses are also available in the following versions:

- welded;

- crab

In welded nurses, the connection of frame elements is carried out through bolted connections of square-section parts that fit into each other. And in crab plates (cruciform and T-shaped plates connected to each other with bolts) - using additional fasteners - crabs. The greenhouse frame pipes are mutually positioned and secured between the crab plates. Crab greenhouses are also available in a width of 2 meters.

The diagram below shows all these types of fastenings on the callouts, but the greenhouse that is depicted on it is already a “Clever Nurse”.

2. And the “Clever Nurse” differs from a regular nurse in that it has a retractable roof and more strict standard sizes, of which there are only two: 3.0x4.0x2.1 m and 3.0x6.0x2.1 m.

And, of course, a more complex design with an abundance of additional elements:

- separate roof frame;

- guides;

- wheels;

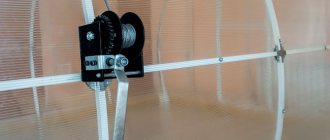

- winch for moving the roof;

- transverse reinforcing element;

- emphasis and platband.

And also, obviously more functionality in comparison with the “Nurse”.

The manufacturer also offers modifications of the “Nurse” greenhouse - “Bogatyrskaya”, “Crab Reinforced”, and also inserts that allow you to increase the greenhouse to almost any length. But at the same time, it is important to remember the need to strengthen the frame by inserting an end section with a door every 4 m.

This insert also allows you to create individual conditions for growing various crops in one greenhouse.

Assembling a nurse's greenhouse with your own hands

The process of assembling a greenhouse, especially Clever, is not so much complicated as it is painstaking. It requires great care, because some mistakes, such as incorrectly cut polycarbonate, cannot be corrected. But, if you strictly follow the instructions and recommendations, then there is not much that is difficult in installing a greenhouse. It must be said that installation of the smallest wet nurse by specialists will cost you from three and a half thousand rubles. And set aside at least 3 times more for assembling a big Clever Girl. But, if you know how to hold a screwdriver and a wrench in your hands, and have a smart and selfless friend as your assistant, you will be able to save this money.

Actually, the video instructions are so detailed and understandable that the assembly section could be closed at this point, but still, we will allow ourselves a few comments.

- When assembling a welded greenhouse, we recommend removing any burrs remaining after drilling. This must be done immediately, on the ground; removing them during the installation process is much less convenient.

- In the crab versions of the greenhouse, pre-assemble them by attaching the coupling bolts, saving both time and an extra pair of hands.

- Cut polycarbonate with a knife. Do not use a jigsaw as it can seriously damage the edges. An incorrectly selected nail file can lead to the formation of microcracks, which will shorten the service life of the material.

- Trimming polycarbonate on end elements, incl. installed as amplifiers inside the greenhouse, do so after it is finally secured to the metal frame, this will allow you to achieve the best fit of the elements and the absence of gaps.

- Check the completeness of the hardware before starting assembly and, if necessary, purchase the missing ones. Unfortunately, their shortage is possible, and finding out about it already in the process of work would be the least correct thing to do.

Not simple, but folding

In short, “Umnitsa” is not an ordinary greenhouse, but “with character and zest.” It deserves special attention if only because it has a sliding roof, which provides special advantages when used.

It is not news for gardeners that greenhouse owners experience no less difficulties in winter than in the summer season. A greenhouse structure in cold snowy times requires supervision and protection. In spring and autumn it protects plants from the cold, but in winter it itself needs help. During the cold season, moisture accumulates on the surface of the coating due to the difference in temperature outside and inside. Due to the fact that the temperature outside is below zero, an ice crust quickly forms, which can damage the entire covering material.

Nurse's greenhouse price

Obviously, the conversation about the cost of greenhouses should start from its price from the manufacturer. Today he declares the price of the little Clever girl from 20,300 rubles.

Novosibirsk dealers add on average about 2 thousand rubles to this price. In Moscow, such a greenhouse costs 5-6 thousand rubles more, which corresponds to the cost of delivery services, etc. It is recommended to calculate the remaining types of greenhouses produced by this plant individually, perhaps due to the abundance of design and configuration options. In trading organizations, the cost of a small nurse made from pipes with a wall thickness of 1.2 mm starts from 6.5 - 7 thousand rubles.

There are a great many greenhouses similar to the nurse produced in our country.

They differ slightly in design, characteristics of the materials used - primarily in the thickness and cross-section of the frame pipes, but have a similar pricing principle. Six-meter polycarbonate greenhouses in Moscow are offered from 8.5 - 10 thousand rubles. They also offer additional accessories. So, a lifting window for ventilation will cost 1.5 – 2 thousand rubles.

Installation and use

Before unpacking the product parts, you need to decide on the installation location and laying the foundation. The greenhouse is quite compact, does not take up much space and fits perfectly into any landscape design. But you need to take into account that neighboring buildings and trees should not block the sides of the greenhouse, and it is advisable to place one of the long sides on the south side.

Foundation

As with any building, to install a greenhouse you will need a ground support. Since the structure consists only of a frame and a light covering, the foundation does not need to be solid, as when constructing heavy buildings. It is necessary primarily for the stability of the frame and the proper operation of the roof mechanism. The foundation can be classic, strip or completely simple - from scrap materials. Usually bricks or timber are used.

A wooden box is the most economical option and will require the use of screws and staples to secure the logs together. The wooden base should be impregnated with antiseptics against rotting.

Installation

Please read the included installation instructions carefully. The installation process is not complicated, but requires careful execution and clear measurements.

According to the instructions, you should have several successive steps:

- installation of ends, fastening of intermediate struts, coating of ends with polycarbonate;

- assembly of the main body of the greenhouse;

- mounting the roof, attaching roller wheels, installing polycarbonate and trimming it;

- covering the greenhouse body with canvas on both sides, attaching the lever and winch;

- installation of platbands and clamps in the grooves, according to the assembly instructions.

The operation of the greenhouse does not contain any restrictions that differ from other types of similar products. Careful handling of the material and the absence of serious mechanical damage will allow you to use the structure for many years.

Reviews about the greenhouse “Nurse”

The best review is the name of the greenhouse itself. Indeed, there could not be a better characterization. The price-quality ratio of these greenhouses is excellent. Even the most inexpensive nurse honestly earns the money spent on her purchase. And the manufacturer’s 5-year warranty on the frame is the best confirmation of the reliability of the product.

But, in this voluminous barrel of honey, sometimes there is still room for one fly in the ointment. And first of all, this is due to the use of thinner frame pipes. The first greenhouses were produced with pipe thicknesses of 1.5 mm and they performed better in Russian weather conditions. Greenhouses with thinner pipes do not allow the slightest deviation from the order and accuracy of assembly, and sometimes require the installation of additional amplifiers.

Obviously, the destroyed greenhouse in the photo required the installation of an additional partition or, at worst, supports or cross ties. With shorter greenhouses or greenhouses equipped with additional reinforcement, this does not happen even with a very serious snow load.

“Umnitsy” doesn’t have such problems either. Their retractable roof is set to the open position for the winter, and it becomes a kind of snow catcher, which has a beneficial effect on the characteristics of the soil inside the greenhouse, and even more so removes the problem of snow load.

We have already mentioned one more drawback, which more often than others causes complaints from buyers of wet nurses: rarely when the amount of fasteners corresponds to the declared one, which most likely refers to a lack of production culture, rather than products, but this does not make it any easier for the consumer.

Well, one more significant, in our opinion, disadvantage of the product is the service life of polycarbonate of 4–5 years. Rare specimens last longer, which is partly due to operating conditions, but to a large extent is due to the poor quality of the plastic.

Advantages of a sliding roof

The main advantages of the open roof of a greenhouse complex include:

- the open top eliminates the formation of drafts and allows for gentle ventilation of the room;

- rainwater easily penetrates the plants, which significantly increases the growth of crops and improves their taste;

- fills the soil with nutrients, this process occurs naturally due to the occurrence of leaves;

- in the summer, thanks to the wind, pollination of plants occurs;

- during the period of snow melting, the soil is moistened, which allows creating a favorable atmosphere inside the complex;

- the design is durable and can withstand even heavy snow loads;

- In winter, the ground is covered with snow, which helps protect the soil from freezing.

For information! The greenhouse complex provides for the additional completion of the Nurse's automatic transom for shifting the roof.

DIY greenhouse

Given the low cost of the simplest nurses, with the possibility of their subsequent radical modernization, the process of building such a greenhouse with your own hands seems somewhat doubtful. But if we are talking about improving consumer characteristics or seriously increasing the service life of a structure, it definitely makes sense.

First of all, we can talk about the frame material. If the greenhouse is regularly and effectively ventilated, then it makes sense to consider wood in this capacity.

- Firstly, wood is more resistant to static loads: it bends, but does not break, and after they are removed, it restores its original configuration better than metal.

- Secondly, it is much easier to work with than metal.

- Thirdly, with appropriate treatment, it can last longer than metal, and if you take larch, then many times longer.

You can also use polypropylene water pipes for the frame of the “Nurse” type greenhouse.

The only thing we would recommend to improve is their connection. The use of standard welding and standard components for such systems will be much more justified. At the same time, it would be rational to introduce either steel reinforcement of the appropriate diameter or its fiberglass analogue into the arched elements of the frame, which is even better. The durability of this design is beyond doubt. Also, pipes can be secured using the same crabs with various options for their use.

And finally, to stimulate your creative searches - a selection of options for replacing polycarbonate.

This coating will not last very long with constant exposure to ultraviolet radiation, but certainly no less than polycarbonate.

We recommend other articles on the topic

Construction of a drip irrigation system at the dacha

How to fence the beds? - types of borders for garden beds

Principles of hydroponics, making a hydroponic installation with your own hands

Selection and operation

The classic nurse-clever greenhouse or options with a removable top part are convenient and practical, but any type of structure must be installed correctly, as well as provide comfortable conditions for the plants.

In this case, the soil, the location of the product, the irrigation system, and the illumination of the area play an important role. All factors should be taken into account when installing a greenhouse with a sliding top or a classic type structure. This approach will ensure a high-quality, rich harvest and eliminate many problems during the growth and development of plants. When choosing a nurse-clever greenhouse with a sliding roof, you should consider the following features:

- Dimensions and shape of the structure. There are small compact models and larger ones. Each option has certain characteristics, and the choice depends on the area of the site, the required volume of plantings and other factors;

- . ;

- The quality of the frame elements, polycarbonate and all parts of the mechanism is an important factor, because the ease of use and durability of the greenhouse depend on it;

- To assemble it yourself, you should take into account the complexity of the product, the number of parts and the type of mechanism for opening the top part.

A wide variety of greenhouse options makes it easy to find the optimal type. The cost of a nurse with a sliding roof depends on the quality of the frame elements and the density of the polycarbonate, the size and complexity, and the manufacturer. That is why it is worth first determining the necessary parameters that a greenhouse with a removable roof should have, and then purchasing the product.

The installation of a sliding structure deserves special attention. It is first necessary to determine the location on the site where the nurse-clever greenhouse will be installed. Free and well-lit space, the absence of parts that interfere with the comfortable operation of the greenhouse, as well as the close location of the irrigation system are the main important points. A high-quality greenhouse with a sliding roof is installed according to the instructions and taking into account all the features of the frame elements. The operation of these structures involves regular cleaning, repair and adjustment of mechanisms and polycarbonate surfaces. Any greenhouse with an opening top requires careful and correct installation. Before planting and after harvesting, the walls of the greenhouse with a sliding or removable polycarbonate roof should be thoroughly treated with disinfectant compounds. The soil also needs preparation and cultivation. Thanks to a simple set of measures, a clever nurse, that is, a greenhouse with an opening top, will ensure a rich harvest.

Comments

- Tatiana:

03/16/2017 at 11:56If you have your own plot, then such a nurse greenhouse is irreplaceable. Their choice is really great and sometimes you can even get confused. Ten years ago we could only dream of a normal greenhouse, but now we have one in our garden and it works great. We were frightened by the photo where the tablet was covered with snow, we need to go measure the thickness so that such an incident does not happen, it is better to immediately strengthen it

- Gennady:

05/26/2017 at 10:22

The Nurse's greenhouse did not include half of the crab (+). A small thing, but very unpleasant.

- Smirnov Sergey:

04/16/2018 at 09:11

The plant does not meet contractual delivery dates. If you paid without discounts to receive it in the spring, you may receive a greenhouse at the end of summer! (If you get it at all)

- Anatoly:

05/07/2018 at 05:17

I would not recommend purchasing a greenhouse with an open roof - it is very flimsy and will fall apart in the first gust of wind like mine!

- Anatoly:

05/07/2018 at 05:22

mine fell apart at the first strong wind due to the flimsy roof structure.

- Hope:

06/18/2018 at 22:16

06/18/2018 The contract for the supply of two greenhouses No. 198 has not been fulfilled to date, although the deadline was 04/18 - 05/07/2018. The plant does not provide any information about the delivery time, getting off with a promise to deliver in the “shortest possible time”, and the advance payment was 100% produced. There are similar complaints online from other people who have been scammed. This season is lost and it is unclear what will happen next.

- Love:

03.12.2018 at 03:32

Something strange is going on with the plant. Greenhouses are being made cheaper and cheaper as part of a promotion, but for some reason when you find yourself in an unpleasant situation and ask for a refund, they promise to return it within 10 days, but in fact they don’t even answer the phone. So be careful, this is most likely a new scam.

- Gorina Vera:

03/19/2019 at 16:03

I ordered the greenhouse from Metalservice, I paid, they said that within 4 days they will inform me that they have received the money and will prepare the assembly for shipment, 8 days have passed, no answer and they are not answering calls

Manufacturers

Greenhouse "Kremlin"

The history of the production of “Nurse-Umnitsa” is connected with the Metal-Service enterprise, located in Novosibirsk. For many years, the company has been producing traditional greenhouses and metal structures, but in 2008 it began developing a new, improved design, taking into account numerous requests from Siberian gardeners. For two years, the company’s engineers, together with specialists from the Institute of Selection and Plant Growing of the Siberian Branch of the Russian Academy of Sciences, tested the created structure, and at the end of 2010 the model was launched into mass production.

Summer residents quickly appreciated the advantages of the new model and the company began to receive numerous positive reviews. But the company’s employees did not stop there, and in 2015 they launched the first batch of greenhouses with a fully retractable roof, while the first models had only a partially retractable roof. The new product quickly gained popularity and became one of the most popular greenhouse models on the domestic market.