There are so many different types of greenhouses available today that making a choice can sometimes be difficult. Even after taking into account all the needs and familiarizing yourself with all the varieties, the circle of choice is not very narrowed. It’s another matter when a completely specific model with specific characteristics is heard. All you have to do is study it, read reviews and understand how suitable it is for you. This happened with the new greenhouse development of Novosibirsk, called “Nurse-Umnitsa”. People immediately began to call the model simply “Clever Girl,” and it very quickly earned fame as one of the best greenhouses.

Greenhouse “Nurse-Umnitsa” with a sliding roof

History of the development of "Nurse-Clever"

Located in Novosibirsk, they produce several types of greenhouses: “Crabovaya”, “Bogatyrskaya”, “Room Nurse” and a large industrial one.

As the manufacturers explain, since 2008 they have been trying to create another version of the greenhouse, suitable for Siberian summer residents. The new model had to withstand harsh winters and last a long time. In 2010, after the successful implementation of the idea, the tested greenhouse was put into production. Thanks to rave reviews, she received her affectionate name “Nurse-Clever.” The design has received awards at various exhibitions and has been successfully tested by scientists at the Siberian Institute of Plant Growing and Breeding.

Characteristics of the Nursery greenhouse with opening top

But the developers didn't stop there. They managed to fulfill another request of the farmers - the maximum possible ventilation. In 2015, the “Nurse” with an opening top was presented to the public. As Revaz Zarkua, director, said: “The distinctive feature of this greenhouse from all those released previously is the fully opening roof.”

Algorithm for choosing the optimal greenhouse option

The selection procedure involves only a few simple steps, which, however, require serious preparatory work.

Selecting a location

Decide on the installation location. It should be sunny and windless, and not located close to trees and buildings (unless it is a wall-mounted greenhouse).

Size selection

Decide on the size and shape. They will depend on the space that you are able to allocate for a greenhouse on your site, as well as on the crops that you intend to grow in it.

Choice of coverage

Choose the best covering option and frame material for you. After that, all that remains is purchase, delivery, installation and operation.

It would seem that everything is simple, but already at the second stage certain difficulties may arise, and at the third it’s time to get confused by the abundance of market offers. That’s why it’s better to consider one product from a segment to see if it’s right for you, rather than choosing the right one from thousands of options.

Characteristics of the “Nurse”

This type of greenhouse, like other brands from the same plant, is characterized by increased frame strength. Almost all greenhouses on various sites are called durable. But if you evaluate it on a 10-point scale, the “Nurse” is ten strong, otherwise the model would not have withstood the Siberian snows.

The “Clever Nurse” is made from a steel pipe with a square section of 20 by 20 mm. with polymer coating. The arcs of the arched structure are located every meter, the thickness of the walls is 1.5 mm, the width of the greenhouse is 3 m. The length is 4-10 m, and it can be increased in stages.

Greenhouse Nurse-clever

Some versions of “Nurses” are available with a wall thickness of 1.2 mm. Therefore, in topics discussing the greenhouse, there are doubts about its strength. However, the owners of the new product immediately respond that such a frame seems thin, but in fact it is quite reliable.

Attention! If the purchased greenhouse has a flaw, for example, it gets crushed by snow when the roof is closed, the manufacturer promises to completely replace it.

Features of the greenhouse:

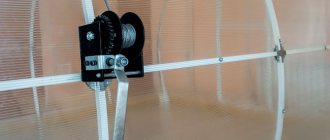

- fully opening roof. It opens with the help of a winch, which even seven-year-old children can easily crank;

- two doors and two windows at the ends;

- The practical polycarbonate cover provides optimal illumination and UV protection.

- Pipe welding seams are reliable. The polymer coating additionally protects against corrosion.

Greenhouse Nurse-clever with opening roof

Comments

- Tatiana:

03/16/2017 at 11:56If you have your own plot, then such a nurse greenhouse is irreplaceable. Their choice is really great and sometimes you can even get confused. Ten years ago we could only dream of a normal greenhouse, but now we have one in our garden and it works great. We were frightened by the photo where the tablet was covered with snow, we need to go measure the thickness so that such an incident does not happen, it is better to immediately strengthen it

- Gennady:

05/26/2017 at 10:22

The Nurse's greenhouse did not include half of the crab (+). A small thing, but very unpleasant.

- Smirnov Sergey:

04/16/2018 at 09:11

The plant does not meet contractual delivery dates. If you paid without discounts to receive it in the spring, you may receive a greenhouse at the end of summer! (If you get it at all)

- Anatoly:

05/07/2018 at 05:17

I would not recommend purchasing a greenhouse with an open roof - it is very flimsy and will fall apart in the first gust of wind like mine!

- Anatoly:

05/07/2018 at 05:22

mine fell apart at the first strong wind due to the flimsy roof structure.

- Hope:

06/18/2018 at 22:16

06/18/2018 The contract for the supply of two greenhouses No. 198 has not been fulfilled to date, although the deadline was 04/18 - 05/07/2018. The plant does not provide any information about the delivery time, getting off with a promise to deliver in the “shortest possible time”, and the advance payment was 100% produced. There are similar complaints online from other people who have been scammed. This season is lost and it is unclear what will happen next.

- Love:

03.12.2018 at 03:32

Something strange is going on with the plant. Greenhouses are being made cheaper and cheaper as part of a promotion, but for some reason when you find yourself in an unpleasant situation and ask for a refund, they promise to return it within 10 days, but in fact they don’t even answer the phone. So be careful, this is most likely a new scam.

- Gorina Vera:

03/19/2019 at 16:03

I ordered the greenhouse from Metalservice, I paid, they said that within 4 days they will inform me that they have received the money and will prepare the assembly for shipment, 8 days have passed, no answer and they are not answering calls

What does an open roof do?

It seems that two doors and two windows are enough for ventilation. In addition, another additional transom with automatic opening has been developed, which can be used to complete the greenhouse. Why then an opening top? Let's consider all the advantages of the new product:

- In winter, the greenhouse is filled with snow, which allows the soil to be preserved under a snow coat and prevents the soil from freezing.

- The greenhouse will not break, because no snow load.

- In the spring, when the snow melts, the soil is moistened naturally, which creates a favorable microclimate before planting seedlings.

- In summer, pollination becomes possible naturally, with the help of the wind.

- In the fall, after harvesting, the natural occurrence of leaves occurs through the open roof, which ensures that the soil is filled with a nutrient medium.

- Abundant rainwater promotes the cultivation of vegetables as close to natural conditions as possible. This means that the taste of the fruit improves.

- Windows and doors do not allow the greenhouse to be fully ventilated and create a draft, which is contraindicated for many plants. The open top promotes gentle ventilation.

Open roof of the greenhouse

Greenhouse Umnitsa: main advantages

The choice of greenhouses is made depending on the climate and the necessary requirements of each individual consumer. Thanks to the emergence and development of new technologies, everyone can afford an early harvest, and throughout the year the opportunity to eat their own vegetables, without chemicals, that are beneficial to health. Gardeners with some experience know that the most difficult task is getting a good harvest in winter.

Large amounts of snow and high humidity create a lot of problems.

To protect greenhouse structures, gardeners have to build additional devices. Here the Umnitsa greenhouse with a sliding roof will come to the rescue. Its unique design, made from high quality materials, is easy to install, and has a huge advantage over its competitors.

The main advantages of Umnitsa are:

- The material of its manufacture;

- Simple and accessible installation instructions;

- Easily opening roof;

- Possibility of planting in moist soil;

- Constant ventilation.

The Umnitsa greenhouse will independently create the necessary microclimate for plants. It can be used for almost any plant. In the summer you can keep it with the roof closed, the presence of windows and doors will allow you to ventilate the space, and in the fall you can leave it open, autumn leaves will be an excellent natural fertilizer, and in winter the snow will be a wonderful watering of the soil, and the structure itself will create a warm climate, due to which the plants will not freeze.

Installation of a factory-made greenhouse

Judging by the reviews from the owners, installing a greenhouse is not difficult, you just need to do it in the right sequence. First, decide whether to place the greenhouse on a foundation or on a rectangular support.

Greenhouse frame diagram Tip. It is recommended to install the bolts from the bottom of the metal. Because the lower part will be installed on a foundation or support.

You can use whatever is at hand as a support. For example, a beam fastened with corners and self-tapping screws. Or bricks laid around the perimeter of the greenhouse. Then you can start assembling:

- Assembly of the greenhouse begins from the ends. The end consists of the door block, as well as the upper, left and right end arches. They are fastened to each other using two end struts. The arcs and spacers are connected to each other with M6 bolts.

- After assembling the end, you need to attach polycarbonate to it. It is better to use roofing screws for this. Then cut the polycarbonate along the contour of the greenhouse.

- When the ends are ready, you can proceed to the roof. It consists of end arcs, intermediate arcs and intermediate struts. All elements must be connected according to the manufacturer's instructions. When assembling, it is better to use bolts, T-shaped and X-shaped fasteners.

- A whole sheet of polycarbonate is placed on the finished roof base, because the kit includes 6m sheets. at 2.100. The sheet must be laid flat on the roof frame. It is better to fasten the covering with roofing screws. Then you need to fix 8 roller wheels on the roof.

- Next, the greenhouse itself is assembled. Transverse intermediate struts are mounted on the ends of the greenhouse. When the greenhouse frame is assembled, it is attached to the base.

- Trellis are installed across the main beams under the roof. They perform two functions. They work as a reinforcing element and as straps for tying tall plants. Polycarbonate is installed on the greenhouse itself on one side and the other. Since the greenhouse opens, a winch needs to be attached to one side.

- The greenhouse kit includes stops, trims and clamps that ensure reliable opening and closing of the top. They must be installed in the designated places.

Attention! The middle pipe should be mounted exactly in the middle between the left and right edges. A small error can lead to malfunctions of the mechanism.

Greenhouse Nurse-clever on the site

How to build

Beginning gardeners often wonder whether it is possible to build a greenhouse with an opening roof with your own hands. Luckily, if you have the right tools and certain skills, it's not that difficult.

To begin with, as with the construction of a conventional greenhouse, you need to choose a suitable location on the site. It should be flat, sunny and warm, protected from the north wind. The presence of large trees nearby is undesirable: they not only block the light, but also draw useful substances from the soil, depleting it. The greenhouse should be located on a slight elevation or at least not in a lowland - stagnant water is harmful to plants.

If necessary, make a foundation. For a lightweight greenhouse with a retractable roof, a wooden one is best.

It is recommended to use oak or larch - these types of wood are resistant to rotting. The beams are pre-treated with antiseptics or iron sulfate. Then they are connected with corners in the form of a rectangle corresponding to the perimeter of the greenhouse, and laid in a pre-dug trench. If it is necessary to level them horizontally, add sand or lay wooden planks in the right places. For greater stability, you can drill a through hole in each beam and drive reinforcement into it.

Next, the greenhouse body is assembled. This procedure may differ depending on the type of structure selected.

For example, let's look at how to make a polycarbonate greenhouse with a sliding roof using the “butterfly” principle.

First of all, two blind ends are made. They can be regular arches or have internal crosshairs for strength. Then they are connected by a central beam, on which the “wings” will be attached, and lower crossbars, at the level of which the threshold will be located. The structure is installed on the foundation.

Then the rounded base of the “wings” is welded: essentially a rectangle with internal cross members for strength. To bend the metal in the desired way, you can use a pipe bender

Please note that the curves of the “wings” must exactly coincide with the arcs of the ends. They are attached to the top beam using hinges

Finally, supports are installed on the sides of the greenhouse, with the help of which the segments can be held open.

You can also make a convertible-type greenhouse with a rollaway top with your own hands.

The body is assembled and sheathed with polycarbonate, as for a conventional arched structure, but the upper part is left open. Plastic overlays are attached to the rafters near the ends, and narrow polycarbonate strips are attached on top to create grooves. A polycarbonate sheet is placed into these grooves, which will act as a roof.

A greenhouse with an opening top, built with your own hands, will serve no worse than a factory one - the main thing is to be careful about all stages of construction.

Reviews of the greenhouse “Clever Nurse”

There are relatively few reviews on the use of the “Clever Nurse” greenhouse on the World Wide Web. Maybe because the pop-up greenhouse became available to consumers only recently, in 2015, and its benefits have not yet been appreciated. Or perhaps this is explained by the fact that there is nothing to scold her for, but as the saying goes, “a good word lies, a bad word runs.” However, the owners who shared their opinions note that it is easy to open and close the roof, and the winch works without failure. And the fact that plants silently but eloquently thank for the warm summer rains and the fresh breeze is recognized by many commentators.

The roof of the greenhouse can be opened for the winter.

There are so many different types of greenhouses available today that making a choice can sometimes be difficult. Even after taking into account all the needs and familiarizing yourself with all the varieties, the circle of choice is not very narrowed. It’s another matter when a completely specific model with specific characteristics is heard. All you have to do is study it, read reviews and understand how suitable it is for you. This happened with the new greenhouse development of Novosibirsk, called “Nurse-Umnitsa”. People immediately began to call the model simply “Clever Girl,” and it very quickly earned fame as one of the best greenhouses.

Greenhouse “Nurse-Umnitsa” with a sliding roof

Description of design

The nurse greenhouse and its modification, the clever one, are manufactured by Novosibirsk, which specializes in the production of greenhouses made of metal and polycarbonate. This greenhouse was developed in 2008 and today is one of the most popular greenhouse options among gardeners. It allows you to significantly improve productivity, while you have the opportunity to choose greenhouses of different sizes.

Advantages of the greenhouse:

- Excellent durability.

- Affordable price.

- Easy to assemble.

- Reliability and durability.

- Versatility of use.

- Wide possibilities for modernization.

- The presence of a lifting, opening roof.

One of the features of the clever nurse's greenhouse with an opening top is its excellent strength of the frame, which is made of steel pipe 20 by 20 millimeters. To protect against corrosion, all steel elements are coated with a special polymer composition, which eliminates the appearance of rust on the metal elements of the greenhouse.

The features of the clever greenhouse include the following:

- The polycarbonate coating provides UV protection and provides optimal illumination.

- There are two windows at the ends, as well as two easy-to-use full-size doors.

- The roof is opened with a winch, and no physical effort is required for such work.

- Reliable welds are coated on top with a polymer composition, which protects the metal from corrosion.

The arched arcs are spaced at a distance of 100 millimeters and are sheathed on top with one and a half millimeter polycarbonate, which has excellent light transmittance. Depending on its modification, the length of a nurse's greenhouse with an opening top can be 4-10 meters, and the width is 3 meters. The gardener is offered the opportunity to gradually increase sections, which increases the overall length of the nurse.

Benefits of an open roof

The manufacturer recommends opening the roof not only to ventilate the plants directly during the growing season, but also raising the top flap in winter, which allows you to fill the greenhouse with snow, preventing the soil from freezing.

In the summer, thanks to the presence of an open roof at the greenhouse, issues with pollination of flowering plants are resolved, which can be done either naturally due to the wind, or by bees or other pollinating insects. High-quality ventilation of plantings is ensured, so-called heat stroke is prevented, when in the summer heat in a closed greenhouse temperatures can rise to 50 degrees, which negatively affects the condition of the grown vegetable and fruit crops.

Most gardeners agree that the presence of such a design in a nurse's greenhouse with an opening roof significantly improves productivity indicators and makes caring for the crops much easier. The gardener is spared the need to visit the dacha every two or three days to ventilate the greenhouse and water the plantings.

Cost of a nurse's greenhouse

One of the advantages of using a greenhouse is its affordable cost. Gardeners are offered both a basic kit, which costs about 20,000 rubles, and a greenhouse with additional sections costing from 20 to 30 thousand rubles. Taking into account the quality of workmanship, the size of the greenhouse and the materials used, this cost is not too high, and due to the increase in productivity, the gardener will quickly recoup his purchase.

Assembling a nurse's greenhouse is not particularly difficult, so any gardener can handle this work. You just need to act strictly according to the instructions, observing the sequence of work, which will allow you to equip a high-quality and durable greenhouse on your personal plot. Such a greenhouse can be easily expanded in the future through the use of additional modules.

Not simple, but folding

In short, “Umnitsa” is not an ordinary greenhouse, but “with character and zest.” It deserves special attention if only because it has a sliding roof, which provides special advantages when used.

Retractable roof structure

The lid opens/closes thanks to roller wheels and special guides

It is not news for gardeners that greenhouse owners experience no less difficulties in winter than in the summer season. A greenhouse structure in cold snowy times requires supervision and protection. In spring and autumn it protects plants from the cold, but in winter it itself needs help. During the cold season, moisture accumulates on the surface of the coating due to the difference in temperature outside and inside. Due to the fact that the temperature outside is below zero, an ice crust quickly forms, which can damage the entire covering material.

Design diagram

If heavy snowfalls occur, and they are not uncommon in our latitudes, the roof of the greenhouse must be cleared of snow. Having exceeded the permissible load threshold or turned into a wet caked crust during a thaw, the snow layer will simply break the roof of the greenhouse, no matter what shape it (the cover) may be. As a result, in the warm season the structure will need restoration, which will entail serious expenses.

Greenhouse "Nurse-Clever" (inside view)

Model description

Such a greenhouse is not quite ordinary, since it has its own characteristics and advantages. For many gardeners and summer residents, the winter period is a problem. This is due to temperature changes when moisture accumulates inside the greenhouse. As a result, an ice crust forms, which spoils the covering material. The roof of greenhouses is often covered with snow and may not withstand the thick layer of Siberian precipitation.

The Umnitsa model, like other greenhouses from the manufacturer, is distinguished by increased frame strength and received the maximum rating on a 10-point scale. This structure is made of a steel square pipe with a cross section of 20x20 mm with a polymer coating.

There are arcs every 100 cm of the arched structure. The thickness of the greenhouse walls is 1.5 mm, and the width of the products is 3 meters. Crab products are produced in a width of 2 meters. The length of the greenhouse can be from 4 to 10 meters. The product must be increased in stages if necessary.

In the field of gardening, the Umnitsa with a sliding roof has become an innovative technological solution. The coating is offered in two polycarbonate versions with a thickness of 1.2 or 1.4 mm. Its roof is the main feature of the greenhouse. In winter, it opens completely so that snow can cover the soil and saturate it with moisture. The product has 2 windows and doors for ventilation of the room. However, according to experts, they do not provide such effective ventilation and often lead to drafts.

The convertible roof can be opened fully or partially. This makes it possible to ventilate the greenhouse over the entire area, and during rains to water the plants naturally. This feature has a positive effect on the development of heat-loving plants.

Delta

, Dubna. The roof is removable. No foundation required. Profile 20 mm. The price of the frame is 20,800 rubles.

Advantages: Galvanized. Polycarbonate 4 mm Premium with a density of 0.7 kg/m2, service life 15-20 years. Rubber seals included. “House” shape with straight walls. Polycarbonate runners. Collapsible, takes up little space.

Disadvantages: The complex roof structure, which consists of two parts and is latched in the middle, requires additional time to assemble it yourself. It is demanding on the condition of the soil; when installed on a heaving and swampy area, it is better to mount it on a foundation. In summer, it should not be opened more than 20 cm.

Greenhouse Flora-Cabriolet

, Vladimir region. The frame is galvanized or painted. Profile 20 mm. The roof is removable. A foundation is required. The frame costs 22,300 rubles. + foundation for 4000 rub.

Advantages: Straight walls. You can order a galvanized frame.

Disadvantages: The painted frame will rust over time. Welded, welding seams rust. High walls have greater windage. Bulky, inconvenient to transport in a car. Not convenient to use. The edges of the removable roof are located at a height of 2 meters, making it difficult for short people to use. Before winter, it is necessary to completely remove the roof and put it away, and in the spring, insert a long three-meter sheet into the guides in place; this requires two tall people and a free space of 2-3 meters on one side. The length of the polycarbonate sheet on the roof is 3 meters; you need to have a free space of 2-3 meters on one side to use it. In summer, the sheets cannot be extended more than 20 cm, otherwise the wind will fray the free ends and may even tear them out of the guides or break them. There are no seals, the heat will escape through the cracks. The kit does not include high-quality, durable polycarbonate. Greenhouses “Flora Cabriolet” are equipped only with cheap polycarbonate from the KS Profplast plant without UV protection on the surface in the form of a film, but only “in bulk”. Such polycarbonate can be destroyed by the sun within 5 years. The walls are covered with weak, “lightweight” polycarbonate with a reduced density. Difficulty in self-assembly.

Study of the “Clever Nurse”

We will also divide the detailed study of the “Umnitsa” greenhouse into several stages. We will get acquainted with the new product gradually. First, let’s figure out what the greenhouse “can do.”

Photo of the “Clever Nurse” assembled

Exploring Opportunities

- “Umnitsa” can regulate the inside greenhouse air temperature throughout the year, regardless of weather conditions, due to the fact that air enters from outside through the folding roof.

- She is able to maintain a high level of natural light due to a design that has a minimum of details. The main element that occupies the maximum area of the structure is a transparent coating. This fact cannot but affect the good growth of crops.

- In winter, snow enters the greenhouse through the open roof. There is no need to spread it onto the greenhouse beds by hand. And in the spring it melts and moistens the soil with valuable melt water, which is necessary for the comfortable growth of future plantings.

Open sliding roof structure

Technical and user characteristics

- The basis of the structure is a steel pipe with a square cross-section. Size 20x20 mm. A protective polymer coating that protects the frame from corrosion and ultraviolet radiation.

- The arches are made according to the arched principle. The distance between them is 1 m, and the wall thickness is 1.5 mm.

- The width of the structure has a fixed size - 3 m. The length starts from 4 m, but many consumers, after trial use, increase the size of the structure using special tabs provided by the manufacturer. The length can be gradually increased up to 10 m.

- The design includes at least 2 doors and windows, as well as a roof that can be adjusted.

- The defined arc contour provides excellent wind resistance, and the cellular structure adds strength to the structure.

- The greenhouse covering is cellular polycarbonate, a modern and popular covering material.

Key features of the “Umnitsa” greenhouse

Advantages

- The undoubted advantage is the speed and ease of assembly - the “Clever Nurse” can be assembled in about 4 hours.

- High-quality material is used in production, which guarantees a long service life.

- The greenhouse comes with clear instructions, following which any summer resident can assemble “Clever Girl” on his own.

- The roof opens easily, allowing ventilation, soil moisture (including during rainy summers), and also increasing the strength of the entire structure in winter.

- If any defects are detected, the manufacturer unconditionally replaces the product with a new one.

"Nurse-Clever" on the site

Shapes and dimensions of the structure

The smallest justified size for a greenhouse would be 2x4 m. And the most rational type is 2x10 m.

In such a structure you can grow:

- cucumbers;

- shrubs of small height;

- seedlings of apple trees and other fruit trees.

The demand for such a solution as a “convertible” is explained by the ease of installation. The vents are designed in such a way that the roof moves only from the sides. There is no need to remove it. When the air temperature is positive, such a greenhouse is used in ventilation mode. And when the cold season comes, you only need to move part of the roof. Then the snow cover will form quickly and protect perennial plants from the cold. “Convertibles” have two segments, so in one greenhouse you can grow crops that require quite different development conditions.

The Lotus greenhouse is an attractive choice for many people.

Its dimensions are as follows:

- width – 89 cm;

- height – 80 cm;

- length – 210 cm.

It is the Lotus greenhouses that are recommended by professional agronomists for beginning gardeners. They have a small height, but at the same time completely protect the plants from bad weather. The frame of the “Lotus” is formed from a steel pipe with zinc coating. Polycarbonate with protection against contamination is used to cover the structure. The developers can use it to accelerate the development of seedlings.

Greenhouses with a sliding roof are made in the form of an arch or a tent. The tent type is equipped with four vertical walls. It has a roof with one or two slopes. There are also arched and flat roofs. Some greenhouses have elongated walls that are parallel to each other and slope inward.

The arched structure is more like a tunnel. Its main parts are arcs. Flat walls are installed at the ends. To make the frame, angles made of steel and aluminum are used, which can be welded or connected with screws. The steel is primed, then painted or coated with a layer of zinc; aluminum is used without protective layers.

Features of the creation of the “Clever Nurse”

The history of the production of this greenhouse began with improvements. has been making greenhouses for quite some time. Among his popular developments, especially in Siberia, are “Bogatyrskaya”, “Crabovaya” and several more that are widely known, but in narrow circles. Following numerous requests from Siberian summer residents, the company set out on a creative search in 2008 and built a new, especially durable model, ideal for Siberian winters.

, Novosibirsk city

It took 2 years to test the product. Serious tests were carried out at the Siberian Institute of Selection and Plant Growing. Already in 2010, “Nurse-Umnitsa” was put into mass production. And then it turned out that harsh snowy winters are not only a Siberian problem. Summer residents across the country, even in the Moscow region, began installing the greenhouse. And enthusiastic reviews poured in from everywhere for “Umnitsa”. Thus, the brand quickly gained well-deserved popularity, and summer residents gained an ideal greenhouse that can withstand the harsh domestic cold without damage.

"Nurse-Clever" in winter

But the turning point in the history of “Umnitsa” was 2015 - it was then that the manufacturers thought of making a folding roof in the greenhouse, thereby obtaining:

- maximum ventilation;

- maximum hydration;

- incredible durability of the structure in winter.

The fully opening roof turned the “Nurse” into a “Clever Girl”, which is significantly ahead in its characteristics of other greenhouse structures.

A special feature of the greenhouse is its fully opening roof.

Table. Advantages of a retractable roof over a stationary one.

| Advantage | The resulting effect |

| Filling the greenhouse with snow | Preservation of soil from freezing in cold weather. Soil moisture during warming. |

| No snow load on the entire structure through the roof | The greenhouse will not break, no matter how heavy snowfalls are expected. |

| Ventilation | Helps free air circulation, which is necessary for plants. Promotes natural pollination of plants. |

| Watering | Thanks to the open roof, watering is carried out naturally (through precipitation). |

| Formation of a humus layer | In autumn, fallen leaves naturally fall into the greenhouse, which helps form a humus-rich fertile soil layer without additional compost. |

Device Features

The “Nurse-Umnitsa” greenhouse is presented in the form of a multifunctional structure made of polymer materials. The main design feature of greenhouses is a sliding roof, the mechanism of which is quite convenient and practical. The use of a sliding roof allows you to create a microclimate that is comfortable for plants in the greenhouse and significantly improves the condition of the greenhouse soil in winter. The main difference between the “Nurse-Clever” and models of the classical type is the absence of drafts during ventilation.

The convenience of structures with an opening top is that during heavy snowfalls, the owners of such greenhouses do not have to worry about the integrity of the roof and regularly clear it of snow. To ensure that the coating does not fail or deform under a heavy snowdrift, it is enough to leave it open. The opening and closing of the top occurs thanks to a roller system with special guides, which even a child can handle.

The frame of the product is made of steel tubes and polymer components. Due to the absence of external load in winter, reinforcing arcs in such greenhouses is not practiced. Thanks to its lightweight design, the structure is characterized by low weight and ease of installation. The thickness of the cellular polycarbonate coating is 1.2–1.5 mm, the cross-section of the metal profile is 2x2 cm. The distance between adjacent arched arches does not exceed one meter, which, in combination with a high-strength cellular coating, allows the structure to easily withstand high wind loads.

Products are available in various sizes. The most common of them are lengths of 4.6 and 8 meters. With a standard height of 210 cm, the width of all models is three meters. Greenhouses are equipped with two doors and several windows, the number of which is determined by the configuration. It can be increased at the request of the buyer.

Assembling the “Clever” greenhouse with your own hands - step-by-step instructions

Manufacturers made sure that the installation of the greenhouse could be done independently, without the involvement of additional forces and resources. This circumstance also makes “Umnitsa” closer to the people. There is no need to call specialists or rely on someone else - everything is in your hands. You just need to follow the instructions and go through all the assembly steps.

Greenhouse equipment

Stage one. Foundation issue

Long gone are the days when the foundation for greenhouses was always poured with concrete or built of brick. However, when installing this greenhouse, which is particularly durable, you need a special foundation. This can be a classic foundation or a rectangle made from everything that is available on the farm.

Assembled greenhouse on a simple timber foundation

So, the foundation can be:

- brick;

- concrete;

- from timber

The last type of foundation is the simplest - you only need timber, screws and corners. You can fasten the logs with staples. The optimal cross-section of the beam is 100x100 mm. The beams, pre-treated with a wood antiseptic (such as “Senezh”), are connected into a box equal in size to the size of the purchased version of the greenhouse.

Then it is necessary to level the soil in the place chosen for installation and lay the base evenly on it. If it lies unevenly, the frame will also rise unevenly, and in this case the manufacturer does not guarantee the proper operation of the mechanism that opens/closes the roof. To level the foundation, it is better to use a building level. The beams are connected using brackets along the length and width of the greenhouse, as shown in the image. Accordingly, diagonally and horizontally everything should be smooth and identical.

Timber foundation

Having prepared in this way, proceed to assembly.

Parts for assembling the frame

Stage two. Assembly

The process starts with the end pieces and involves 12 steps.

Step one. Installation of ends. The end contains a door block and 3 end arches - top, left, right. End arches and spacers are installed on the door frame. The elements are connected by using end struts. Bolts and crab fastenings are used to attach the arches to the struts and frame.

Installing the upper end bow and end spacers

Fastening the side end arches

Step two. Intermediate and lower struts are attached to the ends using “crabs” and self-tapping screws. All of them are connected in series up to the second end.

Attaching intermediate struts

Step three. Polycarbonate is attached to the assembled ends. Self-tapping screws are used for fastening, preferably with thermal washers.

Cutting polycarbonate

Scheme of fastening polycarbonate with self-tapping screws

End covered with polycarbonate

Step four. The attached polycarbonate is cut with a construction knife along the contour of the greenhouse body.

Important! Fastening the polycarbonate can be done after assembling the entire frame, as shown in the photo.

Frame assembly

Step five. Mounting the roof, which is made up of end arches. They are attached to the intermediate arches using spacers for connection. All elements are fastened to each other with bolts in accordance with the instructions.

Assembling a sliding roof

Step six. 8 roller wheels are attached to the finished roof covering.

Wheel mounting scheme

Step seven. A polycarbonate sheet (entirely) is laid on the roof. Smoothly attached to the frame with self-tapping screws.

How should polycarbonate be attached to the roof (installation of the roof should be done at the very end)

Step eight. The “body” is assembled. Transverse struts are attached to the ends.

Step nine. The fully assembled frame is attached to the base.

Step ten. The installation of trellises is carried out transversely under the roof. They not only serve as a reinforcing element, but can also be useful as a bar for attaching tall and vine-like crops.

Installation of trellises

It may be better to secure the trellis in advance with self-tapping screws to the upper intermediate arches on the ground, and only then carry out the installation

Step eleven. Polycarbonate is installed on both sides of the greenhouse body. A winch is attached to one side. A cable is pulled from the inside into the winch and secured to the bottom of the central arc, which forms the roof frame.

Sheathing the frame with polycarbonate

End trim (if you haven't done this before)

Installing a winch on the central arc of the middle part of the greenhouse on the opposite side from moving the roof

Step twelve. Platbands, as well as clamps and stops that ensure the opening of the roof, are installed in the designated places.

The guides are bent into an arc and mounted on top of the polycarbonate

The stop is attached to the third tier of spacers on the winch side

The roof must be installed on the greenhouse, aligning the wheels with the guides

From the inside of the greenhouse, a cable from a winch is attached to the lower part of the central arch of the roof. The cable from the winch must be pulled to the roof, passing under the stop

Clamps are attached to the end of the greenhouse, taking into account the extreme positions of the roof

Note! The roof must be secured in both open and closed states.

Stage three. Exploitation

Everything is simple here - just remember to open and close the sliding roof in time. Opening/closing is easy, even a child can do it. A reliable winch works smoothly, without failures - this is noted by all users. They also note that the plants grown in the “Nurse-Umnitsa” express gratitude for the fresh air and sufficient moisture from the generous harvest.

Greenhouse "Kremlevskaya"

The Kremlevskaya greenhouse has long been known among specialists as an effective, practical, and very promising structure. It attracts with its durability, relative ease of assembly, and increased wear resistance. Read in more detail.

Pros and cons of the “Nurse” model

If you have already appreciated all the advantages of a sliding roof in a greenhouse, then it would be useful to familiarize yourself with the other advantages of this model.

- Reliability of the design. The materials used in production can withstand strong gusts of wind and low temperatures, all connecting elements are securely welded.

- Convenience of opening the roof. The manual mechanism through a rotating lever allows you to smoothly and easily open and close the top of the greenhouse.

- Easy to assemble and install. Each copy includes detailed instructions that any summer resident can understand.

- Possibility of completing the product with automatic windows and grilles for tying up plants.

- Long service life and warranty from the manufacturer for several years.

- The thickness of polycarbonate allows the maximum amount of sunlight to pass through, while at the same time it is a protective layer against plant burns.

The second negative nuance relates to the sliding roof. Not every fruit crop may like the abundant supply of air, because closed greenhouses form their own microclimate, and plants get used to growing in certain conditions from the very beginning. Therefore, before making a choice in favor of such a greenhouse, study the needs of the crops that you are going to plant in it.

The greenhouse has a classification, and its most modern models are quite expensive. Waiting for delivery may take some time, sometimes reaching several months, since the product is most often made to order. Therefore, you should order a greenhouse in advance, at the end of autumn.

Greenhouse "Nurse" from the manufacturer's plant

We sell high-quality “Nurse” greenhouses in Novosibirsk at factory prices. The Nurse is our budget version of the greenhouse. This solution is suitable not only for our beloved summer residents, but also for individual, educational and farm enterprises. It is distinguished not only by its affordable cost, but also by ease of installation and maintainability of all elements. The model is based on a durable frame made of galvanized profile pipe; thanks to the zinc coating, the product is not afraid of corrosion.

- Characteristics of the greenhouse “Nurse”

- frame made of galvanized pipe 20x30 mm

- reliable pipe-to-pipe connection

- distance between arcs 1 m

- SPK 4 mm thick with UV protection

- presence of vents on both sides

From us you can buy a Nursery greenhouse from a factory in Novosibirsk with an official guarantee. If you are interested in this offer, please contact our managers. They will be happy to accept your application and advise you on all issues. Delivery and assembly services are provided at the customer’s site. We are waiting for your calls and orders!

Recommendations for placing a greenhouse

When choosing a location for the “Nurse”, you need to consider a few simple rules:

- It is better to install the greenhouse at a distance of 5 m from any buildings, and at least 3 m from any trees. The reason for such recommendations is that no shadow should fall on the structure;

- if the site allows, it is better for the greenhouse to “look” with its long side to the south. In this case, it will warm up better.

DIY greenhouse

Given the low cost of the simplest nurses, with the possibility of their subsequent radical modernization, the process of building such a greenhouse with your own hands seems somewhat doubtful. But if we are talking about improving consumer characteristics or seriously increasing the service life of a structure, it definitely makes sense.

First of all, we can talk about the frame material. If the greenhouse is regularly and effectively ventilated, then it makes sense to consider wood in this capacity.

- Firstly, wood is more resistant to static loads: it bends, but does not break, and after they are removed, it restores its original configuration better than metal.

- Secondly, it is much easier to work with than metal.

- Thirdly, with appropriate treatment, it can last longer than metal, and if you take larch, then many times longer.

You can also use polypropylene water pipes for the frame of the “Nurse” type greenhouse.

The only thing we would recommend to improve is their connection. The use of standard welding and standard components for such systems will be much more justified. At the same time, it would be rational to introduce either steel reinforcement of the appropriate diameter or its fiberglass analogue into the arched elements of the frame, which is even better. The durability of this design is beyond doubt. Also, pipes can be secured using the same crabs with various options for their use.

And finally, to stimulate your creative searches - a selection of options for replacing polycarbonate.

This coating will not last very long with constant exposure to ultraviolet radiation, but certainly no less than polycarbonate.

We recommend other articles on the topic

Popular posts

- Greenhouse for greenery all year round. Types of greenhouses? Mini-greenhouse Compact greenhouse, used for growing greenery in an apartment. It is a glazed box…

- Greenhouses for a summer residence How to choose inexpensive but effective greenhouses for a summer residence A greenhouse for a summer residence is a great way to get…

- Greenhouse retractable roof Retractable roof The appearance of modern cities is now impossible to imagine without new, special technologies in the design of space.…

- Polycarbonate greenhouse in winter Treatment of the internal surfaces of the greenhouse First, you need to carry out fumigation in the greenhouse to remove it from the honeycombs...

What do its owners say about this greenhouse?

This is what especially pleases the owners of the “Nurse”: there is no need to dump snow in winter, the coating on the metal is good and lasts a really long time. And the “Nurse” has another little-known significant advantage: if it is crushed in winter (even due to improper assembly), it will still be replaced with a new one - this is how its manufacturer protects its reputation.

Let us tell you one secret: if you place the greenhouse sideways to the wind that prevails in winter, then the snow will simply blow away from it. Also, this is what pleases the eye of those who purchased the “Nurse” - welding without holes, even painting, and everything is quite easy to join without scrap.