Their service life is tens of years. At the same time, like any metal product, they are susceptible to rust and corrosion, but there are quite a lot of products that can be treated to avoid this. Otherwise they are invulnerable and very reliable.

The construction of a greenhouse at your dacha can be entrusted to a greenhouse manufacturing company, or you can do it yourself. In the second case, you will need to calculate the amount of materials, and in this article we present you with an online greenhouse calculation calculator. The calculator will easily determine the required amount of materials, the perimeter of its foundation and the area of its glazing. If the greenhouse is built from polycarbonate, then when designing it you need to take into account the size of the sheets of material in order to avoid unnecessary waste. To use the calculator, click on the image below depending on what shape of greenhouse you have chosen.

How to make a greenhouse from arcs without extra expenses? You will need plastic pipes or steel rods, special tools and a little patience.

What to look for when buying a greenhouse

Have you decided to buy a greenhouse for cellular polycarbonate, but can’t make the final choice?

Let's figure it out together... Frame material

Firstly, you should pay attention to the material of the structure frame. This can be either a galvanized profile pipe or a square profile without galvanization with a cross-section of 20x20 or 25x25 mm; it is not uncommon to find a straight or wave-shaped profile made of galvanized steel.

Let's look at each of them.

So, a square steel profile. The wall thickness varies, depending on the manufacturer, from 0.5 to 2 mm. Before assembly, the profile is primed and coated with powder coating or enamel. But this does not provide complete protection against corrosion. There is a high probability that the frame of the greenhouse will quickly become covered with rust and after each subsequent winter the metal will “bloom” more and more until the profile “rots” completely.

Galvanized steel profile pipe. This material inspires confidence: it is both durable and not subject to corrosion - galvanization saves the day. The wall thickness also ranges from 0.5 to 2 mm. But here you need to “keep your eyes open.” Welded galvanized greenhouses began to appear on the market, the welding points of which are painted over with silver, and instead of a profile seamless pipe there is a pipe with a welded seam (there appears to be a black stripe along the entire length of the pipe). These places will rust within a year or two, don’t fall for the scam! Remember, a real galvanized greenhouse, which is not subject to corrosion, must have no welds. Conscientious manufacturers, where there must be welding between parts, use such elements as “kerchiefs”, “corners”, etc.

And finally,

galvanized steel profile. Standard profile sizes are 44x15 mm and 60x20 mm, wall thickness ranges from 0.7 to 1 mm.

At first glance, this type of profile is inferior to its “brothers” made from pipes in terms of structural strength. In reality this is not always the case. The leading manufacturer of greenhouses in Russia has in its assortment a lancet-shaped greenhouse “Strelka”, the snow load of which is 450 kg/sq.m., and believe me, this is a lot. Distance between arcs

An important aspect when choosing a greenhouse is the distance between the arcs. The optimal distance between the arches is 50 - 75 cm. If the distance between the spans is 1 meter or more, the rigidity of the frame must be increased by using arch reinforcements. They are assembled quite simply, but the strength of the structure increases significantly. For reference, the arc amplifier consists of a horizontal tie and two slopes. It is these slopes that bear the main load.

Many manufacturers of pipe greenhouses make spans of 0.9 m, 1 meter and even 1.2 m without arc amplifiers. But this is very risky - despite the fact that such a design looks impressive, this apparent strength will not protect your coating from breaking. If you reduce spans by using additional arches or reinforcements, this will increase the cost of the structure - not all manufacturers agree to this. Remember, if a pipe structure is cheaper than a galvanized profile structure, it means it is weaker.

If you, as the future owner of a greenhouse, can take care of it in winter, constantly monitor it and, if necessary, remove snow from it, then you can save money and buy a model with a small snow load.

Foundation

Due to their enormous weight, greenhouses made from pipes should be installed on a concrete foundation or timber. It is not difficult to make a foundation from timber, but wood in a greenhouse is short-lived, there is a risk that the tree will rot into dust in 3-4 years, no antiseptic impregnation will save it. A strip foundation is more reliable, it is not afraid of either water or temperature, but this is a rather complicated and labor-intensive task.

Greenhouses made of galvanized steel profiles are lighter in weight than greenhouses made of pipes, so they do not require a foundation; it is enough to bury the special T-shaped ends of the frame in the ground and the structure is ready. But if there is a desire, the frame can be placed on the foundation, so to speak, for reliability.

Coating

How to choose cellular polycarbonate. Let's figure out what it is and, as they say, what it is eaten with.

Cellular polycarbonate is a sheet of several thin plates arranged in parallel and connected by special ribs - jumpers, which determine the strength of the material. According to technical characteristics, polycarbonate is stronger when it has more bridges and weight, and weaker when there is a lack of high-quality binders.

The service life of cellular polycarbonate depends on the raw materials used by the manufacturers (which is very difficult to verify) and on the method of UV protection. Almost all domestic manufacturers make such cellular polycarbonate, which already contains a UV stabilizer. And despite this, for additional guarantee, they produce sheets with protection from ultraviolet radiation in the form of a co-extruded one-sided layer of UV absorber (up to 50 microns thick), which makes it possible to use polycarbonate outdoors for a long time without changing the properties and necessary qualities (up to 15 years).

The distance between the arcs of the greenhouse. How to choose a greenhouse

A polycarbonate greenhouse is not a cheap pleasure. In order for it to last a long time, when choosing a greenhouse you should pay attention to the distance between the arcs - the smaller it is, the better. Nowadays, greenhouse models with distances between arcs of 50 cm, 67 cm and 1 meter are widely available on the market. The former are more preferable. The more often the arcs are located, the stronger the greenhouse, the greater the snow load it will withstand. Often installed arcs will allow greenhouses to successfully withstand not only snow piles, but also strong, often hurricane-force winds. Such greenhouses can withstand any operational loads well, for example, when ropes are tied to the frame arches for better plant growth.

The fact is that with a distance between the arcs of 1 meter, a polycarbonate sheet measuring 6 x 2.1 m will lie on three arcs. If the step between the arcs is 50-67 cm, then the polycarbonate sheet will lie on four arcs, thus, the weight of the snow on the polycarbonate will be distributed more evenly and the overall load capacity of the greenhouse will be higher. Which ultimately affects the strength of the structure and the service life of polycarbonate. The larger the area on which the polycarbonate rests, the more evenly the support points are distributed over it, the better the snow load is distributed. If the area on which the polycarbonate rests is small, then in the places where the polycarbonate adheres to the frame it will experience increased load and may be pushed through. Large distances between supports lead to creases and sagging of polycarbonate. Which will result in rapid deterioration of even the highest quality polycarbonate sheet.

If you want to buy a greenhouse 4 or 6 meters long, then you can consider frame options with 1 meter increments. When choosing a greenhouse with a length of 8 meters or more, we recommend choosing greenhouse models with a pitch of 50-67 cm. You should also pay attention to the distance between the runs and the presence of additional amplifiers. Additional reinforcements increase the load-carrying capacity of the structure.

Source of the article: https://teplicavdom.by/kak-vybrat/rasstoyanie-mezhdu-dugami-teplitsy.php

Description and Application

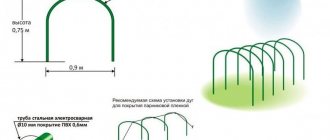

Arched greenhouses are arcs installed above the bed and covered with film or non-woven material. The height of the greenhouse can be from 0.5 to 1.3 m, which allows them to be used for different crops. The width is 0.6-1.2 m, and the length depends on the number of arcs and the distance between them. The most popular greenhouses are 4.6 and 8 m long.

A greenhouse made of arcs is used for the following purposes.

- For growing heat-loving plants throughout the season . In this case, it is necessary to select a greenhouse of sufficient height and strength, with strong fastening of the covering material and convenient access to the plants. It is recommended to fence the bed with boards, slate or brick.

Assembling and installing the greenhouse is very simple. Purchased sets of arcs and prefabricated greenhouses are equipped with pegs with which they (the arcs) are stuck into the ground. Non-woven material is placed on top and secured using special clamps or available materials. In some greenhouse models, the arcs are already sewn into the material, which makes installation of the greenhouse easier. The arc installation step depends on the design and is usually 0.5-1.2 m.

Note! The distance between the arcs is chosen so as to prevent sagging of the film. In strong winds, sagging film can damage the tops of plants.

Plastic arches

Greenhouses made on the basis of plastic arcs can be increasingly seen in gardening areas. The fact is that since plastic has firmly entered our lives, it is used almost everywhere. It is light, cheap, easy to process - what else is needed to build various structures from it with your own hands? That’s why greenhouses on plastic frames appeared at dachas.

Plastic arches are good because they are not afraid of corrosion, which means they will withstand snow, heat, and torrential rain. This explains their durability.

Plastic is also very light, and a greenhouse made on the basis of such arcs can be easily assembled, carried and installed by anyone - even a child. True, plastic arcs are usually used only to create small structures.

One of the main disadvantages of plastic is some fragility. If you apply some effort, the material will crack and break. Although, again, everything is individual here - there is also such plastic that is not afraid of anything at all.

On a note! Arched plastic-based greenhouses can be purchased ready-made. They are usually inexpensive. The trouble with these greenhouses is that often their arcs crack at the bottom, which sticks into the ground.

How to make arcs for a plastic greenhouse? It's simple - there are two main ways. You will need a regular plastic plumbing pipe for water supply and a hair dryer.

Method No. 1

Step 1. Cut the pipe into required lengths.

Step 2. While heating each piece of pipe in the middle, carefully bend it to the desired radius.

Step 3. Along the perimeter of the bed where the greenhouse will be installed, insert metal or plastic pins in pairs opposite each other. The distance between each pair should be no more than 50 cm.

Step 4: Simply slide the arcs onto the pins.

Step 5. At the top, connect the arcs with one straight pipe, securing it with clamps. She will not let the greenhouse collapse.

Method No. 2

It appeared when gardeners realized that the ideal frame for a greenhouse was a combination of metal and plastic. Here the frame installation system is almost the same, except that a metal rod, turned into an arc, is inserted inside each pipe. It looks like metal in a plastic wrapper. This will protect it from excess moisture.

Industrial Arc Sets

The kits are arches made of insulated wire or pipes bent according to one template. The set usually contains 6 arches, they are designed for a tunnel shelter or a temporary greenhouse 4-6 m long. The dimensions of the arches - width and height - can be different, from 65 to 120 cm. The arches can also be sold individually - in this case, you can complete a set for greenhouse of the required length.

For the manufacture of arcs the following can be used:

- steel wire Ø5 mm in PVC sheath;

- steel tube Ø10-Ø12 mm in PVC sheath

- PVC pipe Ø20-Ø25 mm.

The wire and tube arches are rigid enough to maintain their shape for several seasons. PVC insulation protects them from corrosion, and pins at the ends make it easier to anchor them in the ground. The arcs are simply stuck into the ground to the required depth.

Arcs made from PVC pipes are more flexible, due to this you can adjust the width and height of the greenhouse. To secure it in the ground, you can use special pegs for PVC pipes or cutting reinforcement.

Special clamps are used to attach the covering material to the arches. To hold the canvas on the ground and protect it from the wind, you can purchase a set of pegs and rings. The pegs are stuck into the ground, covered with covering material and clamped with a ring. Covering material, sets of clamps and pegs, as a rule, are purchased separately, focusing on the number and size of the selected arches.

Note! Sets of arcs can be used to make a permanent greenhouse. To do this, it is enough to assemble a frame from boards and bars and attach the arcs to it.

Prices for arches for greenhouses

Option one

In the place where the greenhouse will stand in the future, it is necessary to drive pins around the entire perimeter, but not too deeply. They should stick out about 15 cm from the ground. Strong curved pipes are placed on these pins. To correctly calculate how much pipe is needed? You just need to know how tall the greenhouse will be. Also, the distance between PVC structures should be at least half a meter.

To strengthen the structure from above, it is necessary to lay an additional pipe across and attach arcs to it.

Arched greenhouses for industrial production - review

The greenhouse kit usually includes arcs, crossbars, pegs for installation in the ground and clamps for covering material, and in some models the canvas itself. A greenhouse, unlike a set of arcs, is designed for a certain length of the bed, and the distance between them cannot be changed. The most common models of industrially produced arched greenhouses are described below.

Greenhouse "Quickly ripened"

Prefabricated greenhouse with a wide variety of arc sizes. The width, depending on the model, can be 1.0 or 1.1 m; height – 1.2 or 1.6 m; length – 3 or 5 m.

The greenhouse kit includes:

- arcs made of steel wire in a PVC sheath, 4 or 6 pcs. depending on length;

- crossbars – 1 or 3 pcs.;

- clamps for attaching material to arches;

- pegs and rings for fastening to the ground.

Installation of covering material for a greenhouse

Usually, the covering material from the ends of the greenhouse is cut to the size of the end with an overlap for sufficient rotation around the arc and is fixed with special clamps. Homemade clamps can be made from an old irrigation hose by cutting it lengthwise.

The upper part is covered with material so that at the bottom on each side there is an overlap of 40 - 50 cm. This will allow it to be securely fastened to the base. It can also be fixed to the arches with clamps.

DIY arc greenhouse

If you have available materials, it is not at all necessary to spend money on a ready-made greenhouse - you can make it yourself. It is most convenient to make arches from water pipes Ø20 mm. PVC and HDPE pipes, polypropylene and metal-plastic pipes are suitable for the greenhouse. To strengthen the structure, it is recommended to install pipes on a wooden base.

The technology for assembling and installing a greenhouse made of arcs with covering material with your own hands is shown in Table 1.

Table 1. Do-it-yourself greenhouse made of pipes on a wooden base.

We assemble the greenhouse ourselves

And finally, we’ll tell you and show you one of the ways to make a greenhouse with your own hands very quickly and easily.

To do this you will need:

- metal-plastic pipe, which is used to equip the heating system in the house;

- several meters of thick plastic film to cover the greenhouse;

- nylon twine;

- hacksaw for metal;

- wooden pegs or beads with a diameter slightly smaller than the pipe.

Prices for polyethylene film

Step 1. Cut the metal-plastic pipe into equal lengths with a hacksaw. Their length will be equal to the length of the frame arcs.

Step 2. Bend the pieces into neat arcs.

Step 3. Saw the glazing bead into pieces approximately 25 cm long and sharpen on one side.

Step 4. Insert bead pieces into the edges of the arches. The sharp end of the bead should point outward.

Step 5. Stick arcs in the garden in the place where you plan to install the greenhouse.

Step 6: Stretch the twine between the arches along the sides of the arches.

Step 7. Make the central piece of twine that will run along the “ridge” part of the greenhouse longer, and tie the edges to pegs stuck in the ground. This will help, as it were, stretch the greenhouse and make it stable.

Step 8. Cover the greenhouse with film. It can be fixed around the perimeter of the greenhouse with boards, bricks, and stones.

This kind of greenhouse can be made in literally 30-60 minutes of your time. Of course, this is not a permanent structure, but if weather forecasters have promised frosts, then this way you can quickly build a temporary greenhouse.

Polycarbonate thickness

The optimal thickness of polycarbonate for frame arched greenhouses is considered to be 4-10 mm, and its density should be at least 0.7 kg/m2.

Which option to choose depends on the climatic conditions in which the greenhouse will be operated:

- a thickness of 4 mm will be sufficient only in areas with a mild climate and little snow;

- in regions where the climate is more severe and a thick snow cover forms in winter, 6 mm polycarbonate is suitable. Sometimes in house-shaped greenhouses two types of panels are combined: for walls - 4-6 mm, for pitched roof - 6-8 mm;

- polycarbonate with a thickness of 8-10 mm is used in greenhouses intended for growing seedlings in cold weather in the middle zone, as well as in the northern regions.

If you want to save money and buy a sheet less than 4 mm thick (even if it is slightly thinner - 3.7 mm), it is strongly recommended not to do this. The plastic covering will not be rigid enough and may not withstand the load of snow and wind.

But you also can’t overdo it. Take into account this fact: the thicker the polycarbonate, the more stiffeners it has and, accordingly, the stronger the sheet. But the less the material transmits light. And for growing light-loving plants, this indicator is very important.

UV protective layer

Polycarbonate, which is used in outdoor conditions, urgently needs protection from ultraviolet radiation. Under the influence of the sun, the material becomes cloudy, becomes covered with microcracks and gradually crumbles. Therefore, manufacturers apply a special protective coating to polycarbonate.

A material that does not transmit ultraviolet radiation is melted into the top layer of the sheet at the factory. A thin, inseparable film is formed - the human eye cannot see it. Therefore, the UV protected side must be marked.

Be careful when installing polycarbonate on the greenhouse - turn the sheet outward with the intended side. There are options with double-sided UV protection. But for greenhouses this is unnecessary.

Metallic profile

An important quality indicator for a greenhouse is its frame. It must be tough and able to withstand any load. As a material for the frame, choose a galvanized metal profile with a square or rectangular cross-section. U-shaped ones will have insufficient rigidity; a greenhouse made from them will not last long.

When choosing a profile for the frame, consider the following characteristics:

- metal thickness - at least 1.2 mm, otherwise there is a high probability that it will bend under high load;

- The cross-section of the frame profile must be at least 20x20 mm. But for the base it is better to use a more durable, rectangular 20x40 mm;

- the profile pipe must be galvanized outside and inside. Other methods of coating are less durable - the metal will quickly begin to rust;

- For a greenhouse it is better to use solid-bent arches. If transportation is difficult, choose composite arches with a small number of joints and strong fastenings of the butt joints.

Expert advice

Since PVC parts are quite strong and bend well, a greenhouse of any shape can be made from them. The only thing that should be done correctly is to successfully secure the structure so that it is resistant to wind and other adverse weather conditions.

But you should not come up with new ways to connect the building. It is recommended not to deviate from standard templates, because in the end the greenhouse may simply not perform its functions. It will be better if you try to come up with a new type of inexpensive and convenient greenhouse from existing materials.