It is not difficult for current owners of summer cottages or country houses to purchase a greenhouse, because the modern market for these structures offers a fairly wide range of different options made of metal, wooden beams or polycarbonate. They also differ in shape: pyramids, square and rectangular. Thanks to the use of the latest technologies in production, greenhouses are of high quality, reliable and durable, easy to use, functional and cost-effective.

Greenhouse for a summer residence Source samozvetik.ru

No. 1. Determining the main tasks of the greenhouse

Surely, everyone who is looking for a greenhouse understands why he needs it and for what purposes it will be used. However, before you begin to understand the advantages and disadvantages of different materials and shapes, it is necessary to very clearly outline the tasks assigned to the greenhouse. For some summer residents, it will be enough for it to look nice and look good on the site. Those who consider the structure as the basis for a business or as a help in the household, although they will pay attention to the appearance of the structure, will not focus on it when choosing a greenhouse.

Typically, greenhouses are built to grow vegetables and berries for their own consumption, but some summer residents plan to make a business out of this in the future. If in the first case the financial investments will not be so significant, then in the second they will become a serious investment, the size of which will largely determine the maintenance costs.

Another question that requires a clear answer is the type of greenhouse model: collapsible or stationary . If you are at your dacha all year round and are not afraid that in your absence someone may damage or even steal the structure (and this happens), it is better to choose a stationary model - it is less hassle. A collapsible greenhouse is an ideal option for those who visit their dacha only in warm weather; it will have to be assembled and disassembled twice a year.

The choice of certain greenhouse parameters also depends on what plants will be grown , because each crop has its own requirements for light and humidity levels. The height of the greenhouse also depends on the characteristics of the plants. For example, for tomatoes and other tall crops it is better to choose a rectangular structure.

No. 2. Where to put the greenhouse?

Choosing a location for a greenhouse is a question no less important than selecting the most suitable design. If the greenhouse is placed incorrectly on the site, the money for its purchase and installation can be considered wasted, as well as the efforts to grow plants. When choosing the optimal location for a greenhouse, it is worth considering the following factors:

- light level – a key parameter when searching for a suitable location. The greenhouse should receive maximum possible amount of light, not be shaded by trees or houses. Otherwise, the cost of artificial lighting will increase, but it will not help grow crops in the expected volume. Experts advise positioning the greenhouse so that one end faces the west and the other faces the east. With this arrangement it is possible to achieve maximum illumination. If plants will be grown in winter, then artificial lighting will not be possible, so it will be necessary to think through the installation of communications in advance;

- winds. The greenhouse must be placed in the calmest and quietest place on the site, protected from winds and drafts, because they will significantly cool the structure, which will lead to serious heating costs in the winter. A nearby house can provide good protection from the winds, but it will cast a shadow, so it is best to protect the greenhouse with a hedge or a low-height blind fence located at a distance (for example, for a greenhouse 2-2.5 m high, the hedge can be placed at a distance 7-7.5 m);

- relief and soil type. The greenhouse must be installed just on level ground, if there is none, then you will have to artificially level the ground. Sandy and swampy soils, like lowlands, are not suitable for placing greenhouses, and clay soil will need to be covered with gravel first, and only then with a layer of fertile soil;

- ease of placement. Many summer residents place greenhouses on the outskirts of their plot. This is justified if, according to all other factors, this is the most suitable place. The farther the greenhouse is located, the less convenient it will be to maintain and the more expensive it will be to connect all communications.

Places where you should not install a greenhouse

Classification by type of polycarbonate used

The most important characteristics of polycarbonate include:

- sheet thickness;

- the presence of a light-protective layer;

- density of polycarbonate.

Sheet thickness

Cellular polycarbonate comes in thicknesses of 4, 6, 8 and 10 mm. In most cases, a sheet thickness of 4 mm is sufficient. Polycarbonate of thinner thickness has insufficient strength, which can lead to damage to the roof during strong winds and precipitation.

The use of thicker polycarbonate creates additional stress on the frame, which can cause it to deform during heavy snowfalls.

Presence of a light-protective layer

Such a layer does not transmit harmful ultraviolet radiation, but transmits infrared rays as much as possible. The presence of a light-protective layer is confirmed by the presence of appropriate markings.

Density of polycarbonate

This parameter determines the strength of polycarbonate sheets. Density is the weight of one square meter. m. polycarbonate. Its value should not be less than 0.6 kg per square meter. m.

Signs of bad polycarbonate are:

- low density;

- turbidity;

- blue;

- "economy" labeling;

- lack of manufacturer's marking.

No. 3. Greenhouse frame material

The resistance of the greenhouse to all negative environmental factors depends on the frame: winds, the weight of snow, mechanical damage, etc. It is better to spend money once on a more reliable and durable structure than to repair or change it every year. Today, manufacturers offer frames made of wood, plastic and metal . Let's figure out which one is better.

Wooden frame

Wood is the most affordable material for constructing a greenhouse frame, so its popularity in domestic spaces is consistently high, despite its imperfections. Many craftsmen who decide to build a greenhouse with their own hands choose wood, since it is easy to process and has a low weight . include :

- high environmental friendliness;

- corrosion resistance;

- good thermal insulation qualities;

- low cost.

Main disadvantages:

- low strength, in this parameter wood is inferior to plastic and metal;

- ability to absorb moisture and rot;

- the need for constant care to protect against the influence of moisture, mold and pests;

- low durability and the need for constant repairs.

If you do not think through a system for removing water from the greenhouse, the wooden frame will not last long. Such designs remain popular only due to their low cost.

Plastic frame

A PVC frame is one of the most suitable options for greenhouses, but so far it is not often used in our country due to its high cost , which is explained by the complexity of processing the material.

Advantages:

- high aesthetics;

- strength;

- resistance to alkalis, acids, fertilizers and other chemicals;

- resistance to corrosion and rotting;

- low weight and easy DIY installation;

- low thermal conductivity.

Aluminum frame

Aluminum frames are assembled from pipes or profiles, their characteristics are almost identical, and the main advantages are as follows:

- ease;

- rust resistance;

- minimal maintenance and ease of installation.

Minuses:

- high price;

- low thermal insulation.

Steel frame

A steel frame is the best choice today in terms of price and quality ratio. Main advantages : strength, durability, ability to withstand heavy loads, and all this at a fairly low price. The main disadvantages are low thermal insulation properties and susceptibility to corrosion.

The steel frame can be made from:

- pipes;

- profile.

The difference is significant, each material has its own advantages, and the debate over which option is better is reminiscent of arguments about what came first, the chicken or the egg.

The steel pipe frame is the ideal of strength and durability. It is not afraid of snow and wind loads, it will not bend or deform in winter, but you will have to pay for all this: a pipe frame costs much more than a similar one made from a profile. Moreover, it is worth taking into account the large weight of the structure and difficulties in transportation and sometimes installation.

A profile frame is cheaper, easier to install, and it’s not a problem to install it yourself, but it is inferior in strength to its pipe counterpart, so it may require reinforcement.

Steel is susceptible to corrosion, and for protection the frame is galvanized or painted . The second option is cheaper, but requires periodic touch-up to avoid corrosion on the metal and rust spots on the covering material. A galvanized frame will cost a little more, but it is considered a more preferable option, since it will not need additional protection for at least the next 10 years.

To ensure that the metal frame lasts more than one season, pay attention to the following parameters:

- The fewer elements were used to produce the arches and pediments, the better. The ideal is solid-bent arches and welded gables ;

- profile cross-section – 20*40 mm, it is impossible to find more;

- metal thickness – at least 1.2 mm;

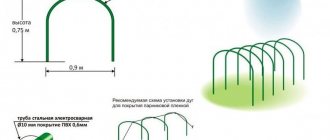

- the distance between the arches is at least 0.67 m , otherwise, at the first light snow, the covering material together with the frame will bend.

No. 4. Does a greenhouse need a foundation?

Experienced summer residents prefer to equip the foundation for a future greenhouse. It helps solve a lot of problems:

- maintaining heat and protecting plants from frost;

- protection of the soil and greenhouse from rain streams;

- ensuring reliable fastening of the frame;

- protecting the frame material from destruction.

And if in some cases you can still do without a foundation, then you will definitely have to equip it if:

- the greenhouse is used all year round;

- the frame is made of wood;

- the structure is buried in the soil below its freezing level;

- the greenhouse is large (more than 6 m in length);

- the structure is located on a slope or in a poorly protected place.

Profile for drywall

The frame for a greenhouse made from a plasterboard profile is not particularly strong and resistant to wind and snow loads. Only lightweight plastic materials and film can be used as an external protective shell for such greenhouses. In addition, there are restrictions on the size of structural elements. This material is not intended for greenhouse construction. A structure made from it can last only a few seasons. The main advantages are the extreme low cost of the profile and the ease of connecting structural elements to each other (rivet gun, self-tapping screws).

No. 5. Which foundation for a greenhouse is better?

Depending on the objectives pursued, choose one of the following foundation options:

- tape , which is organized using concrete, less often sleepers, brick or gravel. Previously, the arrangement of such a foundation was considered mandatory, but is still carried out by many summer residents. The construction is almost permanent; it will be impossible to move it to another place;

- the block foundation is made of reinforced concrete blocks, it is suitable for regions with loose soil;

- pile and point foundations are easy to install and allow you to build a strong, reliable greenhouse;

- timber foundation Recently it has been used more and more often; it can be equipped even by not the greatest professional in the field of construction. The tree will require pre-treatment with antiseptics, but a greenhouse with such a foundation can be easily moved from one place to another - ideal for growing vegetables.

No. 6. Types of greenhouse coverings

It is easy to notice that the largest area of the greenhouse is occupied by the covering material, so summer residents pay maximum attention to its choice. Currently the following materials are actively used:

- regular and reinforced polyethylene film;

- glass;

- polycarbonate

Each of these materials copes with its direct functions differently.

Glass cover

Previously, glass was almost the only suitable material for arranging a greenhouse. Today everything has changed, but it continues to be used due to the following advantages :

- good light transmittance;

- high thermal insulation characteristics;

- resistance to temperature changes and chemicals;

- durability;

- aesthetics.

Minuses:

- heavy weight, requiring a very good frame;

- fragility. Hail can damage the material, and using laminated or tempered glass is too expensive;

- long and labor-intensive installation process;

- lack of a filter against infrared radiation, which can be harmful to some plants.

Glass is chosen with a thickness of at least 4 mm . The larger the sheets, the higher the light transmission (the area of the frame decreases), but the higher their fragility.

Polyethylene coating

It’s worth taking a look at any dacha cooperative to notice that plastic film is most often used to equip greenhouses.

Advantages:

- good light transmission and the ability to softly diffuse light;

- low price;

- ease of use and low weight;

- protection of plants from light frosts (down to -30C);

- Suitable for greenhouses of any shape.

Flaws:

- rapid wear, especially at fastening points, so the film will have to be changed every year;

- accumulation of condensation film on the surface, which can lead to a number of diseases in plants.

For the low price and ease of use, summer residents forgive polyethylene for its fragility.

If you look at it, the material is presented on the market in several varieties:

- ordinary polyethylene film . Sold in rolls 120-300 cm wide, it requires special care when installing on a frame, since the slightest cut can soon increase significantly. It is better to seal especially dangerous places with tape to guarantee;

- PVC film is more expensive than polyethylene film, but is much stronger, can last 5-7 years, retains heat accumulated during the day well, and blocks infrared rays;

- reinforced polyethylene film can serve for several seasons in a row, as it is equipped with an internal frame made of fiberglass, polypropylene, twisted polyethylene or other materials. Can withstand hail and strong winds.

Polycarbonate cover

The most modern and price- and quality-balanced material for covering greenhouses is cellular polycarbonate. Please note that there is also monolithic polycarbonate on the market, but it is not suitable for greenhouses. Cellular polycarbonate has a special structure: inside it there are partitions (honeycombs) filled with air. This structure provides many advantages:

- high strength, 200 times higher than that of glass. Rain, strong wind and even hail will not harm polycarbonate;

- excellent light transmission and much better heat retention abilities than glass;

- ease of work, since the material bends well, is easy to cut and drill, and is light in weight;

- relative durability (up to 15 years);

- great appearance.

When choosing polycarbonate for a greenhouse, you should pay attention to the thickness : it should be at least 4 mm , and preferably 6 mm; for arranging the roof of a greenhouse, it is better to look for sheets 7-8 mm thick. Without special protection, the material does not withstand sunlight well, so there must be a protective layer - do not believe sellers who talk about using protective additives in bulk, this is all short-lived material. When heated, polycarbonate tends to expand, so experienced specialists recommend installation at a temperature of at least +100C and fastening the sheets overlapping.

Other materials for covering greenhouses

The following materials can also be used to cover the greenhouse:

- spunbond – non-woven material obtained from a polymer melt with the addition of stabilizers for resistance to ultraviolet rays. This is a dense white fabric, often called agrofibre. It has good strength, light transmission, high thermal insulation properties, is resistant to rotting, temperature changes and chemicals, and will last up to 5 seasons;

- plexiglass is a durable material, suitable for northern snowy regions. The downside is the high price;

- Fiberglass is made from polyester resins, reinforced with reinforcement, and retains heat well.

How to choose a REALLY GOOD greenhouse and not be disappointed

Everyone wants a greenhouse to be reliable, high-quality, and durable. It is also desirable that it be practical, easy to use and not cost as much as a fighter jet with full ammunition.

How to choose a greenhouse?

Here's what's important: 1. Durability

.

The greenhouse must be durable! So that the snow and wind do not break the greenhouse. 2. Durability

.

The greenhouse must be durable! So that it doesn’t “rust” and fall apart in a year or two. 3. Convenience

.

The greenhouse should be practical, comfortable and convenient! 4. Reliability

.

The greenhouse must be well equipped! 5. Frame design

. One-piece or prefabricated. Equipment. 6. The greenhouse should be “beautiful”! Whatever pleases the eye. 7. Polycarbonate

Let's consider sequentially all the components of the greenhouse.

Frame

The frame is the basis of the design of any greenhouse

, and from what material it is made will depend not only on the ease of use of the structure, but also on its service life. After all, the frame must withstand not only the weight of the coating (in our case, cellular polycarbonate), but also such additional loads as rain, snow and gusty winds.

STRENGTH

The greenhouse is subject to various loads: - loads in the form of snow. - loads in the form of tied plants. - loads in the form of wind.

The number of arcs in the greenhouse, the cross-section of the profile and the thickness of the pipe from which the arcs are made are responsible for ensuring that the greenhouse does not “fold” under the snow in winter, and in summer under the influence of the weight of the plants. It is the arcs that carry the entire snow load.

Let's look at it in order:

a) Number of arcs:

— arcs can be located at 0.67 meters, 1.0 meters and 2.0 meters.

— Greenhouses with arcs every 2 m are, as a rule, industrial greenhouses made of thick, large cross-section pipes.

— In country greenhouses, most often the arcs go through 0.67 meters and 1.0 meters.

— In a greenhouse 6 meters long, there are 10 arcs if they are spaced at 0.67 meters and 7 arcs if they are spaced at 1 meter.

Accordingly, the more arcs, the stronger the greenhouse, but also more expensive!

b) Pipe profile cross-section (ahh).

The profile comes in 10x10, 10x20, 15x15, 15x20, 20x20, 20x30, 20x40, 40x40, 60mm,

Accordingly, the larger the pipe profile, the stronger the greenhouse, but also more expensive!

c) Pipe thickness (s).

Today, pipes come in different thicknesses: 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm - country greenhouses are made from such pipes. You shouldn’t believe it when they say that a country greenhouse is made from a 1.2mm or larger pipe. This doesn't happen now. Greenhouses made of metal with a thickness of 1.0 mm are very rare; such greenhouses are expensive and are bought very rarely precisely because of their high cost. Just don’t compare a real greenhouse made of a 1.0mm pipe and what a girl manager who has never seen a greenhouse “in person” will say on the phone. Once again, there are greenhouses made of 1.0mm metal, they are strong, weigh a lot and are expensive.

Here is an example of the weight of a greenhouse frame without polycarbonate:

- a greenhouse 6 meters long, with arcs made of 40x20 pipe, 0.7 mm thick, with an arc pitch of 0.67 meters, the remaining elements are made of 20x20 pipe - such a greenhouse weighs at least 62 kg.

- A greenhouse with the same characteristics but a metal thickness of 1.0 mm in the arcs, mind you, only in the arcs, will weigh at least 86 kilograms.

For comparison, there are 2 types, one pipe is 0.9 mm, the second pipe is 1.0 mm. When both pipes are side by side, the difference can be noticed, but if there is only one sample and there is nothing to compare with, then it is very difficult to determine the thickness of the pipe by eye. The thicker the pipe, the stronger the greenhouse, but also more expensive!

The shape of the greenhouse also affects resistance to snow loads, but that will come later.

Further. In addition to snow, the greenhouse is affected by wind loads

The arrows indicate the direction of the wind. The direction marked with blue arrows is not dangerous for the greenhouse. In this case, the load falls on the arches, and there are many of them and they are strong.

Let's consider the second case. The wind direction is marked with red arrows. This is already worse for a greenhouse. In this case, stringers and polycarbonate sheets are responsible for the strength of the frame. Yes, it is the cellular polycarbonate sheets that also provide the rigidity and strength of the entire structure.

Advice:

choose a greenhouse with arcs made from a 40x20 pipe, it is twice as strong, and the cost is only 10-20% more expensive than a greenhouse made from a thinner 20x20 pipe.

Stringers are longitudinal metal strips that hold the arches so that they do not fall apart in different directions.

It is not only the number of stringers that is important, it is also important what section of pipe they are made from and what thickness this pipe is. We can responsibly state that a 10x20 or 15x15 pipe is not sufficient for our climatic conditions, unless of course the thickness of this pipe is 2mm, but this is unlikely to happen!

Thin pipe stringers (20x10 or 15x15) will not be able to provide the required structural rigidity; most of the load will be distributed on the polycarbonate, which may not be able to withstand this and then...... When using “thin” stringers (for example, a 10x20 pipe), the entire frame of the greenhouse turns out to be “liquid” .

Advice:

Stringers must be made of pipes with a cross-section of at least 20x20mm

.

The integrity of the elements is responsible for the strength of the greenhouse. The fewer seams, the stronger the frame. For example photo:

There is a very high probability that the stringer, consisting of 2 types of pipes, will fall apart during installation or after 1-2 years, when the spot welding rusts. You can scald the prefabricated stringer on all sides, then it will be strong, but this is time-consuming and expensive, so no one does it. Of course, a solid pipe has an undeniable advantage.

DURABILITY

Durability is the time that your greenhouse can stand and be in “working” condition. This time directly depends on the protection of the metal from rust. To protect metal from rust, it can be painted with various paints and primers, but the most reliable way is zinc coating. There is no point in considering greenhouses that are painted or coated with a primer - this is not relevant and you should immediately move on to galvanized steel. Galvanizing is the coating of metal with a layer of zinc to protect it from corrosion.

Pipes for greenhouses are made from sheets galvanized on both sides. Therefore, any galvanized pipe has a zinc coating on both the outer and inner surfaces. This is not an additional option or benefit, it is standard. The only difference is in the amount of this zinc. In country greenhouses, pipes with a zinc content of 80 to 180 grams per square meter are used. In industrial greenhouses, pipes with a zinc content of 275 grams per square meter are used. The cost of pipes depends on the amount of zinc and this difference is very noticeable.

It is not possible to visually distinguish and determine the amount of zinc; you should simply pay attention to the manufacturer and its history. See recommendations and reviews.

Often, in pursuit of a cheap greenhouse, some manufacturers save money and make greenhouses from pipes with a thin layer of zinc, because such pipes are much cheaper. They don’t care that a thin layer of zinc can be damaged when processing workpieces. And after a short time, the frame of the greenhouse, in damaged areas, will begin to rust. It is more important to get benefits, and today, and what will happen tomorrow does not bother them. Therefore, beware of unknown manufacturers and sellers of ephemera.

A galvanized pipe is not a 100% guarantee of rust protection. Galvanized pipes can be of high quality or low quality. The zinc layer also deteriorates. The zinc layer deteriorates if the pipes are processed incorrectly or insufficiently. Some unscrupulous manufacturers also save on pipe processing. For example photo:

Photo “good galvanized pipe” photo “bad pipe with white coating”

Galvanization is damaged; galvanization has a white coating; good galvanization

It is better not to buy a greenhouse with a white, rough layer of zinc that can be wiped off with your finger.

But do not confuse minor traces from drops that have dried on the greenhouse after rain and damaged galvanization.

Pay attention to what you buy!

Reliability

When choosing a greenhouse, pay attention to the components it is made of.

On the quality of welding of elements. Spot welding means there is a high probability that some elements will fall off on the way to your site. This happens very often. This is what it looks like:

Photo of a bad weld Photo of a good weld

All pipe joints must have minimal gaps.

Convenience

Depending on your requirements, you should choose the size and shape of the frame.

The forms may be as follows:

Arched arrow classic mid-lighter industrial mini

Photos of forms

Here the taste and color, as they say, there are no comrades. We can only highlight a few points and give a few recommendations:

-arched shape is the most practical. Optimal ratio of strength and cost of materials.

-arrow-shaped - the best protection against heavy snow; the snow does not linger on such a greenhouse and melts away on its own. The greenhouse is also higher and it is more convenient to grow tall crops in it.

-classic house - this is for adherents of the classics.

-midlider – strong, due to additional jumpers, greenhouse. In this greenhouse you can create the desired climate conveniently and very quickly. Such a greenhouse can be built even 100 meters long and the ventilation will still be excellent.

-mini – greenhouses are not large in size. Especially for growing certain crops (for example, only for peppers) or for use in places where free space is limited.

-industrial – greenhouses for industrial purposes. Year-round use. To make money.

Height:

The height of the average person is 1.7-1.8 meters. Accordingly, the height of the greenhouse, for a comfortable stay in it, must be at least 1.9 meters inside. It is considered optimal, and this has already been time-tested, that the height of the greenhouse is 2.0 meters. It should be understood that this is the height at the highest point.

The height of the greenhouse should be comfortable and this must be provided for. There are greenhouses with a height of 1.6; 1.7; 1.8; 1.9; 2.0; 2.1; 2.3; 3.0; 4.7; 5.5 meters.

It happens that in pursuit of savings, sellers declare a greenhouse height of 2.0 meters, but in fact they sell a greenhouse with a height of 1.7 or 1.8 meters, saving on the consumption of metal for the frame and completing such a greenhouse with short, cheaper polycarbonate sheets. This way you can save (or get additional income) about 10-15% of the total cost of the greenhouse. It will not be comfortable for an adult to walk upright in such a greenhouse. In the event of a complaint about an unreliable height, the seller can refer to the fact that this is the declared height, taking into account the installation of the greenhouse on the beam or taking into account the height of the lugs. We need to check everything! Measuring the height of the greenhouse with a tape measure is not difficult. Take 2 minutes and protect yourself from the bitterness of disappointment.

It’s a completely different matter when you specifically chose a greenhouse of a reduced size, for example, for peppers 1.7 meters high. This must be a conscious choice.

Width:

Depending on how many beds you want to place in the greenhouse, you should choose the width. The standard is a width of 3 meters. Recently, people have increasingly begun to pay attention to greenhouses with a width of 3.5; 4 meters. There you can use wide doors to drive the walk-behind tractor inside, and also place the beds more conveniently.

Beds in a greenhouse 3 meters Beds in a greenhouse 4 meters

Frame design:

Frames come with all-welded ends and solid arches and prefabricated ones.

The fewer components there are, the stronger the greenhouse. The more components there are, the more difficult it is to assemble such a greenhouse, and the slightly higher the cost. The increased cost is due to the fact that there must be more hardware for assembly; a larger number of parts requires more manufacturing time, plus the additional cost of packaging. But there is also an advantage - a prefabricated greenhouse is easier to transport. If ordered, the assembly of such a greenhouse will cost 50% more than the assembly of an all-welded greenhouse.

Polycarbonate fastening

We advise you to pay attention to the design features of greenhouses, such as the presence of holes for attaching polycarbonate.

This is an important point. To fix the polycarbonate in the greenhouse there must be holes for its installation. There are greenhouses that already have such holes, and there are greenhouses that do not have these holes. There are two options:

- In the greenhouse, all the holes for attaching polycarbonate are already ready. Then you, or the assembler, simply lay the polycarbonate sheets on the already assembled frame and screw the screws into the finished holes.

- The greenhouse does not have holes for attaching polycarbonate. In such greenhouses, self-tapping screws with a hex head and a drill are often included. Yes, you can drill through metal and press polycarbonate with such a self-tapping screw. But you need to take into account that a self-tapping screw is not a drill, it is not so sharp, it slides off the drilling point. The self-tapping screw slipped and a hole was made in the polycarbonate in an unnecessary place. You can, of course, drill holes in advance before mounting. But this is additional work; you need to first mark and then drill more than 200 holes for a 6-meter-long greenhouse.

Advice:

choose the option that is less labor intensive, i.e.

greenhouse with ready-made holes. Let manufacturers use special equipment to drill holes in the right place. Moreover, this does not affect the price! Greenhouses come in various configurations: large and small handles, latches, screws, screws, washers. This affects the price. But it’s not a fact that the most expensive is the best. You just need to clarify what is included in the kit. The difference in cost between a greenhouse with large handles and washers and a greenhouse with the cheapest equipment is not significant at all.

beauty

You should outwardly like what you are buying. That it would bring joy.

You should not buy without at least seeing a picture of the greenhouse you are planning to purchase. They will tell you in words that they are all the same and look similar. Don't believe it. They are different!

Polycarbonate

Polycarbonate is the most painful topic today.

Why? Because a lot of deception is now happening when selling polycarbonate. They promise one thing, but in reality they deliver something completely different.

What you need from polycarbonate: 1. So that it doesn’t fall apart in a year

2. To transmit light well

3. To have “normal” thermal insulation.

Let's understand, but briefly:

Polycarbonate has 2 important characteristics: - thickness - density.

Thickness.

The thickness of the polycarbonate primarily affects the thermal insulation, and secondly, indirectly, the strength of the frame itself.

For country greenhouses, polycarbonate with a thickness of 3–4 mm is suitable. For industrial ones, which are heated even in winter, polycarbonate with a thickness of 8-10mm is used.

Advice:

for country greenhouses, take 3.8-4mm polycarbonate.

Specific gravity (density):

This indicator is much more important. This characteristic shows how much 1 square meter of polycarbonate sheet weighs. In this case, the wall thickness determines everything!

The thicker the leaf wall, the higher the weight of the leaf. For example, take 2 sheets 4mm thick. We can say that these are 2 identical sheets, but if the wall thickness of one is 2 times greater (as in the picture), then the weight of such a sheet will also be 2 times greater, and it will also be 5 times stronger.

Once again, the thickness of the polycarbonate is not the most important indicator for a good, reliable greenhouse. For equal thickness, a sheet with a higher specific gravity is preferable.

Now many people sell greenhouses, citing only one characteristic for polycarbonate - thickness. Standard – 4 mm. But, an uninformed buyer receives 4mm thick polycarbonate, only it is of the lowest weight and the cheapest. It is very soft, “flimsy”, “like a blotter”. After all, this was not discussed during the purchase!

If you have a limited budget, it is better to buy 3mm thick polycarbonate with a specific gravity of 0.4 kg/sq.m. than to buy 4mm thick polycarbonate with the same specific gravity of 0.4 kg/sq.m. Because, in this case, the walls of a 3mm thick sheet will be thicker than a 4mm sheet (there are fewer of them and they are shorter, and the total mass of material spent on both sheets is the same).

Advice:

If you want a good one, take 4mm polycarbonate with a specific gravity of 0.6 kg/m2.

Guaranteed that you will be satisfied! Polycarbonate must be protected from UV (ultraviolet) radiation. We will not go into details; this is impossible to check without special equipment. Just remember, a UV coat is a MUST! Without this layer, the sheets will turn yellow, crack and crumble after 1-2 seasons.

Don’t believe the words that skilled salespeople will tell you, they have learned, they have 1000 answers prepared. CHECK.

This is what happens to polycarbonate without UV protection after 1-2 years.

Belarusian producers are constantly monitored and inspected by government agencies. Making a low-quality product means getting into huge problems and huge fines. Belarusian manufacturers try to meet all their declared characteristics.

Now a lot of polycarbonate comes from Russia. Russian manufacturers do not always sell high-quality goods, and intermediaries do not always want and are ready to buy high-quality material; it also costs more. You can make much more money on cheap, low-grade material if you pass it off as high-quality material.

Signs of low-grade polycarbonate made from recycled materials are: - turbidity - blue - lack of manufacturer's markings.

Each manufacturer labels quality products. If it is not written who produced these sheets, then we advise you to refrain from purchasing such a product.

Don’t take the seller’s word for it, you can say anything, all products must be signed by the manufacturer. The manufacturer should write the thickness, weight, density, dimensions on the cellular polycarbonate sheets themselves; if this is there, great. If not, it’s worth thinking about why?

How to check the density of sheets - place the rolled roll on the scale.

Size. Standard polycarbonate sheets are 6 meters long. When selling a greenhouse

HOW TO INSURANCE AGAINST FRAUD?

In order not to regret the money and time spent later, approach the problem seriously.

The manufacturer is responsible for product quality. Any seller, in the event of a warranty case, refers to the manufacturer or the manufacturer’s examination. Ask yourself a question and try to find the answer: - “If the manufacturer is not listed, is not known, then who to contact?”, “If the manufacturer is located in another country, how do you think the issue will be resolved and will it be resolved at all?”

Choose trusted manufacturers and sellers. So that if a problem arises there is somewhere to turn. Most likely, when choosing products from a well-known manufacturer, there will be no problems. Find out who the manufacturer of the goods is. If you are offered a greenhouse from an unknown manufacturer, we advise you to be even more careful in checking the quality and declared parameters.

Warn the seller in advance that you will check the profile size and refuse the purchase if the characteristics do not match. This will not scare away a conscientious seller, but you will insure yourself against a deceiver.

Warn that you will weigh the polycarbonate sheets on scales and if they do not correspond to the declared density, refuse to purchase. (even if you don’t weigh it). How to calculate specific gravity (density): A standard polycarbonate sheet has a size of 2.1x6 meters, i.e. area is 12.6 square meters. Next, weigh the polycarbonate sheet. We make a calculation.

A simple formula to check: sheet weight (kg)/12.6 (sheet area) = density of 1 square meter. Those. if you were told that the density is 0.6 kg/sq.m. You weighed the sheet and its weight was 7.56 kg. 7.56/12.6=0.6 - that's right. It happens differently: You are told the density is 0.6 kg/m2, you weigh the sheet, and the weight of the sheet turns out to be 6.45 kg. Calculation: 6.45(sheet weight)/12.6(sheet area)=0.51 kg/sq.m. DECEPTION! There are exceptions when a polycarbonate sheet is sold without a bottom protective film; if there is no film, the weight of the sheet is accordingly 0.35 kg less.

Don’t be lazy and carefully study the properties of the product offered.

Carelessness during inspection and agreement with an unscrupulous or unqualified seller will result in unpleasant surprises during operation.

What should you buy additionally:

- The first thing you should spend money on is to buy end profiles for polycarbonate. They are designed to protect polycarbonate so that dirt, dust, flies, and worms do not get into the open honeycombs.

:

This type of polycarbonate takes on the ends in a short period of time.

Correct installation involves the use of steam-hydro insulating tapes and an end profile.

The profile is very cheap and you shouldn’t skimp on it.

- Punched paper tape – designed to protect the ends of polycarbonate; it is glued to open honeycombs before installing the end profile.

- Rubber seal for ends.

Designed to get rid of possible gaps between the frame and polycarbonate.

- Additional side window. Designed to improve air exchange in greenhouses longer than 6 meters.

- Automatic for ventilation of greenhouses. Designed for automatic opening and closing of the window depending on the temperature inside the greenhouse.

- Well, then everything your heart desires: -automatic watering -garters -beds -auto-darkening -mosquito nets -heating -lighting -and much more.

We hope that our advice will help you make the right choice of greenhouse in order to grow a rich harvest in it. Go to the greenhouse catalogue.

No. 7. Greenhouse shape

To ensure a good harvest, it is not enough to choose a suitable frame and covering material; you also need to find the optimal shape. The most common options:

- arched greenhouses , as well as domed and teardrop-shaped ones, retain heat well, are easy to arrange, do not contain sharp corners, therefore they require much less covering material, and precipitation does not linger on them. Such structures can be transformed, but they are limited in the choice of coating - mainly polycarbonate is used. In addition, access to the outer beds will be difficult;

- greenhouses with a gable roof will require more material for arrangement, but the area for planting in them is significantly larger. The design provides excellent lighting even under cloudy skies, withstands snow loads well, but is more expensive than the arched one;

- lean-to greenhouses are often installed near the wall of the house, which allows for significant savings. It is better to direct the roof slope to the south side;

- A pyramid greenhouse is an option for those who love everything unusual. The designs are complex in execution and are in demand among gardeners;

- polygonal greenhouse - an impressive and expensive structure, but due to the presence of a large number of sides, the structure warms up well at any time of the day.

Ferrous rolled metal

The materials for frame construction are mainly used:

- equal corner,

- Taurus;

- Channel;

- Square pipe (the most reliable option).

The frame for a greenhouse made of rolled metal is usually made with your own hands using manual bending devices (if the shape of the greenhouse is arched) and welding joints of the elements. This type of material is extremely durable and reliable, and has the highest load-bearing capacity. Recommended for use in regions with significant snow load. The main disadvantages are the need for anti-corrosion treatment - painting, which is done once every 2-3 years and the labor-intensive nature of metal processing.

There are many solutions for a greenhouse frame made from a profile pipe, drawings and diagrams indicating dimensions, as well as recommendations for connecting elements for self-production. The most popular and easiest to implement form is a house with a gable roof and its variations. Modern industry produces quite a lot of ready-to-assemble kits. It is quite simple to install such a greenhouse frame from a profile pipe with your own hands.

Dutch model of a greenhouse, in the photo the walls of the metal frame expand towards the bottom

No. 8. Greenhouse dimensions

Everyone decides for themselves whether to purchase a ready-made greenhouse or build it themselves, what type and size it should be, but when choosing, take into account some useful recommendations. The optimal width of the greenhouse is 3-3.5 m ; if it is narrower, then the required number of beds will not fit, and you will have to save on aisles. The length can be any, a common option is 4-6 m. It is not recommended to make a greenhouse longer than 6 m - it will be more difficult to care for the plants. It is better to make two greenhouses 6 m each than one 10-12 m. The optimal height to the ridge is 2.5 m, the height of the low wall is 1.5 m. The doors should be wide enough (about 1 m) so that you can easily was to stop by the greenhouse with a garden cart.

No. 9. Attention to the package

If you, like many summer residents, have opted for a ready-made greenhouse , then when purchasing, pay attention to what is included in the kit. In addition to the frame and covering material, there must also be seals, as well as doors and vents. The location of the latter is of great importance: in the summer heat, without normal ventilation, the plants in the greenhouse will burn, so ideally the doors should be on both sides, and the presence of windows is also necessary. The prefix “economy” in the name of the greenhouse model means that the greenhouse can only be used in warm weather or its design can be significantly modified, since often the step between the arcs is too large. A responsible manufacturer will always provide the design with assembly instructions.

No. 10. The best greenhouse manufacturers

The secret to choosing a high-quality greenhouse is simple: do not buy at too low prices (often these are Chinese-made products of very low quality) and trust large manufacturers, and it is advisable to contact a company store or the company’s website, and not an intermediary. Little-known fly-by-night companies are not the best option - they may close soon, you won’t be able to file a claim against them, and you won’t be able to buy a new greenhouse with the couple of thousand rubles you saved.

Among those presented on the domestic market, the products of such companies perform best:

- Volya is the largest domestic enterprise in the sector, operating since 1993, producing polycarbonate greenhouses, film greenhouses, various materials and accessories for greenhouses, as well as industrial greenhouses and a number of related products and irrigation systems;

- produces only polycarbonate greenhouses. The frame is distinguished by a reliable zinc coating, firmly welded, polycarbonate is represented by products from different manufacturers. Product warranty 7 years;

- “Factory of ready-made greenhouses” has its own production of polycarbonate with a thickness of 4 to 16 mm and steel square pipe. Warehouses are located in all regions of the country;

- “People's Greenhouse Plant” independently produces a metal square pipe for constructing a frame; ready-made greenhouses are completed with domestically produced polycarbonate 4-10 mm thick with a protective coating. The range also includes a number of related products;

- "Rus-Teplitsa" offers easy-to-install greenhouses made of painted and galvanized pipes coated with polycarbonate;

- "Greenhouses of the North" . The company has been operating since 2010, producing frames made of galvanized profiles coated with polycarbonate in various shapes and sizes.

The selection of ready-made greenhouses is impressive, and gardeners with “hands on” can try to build a greenhouse themselves. Be that as it may, when choosing and constructing a greenhouse, take into account the nuances described above.

The article was written for the site.

Tags:Greenhouse

Classification according to the method of attachment to the ground

Polycarbonate greenhouses have significant windage and must be securely fastened to the ground. For their fastening, special fittings are used, included in the delivery kit or purchased separately.

Installation on the ground without a foundation

The absence of a foundation allows:

- quickly assemble the structure;

- do not spend money on materials for the foundation;

- it is easy to dismantle the structure at the end of the season.

To install greenhouses on the ground without a foundation, special elements are used, the so-called. lugs - T-shaped structures buried in the ground, to which frame elements are attached.

The disadvantages of installing without a foundation are:

- heat losses reaching 10%;

- penetration of agricultural pests.

Foundation installation

When installing on a foundation:

- the design is more resistant to strong gusts of wind;

- the greenhouse retains heat better;

- the penetration of insects and other pests is difficult.

To attach the greenhouse frame to the foundation, the following are used:

- anchor bolts;

- rigid galvanized corners.