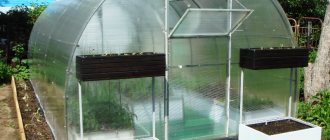

Some owners of summer cottages and garden plots do not consider it necessary to build a foundation for a greenhouse, but install the frame directly on the soil. However, if you do not install the greenhouse on a foundation, its service life will be significantly reduced. Therefore, even lightweight polycarbonate structures should be placed on a foundation. Regardless of the type of foundation, temporary and permanent structures can be installed.

Selecting and installing a foundation for a greenhouse.

The foundation for a greenhouse is the basis that will ensure the stability, integrity, and strength of the building.

Whether you build with your own hands or have the opportunity to buy a ready-made structure and carry out independent installation on the site, the site must be equipped in accordance with the specifics of the structure. What is the best foundation for a polycarbonate greenhouse?

In the article we will tell you why you need a foundation, what is the best foundation for a greenhouse made of polycarbonate, glass, with a frame made of timber, for metal structures, light buildings made of boards, film, old window frames, etc. And we will provide detailed step-by-step instructions on how to make a foundation for a polycarbonate greenhouse with your own hands.

Wooden foundation for a greenhouse. What is the best foundation for a polycarbonate greenhouse?

The foundation ensures the reliability, safety and stability of the building. But light structures on the site are temporary, so the question reasonably arises: in general, is a foundation made of polycarbonate or other materials needed for a greenhouse and why? The answer is clear – it is needed, it is a base that performs a number of important tasks:

- fixes the greenhouse frame, holds it during gusts of wind, heavy downpours, when the area is flooded and from other atmospheric surprises;

- isolates the structure from contact with the ground, protects materials from the harmful effects of the soil, significantly extends the service life of the building;

- helps retain up to 10% of heat inside, promotes a favorable microclimate and saves on heating;

- prevents fog and cold air currents from penetrating into the greenhouse;

- helps protect the structure and crop from harmful insects and rodents.

What kind of foundation is needed for a polycarbonate greenhouse?

How to make a foundation for a greenhouse with your own hands, photo of a lightweight structure on tape.

Types of foundations for greenhouses.

There are 4 types of foundations in total and each of them can be equipped for a greenhouse:

The choice of foundation depends on the specifics of the soil on the site, its relief features, the scale of the construction, climatic conditions in the region, and much more. etc. Next, we’ll talk in detail about each type of foundation for a greenhouse and the materials for its construction.

Strip foundation is the most popular base for almost all types of buildings. According to the construction principle, it can be:

- not buried - lying on solid ground, it is enough to remove the top, fertile layer, usually serves as a grillage for pile foundations;

- shallow - placed in a trench 700-800 mm deep, on a specially prepared cushion; such a device is not advisable if there is high groundwater in the area;

- recessed - recessed 200-400 mm below the soil freezing level, this parameter is individual and depends on the region, the average is 1200-1400 mm, exact information can be found in the table.

Note: We will not delve into the technical nuances, but when installing a strip foundation, it is important to follow the rules: in the cross section, the height should be greater than the width (thickness), and the total length of the structure is in a proportion of 1.5-2:1 to its width.

What kind of foundation for a greenhouse?

Foundation for a greenhouse made of brick, diagram of the correct foundation.

Optimal ratio, depth and height: 700:300-400 mm. Before making a foundation for a greenhouse, you need to decide on the materials for the tape:

- Monolithic concrete, consisting of a reinforcing frame and filled with mortar.

- The base is made of special ready-made concrete blocks interconnected by reinforcement.

- Rubble structure made of stones and clay.

- A strip of bricks, foam blocks, it is advisable to still pour a monolithic concrete base and build a base on it.

- Construction from scrap materials: thick timber, bottles, logs, etc.

Wooden foundation for a greenhouse.

A non-buried foundation for a greenhouse made of polycarbonate, made of timber on concrete supports.

Good to know: It’s faster and cheaper to make a foundation for a greenhouse from timber with your own hands. But the tree does not tolerate physical, chemical and biological influences well; the soil becomes saturated with moisture, fungus appears, and signs of rotting appear. To extend the service life, it is better to make a foundation for a greenhouse made of timber from hard wood, for example, larch; the frame must be impregnated with protective compounds, covered with bitumen mastic, machine oil, and covered with roofing felt.

Which foundation is better for a greenhouse?

One of the inexpensive ways to install a polycarbonate greenhouse.

A slab foundation is a strong, reliable foundation for construction in areas with high groundwater and unstable soil; pyramids in the sand have just such a base. The greenhouse can be installed on two types of slabs:

- Floating - a concrete platform lies almost on the surface.

- The base with stiffeners is a combined structure made of concrete strips, with a monolithic slab attached to them on top. If a strip foundation must necessarily be closed along the contour, then in the case of a slab this requirement is absent.

To organize the slab, a pit with a depth of 300-700 mm is dug, a sand-crushed stone cushion is laid on the bottom, covered with geotextiles, roofing felt, this helps to avoid siltation. The optimal thickness of the foundation depends on the expected loads: for outbuildings and light greenhouses - 100 mm, for large stationary greenhouses, designed for the winter period, 200-250 mm.

As a rule, a slab foundation for a greenhouse is made of concrete, but tires filled with earth and other available materials can be used.

What is the best foundation for a polycarbonate greenhouse?

Scheme of arrangement of the slab base.

Columnar.

A column foundation is a simple, inexpensive, quick way to build a foundation. The pillars are deepened by 700-800 mm; for small buildings they may not be sunk into the ground. The optimal distance between pillars is 1.5-2.0 m.

A columnar foundation for a greenhouse can be made from the following materials:

- Bricklaying, rubble stone.

- Use ready-made T-shaped concrete pillars.

- Install, reinforce and fill metal, asbestos and roofing felt pipes with mortar.

- Foam blocks, flat rubble stones, even wooden stumps are suitable for organizing a non-buried columnar foundation.

What is the best foundation for a polycarbonate greenhouse?

Pole arrangement diagram.

A significant disadvantage of a columnar foundation for a greenhouse is the gap between the ground level and the base of the building, through which cold gets inside. Such conditions contradict the functionality of the building, so the perimeter should be insulated: make a brick frame, cover it with boards, etc.

Which foam block is suitable for the foundation of a greenhouse.

The foundation for the greenhouse is made of foam blocks, a high base will protect the timber from harmful influences.

A pile foundation is an ideal solution for building a greenhouse on a swampy or uneven area. It is installed below the soil freezing level by 200-300 mm. There are 2 types of piles:

- driven - pipes, sleepers, channels;

- screw - poles equipped with blades that are immersed in the ground in a circular motion using a drill or special equipment.

Important: The pile type of foundation does not require concrete work, the time spent on installing the foundation is much less than for other types, but it is very difficult to screw the supports strictly vertically with your own hands, so it is recommended to use the services of specialists. If you are making a pile foundation for a greenhouse yourself, if the geometry of the support is violated, you should pull it out and screw it in another place.

The optimal installation of piles is 1.5 - 2.0 m from each other. After installation, the upper heads are sawn to size and tied together with a grillage, which ensures the integrity and strength of the structure. The grillage can be made of timber, sleepers or monolithic concrete.

What is the best foundation for a polycarbonate greenhouse?

Organization of a pile foundation for a greenhouse with a monolithic concrete grillage.

Let's summarize.

If you choose bases for glass structures, film buildings, bases for structures made from old window frames, ready-made prefabricated metal structures, foundations for a polycarbonate greenhouse, which one is better, it is impossible to say with any certainty. You should rely on geodetic research, soil quality, dimensions and materials; the weight of the building and climatic conditions depend on them.

For capital warm buildings, it is recommended to make a strip foundation - this option is suitable for almost all conditions. Temporary and lightweight greenhouses, if you want to save money, can be safely installed on a point columnar base.

What is the best foundation for a polycarbonate greenhouse?

Internal structure of a strip base for a greenhouse.

Preparing to build a foundation

To begin with, it is important to choose the right place for the greenhouse, determine its size and select the appropriate type of foundation, based on all the data about the future construction and the soil on the site. Next, you should draw up a drawing plan for pouring the foundation, including accurate measurements and calculations. Based on this plan, the necessary building material will be selected and its quantity calculated.

A greenhouse made of HDPE or PVC pipes, covered with polycarbonate, is rarely heavier than a hundredweight. Therefore, a shallow and narrow “ribbon” (monolithic or prefabricated), columnar, pile or pile-grillage foundation is suitable as a foundation for it.

You can also use metal pins, which must be concreted into the pillars of the concrete foundation, but pouring the pillars separately is a long and labor-intensive task, although it saves mortar.

A greenhouse made of pipes on concrete rods is a rather complex and impractical solution

Foundation for a polycarbonate greenhouse - photo and step-by-step instructions.

We will build a strip foundation for the greenhouse, size 3*6 m, with a high brick base and insulation around the perimeter.

We make a drawing.

Before building a greenhouse, you should choose a project or make a drawing with your own hands, indicating the dimensions and main components of the structure. The materials, their quantities, and the main stages of work are also determined here. It is better to use a standard project and adapt it to your own conditions.

How to make a foundation for a greenhouse.

Typical ergonomic greenhouse design.

We choose a place.

The choice of location depends on the individual characteristics of the site. It is better to build a greenhouse on the southern and most windless side, behind the house. We clear the site of debris, tree roots, and weeds. We fence the perimeter with pegs, tighten the rope, and check the geometry. The diagonals must be equal. Remove the top, soft layer of soil.

Foundation construction.

We dig a trench 800 mm deep around the perimeter. Level the bottom. We cover it with roofing felt in 2 layers, you can lay geotextiles. We fill in crushed stone, sandstone, layers of 100-200 mm, and compact the pillow.

We install the reinforcing frame. There will be two horizontal belts, two parallel rods in each, vertical ties every 300-500 mm. The reinforcement is corrugated, with a cross section of 8-12 mm. We place pebbles, 50 mm high, or stands on the bottom.

We lay 2 lower horizontal rods, the distance between them is 200 mm, we lay smooth thin rods perpendicularly to better preserve the shape of the frame. At the corners we bend the reinforcement to the adjacent side, extending it to 500 mm or more. Also on the other hand, a double overlap is obtained to strengthen the structure. We drive in vertical rods and tie the parts together with wire. We mount the upper horizontal belt in the same way.

What is the best foundation for a polycarbonate greenhouse?

How to knit reinforcement correctly.

The distance between the horizontal belts depends on the height of the foundation for the greenhouse. If the tape is 400 mm high, then there should be a distance of 300 mm between the upper and lower rods, +50 mm per concrete layer on each side. The width is calculated in the same way, if the total dimension is 300 mm, then the frame is 200 mm. Don’t forget, the height must be greater than the width of the tape.

We install formwork in the trench; these can be knocked together boards, moisture-resistant plywood, or durable plastic panels. For the correct geometry, we make a tie along the top of the sheathing with bars, and install spacers on the outside, they will hold the structure when pouring concrete.

Note: In order to retain heat in the greenhouse as much as possible and protect the building from harmful influences, the height of the foundation must be calculated so that it rises 1/3 above ground level.

The tape should be poured at once to avoid the formation of seams and cold bridges. Proportions of solution for the foundation for a greenhouse: cement (binder) - 1 part, sand - 3 parts, crushed stone, fraction up to 40 mm (preferably 10-20 mm) 4-5 parts, water 4-5 parts, until the consistency of thick sour cream. First, the dry ingredients are thoroughly mixed, then water is added.

What is the best foundation for a polycarbonate greenhouse?

The photo shows how to properly fill the base for a polycarbonate greenhouse with your own hands.

Pour the mixture into the sheathing, tamp it, remove the air. Bubbles in hardened concrete will lead to destruction. The solution needs to harden, until it is fully formed - 4 weeks, only then load the foundation.

We remove the formwork, glue the sides with roofing felt or coat them with bitumen mastic in 2 layers, attach foam sheets on top, you can order insulation - sprayed polyurethane foam. We cover the top of the sheets with 2 layers of roofing felt, the seams overlap 100-200 mm, seal with tape, and weld with a blowtorch. We backfill the soil. For horizontal waterproofing, roofing felt is laid on top of the foundation under the greenhouse.

How to install a polycarbonate greenhouse on a foundation.

Along the fresh concrete in the center of the tape, in the corners and every meter, it is recommended to install and extend out reinforcement for metal structures or special corners with welded anchors for fastening the bars; the greenhouse frame will be attached to them. If the mortgages were not provided during the process of pouring the foundation for the greenhouse, then the frame can be fixed with anchor bolts.

Wooden foundation for a greenhouse.

Method of attaching the frame to the foundation.

Installing a polycarbonate greenhouse on a foundation has one more important step: in order to avoid drafts, ice, and freezing, the gap formed when the base of the greenhouse adjoins the foundation is sealed with elastic sealants, and a gasket with rubber edges is placed in the gap. This is especially important if the structure is insulated and you plan to grow crops in it all year round. When setting up a winter greenhouse, do not forget about additional lighting and heating.

What is the best foundation for a polycarbonate greenhouse? What is the best foundation for a polycarbonate greenhouse?

Which one is better to choose?

Taking into account financial capabilities and the size of the greenhouse, preference is given to the most suitable foundation option:

- Made of wood. For greenhouses of small and medium dimensions, a foundation made of wooden beams is suitable; it is chosen by summer residents who use greenhouses only in the summer months.

Pros:- low cost;

lightness and mobility - can be moved to a new place;

- simple installation (in one day) and operation;

- good thermal insulation qualities.

- Concrete strip. The option is difficult to install and expensive; when fully assembled, it is heavy and has low thermal insulation properties. Ideal for the most bulky and heavy greenhouses or for common ones made of polycarbonate on a metal frame.

Pros:- durable;

guarantees reliability of the entire structure;

- resistant to increased humidity, frost, bad weather.

- Columnar or pile. An inexpensive columnar option is appropriate in combination with rigid piping followed by insulation of the base. The base is strong and durable.

The pile type is indispensable on soils with complex terrain and moving soils. Installation is simple and accessible in any weather; you can disassemble and “move” structural elements to other installation points. Among the disadvantages, experts include the tendency of metal piles to corrosion and the need for additional piping. - Made of concrete and brick. Brick and concrete foundations are suitable for large and heated greenhouses.

Pros:- minimum weight;

simple installation;

- availability of materials in stores;

- resistance to deformation and pressure of the structure.

- Blocks or slabs. The block type has sufficient strength, is resistant to negative weather conditions and is easy to install, but does not retain heat well. This is an affordable budget option.

Durable slabs have the following advantages:- the strongest possible fixation of the entire structure;

durability;

- excellent durability on any soil;

- ideal protection of the inside of the greenhouse from bad weather and pests.

- high costs for materials and installation;

- heavy weight;

- additional insulation is required.

The disadvantages include a short service life, especially in climates with high humidity. Low strength is sufficient for structures made of lightweight materials such as polycarbonate. Not suitable for use in cold season.

Installation should be carried out step by step in compliance with technology.

The disadvantages include the ability to accumulate moisture with further destruction. In cold climates, additional insulation is recommended. This is an expensive option.

The disadvantages include:

Experts also recommend installing a drainage system in the greenhouse and monitoring the microclimate.

Why do you need a foundation for a greenhouse?

There are several reasons to build a polycarbonate foundation for a greenhouse:

- The foundation ensures the stability of the greenhouse. If not secured to the base, the structure can easily be torn off by strong gusts of wind or knocked over. If it is intended to erect a large stationary structure, then the construction of a foundation is a prerequisite;

- Greenhouses installed on the base of a wall are protected from contamination, so such a structure looks more solid, polycarbonate sheets do not need to be buried in the ground, and its lower part does not suffer from moisture;

- The foundation protects plants from late frosts in spring and early frosts in autumn;

- In a greenhouse on a foundation, it is easier to protect the interior space from the invasion of pests and weeds.

Functions and features of the foundation for a greenhouse:

A greenhouse in the garden, built on a solid foundation, will be more reliable in operation. In addition, it has a number of other advantages:

Functions and features of the foundation.

- The greenhouse will stand firmly on the ground, which means it will not be carried away by strong winds.

- Garden pests will not reach the plantings.

- The building on the foundation will rise above the ground, and this will reduce the percentage of heat loss.

- Plants will be completely safe from precipitation and frost.

However, when choosing the type of base, you should also take into account the dimensions of the greenhouse itself. For small greenhouse boxes, a foundation may not be needed if the frame is stable, but for large buildings a base is necessary.

Modern materials for greenhouses require the creation of a rigid foundation

, therefore, it is advisable to build a monolithic or strip concrete base for them.

Types of foundations for polycarbonate greenhouses.

Usually a strip foundation is installed under the greenhouse, and it can be made from the following materials:

To decide which foundation is best to choose, you first need to decide on the scale of the structure and its purpose. A wooden foundation has the simplest design, good for small greenhouses, and is suitable if it needs to be moved.

Block and brick foundations are much more reliable and have greater advantages than wooden ones. But if you intend to make a solid structure, in the expectation that it will serve you for decades, it is better to make a combined strip concrete-brick foundation. Such a foundation is especially good to build in areas with marshy soil to limit the access of moisture into the greenhouse from the outside.

Tools and materials

To build a block base you may need:

waterproofing (in liquid form or in rolls);- reinforcement (if hollow blocks are used);

- hammer drill and grinder;

- concrete mixer (can be replaced with a construction mixer or an attachment for a hammer drill) and containers for concrete;

- shovel and wood saw;

- building level;

- trowel or spatula;

- marker, pegs and thread.

Technology for constructing a concrete-brick foundation for a greenhouse.

The construction of the foundation begins with the preparation of the trench. It is dug according to the plan outlined on the site, in accordance with the length and width of the future greenhouse. A depth of 20 cm is enough to grow seedlings in the spring and then transplant them into open ground.

What is the best foundation for a polycarbonate greenhouse?

If you plan to grow seedlings and herbs in the winter, then you might want to think about whether a deeper foundation is needed. By deepening it 40 cm into the ground, you will prevent freezing of the greenhouse. The width of the trench is not important, but should not be less than 20 cm.

When the soil on the site is loose, the inner walls of the trench are strengthened with formwork - it will prevent the earthen walls from collapsing during concrete pouring. It can be made from any available materials: old boards or plywood, and spread inside with transverse planks. The space between the formwork and the walls of the trench is filled with previously excavated soil and compacted.

If you are installing a very large greenhouse, you can raise the concrete foundation belt 20 cm above the soil level. Accordingly, the formwork must be raised to the same height. The upper edge of the formwork boards is leveled so that the brickwork laid on concrete does not warp.

A layer of gravel up to 5 cm thick is poured into the bottom of the prepared trench, moistened with water, and then filled with concrete.

Concrete proportions for the foundation:

- 1 part cement;

- 2.5 parts fine-grained sand;

- 4 parts filler (gravel or broken stone).

What is the best foundation for a polycarbonate greenhouse?

Concrete is poured in one day so that weak joints do not form in the base, through which moisture and cold can penetrate into the greenhouse. As concrete is laid, it needs to be compacted. Usually a vibrator is used for this, but for such a small structure this can be done by the simplest method: punch the concrete pour several times with a bayonet shovel so that the solution shrinks and becomes denser.

When pouring concrete, you can lay pieces of reinforcement, rod or wire along the entire perimeter in the longitudinal direction, which will further strengthen the base and prevent it from cracking.

The top layer of concrete is leveled, and anchor bolts are installed on its surface, onto which the greenhouse frame will be attached. The concrete will harden within a week, and if the weather is hot, it should be moistened with water from time to time during this time to prevent cracking of the concrete surface.

Construction of the brick part of the foundation.

A low brick wall is laid on an established concrete base. Its height varies from 20 to 40 cm - this is enough so that the lower part of the walls of the greenhouse is not splashed with dirt during rain, and so that the plants inside the greenhouse have sufficient access to light.

First, the corners of the structure are laid out, and then the wall space between them. Previously installed anchor bolts are located in the seams between the bricks, and all seams are tightly filled with cement-sand mortar.

What is the best foundation for a polycarbonate greenhouse?

Subsequently, the frame of the greenhouse will be screwed to the bolts using nuts, and, if necessary, they can be unscrewed and the walls can be replaced or repaired. But you can do it another way: instead of bolts, install embedded parts into concrete, and then weld the frame to them using a welding machine.

What is the best foundation for a glass greenhouse?

The final stage of work is the installation of a small blind area around the brick wall. Soil is selected along the entire perimeter to a depth of 3 cm and a width of about 30-40 cm, and the recess is filled with gravel and compacted. If you don’t want to fight weeds growing through the blind area, fill it with cement-sand mortar and level it with a slight slope from the wall. Rainwater will flow down the slope and will not flood the greenhouse.

Advantages of a combined foundation.

- Brickwork is always beautiful.

- A concrete foundation is a monolithic foundation, therefore the most durable.

- The concrete base can be used for repeated construction, including for heavier structures.

What is the best foundation for a polycarbonate greenhouse?

What and how to make a stationary base for a polycarbonate greenhouse most often depends on the availability of certain materials. But the main thing is that you are confident in the reliability and strength of the structure.

Monolithic slab foundation

Are you interested in a design that can provide stability even on soft soils and at the same time protect the greenhouse from drafts, pests and hypothermia? Have you decided to build a very large building suitable for growing vegetables on an industrial scale at any time of the year? If so, then in such a case a monolithic concrete slab as a foundation is the best choice. This is the most expensive, but at the same time the most reliable and effective option. The design of a monolithic concrete slab has no fundamental differences from a shallow strip foundation; you can see it in the image below.

Monolithic foundation diagram

Now let's look at the stages of creating such a foundation.

Step 1. Mark using pegs and rope. Particular attention should be paid to controlling the diagonals and perpendicularity of the sides.

Step 2. Dig a pit at least 50 cm deep.

Foundation pit

Step 3: Add layers of sand and gravel. Their total thickness should be 25-30% of the pit depth. Compact them and, if necessary, cover them with geotextiles.

Step 4. Install formwork around the perimeter of the pit. Fill the space between it and the ground with gravel.

Formwork diagram

Step 5. Install fittings and drainage pipe.

Laying reinforcement

Step 6. Pour concrete to the edge of the formwork. This stage is very important and requires a professional approach - it is necessary to ensure a perfectly even screed. Insert anchor bolts or other fasteners for the greenhouse frame.

Fill

Step 7: Wet the concrete for a week.

Step 8: Next, let the foundation slab set. This usually takes 3-4 weeks, but in warm and dry climates the process will go faster.

Step 9. Remove the formwork and fill the gap between the slab and the surrounding ground with crushed stone.

A good foundation for a polycarbonate greenhouse: which one is better.

What kind of foundation for a polycarbonate greenhouse?

The foundation for the structure must meet the criteria of durability and convenience. A durable foundation for a polycarbonate greenhouse. Only a thorough analysis of many parameters will help you choose which one is better. The size of the plot, the chemical composition of the soil and the depth of its freezing, the volume of the greenhouse and the duration of its use - all this needs to be analyzed in order not to waste money. Once all the information is presented in the form of mathematically precise values, you can start working.

Pros and cons of block support

Positive qualities include:

- quick installation;

- strength and durability;

- low thermal conductivity;

- the cost is lower than that of tape.

Among the disadvantages it should be noted:

- the difficulty of selecting products of the right size, since most often they have standardized indicators, which is why they may be too large;

- installation of some types will require the use of special equipment;

- for some types of blocks it is necessary to carry out external finishing, as they can absorb moisture, which is why they will begin to collapse;

- Suitable for medium and non-heaving soils.

How to make a foundation for a polycarbonate greenhouse using bricks.

Regardless of the chosen material, creating a foundation for a greenhouse begins with the formation of markings corresponding to the parameters of the structure. At the next stage, it is necessary to excavate the soil to a depth of 210 to 255 mm.

How to make a foundation for a greenhouse.

The bases for greenhouses are made from materials traditional for the construction of foundations.

The maximum value is taken only in the absence of severe frosts in the region. After this, fine gravel is added to the resulting pit and then leveled.

The final step in compaction is re-measuring. If the level of gravel is less than 50-60 cm, then in this case you need to fill it up to the specified value. The more accurately the gardener maintains this parameter, the less the greenhouse depends on changes in the soil level.

In the future, you should adhere to the sequence below:

- Concrete is prepared in the required quantity;

- Waterproofing of brickwork is carried out using roofing felt;

- Before laying the brickwork, all elements of the future greenhouse base should be fixed in the ground;

- It is recommended to use a building level to get rid of unevenness;

- Even a small space between the bricks must be filled with mortar.

Novice builders pay attention to the difficulties associated with correctly determining the size of the “pillow”. There are no universal values here, so you need to proceed from the dimensions of the future structure and the expected weight. The duration of use of the greenhouse plays an important role. For example, for a winter one it is better to make a smaller “pillow”, and for a year-round one – a larger one. This will prevent rapid wear.

Calculation of quantity and laying step

The calculation of the number of blocks depends on the type chosen, since FBS differ in standard sizes from the rest. Most often, the calculation is carried out using the formula:

K=Vf/Vb, where:

- K – number of required products;

- Vf – total volume of the foundation (m3);

- Vb is the volume of one block (m3).

For example, FBS 9-3-6 has a volume of 0.14 m3, and the total value for a base 2 by 6 m is 2.3 m3, then 2.3/0.15 = 16.42 (rounded to 16).

also use special calculators for calculations that are available on the Internet. In them you can enter the approximate dimensions of the foundation and blocks, from which the required number of products for the foundation will be obtained.

If the foundation of blocks is made solid (ribbon), then all parts of the structure are laid out according to the principle of brickwork (in a checkerboard pattern). For a columnar base, installation is similar. The distance between the pillars usually does not exceed 1-2 m, since the lower parts of the frame or grillage (crowns) can sag.

Which foundation is better for a polycarbonate greenhouse: strip structure.

Beginning gardeners and more experienced gardeners often cannot choose between two, as it may seem at first glance, equivalent options. The first alternative is represented by a strip foundation, which is one of the most durable.

What kind of foundation for a greenhouse?

A reliable foundation for a polycarbonate greenhouse can be a row of bricks placed on a concrete base.

At the same time, you should not think that by installing it you can make the greenhouse practically invulnerable. Its arrangement is advisable only when a year-round greenhouse is being built.

In other cases, a strip foundation is a waste of money. In addition to the minimum required greenhouse size, it is worth taking into account the climatic features of the region. Strong winds and harsh winters are another possible reason for a strip foundation.

In addition, you need to remember the following:

- Its creation begins with excavating the soil to a depth of 350 to 400 mm;

- After this, the dug base is filled with gravel and leveled;

- The stage ends with checking the evenness of the surface.

If we talk about pouring concrete, it is mixed exclusively by hand. After this, you need to carefully pour everything onto the base in one go and wait for it to dry. You can move forward only after checking the quality of the coating. The presence of cracks will indicate the heterogeneity of the concrete floor. Before starting direct pouring, you need to install the formwork and all the base fastening elements;

Polycarbonate greenhouse: clay foundation.

The second alternative is a clay base, which is mistakenly considered an insufficiently strong material. Experts say that the strength of a self-made structure largely depends on the physical parameters of the clay. The secret lies in the mandatory addition of sandstone (stone). Even with strong changes in temperature and humidity levels, even wooden structures will not lose stability.

What should be the foundation for a glass greenhouse?

It was this type of foundation that builders used in Ancient Rus'. This is proven by the fact that ancient Russian buildings with clay foundations are still preserved.

In addition to ease of installation and durability, clay is low cost. Thanks to this quality, a polycarbonate greenhouse can be installed with minimal financial costs. The key parameters here are 2: density (2750 kg per 1 cubic meter) and maximum compression ratio (400 MPa).

The recommendations below will help you create it correctly:

- Place the proposed area with pegs;

- A trench is dug taking into account the depth of freezing;

- From the lowest freezing point, 200 mm is deposited and a trench is dug;

- Stone is poured onto the leveled surface;

- Dilute the clay and pour it over a layer of stone;

- Lay out another layer of stone and repeat the filling as described above.

In this way, you need to fill strictly 2/3 of the height of the dug trench. The final stage of pouring is carried out using a mixture of slaked lime and clay in a 1:1 ratio.

An easy way: how to install a polycarbonate greenhouse without a foundation.

If there are favorable climatic conditions, it is possible to install a greenhouse without using a full foundation. At the same time, you should not think that the greenhouse literally just stands on the ground. In this case, you cannot count on any harvest. Properly organized preparatory work will help reduce the negative impact of the heavenly office.

What foundation to make for a polycarbonate greenhouse.

A greenhouse without a foundation can be installed independently. This installation will save significant money on the device.

There are several ways to securely secure structures on a site. The first involves installing not only the main base fastening elements, but also several additional ones.

The number of the latter is determined by the size of the structure. The second option is based on the use of a thermal insulation coating. It is installed strictly along the perimeter of the greenhouse.

Its advantages include the following characteristics:

- Resistance to prolonged exposure to moisture;

- Does not allow frozen soil to negatively affect seedlings;

- Durable - guaranteed service life is 2-3 years.

Paying attention to detail will help you avoid common mistakes when installing a protective coating. You need to make sure that all elements fit snugly together. A lit match will help with this. If the flame “dances” even a little, this indicates the need for additional thermal insulation.