A greenhouse built without a foundation will be cheaper, but it can shift or deform under the influence of its weight.

This is especially likely in swampy areas or where there are frequent heavy rains and winds. When building a greenhouse, it is necessary to weigh the arguments for and against the foundation. If the structure is reliable, it can be used for many years.

We will talk about the option of installing a greenhouse on piles in the article.

Why do you need a foundation?

First, let's figure out why a foundation for a polycarbonate greenhouse is needed at all. The question is really controversial, because the total mass of the frame and cladding of the structure rarely exceeds 150-200 kg and is unlikely to sag under its own weight in the summer. But in winter, when a lot of snow falls, this may well happen. And yet, unless we are talking about impressive buildings, comparable in size and weight to a good cottage, the risk of the greenhouse sagging under its own weight is not a factor determining the need for a foundation.

Beam foundation for a polycarbonate greenhouse

This factor becomes the protection of plants from sudden temperature changes. Night frosts in August-September are not uncommon, and their consequences for crops in greenhouses without a foundation can be very sad. Cold air entering through the gaps between the frame and the soil can lead to the death of some plants. In addition, their condition will not be well affected by a sharp cooling of the upper layers of soil in the greenhouse if there is no barrier between them (the layers) and the open ground. The foundation will be a good barrier against frost.

Important! Continuing the topic of protecting crops from the cold, it is worth saying that for greenhouses designed to operate in winter, the presence of a foundation is mandatory. Otherwise, the efficiency of the heating system will be extremely low, and heating costs will be monstrous for your wallet.

A correctly selected and executed foundation for a polycarbonate greenhouse is a guarantee of long-term and high-quality service of the structure.

It should also be mentioned that the presence of even the simplest foundation for a polycarbonate greenhouse will significantly reduce the risk of weeds, mole crickets and other pests.

Although protection is required not only for vegetables and flowers grown in a greenhouse, but also for the structure itself. If a metal or wooden frame is simply installed on bare ground, then over time excess moisture will contribute to corrosion or rotting of the structure. And this will directly reduce the service life of the greenhouse and will force you to spend money on repairs or reconstruction in a few years.

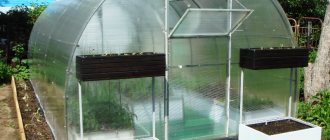

This greenhouse can be used almost all year round

And the last, but probably the most important reason why a polycarbonate greenhouse should have a foundation is the windage of the building. This means that with sufficiently strong gusts of wind, the structure will be torn from its place. And then the greenhouse can simply “travel” around your site, breaking bushes and collapsing itself. Or it may “fly” to a neighbor’s property and damage something there, which is unlikely to please both him and you.

Polycarbonate greenhouse on a concrete foundation

Prices for timber

timber

When and how to install a greenhouse correctly: general principle of work

The most favorable period for installing a greenhouse will be autumn or early spring. It is, of course, better to install a greenhouse in the fall, at which time the plants stop producing crops and are simply removed. Therefore, nothing will interfere with you when constructing the structure, since its assembly will require a lot of free space. You can do this in early spring, then you can immediately start planting plants, but the prices for materials will be inflated.

How to properly install a greenhouse so that it can be useful and perform its intended functions? To do this, you will need the services or advice of specialists, which will be useful to you during the assembly process.

The material must be selected based on the purpose of the greenhouse. Will it be a greenhouse that will only last for a season? Or it is planned to build a large fundamental greenhouse that will serve us in the winter. When we have decided on the purpose of the design, then we choose a reliable, convenient and high-quality material. The most convenient and practical material is polycarbonate. It can be used both for a portable seasonal greenhouse and for a fundamental year-round greenhouse.

General work plan for installing the selected structure:

- A marking of the area is made that corresponds to the size of the greenhouse; to do this, pegs are driven into the edges and a construction cord is pulled between them;

- The area is leveled; it should not have any bumps or holes;

- Then the frame is assembled; it can be metal or wood;

- After this, the roof is installed;

- The frames and doorway are attached;

- Finally, we cover the greenhouse with glass, film or polycarbonate.

The greenhouse has been installed, now we can install special devices at the bottom of the structure that can protect against the penetration of harmful insects and voracious rodents. Now you can admire your creation.

Foundation selection criteria

Factors influencing the choice of the type of foundation for a greenhouse made of cellular polycarbonate include:

- stationarity of the building;

- expected service life;

- dimensions;

- seasonality of use;

- construction time;

- budget;

- soil freezing depth and soil type;

- aesthetics.

Stationarity. If the greenhouse is moved to a new location every season, then it is simply impractical to build an expensive and complex monolithic foundation. In this case, it is better to give preference to a structure that can either be easily dismantled and moved along with the greenhouse, or quickly and cheaply re-equipped.

Polycarbonate greenhouse

Estimated service life. When properly constructed, a polycarbonate greenhouse can last for 8-10 years. Next, you will need to replace all the skin and some damaged frame elements. And if you assume that the building will “work out” all the time allotted to it and after repairs will continue to perform its functions, then the foundation for it must be durable. Accordingly, if a greenhouse is designed for use for two or three seasons, then the opposite is true.

Dimensions . Everything is simple here - the greater the width, length and height of the building, the greater the mass. And so that the frame of a greenhouse of an impressive area does not sag under its own weight, it needs a good foundation.

Seasonality of use. If you intend to use the greenhouse not only during the summer season, but also in late autumn or winter, then the foundation should lie deep enough and protect the soil inside from freezing.

Photo of one of the proposed types of foundation

Construction time. It may take a couple of days to lay out the simplest foundation. And for monolithic options - several weeks. Therefore, the faster you want to start growing plants, the more simple the foundation design you need.

Budget. If you don’t skimp on the construction, then it makes sense to think about building a concrete foundation with a brick base. And vice versa, if there are few funds allocated, then creating complex structures for a polycarbonate greenhouse is impractical.

Soil freezing depth and soil type. If you are building a greenhouse with a high base or a thermos greenhouse, these factors should be taken into account when arranging the foundation. Neglecting them is fraught with damage to the building when the soil swells in the spring.

Aesthetics is the last, but not least, factor influencing the choice of the type of foundation for a greenhouse. Of course, a building supported by metal pipes or beams will look less attractive than a structure with a brick plinth, concrete blind area and gutter.

If you live near the sea, you can use ordinary stones for the foundation

For a greenhouse made of cellular polycarbonate, the following types of foundation can be used:

- from timber;

- strip concrete;

- tape with base;

- tape block;

- columnar or pile foundation;

- monolithic slab.

Polycarbonate greenhouse dimensions, drawing

The size of the greenhouse is selected based on the area of the plot, the budget for construction and the goals that the owner of the personal plot sets for himself. All greenhouses, except domed ones, have the shape of an elongated rectangle. Read more here.

Pros and cons of installing a pile

A pile foundation can be laid in areas where the soil is weak and there is low groundwater, which is one of its main advantages. Piles can also be used on hard soils, where it is impossible to use another type of laying the base for a greenhouse.

This type of foundation is easier to dismantle, which is also a plus. The only drawback of the pile base is the complexity of its construction.

Wooden beam foundation

The most common type of foundation for a cellular polycarbonate greenhouse is a wooden beam structure. This design has the following advantages.

- Low cost and construction time - it is impossible to create something faster and for a lower price.

- Minimum of parts and tools used.

- Working with wood is relatively simple.

- No need for overly tight sizing control.

- After arranging the foundation, you can immediately begin assembling the greenhouse.

- Easy to dismantle the foundation, repair it or move it. The latter is especially true for those summer residents who constantly move the greenhouse from depleted soil to a new place on the site.

Wooden beam foundation

But with all these advantages, you should know that a foundation based on timber is not the most durable - depending on the type of wood used and the presence of a protective coating, the service life ranges from 5 to 10 years. In addition, it is not possible to protect the soil from freezing in this way.

To build a timber foundation you will need the following materials and tools:

- timber with a section of 100x50, 100x100 or 150x150 mm;

- corners with self-tapping screws or dowels for fastening;

- antiseptic impregnation and brush;

- sand;

- rope and pegs;

- roulette;

- ruler for controlling angles;

- level;

- pencil or marker;

- electric jigsaw or saw;

- shovel.

Important! Choose larch timber that grew in Siberia. Its wood is highly durable and resistant to moisture and rot. When purchasing, make sure that the geometry of the timber is in order, and that it itself does not have a large number of knots or other defects.

Beam 150x150 mm made of larch

Step 1: Clear the area of debris, tall grass and rocks.

Step 2: Level the area.

Step 3. Using pegs and a stretched rope, mark the outer and inner edges of the foundation.

Marking the site for the foundation

Step 4. Dig a trench according to the height and depth of the beam.

Step 5. Level the walls of the trench, fill the bottom with a layer of sand or gravel (25% of its depth).

Step 6. Compact the layer.

Step 7. Measure and mark the length of the timber, taking into account the method of fastening (on corners or “half-tree”). Then cut with an electric jigsaw or saw.

Timber trimming

Step 8. Treat the material with an antiseptic and let it dry.

Antiseptic

Step 9. Assemble the timber into a rectangular box without joints, check the lengths and diagonals with a tape measure.

Laying timber in a trench

Step 10. Connect the structural elements to each other. If dowels are used for this, make cuts in the timber and drill holes for fasteners.

Connection using reinforced corner

Half-tree connection using a dowel

Half-tree corner connection

Step 11. Place the timber box in the trench. Please note that the weight of the structure can be from 150 kilograms or more, so carry out the work with several assistants.

Step 12. Fill the gap between the timber and the walls of the trench with sand. On top of the foundation you can lay waterproofing made of roofing felt or other coating with the same characteristics.

After completing all twelve steps, you can begin installing the greenhouse frame on the foundation.

Advice! If you plan to build a greenhouse of large height and area, then the foundation for it should be stronger. Therefore, instead of one beam, it is wiser to use two, as in the image below.

The principle of building a foundation from two rows of timber

Video - Example of assembling a support structure from timber

How to install a greenhouse: choosing a suitable location

Before you start installing the structure in your garden or garden, you need to choose a suitable place for construction. Location is the most important factor in building a greenhouse. The yield of vegetables and other crops will depend on the choice of location.

How to install a greenhouse in the right place so that it can provide favorable conditions for the growth and development of plants? To do this, it must be installed at some distance from large trees and construction sites. It is also desirable that it be protected from drafts by small fences.

Scientists have calculated that if you do not choose the right place to install a greenhouse, you can lose 30–35% of the crop. Therefore, you need to know some rules in order to choose the right place on the site.

Basic rules for choosing a suitable location:

- The distance from buildings to the structure must be at least 3 m, then their shadow will not cover the plants from the sun’s rays;

- The structure must be installed with walls facing north and south, so the sun will illuminate the greenhouse all day;

- The structure must be built at a certain distance from large trees and bushes so that their roots do not interfere with the plants receiving nutrients from the soil.

Having chosen a convenient place, then you need to carefully study the soil, to do this you need to find out what the composition of the soil is in the selected area. If sand predominates in the soil, then this is the best option for planting vegetables, but if it is clay, then the top layer is removed, and the brought, fertile layer is poured in its place. After all these steps, you can begin installing the greenhouse at the selected location.

Strip foundation with plinth

To build a solid greenhouse made of cellular polycarbonate for a long time, it makes sense to equip a strip foundation made of concrete. Given the relatively small mass of the building, the structure can be shallow, that is, not reach the freezing line of the soil. By adding a brick base to the concrete “ribbon”, you will improve the appearance of the foundation and its thermal insulation properties.

The disadvantages of such a design include the labor intensity of the work and the construction time - from the completion of concrete pouring to the start of work directly above the greenhouse, it should take from two weeks to one month. Due to this circumstance, the first growing season in such a greenhouse is somewhat “cut down”.

Advice! To set up a polycarbonate greenhouse in which you can grow plants in winter, the depth of the foundation should be 20-40 cm greater than for a building designed for use only during the summer season.

A strip foundation requires the creation of concrete of a grade (compressive strength) not lower than M200. This indicator determines the compressive strength of the mixture and its ability to resist loads. The composition of concrete (depending on the brand) is given in the table below.

Table. Mass proportions of cement, crushed stone and sand for preparing concrete.

| Concrete grade by compressive strength | Cement M400, kg | Sand, kg | Crushed stone, kg | Volume of concrete produced from 10 liters of cement, l |

| M200 | 1 | 2,8 | 4,8 | 54 |

| M250 | 1 | 2,1 | 3,9 | 43 |

| M300 | 1 | 1,9 | 3,7 | 41 |

| M400 | 1 | 1,2 | 2,7 | 31 |

Advice! The amount of water required to prepare the mixture can be found from the instructions printed on the bags of cement. On average, one liter of dense cement requires one and a half liters of water.

Concrete preparation scheme

Step 1. Remove stones, branches and debris from the greenhouse area.

Step 2. Using a tape measure, pegs and rope, mark the future trench for the foundation.

Step 3. Using a bayonet shovel, dig a trench for the foundation. The depth is from 20 to 50 cm, depending on the mass of the future greenhouse, and the width is 25-30 cm.

Trench for the foundation

Step 4. Level the walls of the trench and compact its bottom. In the latter case, it is advisable to use a manual or automatic rammer, which can be rented from companies that own special equipment.

Tamping the bottom of the trench

Step 5. Pour sand or gravel into the bottom of the trench and compact it. The layer thickness should be 25-30% of the trench depth.

Gravel backfill

Step 6. Install formwork from boards or plywood on the sides of the trench. The formwork must necessarily rest on pegs driven into the ground, otherwise the concrete can “pull apart” the lower edge and the foundation in cross-section will become not rectangular, but trapezoidal. Installing additional ties on top is advisable.

Formwork diagram

Construction of formwork

Step 7. Prepare the concrete mixture. From the point of view of labor and time, it is better to use a concrete mixer rented from a company that deals with special equipment.

Step 8. Pour concrete to half the height of the formwork. Using a shovel or trowel, try to level it out.

Pouring concrete

Step 9. Place reinforcement on the concrete mixture in the corners and along the length of the strip foundation. Fasten the individual parts together by welding or wire. If there is a risk that the reinforcement elements will “sink” in the concrete or move, then use supports called “crackers” or factory-made clamps.

Laying reinforcement

Schemes of reinforced reinforcement of the corner of a concrete strip

Plastic reinforcement clamp

Step 10. Pour the rest of the concrete on top of the reinforcement to the border of the formwork. Control horizontality using tensioned threads and a level.

Step 11. At a certain distance, insert fasteners into the concrete for anchor bolts - this is necessary to fix the greenhouse frame to the foundation. Carefully consider installation locations. If you plan to build a plinth, the anchor bolts should be located at the junctions of the bricks with each other.

Advice! In addition to anchor bolts, fixing the greenhouse frame to the foundation can be done using profiled pipes embedded in concrete, as in the image below.

Laying a profile to fix the greenhouse frame

Step 12. Over the next 3-5 days, add water to the concrete so that the difference in humidity between the inner and outer layers does not cause defects and cracks in the foundation. In rainy weather, do not forget to cover the tape with polyethylene.

Step 13. After finishing the pouring, leave the concrete to dry for 2-3 weeks, depending on the width and depth of the foundation. In dry and hot weather, this period can be reduced by 1.5 times.

Step 14. After the drying period, remove the formwork.

Step 15. Start building the base. It is advisable to use red brick for it, since its other types or brands of blocks are too susceptible to moisture, to which the base will be constantly exposed. Lay the bricks in half or in whole bricks.

Various masonry methods

Step 16. Lay a layer of roofing felt or other material with similar properties on top of the brick. If you decide not to equip the base, then the waterproofing is placed directly on the concrete.

Greenhouse foundation diagram

There is a type of strip foundation, where instead of concrete, brick or ready-made concrete blocks are laid in the trench. It differs from the conventional design in its ease of installation and the ability to begin construction of the greenhouse literally a couple of days after completion of work on the foundation. At the same time, the depth of the bricks and their strength characteristics are inferior to concrete grade M300 or M400.

Concrete block foundation

Prices for fittings

fittings

What do you need for work?

To build a good foundation and frame for a greenhouse, you need to choose the right place for construction, as well as select the materials from which the greenhouse will be built. What to look for when choosing a material and what tools you should definitely have with you during installation work, read below.

Material and tool

The greenhouse frame is made of the following materials:

- glass;

- polycarbonate;

- film.

It is best to opt for a polycarbonate building. This material, unlike film, is stronger and more durable. The glass frame is too heavy and fragile, which creates additional load on the foundation and complicates its installation.

In order to build a foundation, you need to prepare the following tools:

- a shovel to level the area;

- magnetic level to determine the vertical level of the pile;

- roulette;

- sledgehammer;

- a screwdriver with an attachment for a Phillips screwdriver and an 8 mm deep bit;

- marker for marking;

- gloves made of dense material so as not to injure the skin of your hands when working.

Selecting a location

Before installing a pile foundation, you need to choose a suitable location for its location. The site for construction should be well-lit and spacious so that the greenhouse is always in direct sunlight. You should not build a structure in an area where there is strong wind, because this will affect the stability of the greenhouse.

The site must have a high groundwater table. If there is an underground flow at a level of 1 m, then dehydration work should be carried out, which consists of forming a special embankment of sand, crushed stone and soil in order to create a hill at the site where the pile is installed.

Blueprints

Below is a ready-made drawing of a pile foundation that you can use when carrying out work:

Pile foundation

The construction of any building, even the lightest one, on soft soils prone to heaving is a difficult task. Uneven changes in ground level that occur in such areas every season can lead to damage to the greenhouse. The solution to this problem is to build a foundation on piles.

An example of a polycarbonate greenhouse using steel screw piles as support

Piles can vary in material (steel, reinforced concrete, wood) and installation method (driving, screwing, laying or pouring into drilled holes). Let's consider the two most popular methods of arranging a point foundation for a polycarbonate greenhouse - on screw piles and on concrete piles.

Pile foundation diagram

The main advantage of the first type of piles is ease of installation. The durability of steel screw structures is comparable to the service life of a polycarbonate greenhouse frame. Perform the installation process step by step as follows.

Steel screw piles

Step 1. Mark the area and places for screwing the piles. They should be located in the corners of the greenhouse and along its walls at intervals of 1-2 m, depending on the mass of the entire structure.

Step 2. Dig holes at the installation points of the piles with a depth of 20 to 50 cm and a diameter 3-4 times larger than that of the piles. This can be done quickly and efficiently using a drill.

Drilling a hole

Step 3. Install the first pile and start screwing it into the ground. To do this, you can use both manual tools and special equipment. The screwing depth should be 1.5-2 m - it is necessary to go below the freezing line of the soil and get to its harder layers that are not subject to swelling.

Screwing the pile

Step 4: Repeat the previous step with the remaining piles.

Step 5. Align the piles in height. The easiest way to do this is with a grinder. As a result, the piles should protrude 10-15 cm above the ground level.

Trimming a screw pile with a grinder

Step 6. Place a grillage on top of the piles, to which, in turn, the greenhouse frame will be attached. The most popular option is made from timber with a cross-section of 100x100 mm; use long self-tapping screws as fasteners. Other examples of grillages can be seen in the image below.

Examples of grillages

Advice! It makes sense to lay a layer of waterproofing between the pile head and the grillage.

An example of a pile foundation installed on a site with a large slope. Between the grillage and the piles you can see a layer of waterproofing

Reinforced concrete piles, unlike screw piles, are not screwed into the ground, but are poured into pre-dug wells. They are used in cases where, due to soil heaving, the construction of a shallow strip foundation is risky. Such reinforced concrete piles are also called bored piles.

Step 1. Mark the points where the piles will be located.

Step 2. Using a manual or automatic drill, drill holes 1.5-2 m deep.

Drilling a well using special equipment

Step 3. Install the formwork in the well. This could be an asbestos pipe or roofing felt.

Roofing felt formwork

Use of asbestos pipes

Step 4. Place layers of sand and gravel at the bottom of the well, then, if possible, compact it.

Foundation from the inside

Step 5. Place a pre-welded or wire-twisted reinforcement structure inside the formwork.

Laying the reinforcement structure

Step 6. Then pour concrete grade M200 or higher into the formwork. Carry out the process in separate layers, giving each of them time for initial setting. Usually this period is several days. After this, give the entire mass of concrete time to fully set and harden.

Pouring concrete

Step 7. Remove the formwork, level the piles in height and install the grillage.

Important! When thinking about choosing a pile foundation, you should always take into account one drawback - such a design does not provide good thermal insulation and protection of plants in the greenhouse from drafts and pests, and the soil from freezing. Give preference to piles only if installing another type of foundation on your site is impossible.

Prices for screw piles

screw piles

Turnkey installation cost

Prices depend on the number of piles that make up the foundation and their sizes .

For example, piles 3 m long, with a square section of 15x15 cm will cost (turnkey) 5,500 rubles for each, if their number does not exceed 50. If it is more, then you will need to pay 5,200 rubles. If the depth is 5 m, then the cost of turnkey installation will be 7800 and 7500 rubles, respectively.

Everything you need to know about the design and construction of a pile foundation can be found here.

Columnar foundation

Another type of foundation, reminiscent of a pile foundation in its design, is a columnar foundation. It is cheaper and simpler than previous options, but, given the low mass of the greenhouse, it is also capable of performing its tasks well.

Step 1. Mark 40x40 cm squares at the corners of the future greenhouse.

Step 2. In these squares, dig rectangular holes 30-50 cm deep.

Step 3. Level the walls of the pit and compact the bottom.

Step 4. Place a 15 cm thick layer of sand on the bottom.

Construction of a columnar foundation

Step 5. On top of this, create a column using masonry or ready-made concrete blocks. As a result, its height should be 10-20 cm above ground level.

Important! If possible, avoid using types of bricks and blocks that tend to absorb large amounts of moisture.

Step 6. Install a timber grillage on the brick pillars, and on it, in turn, a polycarbonate greenhouse frame.

Laying the grillage

Design Features

Greenhouses on screw piles are installed in two cases. If the area on which the building will be built has weak floating soil or, conversely, hard rock.

Moreover, the technology of arrangement on different soils is different. For example, on peaty or clayey soils, piles must be driven into hard, stable layers. In this way, an even distribution of the load is achieved.

On rocky soils, the screw-in depth may be minimal.

The piles themselves come in different types. They are divided mainly according to the following parameters:

- by material of manufacture (wood, metal, reinforced concrete);

- according to the shape of the sections (round, rectangular, pyramidal);

- according to the method of construction (solid and hollow).

They are selected mainly according to the type of soil and climatic conditions that will constantly influence them. To make your choice easier, you can use the table

Monolithic slab foundation

Are you interested in a design that can provide stability even on soft soils and at the same time protect the greenhouse from drafts, pests and hypothermia? Have you decided to build a very large building suitable for growing vegetables on an industrial scale at any time of the year? If so, then in such a case a monolithic concrete slab as a foundation is the best choice. This is the most expensive, but at the same time the most reliable and effective option. The design of a monolithic concrete slab has no fundamental differences from a shallow strip foundation; you can see it in the image below.

Monolithic foundation diagram

Now let's look at the stages of creating such a foundation.

Step 1. Mark using pegs and rope. Particular attention should be paid to controlling the diagonals and perpendicularity of the sides.

Step 2. Dig a pit at least 50 cm deep.

Foundation pit

Step 3: Add layers of sand and gravel. Their total thickness should be 25-30% of the pit depth. Compact them and, if necessary, cover them with geotextiles.

Step 4. Install formwork around the perimeter of the pit. Fill the space between it and the ground with gravel.

Formwork diagram

Step 5. Install fittings and drainage pipe.

Laying reinforcement

Step 6. Pour concrete to the edge of the formwork. This stage is very important and requires a professional approach - it is necessary to ensure a perfectly even screed. Insert anchor bolts or other fasteners for the greenhouse frame.

Fill

Step 7: Wet the concrete for a week.

Step 8: Next, let the foundation slab set. This usually takes 3-4 weeks, but in warm and dry climates the process will go faster.

Step 9. Remove the formwork and fill the gap between the slab and the surrounding ground with crushed stone.

Ways to secure a greenhouse to the ground

Greenhouses can be portable or stationary. For portable greenhouses, a foundation is not needed; they are attached to the ground with small, T-shaped legs, or they are simply sprinkled with earth. But for greenhouses that are installed for many years, a foundation is required, so it will be attached to the ground.

How to secure a greenhouse to the ground so that it can serve its owner for a long time? To do this, you need to build a strong and reliable foundation.

You can make the foundation for the greenhouse yourself. This requires little preparation. You will need to purchase some materials and purchase special tools. There are several types of foundation, but you decide for yourself which one is most suitable for you.

Types of foundation:

Using these materials, you can build a reliable and durable foundation that will protect your greenhouse from strong gusts of wind, rain streams, rodents and harmful, annoying insects.

Summing up

So, what type of foundation is best for a polycarbonate greenhouse? It all depends on what you expect from him. Do you need a cheap and simple structure that you can build in a couple of days and immediately begin installing the greenhouse? Choose a foundation made of timber or on brick pillars. Do you want to build a permanent greenhouse that is designed to work in winter and has an attractive appearance? Then you should choose a strip foundation with a red brick base.

Are the soils on the construction site less than ideal or should the building be located on a slope? In this case, pay attention to concrete or screw piles.

Are you planning to build an industrial greenhouse with multi-tiered beds and hydroponics? Do you want to receive fresh vegetables or berries all year round, without fear of any misfortunes or frosts? An expensive but effective monolithic concrete slab is your choice. In any case, the main thing in this matter is compliance with construction technology and a competent approach to business.

Types of screw piles and their prices

When purchasing screw piles, you need to choose those that suit their characteristics. For small greenhouses, you can use those with a diameter of 57 mm.

They are available in various versions:

- standard,

- Premium,

- galvanized.

At the same time, prices for these products range from 700 rubles to 3000 rubles. Their price depends not only on the type, but also on the length. For example, in the simplest version, you will have to pay 700 rubles for a pile 1.5 m long, 1000 rubles for 3 m, and 1900 rubles for 6 m.

Stronger structures will require more massive piles . If the diameter is 108 mm, then a one and a half meter pile of standard quality will cost 1300 rubles, for 3 m - 2000 rubles, and for 6 m - 3700 rubles.

You can find out about the types and sizes of piles for greenhouses here.

We build a polycarbonate greenhouse in one working day

Owners of summer cottages, as in previous times, often do gardening work. Since in most regions of Russia the climate does not allow one to do without greenhouse farming, either temporary greenhouses are installed in summer cottages, which are dismantled before the winter season, or stationary greenhouses made of polycarbonate and other materials. When choosing the second option, land owners have to resolve quite a lot of issues. One of them is the foundation for the greenhouse, the type of which is chosen carefully, taking into account many factors.