What is the problem with profile bending?

Rolled metal with a rectangular cross-section is easy to work with, and the workpieces can be joined at different angles.

Difficulties arise when there is a need to give the design parts a curved shape. This is due to the fact that a tensile force acts on the outer wall of the product, and the inner side is subjected to compression. Attempts to bend a profile pipe without a pipe bender are associated with the following problems:

- The appearance of cracks in the material. If the wall thickness is small, then metal rupture is possible.

- Crinkling of sides. A similar effect occurs when excessive pressure is applied while passing workpieces through bending fixtures.

- The appearance of internal folds. The greater the height of the product profile and the smaller the straightening radius, the greater the likelihood of such a defect occurring.

- Section break. Occurs when sudden force is applied to the workpiece.

- Changing the section configuration. If the technology is violated, the planes, the longitudinal axis are displaced, and the part is bent in the form of a spiral.

- Reduced metal strength. Such a flaw is a consequence of overheating and, as a result, a violation of the crystalline structure of iron.

It is not difficult to avoid such complications. It is enough to approach the matter competently and thoughtfully.

Methods for bending profile pipes

Dacha owners often have to think about how to bend a profile pipe for a greenhouse quickly, without spending money on professional equipment. Even with financial resources, it is not always possible to immediately find arches of the desired shape and size.

You can use one of the suggested methods:

- Cold pipe bending. It is used when working with small section profiles 10x10 mm and 10x20 mm, with a wall thickness of no more than 1.5 mm. In such cases, the deformation is carried out by the muscular power of the master, and he himself can control the condition of the metal. It is necessary to constantly measure the position of the section horizontally and vertically. The correctness of the work is checked by the template.

- Preheating. A flame source is used in which the workpiece is heated until it reaches a red color. After this, it is bent to the desired configuration. The bent workpiece must be kept under tension until it cools completely. For heating, a gas boiler, stove, blowtorch or country grill with a high content of charcoal is used.

- With internal filling. Sand, machine oil or water are used as filler. It is necessary to ensure that the cavity is filled as tightly as possible. The best effect is achieved by freezing water. Ice prevents the pipe from collapsing under pressure. Tightness is achieved by welding the holes or hammering wooden plugs into them.

- Sector cutting. To do this you will need a grinder with a cutting disc. Triangular slits are made in the profile and the sawn fragments are removed. Then the pipe is bent, and the edges of the cuts are welded with thin electrodes. This method is long but reliable. Its use eliminates bending and deformation.

Given time and creativity, unconventional approaches can be used.

Pipe bending technologies

In practice, special bending machines are used. They are divided according to the principle of action:

- rental Rolling is carried out on guide rollers. During the execution process, you have to roll between the support rollers;

- profiling. In tools of this type, pipes are bent along specific profiles;

- tension. The plastic properties of the material are used. This method is only possible for long workpieces.

Rolling machines for bending profile and round pipes

Industrial bending machine

The design of rolling equipment uses rows of rollers. Two of them are located below. Another one is installed on top. The process occurs in the following sequence.

- The middle roller rises to the top position.

- The pipe is started and placed on the two lower rollers.

- The upper roller presses the pipe.

- By rotating the handle, the pipe is forced to roll along the roller back and forth.

- Press the upper roller. Now the pipe begins to move not in a straight line, but along a certain radius.

- Rolling repeatedly, constantly press the upper roller to a given mark.

- When they reach a certain position, the process is stopped.

- The bent pipe is removed from the machine and placed on a template to check the compliance of the dimensions and bending radius.

- If necessary, they put it on the machine again and bring the product to the required standard.

Some homemade homemade machine designs use additional chains. Manufacturers of such machines claim that during operation, traction on all rollers occurs with the same force.

Push action rolling pipe bender

Most DIYers take a different route. There are bending machines. In them, the radius is set by one of the lower rollers, which is raised using a mechanical or hydraulic jack.

Bending pipe bender

Practice shows that such machines are much easier to manufacture. It is enough to use several channels and rollers mounted on powerful bearings.

To roll round pipes, you need to make rollers, the stream of which has a profile corresponding to the profile of the workpiece. For stainless steel products, the rollers are machined from textolite. Such material does not mark the surface. Many people can see bent products in the entrance areas of the retail chain, as well as in fencing on stairs (fencing made of stainless pipes with a diameter of 50 mm).

Profiling machines

It is necessary to make bent products in the production of towel dryers. These wall products are made according to different patterns. Hot coolant circulates in them. Laundry hung on tubes dries much faster than clothes hung on regular lines. Therefore, similar heating equipment is installed in most bathrooms.

Stainless steel pipes are used to make heated towel rails. To bend to specified dimensions, simple bending machines are used.

Profile bending machine

- profiling roller. It stands motionless, fixed on an axis;

- stop for fixing one end of the workpiece;

- rolling roller, which is located on the lever. The lever itself rotates about the same axis.

- The pipe is installed firmly.

- The rolling roller is pressed against the outer wall of the workpiece.

- By moving the lever, the workpiece is bent.

- The finished product is removed from the machine.

Manufacturers often have several bending machines in their arsenal to combine production of different radii.

To prevent the walls from collapsing, they are first filled with sand, and then plugs are hammered into the ends. The internal volume remains unchanged. Therefore, the quality of the product remains quite high.

To reduce the effort on the levers, a complex lever design is used. Here, by increasing the radius of application of force, a decrease in the values of forces at the ends of the lever is achieved. Even women can do this kind of work. The amount of force applied does not exceed 4...6 kg.

Bending of long workpieces

In practice, suspended structures are made. For the canopy, you need to use a template according to which the pipe will be bent and then welded to the support posts.

Canopy made of profile pipe

Huge areas can be protected by spatial radius supports. Anyone can try applying force to a square pipe. It bends quite easily. All that remains is to choose a suitable template to give the final shape to the product.

Pipe blanks

To obtain a rigid structure, an equidistant bent surface is built. It turns out an arch with an internal amplifier. It is able to withstand high snow loads in winter. In summer, atmospheric moisture will flow down the sides.

Reinforced canopy truss

Alternative bending methods

In order for radial bending of profile pipes to bring the desired results, it is necessary to take into account factors such as:

- plasticity of facing material (tin, plastic, monolithic and cellular polycarbonate);

- cross-sectional shape and wall thickness - square products withstand deformation better;

- elasticity of the metal - when cold forming, the workpieces need to be deformed 10-15% more than the required radius.

The following alternative methods for bending rectangular pipes exist:

- Forging. Bending is done by methodically striking the workpiece with a heavy hammer. An anvil is pre-made, the top of which has a rounded shape. The workpiece is rigidly attached with clamps to the base of the anvil. After this, blows are applied to the profile. Care should be taken as Excessive force may cause the product to flatten. It is more convenient to work with segments no longer than 1 m.

- According to the pattern. The basis for placing the part can be a concrete, asphalt or tiled area. The outline of the arc is drawn on it, after which reinforcing pins or thin steel pipes are driven into the ground. The part is fixed to the first pin. As bending progresses, welding is carried out with pins. When the elastic force weakens, the arch is cut off from the pins with a grinder.

- Rental under pressure. To create pressure, a vehicle with side-mounted wheels and without wings is used. The lath is placed in a pre-prepared groove made of steel or concrete. After this, the wheel is methodically rolled along the profile. Axial alignment is controlled manually or by metal guides.

To reduce the likelihood of deformation of the walls of the product, you can insert a thin and long steel spring into it. When heating is used, do not cool hot steel with water. This may cause it to crack or burst. It's better to use working out. When using muscular force, it is recommended to attach a long and strong lever to the free end of the link. This way you can achieve your desired goal with less effort.

Bending methods and their features

They bend profile pipes in both cold and hot states. Heating with a gas burner will significantly increase plasticity. However, material with a small cross-section bends excellently even without unnecessary temperature effects, because thin pipes are quite flexible and more easily amenable to the force applied to them.

There are no exact instructions regarding the use of heat for bending. The standards indicate only the dimensions of round products, according to which it is necessary to apply flame to the treated area with a diameter of 100 mm or more. With square and rectangular shapes, everything happens a little differently. Based on the experience of folk craftsmen:

- with a profile height of up to 10 mm, the workpieces are definitely cold bent;

- with a profile height of 40 mm or more, the pipes are bent with heating.

How simpler and easier it is to bend a profile at home with a height in the range from 10 to 40 mm, the performer will have to decide on his own. If the craftsman has a profile bender in his arsenal, he can use it to create an arched curve without heating. There is no apparatus, it is better to try your hand in advance. To do this, clamp one end of the material in a vice. Place a pipe larger than the height of the profile onto the other end and pull the “shoulder” enlarged in this way. If it works, there is no point in heating metal products.

Option #1 – bending with heating

We will deform the unyielding material using the hot method, after filling it with sand. This will improve the quality of processing and ensure uniform bending. Let's stock up on canvas gloves for hot work and get started:

- from scraps of timber or logs we will make two pyramidal plugs, the length of which should be 10 times the width of the base. The base area of each homemade plug should be almost 2 times larger than the square or rectangular hole that it will plug;

- Let’s try on how the plugs “fit”, then select longitudinal grooves on one of them on four sides. They are needed to release the gas that accumulates when the filler is heated;

- pre-anneal the workpiece in the area of the future bend;

- Let's prepare the filler. We will use clean construction sand of medium grain size. In the absence of bulk building materials, we will use sand from a children's sandbox. We first sift it through a sieve with 2 or 2.5 mm mesh to remove gravel and trash from the packing. Large inclusions on the surface of pipes can form unnecessary relief. Then we will “pass” the sifted mass again, but through a fine sieve with 0.7 mm cells, so that the dusty particles do not sinter when heated. We will return all the screenings, as well as the filler, to the sandbox upon completion of the actions;

- calcinate the filler at a temperature of 150ºС;

- Let's plug one end with a wooden plug, which has no channels for venting gases. We will install a funnel at the second end. Depending on the size, we will install the workpiece at an angle or perpendicular to the ground. We will pour the filler in portions through the funnel. Periodically tap the walls of the product from bottom to top with a wooden or rubber mallet to compact the sand. A dull sound will indicate sufficient compaction;

- close the filled blank with a second plug;

- Mark the heating area on the workpiece with chalk;

- We secure the workpiece either in a vice with a template or in a clamp. We install the material with the welded seam so that the welded joint is on the side. It is not advisable to stretch or compress along the seam;

- heat the marked area red-hot and carefully give the workpiece the required shape. We bend in one step with a progressive, unsharp movement in a strictly horizontal or vertical plane;

- After cooling, compare the result with the template. If everything is in order, knock out or burn out the plugs and pour out the sand.

The described method is good for forming single corner bends, because It is strongly not recommended to heat the pipes several times. Metal loses strength from repeated temperature shock. However, when creating a rounded arch, repeated heating is inevitable. After all, it’s impossible to do the job in one go, but when cooled to a light cherry hue, i.e. up to 800ºС, the workpiece may simply burst.

Option #2 – cold method

Plastic deformation of rolled profiles “cold” is carried out both with and without filler. Material with a profile height of up to 10 mm does not require filling. It is better to fill a thicker pipe with sand or rosin. An alternative to sand filler is a tightly wound spring, the dimensions of which will allow it to be tightly installed in the cavity at the processing site. The spring gasket will prevent sudden changes in the profile section at the bend points.

You can cold bend at home:

- manually using simple devices such as bending plates, vices and mandrels;

- using a mobile profile bender - an improved analogue of a manual pipe bender. The profile bender differs from the device for bending round pipes only in the shape of the recess of the working roller;

- by rolling on a home-made or factory-made profile bending machine, which you can make yourself or purchase ready-made.

It is wiser and more profitable to rent technical means of bending mechanization if they are needed for a one-time construction of a greenhouse. If you plan to build green houses for relatives and neighbors or erect a beautiful metal fence, for example, there is a reason to acquire your own bending installation.

How to bend a square pipe for polycarbonate structures

When installing polycarbonate greenhouses, a square-type structure is usually used. In order to bend such a pipe at home, you will need the following tools:

- Special bending machine;

- The structures themselves for making arcs;

- Ruler;

- Bulgarian;

- Welding unit.

To get started, you need to divide the structure into equal parts. Then filing is carried out using a grinder. The undercut areas need to be processed using a spot welding machine. You can bend a profile pipe using a special machine. This is not an easy job, because you need to turn the unit manually.

If you don't have a machine, you can do the work yourself. To do this, two structures are fastened parallel to each other. A drawing with the desired bend is made on the ground. Then, in accordance with it, you need to bend the first structure. According to it, similar work is carried out with the second profile pipe.

DIY pipe bender

For large-scale bending volumes, it is worth using a pipe bender, but their prices are quite high. You can make it yourself from scrap materials - this will speed up the process and will not greatly affect the family budget.

Important! At the initial stage of work, you should draw up an accurate drawing of the pipe bending machine with calculations and proportions.

Materials

To make it you will need:

- the corner is durable;

- channel or plate made of durable metal;

- rollers and roller;

- chain;

- tensioner;

- drive sprockets;

- bearings with housings;

- jack;

- rod for handle;

- springs for the jack;

- fastener

The amount of material depends on the drawing you choose. It is better to order drive shafts and pressure roller from a turner. All other parts do not have to be new.

Most of the parts for making a homemade profile bender can be found in every garage.

Tools

During the installation process the following will be used:

- welding machine;

- drill;

- Bulgarian;

- grinding equipment or file;

- metal drills;

- hammer;

- open-end and socket wrenches.

How to bend a pipe using a pipe bender

1 Type of machine is designed for radius bending of profile pipes.

Characteristics of the standard machine:

Maximum pipe section #8212; 40 x40x2, 50x25x2 mm.

Minimum circle diameters:

- 20x20x2, 25x25x2, 15x15x1.5 –560 mm

- 30x30x2 #8212; 650 mm,

- 40x20x2 #8212; 650 mm,

- 40x40x2 #8212; 1800 mm,

- 50x25x2 #8212; 800 mm.

The maximum arc diameter is unlimited.

Drive type: manual.

Hardened rollers – all 3 pcs.

Price: 25,000 rubles.

2 Type of machine is designed for radius bending of profile pipes, round pipes and strips.

Characteristics of the universal machine:

Maximum pipe section #8212; 40x40x2, 50x25x2 mm.

The maximum cross-section of a round pipe is 32x2.8 mm.

Minimum diameters of a circle of profile pipes:

- 20x20x2, 25x25x2, 15x15x1.5 –560 mm

- 30x30x2 #8212; 650 mm,

- 40x20x2 #8212; 650 mm,

- 40x40x2 #8212; 1800 mm,

- 50x25x2 #8212; 800 mm.

The maximum arc diameter is unlimited.

Drive type: manual.

Hardened rollers – all 3 pcs.

Price: 30,000 rubles.

At the Customer's request, for an additional fee, the machine is equipped with a dial indicator for the production of more accurate all subsequent workpieces.

For an additional fee, the machine can be equipped with a 220-380V electric drive

2 year warranty

Saratov region Engels

The profile structure can be bent by pre-heating the bend with a gas burner or blowtorch. However, this method has its disadvantages: labor-intensive work, poor appearance of the bend.

It is much more reasonable to do the work with the profile structure for the greenhouse using a pipe bender. Bending occurs due to the pressure of the roller. In this case, you can control the bending angle. You can do the pipe bending yourself.

For this you will need:

- Three rollers;

- Metal table;

- Bracket;

- Concrete mortar;

- Welding machine;

- Steel structures with dimensions from 70 to 150 mm;

- Lead screw;

- Channel.

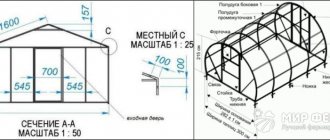

The structure is made of two steel pipes. They are fixed in the slab using a solution, and then attached, using a welding machine, to the channel. A distance of 600 mm must be maintained between structures.

The rollers are mounted on axes in one line. There must be at least 50 cm between them. The third roller is installed in the middle. It is mounted above two already installed rollers by 100 mm. This roller is lifted with a jack and is responsible for the angle of bending.

When performing work, the roller is attached to a metal table. A bracket with a clamping axle is fixed to the axis. A roller similar to the profile of the structure is mounted on it. The structure itself, during operation, passes through the rollers. At the same time, she holds on with her hands. At the end of the work, you need to check the angle of the profile pipe for the greenhouse by attaching it to the template.

How is the calculation done?

To figure out the number of cuts, you need to perform a simple calculation. Let's assume that the following conditions need to be met:

- there is a pipe measuring 30·50 mm;

- a turn at an angle of 180 ⁰ is required;

- full turning radius R = 100 mm;

- movement is carried out along the wall b = 30 mm.

It is necessary to determine the outer length of the formative half of the circle.

here π = 3.14 is the ratio of the circumference to the radius.

Along the way, half of the generatrix is determined along the internal radius.

The difference between the values determines the overall width of the cuts.

Knowing the thickness of the saw blade (h = 2 mm), it is easy to determine the number of cuts.

All that remains is to substitute all the data into the calculation formula and determine the number of cuts for a 90⁰ rotation. The total quantity can be determined as:

Calculation scheme for determining the parameters of cuts

It is better to present the calculation in the form of table 1

Table 1. Determination of the number of cuts for initial conditions

| Pipe width b, mm | 30 |

| Radius of the inner layer R, mm | 100 |

| Outer radius R out, mm | 130 |

| Length of half a circle along the outer layer Lout, mm | 408,2 |

| Half-circle length along the inner layer Lin, mm | 314 |

| Difference between the length of the outer and inner layer C, mm | 94,2 |

| Cutting width h, mm | 2 |

| Number of cuts n | 47 |

| Total number of cuts N | 94 |

People who want to build a greenhouse often ask about bending pipes using cuts. They are interested in: “How many times do you need to saw through the walls to obtain a bend with a certain radius of the generatrix?” Using the proposed dependencies, you can easily calculate the pipe grooves for the greenhouse. Table 2 shows calculations for pipes of different diameters and radii of the internal generatrix.

Table 2. Calculation for greenhouse profile pipes

| № | Pipe width b, mm | Radius of the inner layer R, mm | Outer radius R out, mm | Length of half a circle along the outer layer Lout, mm | Half-circle length along the inner layer Lin, mm | Difference between the length of the outer and inner layer C, mm | Cutting width h, mm | Number of cuts n | Total number of cuts N |

| 1 | 20 | 1000 | 1020 | 3202,8 | 3140 | 62,8 | 2,4 | 26 | 52 |

| 2 | 25 | 1000 | 1025 | 3218,5 | 3140 | 78,5 | 2,4 | 33 | 66 |

| 3 | 30 | 1000 | 1030 | 3234,2 | 3140 | 94,2 | 2,4 | 39 | 78 |

| 4 | 35 | 1000 | 1035 | 3249,9 | 3140 | 109,9 | 2,4 | 46 | 92 |

| 5 | 40 | 1000 | 1040 | 3265,6 | 3140 | 125,6 | 2,4 | 52 | 104 |

| 6 | 20 | 1250 | 1270 | 3987,8 | 3925 | 62,8 | 2,4 | 26 | 52 |

| 7 | 25 | 1250 | 1275 | 4003,5 | 3925 | 78,5 | 2,4 | 33 | 66 |

| 8 | 30 | 1250 | 1280 | 4019,2 | 3925 | 94,2 | 2,4 | 39 | 78 |

| 9 | 35 | 1250 | 1285 | 4034,9 | 3925 | 109,9 | 2,4 | 46 | 92 |

| 10 | 40 | 1250 | 1290 | 4050,6 | 3925 | 125,6 | 2,4 | 52 | 104 |

| 11 | 20 | 1500 | 1520 | 4772,8 | 4710 | 62,8 | 2,4 | 26 | 52 |

| 12 | 25 | 1500 | 1525 | 4788,5 | 4710 | 78,5 | 2,4 | 33 | 66 |

| 13 | 30 | 1500 | 1530 | 4804,2 | 4710 | 94,2 | 2,4 | 39 | 78 |

| 14 | 35 | 1500 | 1535 | 4819,9 | 4710 | 109,9 | 2,4 | 46 | 92 |

| 15 | 40 | 1500 | 1540 | 4835,6 | 4710 | 125,6 | 2,4 | 52 | 104 |

To assess the effectiveness of such technology, it is advisable to estimate the labor intensity and costs of materials (Table 3).

Table 3. Labor costs and cost of consumables for bending arcs for a greenhouse

| Number of cuts | Duration of one cut, min | Total duration of pipe sawing, min | Consumption of cutting discs with a diameter of 125 mm, pcs. | Total consumption of cutting wheels, pcs. | Duration of bending along the grooves, min | Duration of welding a seam along a cut, min |

| 52 | 0,3 | 15,6 | 0,2 | 10,4 | 0,3 | 1,3 |

| 66 | 0,3 | 19,8 | 0,2 | 13,2 | 0,3 | 1,3 |

| 78 | 0,3 | 23,4 | 0,2 | 15,6 | 0,3 | 1,3 |

| 92 | 0,3 | 27,6 | 0,2 | 18,4 | 0,3 | 1,3 |

| 104 | 0,3 | 31,2 | 0,2 | 20,8 | 0,3 | 1,3 |

| – | – | – | – | – | – | – |

| Number of cuts | Total duration of welding grooves, min | Electrode consumption 3 mm per groove on three sides | Total electrodes required, pcs. | Total process duration, min | Total duration of the process, hour | Given costs for the purchase of disks and electrodes, rub. |

| 52 | 67,6 | 0,25 | 13 | 83,5 | 1,39 | 322,4 |

| 66 | 85,8 | 0,25 | 16,5 | 105,9 | 1,77 | 409,2 |

| 78 | 101,4 | 0,25 | 19,5 | 125,1 | 2,09 | 483,6 |

| 92 | 119,6 | 0,25 | 23 | 147,5 | 2,46 | 570,4 |

| 104 | 135,2 | 0,25 | 26 | 166,7 | 2,78 | 644,8 |

How much does one steel profile pipe of size 20·20 mm cost? According to the latest data, a six-meter section can be purchased at a price of 320...360 rubles. It turns out that the cost of the process will cost about the same as the pipe itself costs. In this case, you will have to spend more than an hour and a half on one arc. The appearance of the finished products is far from perfect. To give it a marketable appearance, it is necessary to grind using an abrasive tool. This operation is comparable in time to the costs of welding work. Flap wheels will further increase direct operating costs.

Type of bent products obtained by cutting grooves followed by welding

From the presented calculations it is clear that the technology of bending pipes along a radius can be justified only for bending profile workpieces only in limited quantities. If you need to create a complex spatial structure, you should use special devices for industrial bending.

How to bend a pipe using the hot method

You can give the greenhouse structure the desired angle at home by paying attention to the hot bending method. It has its advantages. In particular, the bend is smooth and smooth.

To complete the work, you need to place sand in the structure, then close its ends with wooden plugs. Afterwards, you need to drill holes in the plugs so that the resulting air escapes when heated. Then a mark is made on the greenhouse structure where it is optimal to bend.

The area is then heated. Following this, the heated structure is placed in a pipe bender and bent to the desired radius.

If you decide to bend a structure for a greenhouse at home, be sure to watch the video and photos that show how to do this work correctly. You can see all the necessary material on our website.

How to bend a profile pipe using welding

Tubular products with a square or rectangular cross-section, the wall height of which is 30 - 40 mm or more, are difficult to bend, especially with small radii. To form a beautiful 90-degree bend from such material with your own hands, you cannot do without a grinder and a welding machine.

Procedure:

- Make a bending template, which makes it easier to make several identical parts;

- Use a grinder to make notches along the pipe along the three walls, leaving one intact. The more notches, the rounder the bend will be;

- Fix one end of the profile securely;

- Using force, grasping the second end, gradually bend the pipe according to the template so that the cuts form the concave part of the bend. The bending plane should not be disturbed; you can use a mallet;

- Weld the cuts and grind the welding areas.

Now let's look at how to bend a pipe using a pipe bender

When constructing complex buildings, square and round profiles with thick walls are used. They are difficult to bend by hand, so a pipe bender is needed. There are two types of machines:

- Manual. The devices are of simple design and inexpensive. Quite suitable for use on the farm.

- Automatic. They are classified as professional and are used by specialists. They are expensive and therefore not suitable for home use.

Photo - mechanical profile bender

Also, the machines differ in operating principles and come in different models. Let's look at the most practical ones:

- Crossbow pipe bender.

- Spring pipe bender.

- Segmental pipe bender.

- Mandrel pipe bender.

Working with a pipe bender is convenient and easy. It holds the profile securely and exerts uniform pressure on it. The bending radius can be adjusted. The output is perfect arcs.

How to bend a profile pipe using fillers

The filler is used to obtain uniform bends without flattening and folds (corrugations on the concave part), filling the internal space, it distributes the compression and tension force over the entire surface of the bent section of the profile. The most tested filler is fine, dry, well-sifted sand.

This method may be accompanied by heating the pipe with a blowtorch or heating it with charcoal; when heated, the metal will acquire plasticity, which makes bending easier. Tubular products with a wall height of 30 mm or more are hot bent.

Pipe products with a wall height of up to 20 mm bend without heating, and with a bending radius of less than 50 mm, no filler can be used.

Procedure for the hot method:

- Anneal the bend section of the prepared pipe;

- Make wooden plugs in the form of pyramids 10 bases long, which are 2 times larger than the lumen, make 4 longitudinal grooves on one for gas removal during heating;

- Plug one end of the pipe, gradually fill in sifted and calcined sand to the brim, compacting it by tapping. Cap the second end with a chopper with grooves;

- Mark the heating area with chalk, clamp the profile, placing the seam not on the concave side relative to the template;

- Heat the pipe until red hot, bend it with translational movements in one approach (re-heating is not advisable), observing the bend plane according to the template. Follow safety precautions;

- After cooling, knock out or burn out the plugs.

With a wall height of up to 10mm, we can safely bend a profile pipe with our own hands without heating or filler. In other cases, instead of sand, you can use a steel spring with dense square or rectangular coils. It should be slightly smaller in size than the internal dimensions of the pipe, so that it fits tightly to the bend. The spring will also prevent unwanted deformations from forming during cold bending. They pull it out by the wire attached to the end turns, which goes out.

Why do you need to know the profile characteristics?

Profile pipes differ from the standard round version in their cross-sectional shape, which can be square, oval, rectangular or flat-oval. According to GOST R regulations No. 54157-2010, a round product is also included in the list of specialized products. However, in greenhouse construction, products with a square and rectangular cross-section are most often used, for example, 40x20 mm profile pipes, because it is easier to attach the coating to their smooth, flat walls.

For a variety of national economic needs, products are produced in a wide range of sizes. It differs in configuration and cross-sectional area and, naturally, in wall thickness. The combination of sizes determines the plastic capabilities. In professional language, they are called the minimum permissible radius of curvature. This means that before you find out how to make a blank for a frame, you need to find out what is the smallest radius of flat round deformation that the blank can “survive” without damage.

To determine the minimum allowable bend radius of a square or rectangular profile, we need the height h because:

- products with a profile height of up to 20 mm will be bent without becoming unusable defective if bending is carried out on a section with a length of 2.5 × h or more;

- pipes with a profile height of over 20 mm will withstand deformation over a section of length 3.5×h or more without loss.

The indicated limits are necessary for those who are planning to make racks, shelves and frames for windows or doors. The thickness of the walls also makes adjustments to the area of limitations. Wide pipes with thin walls up to 2mm thick are generally not recommended to bend. It's better to use welding.

Home craftsmen who decide to make arcs for an arched greenhouse need to take into account that household products made from ordinary carbon or low-alloy steel alloys tend to “spring” slightly after applying force to them. They seem to be trying to return to their previous state. Consequently, after a novice mechanic completes bending all the arches with his own hands, he will have to repeat the processing and again adjust the arches to the template. It is advisable to initially take into account the value of the plastic moment of resistance Wp. It is usually indicated in the documents of the building material being sold. The smaller the moment, the less fuss there will be with the fit.

How to bend a profile pipe at home on a bending plate

This is another option for how to bend a profile pipe without a pipe bender, using devices you make yourself. These include a horizontal metal or concrete slab with holes, a stationary flat template with a fixing element, and a workbench with a mandrel. These designs are good for cold bending of thin tubular products. The principle of operation is simple: one end of the profile is clamped, and the other is pressed under force, bending around the prepared shape. Manual bending requires considerable effort and does not guarantee accuracy.

It should be remembered that rolled steel pipes have a plastic moment of resistance (spring effect), so the bend must be adjusted several times to the template.

How to bend a profile pipe with your own hands and bring it back to its original shape is a difficult task. For everything to work out as planned on the first try, you can’t do without a special machine.

Bending pipes without radius

When creating a spatial frame, designers are faced with the need to manufacture elements in which it is necessary to create parts where sections of pipes are connected to each other at a right angle (90 degrees) or at an acute angle (45 degrees, for example). You can cut the pieces and then weld them together. However, the issue can be solved in another way:

- Make markings for the future cutout.

- Cut out excess metal.

- Perform a bend, connecting the edges of the cut made. Weld the metal along the edges.

Scheme of the technical process of bending at right angles with trimming: 1 – marking; 2 – cutting out excess metal; 3 – bending and welding of edges

This method will allow you to obtain a fairly strong part, in which part of the metal remains intact.

If you do not trim, then the excess metal has nowhere to go. The result is an unattractive appearance of the product.

Direct bending of a profile pipe without trimming

What is the reason for this phenomenon? To understand how simple bending occurs, you should consider the diagram.

Scheme of bend formation in pipes

If a suitable mandrel is available, bending is performed:

- One end is fixed motionless.

- The surface of the workpiece rests against the base surface, relative to which the second end will be moved.

- Force is applied and a new surface is formed.

Why bending profile pipes can be a problem

For a fairly obvious reason - the structure is made of metal, which means the material is quite durable and difficult to modify. But even for these problems, a professional solution exists and has long been invented.

Pipes are bent as follows:

- the metal pipe is heated, when exposed to high temperatures, the metal becomes soft and is better amenable to changes in structure;

- When heated, pressure is applied to the structure; at the point where the temperature rises, coupled with pressure, a bend is obtained in the desired direction.

The most important thing in this matter is not to overdo it, and not to crush the pipe, not to break it, or to reduce its integrity to the point of cracks.

Deformation with internal resistance

For those who are looking for methods on how to bend a pipe at home without corrugation, a method with an internal spring is suitable. We wind it on some suitable workpiece so that the outer side of the spring passes along a profile pipe with a gap of 1-1.5 mm along the entire length of the deformed part. We use wire with a diameter of 1-3 mm, depending on the parameters of the bent pipe.

We warm up the treatment area with a propane torch or blowtorch. Then we insert the pipe being processed into a pre-made matrix with an internal through hole that provides the required radius of curvature. The ratio of the size of the profile pipe and the hole must be taken into account.

The traditional option is one in which sand plays the leading role. It fills the free space inside the profile before bending the pipe. Both free holes will need to be plugged with wooden plugs. You will need clean dry sand. The size of the faction does not matter.

For a small diameter pipe, the use of preheating and river sand is mandatory, otherwise it will burst. Subsequently, they are burned out with a torch, and the sand is poured out.

It is also heated, put on a blank with the required radius and carefully bent. The pipe can cool either in natural conditions or in a bucket of water. This does not have any effect on quality and strength.

As you can see, even in artisanal conditions it will be possible to achieve maximum results. You just need to decide on the processing method and the necessary tools.

Greenhouses using profile designs

The greenhouse frame made of aluminum profile with a multi-pitched roof is a strong, reliable, lightweight structure.

Elements made from profiles are used in many types of modern greenhouses. The multi-pitched roof of the octagonal greenhouse has a durable structure. The material for the frame in this case will be an aluminum profile.

The profile can be forged, shaped, rolled. It rolls up into coils. Aluminum profiles can be processed mechanically: twisted, drilled, cut out. Structures made from this type of profile can be connected with synthetic resins or secured with rivets and bolts.

The profile can be shaped, full, intended for the manufacture of frames for greenhouses and greenhouses, racks, shelving. The shaped profile can be bent, drilled, cut, so that it can be used in the manufacture of the structure.

Types of greenhouses.

The aluminum profile frame is lightweight, durable, requires minimal maintenance, and can be strengthened with your own hands.

The greenhouse has a long service life (20-25 years). A significant disadvantage of a greenhouse is that it is too expensive to build with your own hands.

The leading position on the market is occupied by greenhouses made of galvanized profiles. Products made from it are durable, comfortable, and cheap.

Possible complications during work

The actual bending of such a pipe is the process of giving the element a curved-smooth configuration. This can only be done under pressure, since the part has high strength. To reduce the pressure force required for bending, you can use heating of the bent fragment.

Despite the apparent simplicity of the operation, bending does not always result in elements of the desired configuration. Problems arise quite often. The most common complications include three.

The first is that the inner side of the profile folds in peculiar folds that resemble corrugation. In the correct version, it contracts evenly.

The industry produces many types of profile pipes. They differ in cross-sectional shape, profile height, wall thickness

The second difficulty is the rupture of the outer wall of the profile pipe. During bending it stretches. Sometimes the metal cannot withstand the force and bursts. The third problem is that the pipe, changing its shape, can lose the alignment of the elements.

This means that its fragments in a bent state will lie in different planes. And this is unacceptable. Practice shows that all difficulties occur due to the wrong choice of bending method.

To choose it correctly, you need to take into account the plastic capabilities of the profile pipe. They are determined by the size and shape of the section, as well as the thickness of the walls of the product. Based on these values, you can calculate the minimum possible radius of curvature. Trying to make a round with a smaller radius is strongly discouraged.

To determine the minimum radius, we need the height of the section. It is calculated as follows. The height of the profile is measured, and twice the wall thickness of the product is subtracted from it.

The resulting number will be the desired height, let's denote it h. For pipes with a cross-section in the shape of a rectangle and square, the following rule applies. If the profile height is above 20 mm, the part can withstand bending in a section whose minimum length is hx3.5.

Products with a profile below 20 mm can be bent over a length of hx2.5 or more. This rule applies to all pipes. However, the wall thickness of the part also affects bending limitations.

The thinner it is, the higher the likelihood of a rupture or crushing of the part. Experts strongly do not recommend trying to bend wide products with wall thickness less than 2 mm. In this case, it is optimal to use a welding machine.

When bending a profile pipe, it is very important to perform all actions correctly and carefully, otherwise the part may lose alignment or become wrinkled. This pipe cannot be used

One more thing to be aware of. Pipes made of low-alloy and carbon alloys are very elastic and, after bending, can seem to “spring”, trying to take their previous shape.

This involves additional work with the product, since it will have to be adjusted again according to a pre-made template. Therefore, it is recommended to find out the value of the plastic moment of resistance of a given profile pipe and carry out bending taking this indicator into account. The smaller it is, the less the part will “spring”.

Work at home without a machine

It will be possible to obtain the required bend from a profile pipe without special equipment. All you need is a grinder, a welding machine and yews. The algorithm will be as follows:

- measure out the required pattern, and then draw a template on a free plane;

- We apply the workpiece to it and mark the bending point on it;

- we file three sides of the square profile, and on the fourth you will need to bend the pipe without a pipe bender, clamping the free end into a yew;

- then we weld the resulting part in this position;

- After welding, the seams are cleaned and the workpieces are mounted in the intended location.

Before welding a 2 mm profile pipe, the welder must use protective equipment. We experimentally set the current on the welding machine to use electrodes with a diameter of 3 or 2 mm. Large ones are not suitable here, since if you weld a profile pipe, for example, with a “four”, the cavity will simply be burned through.

Bending pipes along a certain radius with preliminary cutting of grooves

You can often hear the desire to bend a profile pipe by cutting and welding grooves. The process is carried out in the following sequence.

- A cross cut is made on three sides of the pipe. The fourth side is not damaged.

- The inner layer is shifted until the extreme points of the cuts touch.

- After completing the bending along the cuts, welding is performed.

Scheme of the technological process of bending along cuts

Arch (canopy) without pipe bender

As you know, for a canopy, for example, in the shape of an arch, you need a curved profile pipe. It is important to make sure that the arcs are equally curved, otherwise the canopy will not work. Now we will look at how to do this without using a machine, pipe bender and other aids of this kind.

We will need:

- The support on which we will work, for example, a metal table;

- As a beam, you can take a pipe 80 by 60 or 50 by 50 mm, 3 meters long. But this method is universal - so it doesn’t matter what kind of support beam you end up with;

- A profile pipe 20 by 20 or 20 by 40 mm, which we will bend.

Procedure (step by step instructions):

- We divide the support into 6 equal parts. It is very important here - exactly into 6 parts, regardless of how long it is;

- At the dividing lines, it is necessary to weld the posts strictly at 90 degrees to the beam. The middle post is 250 mm, the closest to the middle one is 250 mm * 0.8888 = 222.22 mm, and the outermost (smallest post) is 250 mm * 0.5556 = 138.9 mm;

Photo: welded racks to the beam

- We fix the beam itself to a metal table;

- We take the pipe that we will bend, place it on the racks and move it relative to the beam with an allowance of 10-15 cm, so that there is a lever that we can grab and bend it around the racks;

- We tie it to the beam with a rope (fix it);

Photo: we placed the profile pipe on the posts and tied it with a rope to the beam. Next, we carefully bend the pipe around the posts and weld it to the ends of the beam using a welding machine.

Photo: this is how we get a bent pipe for a canopy - Next, make the required number of such structures (arches), use polycarbonate sheets and your arched canopy is ready!

Upgraded bending plate

If a home mechanic is not deprived of physical strength, for his own needs he will need a simple tool for the rather labor-intensive deformation of a profile pipe. It can be made in the form of a panel attached with clamps to a desktop or workbench. In the case shown in the photo, the bending plate is welded to a metal pedestal, but it is screwed with four bolts to the concrete floor of the workshop. To remove the device upon completion of work, it will be enough to unscrew the bolts. After dismantling, no fastening pins remain and do not rise above the floor surface, which means that nothing will interfere with movement and create traumatic threats.

The principle of manufacturing a working plane is extremely simple:

- The bending plate is a panel cut from thick sheet iron.

- The panel is welded to a profile pipe, installed according to telescopic rules in the pedestal stand.

- Two holes were drilled in the working plane for bolts, which act as stops.

- The bending radius is adjusted by installing nozzles of a suitable size on one of the bolts.

- In order to maintain the alignment of the sections adjacent to the bend, a metal plate is installed above the workpiece, secured with bolts.

The pedestal is multifunctional. Its owner has the opportunity to use it as a miniature workbench to perform an impressive number of plumbing operations.

Mandrel for bending profile pipes

The method is suitable for products with a wall height of up to 25mm. The craftsman will need a large workbench and a significant amount of free space around the work area. One edge of the workbench is perforated with frequently spaced holes for fastening the mandrel and for selecting the optimal position of the part fixing the pipe. A template for the upcoming plastic deformation is cut out of thick plywood. True, the plywood mandrel is suitable only for one-time bending procedures. If there is a lot of bending work to be done, it is better to weld the mandrels from angle steel.