Greenhouse / Types of greenhouses

Greenhouse "Sotka"

A greenhouse or hotbed on a country plot is built for two purposes: personal consumption of fresh vegetables and other crops all year round; growing plants for sale. For this reason, the design must be strong and reliable. A weaving greenhouse has these properties.

- 1 What is the Sotka greenhouse 1.1 Characteristics of the Sotka greenhouse

What is the Sotka greenhouse?

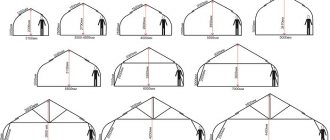

Weaving greenhouses are arched structures that are often used in everyday life. They have the following dimensions:

- Height - 2.15 m.

- Length - 4, 6, 8, 10 m.

- Width - 3 m.

The main advantage of the greenhouse design is that it can be freely supplemented with arcs at a distance of 2 m from the main ones. Let’s take a closer look:

- The frame of the greenhouse is made of galvanized profiled pipe.

- Its thickness is 0.8 mm.

- The greenhouse has windows and two doorways.

- Used for work on the production of V-shaped profile.

- Steel has its own characteristics.

Design:

- Durable and reliable.

- Unable to respond to changes in temperature and exposure to fire.

- It is not afraid of a humid environment, which is inherent in greenhouses and greenhouses, and does not rot.

- This frame is covered with cellular polycarbonate.

- It also contributes well to a favorable microclimate inside the structure.

Recommendations for installing a greenhouse in a suburban area:

- The structure should only be installed in open areas.

- The structure must be connected to water and electricity supply pipes.

Note. Weaving greenhouses are simply installed and also dismantled.

- The base of the greenhouse is stable, as it consists of a rectangular profile pipe with reinforced stiffeners.

Advice. When choosing a finished structure of this type, you need to pay special attention to these profile pipes. They should be made of good durable metal.

Characteristics of the Sotka greenhouse

Sotka greenhouses are in great demand. Grateful customers leave only positive reviews about them on numerous websites. Greenhouse characteristics:

- Large interior space.

- Durability of the structure.

- Practicality.

- Ease of retrofitting a greenhouse.

- Year-round use of the structure.

- Constant temperature support.

- Affordable price.

See photos of the Sotka greenhouse

- The height of this type of greenhouse is quite large. The arches are located with a bend almost at the very top. Thus, there is a lot of space inside the structure, which makes it possible to grow crops in several tiers. Only initially it is necessary to install special stands made of metal or wood.

- The durability of the greenhouse is ensured by the service life of the materials from which it is made. Galvanized steel can last forever, and the cellular polycarbonate used as a coating can last at least 30 years if installed correctly.

- The Sotka greenhouse is quite practical. Installing it is simple. There are instructions for the work. It has step-by-step actions. The design does not require any special maintenance. It is portable.

- A greenhouse or greenhouse of this type has simple retrofitting. You can do it yourself without much difficulty. For this, there is an additional set of arches that are attached to the main frame using special fasteners.

- It is possible to create a favorable temperature regime inside the structure. Due to the fact that the coating is made of polycarbonate, it holds the temperature well. There are also windows in the greenhouse (see How to make a window in a greenhouse) located at the top. This promotes high-quality ventilation of the greenhouse, as heated air rises to the top.

- The design can be used both in the warm season and in the cold. The greenhouse is well heated using modern heating systems. A coating such as polycarbonate has high light transmittance, which makes it possible to warm the greenhouse with sunlight.

- Well, the cost of the Sotka greenhouse is low, which increases the demand for it several times.

Average and record indicators for Russia and other countries

The leaders in potato yields in Europe are: the Netherlands, Belgium, England, France, Germany. More than 400 centners are collected per hectare.

| A country | Output per hectare (t/ha) |

| Ireland | 37 |

| Denmark | 39,5 |

| Belgium | 42,3 |

| Great Britain | 40,5 |

| France | 43,2 |

| Netherlands | 44,7 |

| Germany | 42,3 |

| Ukraine | 13,1 |

| Poland | 0,7 |

| In Belarus | 21,2 |

| Russia | 12,9 |

| By region | Centner per hectare |

| Tula region | 250 |

| Bryansk | 229 |

| Kursk | from 200 to 300 |

| Voronezh | |

| Penza | |

| Bashkir, Tatar Autonomous Republics | |

| Moscow region, Ural, Siberia, Tyumen | up to 210 |

Statistics show that the average in Russia varies from 200 to 300 centners per hectare. The agricultural company KRIMM in Tyumen managed to achieve record figures (500 c/ha).

The main reasons for the low performance in Russia:

- most of the territories belong to the so-called “risky farming zone”;

- use of low-quality seed material, low-yielding varieties;

- reduction in yield due to excessive use of pesticides and mineral fertilizers;

- low level of agriculture;

- use of outdated agricultural machinery;

- violation of crop rotation.

- Planting potato varieties need to be updated every 3-6 years. Regular planting of one type of potato leads to degeneration of the planting material.

More than 80% of potatoes in Russia are grown in private households, in contrast to countries with high yields. In Europe, agricultural crops are grown by farms that use advanced technologies.

Assembling the Sotka greenhouse

Frame of a greenhouse or greenhouse with legs for digging in

Installation of such a structure is quite simple in a suburban area.

More details:

- Install the greenhouse on the base.

- It can be monolithic or made of brick.

- You can not use a base, but dig the greenhouse arcs into the ground to a depth of 50-70 cm.

Work process:

- Initially, pipes are installed, which are the base of the greenhouse.

- They are screwed together with special bolts and screws.

- They are also buried or fixed on a prepared base.

- Next, arcs are mounted to them.

- They are fastened together with a special strip at the top of the frame. It is screwed into factory-made holes.

- Next, the work process proceeds to the installation of cellular polycarbonate.

- It is screwed onto the surface of the frame with self-tapping screws, which are included in the kit.

Advice. You should not install the material in a stretched manner, since the polycarbonate structure expands under the influence of sunlight.

The joints of the material are treated with sealant to prevent air masses from penetrating through the cracks into the interior of the structure. The entire assembly process can be seen in the video.

Advantages and disadvantages of drugs

AMKO fertilizer has a number of advantages:

- does not contain chlorine;

- dissolves in water without sediment;

- a complete set of nutrients satisfies the needs of the plantings;

- microelements are introduced in chelated form, so they are easily absorbed;

- correctly selected formulas make it possible to grow healthy and abundantly fruiting plants;

- amko is compatible with other fertilizers (including pesticides) and serves as an excellent addition to them;

- suitable for spraying, drip irrigation, sprinkling;

- does not clog the nozzles in the sprinkler.

downside to AMKO is the mandatory testing for phytotoxicity and compatibility with other drugs.

Sotka fertilizer has its advantages:

- competitively priced relative to similar mineral supplements;

- includes the number of components required for a particular culture;

- convenient to use;

- the composition is balanced.

The only downside of the drug is the need for additional addition of organic matter in the presence of depleted soils.

Making your own greenhouse

Greenhouse project

For work you will initially need:

- Draw the structure.

- Set its limit parameters.

Note. The greenhouse must be of a size that can fit freely on the site.

- Calculate the required amount of materials.

Consider:

- Initially, a greenhouse project is drawn on the sheet.

- It indicates: the height of the greenhouses, width and other dimensions of the structure.

- They can help in calculating the required material.

Advice. The length of the greenhouse should always be a multiple of 2 m. This will make it easier to retrofit the structure if necessary.

Materials you will need:

- Profile pipes.

- V-shaped pipes.

- Cellular polycarbonate.

- Bolts, self-tapping screws and screws.

From the tool you will need:

- Construction level and tape measure.

- Chalk and grinder.

- Drill and hammer drill.

- Screwdriver.

- Shovels and improvised tools for installing a greenhouse after production.

Note. Pipes that will be used as arcs are initially rolled on a special machine, which gives them this shape.

Recommendations:

- You should not use thin-walled profile pipes for the base of the structure.

- They are fragile and cannot withstand heavy loads.

- Other components may be thin-walled.

Advice. Instead of bolts and screws that hold all structural elements together, welding can be used. Only in this case it will not be possible to call the greenhouse portable. The frame structure will be solid and during dismantling you will have to cut the welding seams with a grinder or other tool.

Work process:

- The base is assembled immediately. All its elements are fastened with bolts.

- Ready-made arcs are attached to it in a similar way.

- At the top, these arcs are fastened with a metal corner.

- Polycarbonate is mounted on top of the frame using self-tapping screws.

Calculating the amount of harvest

Potato yield depends on many factors, including: variety, quality characteristics and size of planting material; type of soil; climatic conditions; cultivation technology.

We calculate the amount of harvest per hundred square meters, hectare. Cultivation using the traditional method, planting in rows.

| Row width | Step between planting tubers | Number of furrows | Number of tubers/bushes in a row | Number of mother tubers | Can be assembled | ||

| 1 weave (10 x 10 m) | |||||||

| 400 mm | 14 | 25 | 350/ weight with reserve 29 kg | 525 – 700 kg | |||

| 1 hectare | Output per hectare | ||||||

| 400 mm | 142 | 250 | 35,500/2.9 tons | 4.350 t - 5.8 t | |||

The use of innovative techniques will double the yield.

Why is cellular polycarbonate so popular in greenhouses and greenhouses?

Cellular polycarbonate

Quite often, greenhouses are made under polycarbonate. On our resource you can learn about the Agrosphere greenhouse, which is very popular. This is due to:

- Practicality and durability of the material.

- Polycarbonate reliably withstands significant loads and is easy to install.

- It does not allow heat to pass out and contributes well to the formation of a favorable microclimate in the greenhouse.

- It does not burn and is not affected by a humid environment.

- Its main advantage is that it evenly distributes the sun's rays inside a greenhouse or greenhouse due to its honeycomb structure.

- This is where the name “cellular” polycarbonate comes from.

Note. Polycarbonate greenhouses can be based on either a metal or wooden frame. Large diameter plastic pipes are also used quite often. The material does not have much mass.

Cellular polycarbonate can be used not only in the warm season, but also in the cold. It is frost-resistant, which means it can withstand low temperatures outside and high temperatures inside.

How to choose a greenhouse (video)

Ability to adjust temperatures

Thanks to the small size and practical location of the ventilation vents, adjusting the temperature inside the room becomes even easier. When the doors and vents are closed, the greenhouse temperature rises, and after opening it drops slightly, which at the same time regulates the humidity.

Use in early and late season

Thanks to the good light transmittance of polycarbonate, the tightness of the greenhouse and the ability to maintain temperature inside, Sotka can be used in early spring as a greenhouse for growing seedlings with stable humidity and temperature. Also, its use is possible until late autumn, provided that additional equipment is installed inside.

In addition, to the advantages of this type of greenhouse I would like to add two concepts that go well together - lightness and high reliability. But we shouldn’t forget about the ease of installation, which can be done even without much experience and in just one day.