Choosing a greenhouse

Of course, before purchasing a greenhouse, it will be useful to think about its strength in advance. To do this, you should choose the safest covering material, for example, glass.

A strong metal frame is also selected for it. With this choice, summer residents do not have to worry about breakdowns during the winter.

When choosing polycarbonate, summer residents are advised to pay attention to its thickness. Sheets from six millimeters are much stronger and can withstand greater snow cover. They bend and are rarely damaged.

Causes of a snow cap

Most arched greenhouse designs have an optimal shape for snow sliding. Why does it accumulate in such quantities and how to strengthen a polycarbonate greenhouse with your own hands? The reasons for the accumulation of snowdrifts on the roof lie in the special properties of cellular polycarbonate (CPC). In winter, in sunny weather, even at an ambient temperature of -15°C in the greenhouse it can be up to +3 - +5°. On the heated surface of the polycarbonate, snow melts, which freezes when the sun sets. The resulting rough surface serves as a reliable basis for the accumulation of snow cover of significant, up to 80 kg, mass. Considering that the frame made of the most common metal profile can withstand a load of no more than 30-50 kg/m2, the need to strengthen it is obvious.

The result of using a budget greenhouse that is not too strong

Weak frame

It has already been mentioned that troubles can arise due to insufficient strength of the frame. This happens because the manufacturer wants to save on a galvanized profile. Therefore, the greenhouse becomes easily accessible and inexpensive, but with a weak foundation. The owner can solve this problem by doing the following:

- As an option, you can disassemble the structure for the winter;

- Or during snowfalls, periodically monitor the construction. Clear the roof of snow cover;

- Use temporary reinforcement of greenhouses - wooden supports;

- You can purchase a greenhouse with a reinforced base;

- Strengthen the frame yourself.

Possible thermoplastic problems

If the polycarbonate has darkened or become cloudy, moisture has appeared in the honeycombs, and the slabs have swollen or bulged during hot weather, it is necessary to urgently address the defects. The best option would be to completely replace the thermoplastic.

If the owner of a greenhouse structure discovers a breakdown, he first needs to determine the cause of the problem, and only then begin to fix the problem. Only with such a sequence can possible troubles be avoided in the future.

Source: web-selo.ru

Detection of greenhouse defects

Planned strengthening of the structure begins with an inspection. It is necessary to inspect the roof made of polycarbonate or glass.

It is worth paying attention to all changes: cloudiness, crack, dent, swelling. All of the above damage can cause damage to the entire structure. Also, don’t forget to check the frame.

Summer residents most often use a level to detect distortion. The metal base is checked for corrosion, and the wooden base is checked for mold.

- To avoid damage to the frame, it is recommended to clean the surfaces every season before planting garden crops.

- Damaged areas must be cleaned with sandpaper, followed by treatment with special means.

- For this purpose, antiseptics, varnish, and anti-corrosion agents are used.

If no damage was found, then the surfaces of the greenhouse must be cleaned from the inside and outside. Then carry out disinfection and partially replace the soil.

Greenhouse supports

Temporary and the most common method of strengthening a greenhouse. Owners of polycarbonate structures often resort to installing wooden supports. They are made from timber and other durable materials.

- Supports for polycarbonate greenhouses come in two types.

- The first type is longitudinal, which are located along the entire structure.

- They are used to support the roof ridge. The second type is transverse supports, which are arranged in the form of arcs.

- Temporary reinforcement gives reliability and strength; it can withstand snow cover.

Some summer residents also strengthen the roof ridge with additional vertical elements. Their best location in the greenhouse is at the intersection of the longitudinal and transverse profiles, as it is the strongest.

It is worth clarifying that temporary reinforcement of the structure must be carried out before the onset of winter cold so that the ground is not very frozen.

How to secure a greenhouse so that it does not blow away in the wind. How to strengthen a greenhouse from the wind

Even if there are good quality greenhouses on the site, many summer residents still build a temporary greenhouse. A greenhouse, purchased or made with your own hands - it doesn’t matter - must be strengthened from the wind. Typically, a greenhouse is used to grow early vegetables or flower seedlings on a plot and is constructed from available materials: old arcs, boards, film, etc. With the onset of stable warm weather, the greenhouse can be removed, but it happens that they continue to use it, sheltering the crops from the hot sun with lutrasil. In our Northwestern region, winds are a frequent occurrence, so I know firsthand how to strengthen a greenhouse against the wind.

A greenhouse on a site can be of various designs: in the form of a tunnel, trapezoidal and even round. But no matter what shape it is, make a greenhouse on a rigid frame. This is the first thing that will help strengthen it from the wind.

You can install arcs from any material on top: plastic pipes, thick wire or pieces of flexible iron, you can even take long willow rods. I had an old thick cable on hand, which I cut into equal pieces and bent as I needed, and it perfectly served as an arched frame. To cover the frame in this case, I used a film of 80 - 100 microns, that is, not too thick and heavy. And since the cable bent well, I secured its ends without using any tools or parts, simply by wrapping them around wooden blocks.

My greenhouse could withstand strong winds, but I still had to press down its sides with pieces of slate.

It is better to immediately make a more advanced greenhouse design that is better protected from strong winds.

- Connect the boards in a way convenient for you, placing them on edge and giving them the desired shape, for example a rectangle. This will be the base of the greenhouse. It must be stable and weighty. If your structure is made of thick plywood, then you can make it heavier by screwing (nailing) heavy metal brackets to it. This is necessary so that the greenhouse does not get torn out of place in a strong wind.

Then prepare arcs, for example from PVC water pipes.

Lay the frame on the ground (prepare the area in advance, level it, fill it with sand around the perimeter), and secure it with wooden stakes or reinforcement. The stakes need to be driven into the inner corners of the base; for additional stability, you can secure the frame and stakes together with clamps.

Now you can install the arcs for the greenhouse. When installing from the inner long sides of the base, maintain the optimal step between them - 60-80 cm. If your arcs are made of PVC pipes, then you should not immediately stick the ends into the ground, this will be difficult. It’s better to first drive in pieces of thick reinforcement or other suitable material, and only then install arc pipes on them.

Connect all the arcs together at the top using strong twine.

After covering the greenhouse with film, secure it with special holders. If there are none, ordinary large clothespins may be suitable, preferably wooden ones, since plastic ones quickly lose their strength in the sun and break. As a film holder on the arcs, you can cut pieces from an old watering hose of a suitable diameter. Each piece must be cut lengthwise on one side and placed on an arc.

In order to save material (film, lutrasil, spunbond), the gables can be closed in separate pieces, having first wrapped them around the arc and pinned them with a stapler.

Near the ground, along the long sides of the greenhouse, it is necessary to put a weighting material on the film and it is better if it is not bricks and stones, but a long block with a cross section of 50 mm by 50 mm. Wrap the block with film a couple of times and staple it through a strip of any narrow fabric, rubber, or other film. This way your film will not tear and at the same time you can additionally strengthen the greenhouse from the wind. If you need to water or ventilate the greenhouse, it will be more comfortable to open it on one side, wrap the film on the block and throw it over to the other.

Note.

The clamp for fastening can be made from any tin, even cutting a strip from a tin can.

As you can see, there is nothing complicated to strengthen the greenhouse from the wind. On my own behalf, I’ll just add that if you do not cover the gables with separate pieces of material, then when deciding on the size of the film, do not forget to leave the excess for the gables; it should hang from the ends of the bar.

Author of the article: Love

When copying text, please indicate the address of our website.

Duplicate arcs for greenhouses

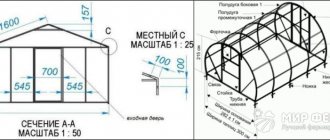

With the help of additional equipment, it is necessary to form arcs that will repeat the shape of the main elements of the greenhouse base; as a rule, they are formed with a smaller radius.

Summer residents recommend making arcs using reinforcement, a metal profile or a pipe. After this, they are welded to the main structure using jumpers, which are also made of metal.

Most often, greenhouses are made with special arcs of the same radius as the frame. They need to be placed next to the base, retreating a distance of about a meter.

Instructions:

- Additional arches are bent.

- The manufactured parts are attached using electric welding to five-centimeter poles, which are also made of metal. Most often, arcs of the same radius are used, but the installation method is different. They are attached side by side at a distance of a meter from each other.

- After the frame of the greenhouse is strengthened, its surface can withstand snow cover of up to two hundred kilograms.

Do not forget that before using electric welding it is necessary to clean the joint areas from scale and apply anti-corrosion paint.

Constant gain

Permanent strengthening for many years can be done using electric welding, if the crossbars are welded to the frame of the greenhouse.

- Reinforcement can protect the structure from damage and reduce the load.

- How often transverse reinforcements need to be installed depends on the quality of the material that was used for the main frame.

- Usually, 1 crossbar is placed at a distance of half a meter, so the structure will be the most durable. The crossbars should be at different heights.

There is a similar method, but the crossbars are installed in a vertical position. They act as supports for the walls of the greenhouse. In addition, you can use the method of duplicated arcs described above.

Autumn processing of greenhouse beds

It all starts with cleaning. On a dry, not rainy, windless day, go to the greenhouse and remove all plant debris from it.

Plant residues in the greenhouse

The first stage is general cleaning

There are not many issues with clearing the beds of annual crops - you simply remove the old plants, and, if possible, all their parts, underground and aboveground. The same applies to the remains of fruits and vegetables - in short, everything that interferes with the cleanliness of the beds must be removed.

Advice! Even if the plants in the greenhouse were not sick, were not affected by pests, and you did not treat them with chemicals, do not send the collected plant debris to the compost pit and do not leave it on the site. There are two ways to dispose of plant waste - burning or burying it off-site. If your gardening association provides organized waste collection, you can send the waste there.

Cleaning up debris within the greenhouse

In addition to annual plants, perennials are sometimes located in the greenhouse. Weed perennials are dealt with in the same way as with the remains of cultivated plants - they are uprooted and disposed of. Cultivated perennials - for example, garden strawberries - are subject to careful inspection to remove rotten, dried, damaged specimens. They are also removed along with the roots, and in the spring new ones are planted in their place.

The second stage - removing the soil

This is the most time-consuming task of all that you face in the process of autumn processing of the greenhouse. But it must be done, and done well. If annual vegetables, flowers or other useful plants are grown (and in most cases this is the case - greenhouses are installed for this purpose), the top layer of soil must be removed annually. This is an immutable rule that underlies the future harvest.

The layer of removed soil is at least 15 cm. There should be no difficulty with where to put this soil - it can be taken out to open ridges, sprinkled on flower beds, under trees, in alpine hills. Only before this it is advisable to disinfect the removed soil.

Soil replacement

The question is more complicated - what to put in the greenhouse instead of the removed soil. In a short period you need to create a new fertile layer. This is not easy to do, since beneficial microorganisms have a limited period of time - before the onset of frost - to begin processing the new soil. Therefore, the soil must be ideal.

There are two ways to replenish greenhouse beds with soil:

- import from outside (purchase);

- independent preparation (composition of various components in accordance with the necessary requirements).

The first way is simpler, but has pitfalls. It is the purchased soil that does not guarantee the presence of all the necessary components. Moreover, contrary to promises, unscrupulous sellers may bring you soil that was previously removed from other greenhouses. It will look loose, dark, humus, fertile, but pouring it into a greenhouse is the same as not removing your waste soil, or even worse. New soil means new bacteria in addition to those already present on your site.

The top layer of soil in the greenhouse needs to be replaced

There is only one way out - to prepare the soil yourself.

Table No. 1. What kind of soil should be used to replace it in a greenhouse?

| Soil parameter | Description |

| Correct structure | The soil should have a structure that does not require loosening after each watering. In this case, the soil fractions should not be small, resembling dust, which when mixed with water produces dirt, and not large, through which water passes like through a sieve. |

| High nutritional value | The soil must contain all the nutrients that plants need for full development. It should be rich in humus, that is, it should allow plants to quickly grow a high-quality and powerful root system, which, as we know, is impossible without its (humus) help. |

| No mineral salts | Yes, the initial soil in the greenhouse should be without mineral fertilizers. The nutritional value of the soil does not mean enriching it with minerals, which will destroy the young shoot instead of providing it with nutrition. The sprout is unable to absorb mineral elements, it's like feeding a newborn baby fried potatoes. The necessary mineral fertilizers will be applied later - in the spring, after planting the seedlings. |

| Moisture capacity | The soil must accept moisture and retain it, this is especially true for heated stationary greenhouses. |

| Neutral pH | This is important - the content of acidic salts and alkali must be balanced. |

| Disinfection | Pathogens should not survive in this soil by spring. This can lead to the death of the entire seedling or subsequent diseases of the seedlings. Only thoroughly disinfected soil can guarantee the absence of bacteria. |

Liming acidic soil

As for the composition of the soil, it is classic and includes:

- raised peat;

- river or lake sand;

- compost or humus.

And then the soil is designed to stop the effects of harmful substances, converting them, if not into useful ones, then at least neutral ones that do not harm plants. Humic acids help the soil in this, which makes it fertile and meets all the parameters of good soil. Manure, droppings turned into humus, processed by insects - this is a simplified scheme for replenishing the soil with such valuable and necessary humus. In this scheme there is no place for mineral compounds, which are probably contained in purchased soils.

But if you don’t have time to wait for beneficial microorganisms to create a fertile layer, you can use humic acids. The soil prepared for replacement is treated with Flora-S according to the instructions. After this, all that remains is to disinfect the soil. But for this it is not at all necessary to pour boiling water, urea into it and poison it with potassium permanganate. Bacillus subtilis, which is contained in the Fitop-Flora-S preparation, will cope with the task much more effectively and with benefit for the soil.

Fertilizers "Flora-S" and "Fitop-Flora-S"

Advice! Whatever type of vegetables you grow in a greenhouse, every five years you need to completely replace the soil in it (not superficially, as every year) to a depth of 35 cm. There is another option - in the fifth year, move the entire greenhouse to a new location.

Prices for humus

humus

The third stage – disinfection

While the soil treated with humic acids is “ripening,” it is necessary to disinfect the greenhouse. All means are good here, but the most commonly used are treatment with urea or other disinfectants and fumigation with sulfur. The second method is good because it can be used to disinfect not only the soil layer remaining in the greenhouse, but also the entire structure from the inside.

Fumigation is considered one of the best and most common methods of greenhouse disinfection

Important warning! Greenhouses that have a metal frame as the basis of their structure cannot be fumigated with sulfur.

Table No. 2. Methods for disinfecting a greenhouse.

| Disinfection method | Description |

| Using urea | An aqueous solution is prepared from the substance. The proportions are as follows: 50 g of urea per 10 liters of water. The water is cold, the urea should dissolve completely. The resulting solution is thoroughly watered over the entire area of soil in the greenhouse, not only reclaimed beds, but also walkways, paths, and row spacing. |

| Fumigation with sulfur | The old-fashioned method is 50 g of sulfur per m² of greenhouse working area. Add kerosene to the sulfur (the proportions are arbitrary), close all the windows in the greenhouse and plug the cracks. Light the sulfur and kerosene on fire and immediately leave the greenhouse, closing the door tightly. The effective temperature for this procedure is +12°C. The modern method of sulfur disinfection involves the use of a smoke sulfur bomb. But it works faster - 6 hours is enough (versus 48 of the “sulfur-kerosene” method). The precautions are the same: respirator, goggles, gloves, retreat after setting fire as quickly as possible. |

| Disinfectant solutions | You can use: - formaldehyde liquid composition 2.5%; - copper sulfate in a solution of 0.75%; - slaked lime with water, diluted to 10%; - creolin solution 2% concentration. |

Video - How to disinfect a greenhouse

Features of strengthening

Replace cladding material.

- Before strengthening the frame, it is recommended to pay attention to the condition of the polycarbonate sheets.

- The most inexpensive options most often correspond to a thickness of 4 millimeters.

- Polycarbonate surfaces are recommended with a thickness of at least six mm, so it will be stronger.

It is important for summer residents not to forget about the period when it is necessary to strengthen the greenhouse. The supports are installed before frost to prevent the soil from freezing.

Temperature changes are important to consider; they can cause soil heaving. Therefore, the soil may push the supports out and cause damage to the greenhouse.

Film and glass

It is recommended to remove the film for the winter. She may not be able to withstand the weight of the snow, which will fall on her like a thick blanket in winter. The material must be washed with laundry soap dissolved in hot water. Then the film is rinsed, wiped with a solution of copper sulfate (5%) and hung out to dry in the sun.

When there is no water left on the surfaces of the film, the material is rolled up. They are packaged in sealed bags and stored in the house.

If the greenhouse has non-removable panels (cellular polycarbonate) and glass that cannot be disassembled, they are washed inside and outside with a window squeegee. In corners, in places of heavy dirt, you will have to work with a hard sponge. The gaps between the frames are cleaned with a wedge wrapped in cotton fabric. In the glass processing process, a solution of laundry soap is used. You can use dishwashing detergent diluted in water.

Then the glass surfaces are rinsed with clean water and additionally treated with a solution of bleach (4%).

Polycarbonate cannot be cleaned with alkaline compounds or chlorine-based products. Also, do not wash surfaces with a metal sponge or a stiff brush. Even a scrap of burlap will not work for these purposes. You should also not use washing powder, glass or dishwashing liquid. Polycarbonate is cleaned with water under pressure and then wiped with a strong concentration of potassium permanganate solution. To wipe off heavy stains, use a flannel cloth soaked in soap suds.