Today we will talk about the criteria by which greenhouse film is selected. What you need to pay attention to first. How much does film cost per meter of roll length? What dimensional parameters should you pay attention to in order to reduce material costs?

The greenhouse is covered with plastic film Source obyava.ua

A little about film and greenhouses

It should be noted that polyethylene film, used by many summer residents as a covering for greenhouses, is a cheap material. But its popularity ends there; this polymer product has never aroused much respect or trust. It's all about its shortcomings, of which there are not so few:

- transparency deteriorates over time;

- at low temperatures compression occurs, at high temperatures sagging occurs;

- low mechanical strength;

- condensation forms on the inner surface;

- under the influence of natural loads it quickly fails.

Today, manufacturers have refocused film production on greenhouses. They began to offer completely unique varieties of material with higher technical and performance characteristics. For example, increased frost resistance, elasticity and strength, the ability to pass fresh air through the greenhouse and remove carbon dioxide back, a high level of transparency and the ability to better diffuse light.

It must be admitted that there are more than a dozen new types of film for laying on greenhouses. This is not to mention the experimental models that sometimes appear on the market. All of them are many times better than ordinary polyethylene. But in terms of price, availability, and ease of use, this is the most ideal option.

Condensation on the film from inside the greenhouse Source kupolvz.ru

Top quality products

Polyethylene film, which can be purchased in Yekaterinburg in various sizes and with the addition of the necessary components, has a very wide range of applications. It is used to protect furniture during finishing and repair work, in agriculture as a soil-protective and covering material in greenhouses and greenhouses, on construction sites for localizing premises, waterproofing floors, walls, and ceilings. You can buy polyethylene film, the price of which is quite acceptable for both retail buyers and wholesalers, for use as packaging material. It is used to protect household appliances, furniture, office equipment and other things during moves; it is durable and reliable packaging for food, garbage, items sent by mail and effectively secures products on pallets.

Types of greenhouse film

Despite the fact that there is a fairly wide range of film material on the market, all of it can be divided into three main groups:

- polyethylene film;

- polyvinyl chloride film;

- perennial

It should be noted right away that each group also has subgroups. Let's consider each option separately.

Polyethylene

Here are several positions that differ from each other in manufacturing technology and the structure of the material itself:

- unstabilized;

- stabilized;

- heat retaining;

- reinforced

Polyethylene film for greenhouses Source incomewm.ru

The first position is a regular film with a thickness of 0.015-0.3 mm, a width of 3 or 6 m, most often it is a sleeve. Based on external indicators, for example, it is difficult to distinguish it from a stabilized model. But it has a short service life on the street - no more than 7 months. Under the influence of natural loads, the material quickly breaks. Plus another serious drawback - drops of condensation accumulate on the inner surface, which fall into them, moistening the soil, which is not always acceptable. But it should be noted that this film has good light transmittance - up to 80%. And one more point: polyethylene film has the same strength in both length and width, regardless of the thickness of the material itself.

The stabilized version has improved performance characteristics due to the introduction of various additives into the raw polymer. Here are the positives:

- the accumulated condensate flows over the surface without forming a drop;

- transparency – up to 90%;

- dust does not settle on the surface because antistatic additives are added to the material, so transparency always remains unchanged;

- Well suppresses infrared radiation.

Stabilized polyethylene film Source besplatka.ua

See also: Catalog of companies that specialize in the installation of metal structures.

The third position is heat-retaining. This model got its name because it retains 10-30% more heat. Therefore, it is chosen by those who close their greenhouses for the winter. After all, energy savings today are not the least important indicator in the expenditure side of the family budget.

The heat-retaining one differs from the two previous options primarily in its whitish color. Hence, in principle, low light transmittance. And its strength is lower. But the rest of the indicators are exactly the same as the stabilized one. Service life - no more than a year.

The reinforced version is also made of polyethylene. But organizations involved in standardization brought it into a separate GOST. This made the film stand out from the rest, but there are special reasons for this. One of the main ones is the frame, which can be made of different materials:

- compressed low-density polyethylene;

- twisted polyethylene;

- fiberglass;

- stretched polypropylene.

Reinforced film for greenhouses and greenhouses made of polyethylene Source liantrade.ru

At the same time, the strength characteristics, as well as the service life of the material, depend on its thickness. For example, a film with a thickness of 0.29 mm will last at least five years. And with a thickness of 0.32 mm, seven years.

It should be noted that the reinforced version is made of a stabilized film into which the frame is inserted. At the same time, transparency due to the frame structure is reduced by 10-15%.

So, having dealt with such a material as plastic film for a greenhouse, which is not a problem to buy today, I would like to outline the price component. It should be noted that in retail, film is sold in meters or rolls, and at wholesale prices the price is set for 1 kilogram. We will be interested in the retail cost, which varies in ruble equivalent depending on the thickness of the material. For example: regular film for a greenhouse - price per meter: 7 rubles. This is taking into account that the thickness is 0.2 mm.

As for reinforced, much will depend on the density of the product. The table below shows the relationship between these two parameters. At the same time, the price is indicated for a roll 50 m long.

| Density g/m2 | 80 | 100 | 200 |

| price, rub. | 2600 | 3200 | 5300 |

Production of polyethylene packaging

Polyethylene film, its types and methods of application

Polyethylene PE film is a thin-sheet polymer fabric that is in demand in various industries. It is used for the production of packaging, construction and finishing materials. The manufacturing technology of polymer fabric is regulated by standard 10354-82. According to this GOST, polyethylene film is produced from appropriate PE granules and additional components using extrusion technology. The raw materials for this material are 2 types of polyethylene: high and low pressure (LDPE, HDPE). Using extruders, various plastic materials are produced, the shape of which is determined by a profiling tool. The film thickness is measured, microns, which depends on the brand and ranges from 15 to 500 microns. Additional equipment ensures cutting of polyethylene tape in accordance with the specified parameters.

What kind of film is there?

This roll material is produced in several versions and formats to suit the needs of the industries for which they are intended.

Based on light transmission they are divided into:

The transparent film is made without adding any dyes. Colored with fade-resistant pigments. The color of the film can be either standard (white, black, yellow, green, etc.) or unusual (gold, silver, etc.). White film is most in demand for the production of bags for chain stores.

Additives used in the film manufacturing process provide improvements in certain properties. These additional components turn the canvas into:

Regular unstabilized - without additional ingredients.

Light-stabilized with an extended service life contains an additive that protects the material from exposure to direct sunlight.

Hydrophilic (antifog) – a smooth surface with water-repellent properties, guarantees rapid drainage of condensation and precipitation. It is recommended to buy this type of greenhouse film, as it prevents the accumulation of large water particles, which create a lens effect and cause overheating of the plants.

Antistatic agents in the composition have a repulsive effect on various pollutants.

Various manufacturing technologies allow you to buy the following types of polyethylene film:

- with reinforcement;

- color, including dark, white films;

- from first-class or recycled materials;

- stretch films, etc.

Single and multi-layer versions are produced, which are available in the following form:

The canvas is a smooth film, without connecting joints or folds.

The sleeve is similar in appearance to a folded pipeline, which is rolled into a roll. There is a classic type of fold in half, and with folds (with side pleating).

The half-sleeve is a fabric folded in half.

Methods of using polyethylene film

Packaging varieties

Polyethylene packaging includes a wide range of products. This category includes all types of packages and bags for products, including food products, medical products, household chemicals, building materials, furniture, etc.

Stretch film

used for packaging and sealing food and non-food products. It is capable of stretching almost 3 times, tightly wrapping objects, and returning to its original parameters. This film is thin and has increased strength. This property makes it possible to secure objects of any size on a pallet and prevent them from moving during transportation. Disposable polyethylene cling films in Moscow are in demand by trade and logistics enterprises. Since they have the property of sticky layers that seem to stick together without any additional means of fixation. The film thickness of this type of fabric varies from 8 to 30 microns.

It is also used: in the construction industry for waterproofing the foundation from groundwater, in agricultural activities for the installation of greenhouses. Many enterprises decide to buy film due to its low cost and versatility of use.

Reinforcing film creates reliable waterproofing of building materials. Its use allows you to increase the service life of buildings and structures whose structure is affected by high humidity. Without the film, elements such as the foundation are subject to a greater reduction in load-bearing characteristics. Spacious greenhouses can be built under this class of film, which will ensure increased productivity.

What does the cost depend on?

The price of polyethylene film is determined by several indicators, including: brand, thickness, and length in linear meters. The most expensive include thick protective films and printed products. Polymer packaging materials are average in cost. For example, a plastic bag is often made from cling film, which meets sanitary standards, and is made from high-quality primary type LDPE, HDPE.

The price for black polyethylene film is determined by the type of raw material. The most inexpensive versions are polyethylene bags made from recycled materials, designed for transporting household, construction and other waste. The price for protective films is slightly higher. It is a thin polymer transparent coating, usually supplemented on 1 or 2 sides with an adhesive solution. High density allows you to protect surfaces from chips and scratches.

Advantages:

It has many advantages compared to natural materials:

Resistance to chemicals, inertness. This property contributes to the widespread use of polyethylene in public catering.

Elasticity. The thin-sheet polymer fabric is easily stretchable and envelops the packaged item.

Steam and waterproof. Polyethylene film is used in the construction industry for waterproofing foundations from groundwater and vapor barrier of finishing coatings.

Tightness. The dense structure of polyethylene molecules creates a barrier to oxygen circulation and bacterial access.

Transparency (versions without added dyes). The canvas has excellent light transmittance. Therefore, summer residents are in demand for film for greenhouses as a covering material. It is also convenient for visual presentation of various products.

Durability. The service life of high-quality and dense variations of polyethylene film from 30 microns is more than 15 years.

Reviews for medium, thin films are mostly entirely positive. Such excellent recommendations are due to the listed properties, as well as the possibility of painting canvases in any shade, branding using logos and other symbols.

Dimensions of polyethylene films

The standard thickness is in the range of 20-200 microns. The price of a polyethylene roll directly depends on this parameter, as well as the density and purpose of the material.

Colored and transparent film in rolls is sold in quantities of 80-200 linear meters. The most popular versions are folded in half “sleeves” 1.5 m wide with a total footage of 100 m. You can also buy roll-type plastic packaging with a width of 6, 10 and 12 m, or in sections of 1-10 m.

Features of film coatings

The choice of film coverings in stores is huge and sometimes it is difficult to decide which film is of high quality and which will not last a season. There are a number of factors that a high-quality greenhouse film must meet.

- acceptable price;

- strength;

- ease of use;

- reliable UV protection;

- sufficient density and thickness.

It should be taken into account that greenhouse films also have weaknesses. Depending on the type, the material will have certain disadvantages, so before choosing film for greenhouses, you should familiarize yourself with the types, their features and disadvantages.

Photo of perennial greenhouse film “SVETLITSA”

Price for polyethylene film

The cost of PE film depends on the composition of the feedstock. She may be:

- primary - made from primary polyethylene granules. The price of such material from manufacturers is 100-140 rubles per kg;

- secondary - with the addition of secondary granules or completely consisting of polyethylene waste. This material is more fragile and has a shorter service life compared to the first type. The cost of recycled polyethylene film varies from 70 to 110 rubles per kg.

When buying in bulk, manufacturers usually give discounts on their products.

When choosing polyethylene film, proceed from the required properties, dimensions, and application. Check with the manufacturer for the characteristics and quality of the material to choose the best option.

How is polyethylene produced?

This polymer goes through complex technological creation processes from raw materials to the final product.

Polyethylene is white granules of polyethylene powder formed using an extruder.

Before production of granulate, polyethylene powder is accompanied by additives that give the material certain properties.

Under high pressure and the highest possible temperature, the polymer mass is extruded through a die and passes through a drum with knives, which turns the melt into granules for the further production of polyethylene film in the form we are familiar with.

Granulation allows you to give polyethylene various properties that are necessary in certain industries: add color, increase mechanical characteristics, provide the future film with an antifog effect.

Questions and answers

Can covering film be reused for repairs?

Yes, if we are talking about material of medium and high density. After use, it is washed, dried and stored.

Is it possible to fix the covering film on the walls if they already have wallpaper on them?

Yes, the material will help protect the decorative coating from dirt. However, to avoid damaging the wallpaper itself, it is recommended to use only masking tape for fixation.

Can covering film be used to protect bathroom fixtures?

Yes, the material is moisture resistant, so it is used even in rooms with high humidity. At the same time, to protect the plumbing fixtures from mechanical damage, it is recommended to first cover the devices with a cloth.

Will a covering film protect equipment not only from dirt, but also from liquids?

The material does not allow moisture to pass through. For this reason, it provides reliable protection of any surfaces from the harmful effects of liquids.

Covering film for repairs is a material that provides reliable protection of surfaces from dirt and the harmful effects of moisture. The main thing is to choose and use it correctly.

Film, analogues

Perhaps someone is interested in the question, what was used before in construction when polyethylene did not yet exist? The answer is simple: previously they used other covering and waterproofing materials, which are still sold on the markets today.

For example, waterproofing, roofing felt. These materials are impregnated with special resins. In certain cases you cannot do without them.

However, in general, the use of technical polyethylene film is more profitable: it is inexpensive and practical, thin, and therefore convenient to use and transport.

Today, the industry offers a variety of types of polyethylene film, including the Leroy Merlin brand. Moreover, each variety has its own characteristics and is used in its own area.

Greenhouse covering colors

Films for greenhouses are sold in different colors. The reason is that depending on the color, the material has additional qualities.

Bubble film allows light to pass through without problems and retains heat.

- Black film does not transmit light, so it is used for mulching beds, and not for arranging greenhouses. Unless there is artificial lighting inside.

- Blue and cyan films have anti-condensation properties.

- The black and white color of the film protects crops from sunburn;

- Yellow and pink film transmits pleasant, soft light.

Still, a simple, transparent, colorless film is recommended for greenhouses. It does not lose color under the influence of sunlight, transmits a lot of light, and eliminates the need for additional lighting.

Important!

The most famous brands of greenhouse films: “Redlight”, “Shar”, “Biosvet”, “Anti-mold”, “Stable”, “Agrotema A”, “Harvest”, “Odyssey”. By purchasing them, you can count on high quality and long service life.

Rules of application

Even an inexperienced user has no problems using the material. It is placed on the surface that needs protection, and the edges are fixed with masking tape. If the base needs to be protected not only from dirt, but also from mechanical damage, then cardboard, a blanket, etc. can be placed under the film.

Manufacturing method of LDPE, HDPE film

HDPE LDPE film is produced using modern professional equipment. By polymerizing ethylene, polyethylene granules are produced, which serve as raw materials for film production. To produce the film, European technology is used for molding, painting, trimming, and also for adding substances that promote light transmission and resistance to mechanical stress. The production technology strictly complies with GOST standards, which allows us to obtain high-quality products.

Polyethylene film - what is it? Its properties and characteristics

Polyethylene film is a polymer material made from polyethylene granules and additives by extrusion.

The material has many advantages that determine its popularity:

- Resistance to chemical environments, inertness. Due to this quality, polyethylene is widely used in public catering;

- Extensibility and elasticity. Polyethylene fabric easily stretches and envelops the packaged item;

- Moisture and vapor tightness. The material is widely used in waterproofing during construction work, as a covering material, and in product packaging;

- Tightness - provides a barrier to air entry;

- Transparency (for unpainted films) – ensures good visibility of the product in film packaging;

- Good dielectric properties;

- Long service life.

Polyethylene films are easy to print (flexo printing, silk-screen printing, etc.).

The disadvantages include:

- Fear of high temperatures. At temperatures above 115 degrees, the film begins to melt;

- Sensitivity to UV rays. When exposed to them for a long time, polyethylene ages and begins to disintegrate, its strength characteristics deteriorate;

- Instability to low temperatures. When left in the cold for a long time, polyethylene becomes brittle.

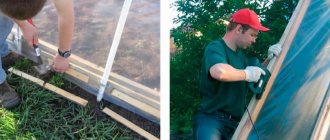

How to cover a greenhouse with film

A do-it-yourself greenhouse made of film is built in 2 stages: a frame, wooden or metal, is installed and covered with the selected material. But there are special requirements for parts, joints and assembly of the structure, as well as for film fastening; we will analyze the technology in detail.

How to build a greenhouse with your own hands from film - frame

It is preferable to build wooden frames using coniferous wood, impregnated with organic compounds, in order to avoid rotting, fungi, and damage by insects. The parts must be well planed, without burrs, it is advisable to chamfer the edges. The connections should be recessed into the material, this will help avoid film breaks.

The metal frames of the greenhouse are heated in the sun so that the film does not deform; it is recommended to make a gasket along the guides: wooden slats, self-adhesive tape, thin plastic panels.

High-quality double-sided tape is a reliable barrier against heating the metal frame, will help avoid deformation and additionally secure the film to the greenhouse

For a greenhouse under film, it is better to use collapsible plastic and aluminum structures; they are most adapted to this method of covering.

Attaching the film to the greenhouse frame - methods for reliable fixation

Calculate the required amount of film based on the size of the greenhouse; when calculating, keep in mind that the rolled material is laid overlapping at the joints - 100-250 mm; to avoid shortages, add 10%. Cut the film to size, cut out the end parts, taking into account +250 mm for fastening.

Wooden slats, 15*30 mm, are suitable for fastening

We fix it using:

- wooden slats;

- strips cut from old linoleum;

- clips - a galvanized guide rail, 3 m long, pre-attached to the frame, a film is laid on it and secured with a plastic insert;

- cord, rope, elastic band;

- plastic packing tape;

- coarse mesh - ideal for windy areas.

Clip for fastening rolled materials

You can make your own clips from plastic pipes of different diameters.

First, installation is carried out on the main structure, then the film is secured to the ends of the greenhouse. The stock of film from below is sprinkled with earth. Watch the video instructions on how to properly solder the material.