Due to unpredictable weather, every gardener strives to make his plantings as safe as possible. The main tool in the difficult struggle for the harvest is a well-built greenhouse that will last for many years. Today there are a huge number of variations in designs, coatings and materials.

Snow, rain, gusty winds, unstable soil on the site are factors that can reduce the life of the greenhouse. Therefore, you need to choose it especially carefully, taking into account all the above conditions. One of the most reliable types at the moment is the “Droplet”; thanks to its universal shape, it is not afraid of snow, wind, or quicksand.

Factors affecting the strength of greenhouses

Numerous publications for gardeners are full of ideas for building a greenhouse, and manufacturers vying with each other to praise their products. How not to make a mistake when choosing a greenhouse, but at the same time, not to overpay extra money for unnecessary elements that are useless in your weather conditions? We propose to figure out together what the strength of the greenhouse depends on.

Table. Parameters that determine the strength of the greenhouse

| Parameter | Description |

| Roof | For regions with frequent snowfalls, greenhouses with a steep roof slope will be most relevant; it is this factor that affects the possibility of rapid snow melting. Therefore, for those areas where snow is a frequent occurrence, it is better to choose steep lean-to structures or teardrop-shaped greenhouses. Classic-shaped greenhouses are suitable only if the roof slopes are located at an acute angle to each other. |

| Type of polycarbonate | When assembling a polycarbonate greenhouse, you should definitely take into account its thickness and density. There are many types of this covering material on the market, but you need to remember that for low-wind areas, a material thickness of 4 mm or more is suitable, and for regions that are not very favorable in terms of weather, you need to look for polycarbonate no narrower than 6 mm. |

| If you want to save money or the seller assures you of the super strength of a material less than 4 mm thick, you shouldn’t take the risk, there is a chance that such a greenhouse will not last even one year. Especially if in winter you do not live on the site and there is no way to regularly clear the roof of snow. | |

| Various manufacturers provide quite a lot of types of frames. The frame can be collapsible or monolithic, reinforced or lightweight. You need to focus on the weather conditions that prevail in your region. Non-removable structures, as a rule, are more expensive for gardeners, as they require additional payment for transportation. We still recommend purchasing a frame with additional structural reinforcement; the overpayment is not so high, considering that it is guaranteed to serve you for more than one season. |

| Profile characteristics | With this parameter, everything is quite simple - the denser and thicker the profile from which the greenhouse frame will be assembled, the more reliable its design will be. This is especially true for snowy and windy regions. |

| The distance between the arcs should vary from 50 to 100 cm, in which case the polycarbonate will have a sufficient number of support points, it will not crack under the weight of snow. The main thing is to secure the arcs together using a fastening strip; usually at least three of them are used. |

When planning to purchase a greenhouse, analyze the weather situation in your region, evaluate the frequency of snowfalls and winds. Carefully study all these parameters and determine which greenhouse will serve you faithfully at your summer cottage.

Next we will talk about the “Kapelka” greenhouse; according to many gardeners, it meets all the necessary requirements and allows you to harvest an excellent harvest.

Preparing the base for a greenhouse

Assembling a polycarbonate greenhouse with your own hands

Before arranging a polycarbonate greenhouse, you should take care of choosing the right base for it. It is not recommended to place the structure in the shade, in wetlands, drafts or slopes. Having chosen a suitable location, you need to carry out preliminary planning - the length of the structure should be oriented from east to west, and one of its sides should be completely open to the warm southern sun.

With abundant groundwater, the construction of a buried greenhouse is possible only if there is a high embankment.

Otherwise, it is better not to use such a variation - there will be no effect in the end

It is important to stop using phosphates, nitrates and other similar substances on the site, and also to develop the optimal land cover using the following recommendations:

- when choosing manure, you should avoid a thick layer of soil, since the fertilizer will lack oxygen;

- a layer of soil 9–12 cm thick is relevant for crops that can bear fruit at elevated temperatures (cucumbers, tomatoes, etc.);

- for crops that feel comfortable at lower temperatures, you should choose a cover of approximately 17 cm;

- areas with a soil thickness of over 17 cm are used when transplanting mature plants with a developed root system.

Arrangement of tall boxes inside

Advantages and disadvantages of the “Droplet” greenhouse

The “Kapelka” greenhouse has earned the recognition of more than one thousand grateful gardeners and gardeners. It has a durable frame, reliable fastenings, an optimal shape to prevent deformation from snow, excellent light transmittance, and various types of modifications. Today there are several leading manufacturers of this type of construction, for example, the trademarks “Orange”, “House of Greenhouses”, Plant of Ready Greenhouses and some others.

We offer you a list of the main advantages of the greenhouse, thanks to which it has become so popular:

- Ergonomic shape. The pointed-arch design allows snow to slide freely down the surface, and the main load falls on the strong side supports. The ceiling inside the greenhouse is quite high, which makes it possible for even a tall person to work there comfortably.

- Durable frame. The frame elements of the “Kapelka” greenhouse are made of durable galvanized steel, which from most manufacturers is treated with a special anti-corrosion compound, which significantly increases its service life. Judging by the reviews from satisfied customers, even in snowy regions this frame has been serving quietly for more than five years.

- Reliability of fastening. All frame elements are securely connected to each other with specially selected self-tapping screws. Possibility to choose the optimal size. Manufacturers offer a fairly large selection of greenhouse size options, the choice of its length is especially variable; the design allows you to purchase additional arcs and zone the internal space.

- Polycarbonate coating. Polycarbonate has long won recognition among millions of gardeners; it is highly durable, easy to install, has a special coating that does not transmit harmful UV rays, but, at the same time, has good thermal insulation and light transmittance.

- Attractive appearance. The greenhouse will be an excellent addition to the exterior of any site; its unusual shape may well become its decoration, and not just a tool for growing vegetables.

Ready-made drop greenhouse with a polycarbonate coating

Making a drop greenhouse yourself is extremely difficult due to its intricate design, but you can buy it in almost any corner of our country, and detailed instructions will help you understand the assembly process.

If the soil on your site is stable and not affected by groundwater, then it is quite enough to simply dig the base of the frame into the ground 20-25 cm. If you are afraid that the greenhouse may be deformed due to the influence of various factors, then we suggest making a wooden frame foundation depending on the planned size.

Manufacturers offer different design sizes. But there is a general trend that can be identified by analyzing the existing proposals:

- The most common structure height is 2.3 or 2.4 meters. This is quite enough for even a tall person to feel comfortable in the greenhouse, and there will be enough space for the plants to grow and produce a good harvest.

- The length of the greenhouse starts from 4 meters and can be any, but a multiple of two (4,6,8,10 meters and so on at the request of clients).

- The width of the greenhouse varies, you can find an option with a width of 2 meters, some companies offer a frame with a width of 2.4 m, 2.7 m, 3 m or 3.7 meters.

- The distance between the arcs in a drop greenhouse ranges from 65 to 100 cm, the smaller the distance, the more expensive the design.

- Polycarbonate can be included in the greenhouse kit, but is most often sold separately. You can choose the thickness of the canvas yourself; the recommended value is 60-65 mm.

- The drop greenhouse is equipped with a window and a door, one or two depending on the length of the building.

The price of a greenhouse without delivery and coverage starts from 14,500 rubles for a 4*3 meter frame and from 19,900 for a structure with polycarbonate included. The price directly depends on the number of arcs, the distance between them, and the thickness of the polycarbonate.

Like any other invention, the droplet greenhouse has a number of disadvantages. We suggest you familiarize yourself with them before making this expensive purchase:

- Complex installation process. Despite the included instructions, the disassembled view of the structure can confuse an inexperienced gardener. In addition, an additional tool is required, such as a screwdriver. Be prepared for the installation of the structure to take several days.

- Insufficient ridge seal. Despite all the meticulousness of the assembly, the seam at the junction of the slopes in the ridge area remains not perfectly sealed. You will either have to use a sealant, which is purchased separately, or give preference to a conventional arched greenhouse if the tightness parameter is extremely important for future plantings.

- Quite a high cost. Greenhouse options advertised by manufacturers typically have a minimum cost to attract customers. Most often, the design requires additional equipment or changes in parameters, which leads to its increase in cost.

Description and characteristics

The main design features of “Kaplya” greenhouses are as follows.

- teardrop shape

This design solution does not allow snow to accumulate on the surface of the greenhouse, and also increases the stability of the structure even with very strong gusts of wind.

- Reinforced frame design

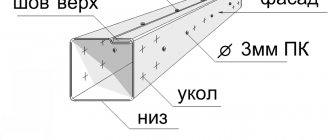

The frame is formed by profiled pipes with a rectangular cross-section of 20x40 or 20x20 mm and a wall thickness of 2 mm. All arcs are fastened with reinforced transverse elements, which allows the greenhouse to withstand significant loads.

- Anti-corrosion coating of main parts and fasteners

Coating the frame with a special composition guarantees protection against rust formation and significantly extends the service life of the structure.

- Complete with high quality polycarbonate sheets

This material is protected from the destructive effects of UV rays and does not form fragments even when the strength threshold is exceeded. In this case, the entire greenhouse is covered with polycarbonate, due to which every centimeter of usable area inside the greenhouse receives the required amount of light.

Installing a purchased drop greenhouse with your own hands: step-by-step instructions

Click on the drawing to enlarge it.

| Work stage | Illustration |

| Assembling doors and windows. It is with these parts that it is best to start assembling the structure in order to get the hang of it and understand the principle of fastening profiles. At this stage, the two side door strips (13 and 13 a) are fastened together using four transverse profiles using holes predetermined by the manufacturers using a screwdriver and self-tapping screws. When installing the door, keep in mind that the left post has additional holes for the handle, and the right post will have hinges (sometimes they are already welded). |

|

| The cross bars are installed so that the grooves are directed towards the ground to prevent condensation from accumulating in them. | |

| The kit includes profiles with beveled ends to strengthen the structure. Using self-tapping screws and connectors, they are attached diagonally from the bottom to the top corner between the transverse elements of the door. | Installation of inclined profiles to strengthen the door |

| Window assembly. For the window, the kit includes 4 parts numbered 7 and 17. Using self-tapping screws, they are connected to each other, forming a rectangle. |

|

| The classic design of a drop greenhouse involves the location of a window in the door structure, so the assembled window is attached to the upper section of the door frame using the included hinges. |

|

| We proceed directly to the assembly of the front elements. The greenhouse frame is assembled in stages from arc-pediments. To do this, two arched profiles are connected to each other using self-tapping screws and a corner tie. |

|

| To strengthen the structure and prevent deformation, the manufacturer has provided an additional fastening-screed - a horizontal profile that is installed between the two gables closer to the ridge at the junction of the arches. | Profile fastening under the gable ridge |

| To install the frame on the ground and ensure its better adhesion to the ground, the manufacturer has provided special elements - lugs, which are attached to the base of the arches (3). In addition, rack profiles (8) are attached to the upper horizontal profile, connected at the bottom by another horizontal profile (12). |

|

| To strengthen the frame, several more profiles (10,11) are attached to the front elements of the droplet greenhouse parallel to the ground. |

|

| The second front part of the greenhouse is assembled in the same step-by-step manner, onto which the door is attached using self-tapping screws and the hinges included in the kit. | Assembling the second end frame |

| Special connecting elements (8 pcs.) are attached perpendicularly to the finished front structure, with the help of which the remaining parts of the structure will be attached. | Fastening the connecting elements |

| According to the instructions, holes are made along the length of the entire arc where the polycarbonate will be attached. |

|

| Polycarbonate sheets are cut independently and fastened using special thermal washers that prevent damage during fastening. The front part is placed on the ground with the outer side up. A polycarbonate sheet is laid on it so that the protective film that prevents the penetration of UV rays is on top. Using a screwdriver, the polycarbonate is attached to the pediment, and the excess is cut off. | Layout of polycarbonate on end structures |

| Next, the assembly of the frame begins. Stringer profiles in the amount of 8 pieces (16) are mounted to the connecting elements that you have already attached to the pediment. |

|

| Once the two main frontal structures are ready, you can begin assembling the intermediate arches. They are fastened together with corners and tightened with a transverse profile. For traction with the ground, lugs are also installed all the way. And for further assembly with other elements, x-shaped connectors are attached along the entire length of the arcs. They do not need to be tightened tightly, so that later they can be easily adjusted to the stinger profiles. |

|

| Intermediate arcs are mounted at the end of the greenhouse parallel to each other. |

|

| After the frame is almost ready, you can begin installing it on a pre-prepared site. If you do not make a foundation frame, then first mark the area and dig holes for digging lugs into them (the approximate size of the hole is 20 cm wide and 25 cm deep). |

|

| Arcs are installed in the holes, the top is properly compacted with earth, and they are fastened together using stringer connections. And so on along the entire length of the structure. | Drilling lugs into the ground |

| All frame elements are leveled with respect to the ground and to each other using a building level. |

|

| Next you need to cut out the holes for the door and window. This should be done strictly along the internal contour, otherwise a gap may appear that will break the tightness of the future greenhouse. To work with polycarbonate, it is best to use a well-sharpened construction knife. | Cutting out doors and windows |

| Particular attention should be paid to cutting out the holes for the hinges; this work is delicate and requires careful preliminary marking so as not to cut off excess. After the door and window are ready, you can install the handle and hinges. | Marking and cutting holes for hinges |

| The frame is ready, the front surfaces are covered with polycarbonate. You can start covering the main area. To do this, measure the finished structure again and cut the polycarbonate sheets. An important point in the work is to allow about 5 cm so that the polycarbonate sheet extends beyond the frame, forming a kind of canopy on the sides of the greenhouse. |

|

| The ridge of the greenhouse is strengthened separately. A special corner (2) is installed on top of it. The main element in its fastening is the middle arc. It is to this that two tie strips are attached on both sides: the long one (4) runs along the entire length of the arc, connecting in several places with the short one (5). | |

| Pre-cut polycarbonate sheets are attached to the first three rows of stinger profiles using special self-tapping screws with a thermal washer. |

|

| Check the joints for leaks and tighten the bolts. Check the quality of installation of the lugs. The work can be considered completed. |

|

When you purchase a ready-made drop greenhouse, you receive detailed instructions for assembling it. We have described to you an example of assembling a classic greenhouse; the installation principle is approximately the same for all manufacturers.

How to install a reliable greenhouse

Be sure to take advantage of useful recommendations.

- Before starting installation, select the location where the greenhouse will stand. It should be in an open place, free from the sun. It is not recommended to locate the structure where water and snow can drain from neighboring buildings and structures. There must be a cleared area of at least one meter around to allow snow to melt in winter.

- When assembling the greenhouse, do not allow any surface damage that could lead to deformation of the frame.

- The structure can be immediately assembled in the allotted area; the frame is laid 25 centimeters into the ground. Another option is to make a solid foundation: mark out the area, remove the top layer of soil, compress the soil, then lay geofabric and fill the hole with sand and gravel.

- The base for the greenhouse can be made from 100x100 mm bars, impregnated with an anti-rotting solution, which are laid like a frame. For a more solid foundation, you can pour concrete using formwork.

- Assembly of the greenhouse takes place without any particular difficulties. The factory version of the model is similar to a children's construction set, only for adults. All parts and guides fit neatly into their grooves.

- Using self-tapping screws and fastening bolts, which are sold as a kit for the greenhouse, all the arcs and elements of the end part equipped with the doorway are fastened.

- Next, additional elements with a window are assembled, which are then placed on the main foundation and secured to it. The next step in the installation will be the installation of the end element, then the parts are secured to the base and to each other.

- By reducing the step between metal arcs, you can increase the strength and reliability of the structure.

- Using reinforced connecting elements that cover the arcs on both sides, the polycarbonate is connected to the greenhouse frame using self-tapping screws with heat-resistant washers. Due to the guides in the greenhouse (stringers), a reinforced, reliable structure is obtained.

- Sheets of cellular polycarbonate are laid in a plane perpendicular to the frame. The sheets are bent across the stiffening ribs.

Making a drop greenhouse with your own hands: step-by-step instructions

A drop greenhouse, as we said above, can be purchased without any problems at almost any large garden center; it is produced by many companies. But if you have metal profiles and a device for bending pipes, then you can make it yourself.

This will be half the price of a finished structure with polycarbonate included.

It is better to choose the standard height and width of the greenhouse - 240 by 300 cm. But the length can be varied, choosing its dimensions based on the area of the site.

Step 1. Drawing up a drawing with the dimensions of the structure

The diagram shows a drawing of the greenhouse with all dimensions. To make it, you will need 10 arcs and at least 24 transverse profile bars, provided that the arcs are installed a meter apart from each other. For snowy regions, it is recommended to make this distance smaller. The window and door frame are assembled separately.

Step 2: Choosing a location

Do not place the greenhouse where there is shade.

Before you begin to install the greenhouse, you need to prepare a site for its placement. This should be a well-lit area, and the ground should be leveled if necessary. If the site is prone to quicksand due to groundwater, then you will need to additionally make a foundation or a strong wooden frame.

Step 3. Construction of the foundation

Work on making the foundation begins with preliminary marking of the place where the greenhouse will stand. Along the perimeter of its location, pegs are driven into the ground, between which a thread is stretched. All soil that falls within the marking perimeter undergoes additional preparation - its top layer is removed, and the remaining soil is compacted very well to prevent subsidence and deformation of the structure. For reliability, we suggest making a substrate from a mixture of sand and gravel, this is especially true for areas with groundwater.

Step 4. Making formwork

We strongly recommend making formwork for the greenhouse for the reliability of the structure. It is made from bars with a cross-section of 10×10, pre-treated with a special solution for wood. Using galvanized corners and self-tapping screws, 4 boards, pre-cut to the size of the greenhouse base, are connected to each other, forming a large frame.

Step 5. Assembling and installing the frame

For the frame, it is necessary to pre-bend the metal profile in the shape of an arc. To do this, using a pipe bender, straight metal profiles are bent with an indentation of at least 7 cm from the bottom and 4 cm from the top. The work is not easy; for beginners it takes at least a week. First, one arc-template is made, along which the bend of the remaining elements will pass. The finished arches are fastened together using transverse profiles, the front arches are complemented by a window and a door. The frame is attached to the formwork using corners and self-tapping screws.

Special attention should be paid to the ridge of the structure. It can be made of 80x80 galvanized steel and should be mounted so that it slightly protrudes beyond the gables of the greenhouse.

Determine the distance between the arcs yourself; the smaller it is, the more reliable your greenhouse will be.

Step 6. Attaching the polycarbonate

When choosing polycarbonate, it is better to consider options for rigidity from 35 mm so that it survives the winter well. You will need about 3 sheets of 6 meters each, 2.1 meters wide. It should be placed vertically, with the side with the protective film facing out.

For a better fit of polycarbonate to the arches, self-tapping screws alone are not enough. The sides need to be further strengthened; manufacturers suggest stretching zinc tape over the polycarbonate. But there is an opinion that under the influence of sunlight such a tape becomes very hot and the polycarbonate underneath it deteriorates faster. Therefore, gardeners recommend placing a thermal insulation gasket under the zinc tape in the form of a tape window seal with an adhesive layer.

Bending polycarbonate to give it a droplet shape should only be done across the stiffening ribs to avoid damage and cracks.

The greenhouse is ready. This is not a quick task, but the result will certainly please you, because a homemade greenhouse will cost much less, and will last no less than a purchased structure if the operating rules are followed.

Preparing the site and foundation

Before assembling a greenhouse on your summer cottage, you should think about where and how this structure will be installed.

First, you must choose a place for it. The greenhouse should be located in a well-lit area at a distance of at least several meters from houses, sheds and other structures. It is also undesirable for tree branches to hang over the structure. Otherwise, during windy weather, something may fall on the greenhouse from above and damage it. How to install a greenhouse according to the cardinal directions

Be sure to level the surface of the soil - it is best to even remove the top layer. This will also get rid of weed seeds. And for the convenience of work, remove the soil in an area that is about a meter wider on each side of the rectangle you need.

It is worth thinking about the presence of a foundation. As manufacturers say, now most greenhouses do not need it, especially if they use them (greenhouses) only in the spring and summer. However, experienced gardeners still recommend making at least a basic foundation from timber. It’s very simple - just connect four pieces of timber with a cross-section of at least 10*10 cm using metal corners and self-tapping screws. The size of such a foundation should be equal to the base of the future greenhouse.

Simple timber foundation

You can also make a strip foundation from concrete. It is more reliable than timber, but requires more financial and labor costs. By the way, a greenhouse that will be used in winter cannot do without it.

Stages of forming a strip base: schematic representation

Rules for operating a drop greenhouse

If you purchased a ready-made structure, assemble it strictly in accordance with the instructions. Most often, they begin to read it after there are unnecessary details left. Don’t take risks and first carefully read the instructions, sorting out any unclear points and checking the presence of all parts of the kit.

Clean frame elements regularly. Metal elements should be wiped to prevent water from accumulating there during condensation. It is necessary to wipe the polycarbonate with a soap solution.

Do not use abrasive substances to clean it; they can damage the coating that protects the greenhouse from UV rays.

Brushes with strong bristles cannot be used to clean it, as polycarbonate is susceptible to cracking.

If the winter was too snowy, and the distance between the arcs is more than 85 cm, then additionally clean the snow from the structure.

At the end of the season, check the fastenings and frame elements for their safety and deformation; identifying the problem in time allows you to minimize the cost of eliminating it.

Tips for use

In order for the “Droplet” to serve for many years, take care of proper assembly and operation.

- Assemble the greenhouse only according to the instructions. There should be no loose parts left. If the greenhouse is assembled incorrectly, it will quickly become unusable.

- Do not forget to clean the greenhouse cover from dirt. Clean with a soft cloth or sponge and soapy water. Under no circumstances should you clean polycarbonate with brushes or abrasives - this can lead to the UV protection simply being erased ahead of time, and the material itself will begin to deteriorate.

Caring for the greenhouse by cleaning the walls and roof with a ready-made product

Now you have become familiar with the Droplet greenhouse and can decide for yourself whether you need to purchase such a design. However, if you read this article, then most likely you were in search of an excellent reinforced greenhouse. And “Droplet” is one of the best options for this type of structure.

Customer reviews and recommendations

The vast majority of summer residents who purchased a drop greenhouse rate it “excellent.” Everyone notes its reliability; it is the drop-shaped shape that allows snow to calmly roll down and not linger on the structure itself, which inevitably leads to its deformation, as, for example, happens with arched greenhouses. In addition, even a tall person can comfortably stay inside the greenhouse. Along the inner perimeter of the greenhouse, as gardeners note, there are many cross beams where plants can be tied up.

Some gardeners, for example, a summer resident with the nickname Serega, are confident that the greenhouse can be used all year round by covering it with very thick polycarbonate or using durable double-glazed windows instead of polycarbonate. But for this it is necessary to additionally heat the greenhouse space from the inside.

Many users, whose reviews can be seen on the Internet, are in favor of purchasing a ready-made design, rather than making it yourself. This, of course, turns out to be more expensive, but you are guaranteed an excellent result.

Among the disadvantages, some note the high cost of the finished drop greenhouse; its cost with delivery, as a rule, is at least 22,000 rubles and more. Another drawback that can be found in reviews from gardeners is the appearance of small cracks at the joints of polycarbonate, especially in the places where the door and window are attached. After prolonged rains, a slight separation of the polycarbonate from the point of adhesion to the foundation may occur. But all these shortcomings can be corrected; they are also found in other designs using polycarbonate.

Customer review from irecommend.ru

The author has been using the drop greenhouse for more than a year; it was purchased ready-made, disassembled, for 32,000.

A gardener under the nickname DNV Logoped says that he previously had the sad experience of using another form of greenhouse on his property, which did not survive the harsh winter and collapsed. In his decision to purchase a drop greenhouse, he was guided by the reviews and recommendations of his neighbors, as well as the description of the greenhouse on the manufacturer’s website.

The author of the review has been using the greenhouse for more than one year and has already managed to appreciate it, noting its visible advantages:

- Reinforced structure made of galvanized pipe 20*20, which is not subject to corrosion.

- Polycarbonate with UV protection, thickness 4 mm. True, the author of the review notes that you can safely choose sheets of greater density and width, expressing your desire with the phrase: “I would like it to be thicker!!!”.

- The door hinges are already welded to the door structure.

The author notes that in addition the manufacturer suggests purchasing a drip irrigation system or making a few more windows. We assembled the greenhouse ourselves using video instructions from the Internet.

The service life of the greenhouse is more than a year, during which time users have no complaints about it. The teardrop greenhouse, 6 meters long (you can choose it yourself), 3 meters wide and 2.5 meters high, has three beds freely included.

Advantages and disadvantages

Like every greenhouse, “Kapelka” has its own advantages and disadvantages both over simple structures and over other polycarbonate greenhouses.

Advantages of "Droplet":

- an unusual shape that does not allow snow to linger on the structure (by the way, this is why the greenhouse does not have to be cleared of snow in winter);

The design will successfully withstand various weather conditions

- the greenhouse is quite spacious inside and allows you to carry out work in comfort;

- The “Droplet” will serve for quite a long time due to the high-strength reinforced frame (if you believe the reviews, the service life is at least 5 years even in harsh snowy winters);

- The greenhouse frame is not afraid of rust due to the anti-corrosion coating;

- for those wishing to expand the dimensions of the structure, it is possible to increase the length due to special inserts;

- The delivery set of the structure includes all elements necessary for installation;

- The “droplet” retains heat perfectly, and due to the doors and windows it creates an excellent microclimate for plants.

Doors and vents ensure proper air exchange

The disadvantages of “Droplet” include the rather complicated assembly instructions, but the model can still be assembled without the help of specialists.

As you can see, “Kapelka” has many more advantages than disadvantages, so you can safely purchase it without fear of wasting money.

Choosing a greenhouse: arched or teardrop-shaped

The arched variety has long been considered the favorite among all other greenhouses available. But over time, its shortcomings became obvious. For many summer residents, the greenhouse could not withstand the snow and ice and became deformed after the winter.

After many similar comments, manufacturers were puzzled by the creation of a more advanced design. This is how the droplet greenhouse appeared. It has fewer joints, which saves money and time for creating additional sealing.

In addition, the droplet shape of the greenhouse prevents snow from accumulating at the top. This helps reduce the risk of deformation and also prevents condensation from appearing on the surface of internal structural elements.

If your region is subject to snowfall and winds, and plantings require staking, then a drop greenhouse will be the ideal solution for your garden plot.

Greenhouse care

Caring for “Droplet” does not take much time and effort.

Shading should be done by spraying the surfaces of the greenhouse with ordinary chalk.

In autumn from the greenhouse you need:

- remove plant debris;

- carry out soil treatment;

- disinfect the structure;

- preserve the greenhouse for the winter.

Thanks to the pointed shape of the “Drops”, there is no need to clear snow from it in winter - it will roll off the surface without loading the structure with its own weight.

The procedure for installing a greenhouse made of cellular polycarbonate

- Using a screwdriver, remove all screwed elements from the side arched parts of the structure.

Remove the protective film from one sheet of polycarbonate.

Carefully transfer and place the sheet on one of the arched side openings and screw it onto the screws, retreating to a distance of 30-40 centimeters. Here you need to say why this needs to be done. Firstly, you won't get confused with the elements for the side part. Secondly, only professionals can fix carbonate in a vertical position, and why do you need all this?

Trim the edges of the leaf. Now we transfer it to another opening and screw it again and cut it. In the same way, following the template, we screw it on and cut it into the side opening of the end part of the greenhouse.

We place a sheet of polycarbonate on the doorway of the end part of the greenhouse (the one on which the sheet has already been screwed and cut), and carefully screw it into place, cutting exactly along the edges.

We place all the arc elements at a certain distance from each other, starting from one edge. We insert the valves into the grooves with their curved ends into the ground.

We connect the arc parts using side elements. We screw the joints onto roofing screws.

After the entire frame is assembled, you need to use a tape measure to measure the diagonals at the lower base of the greenhouse. If they are not equal, you need to slightly trim the corresponding corners and measure again until the distances are the same.

As soon as the diagonals are set, you can dig holes. To do this, you need to outline the crosses where the holes will be dug and then move the greenhouse frame 40-50 centimeters to the right or left. The depth of the hole for pipes for fastening to the ground should be 1 of the height of the shovel bayonet. After this, you need to level the horizontal plane of the base. It may be necessary to knock down some pipes for fastening to the ground and connections and level them.

We gradually bury the pegs in the ground (we added bricks for pressing) so that it does not accidentally get torn out by a strong wind. We secure the joints with screws. Remove the film from the remaining polycarbonate sheets. Carefully place the sheet on the side arch and stretch it from both sides of the frame. The leaf should protrude 20-30 centimeters above the greenhouse door.

We fix the first side with screws, and then move on to the second. We do the same on the other side. There remains empty space between the sheets in the center of the greenhouse.

We place the last fourth sheet of the greenhouse in the center of the greenhouse. We secure it with screws. Add screws to the very top of the greenhouse using a ladder or rafters. We make sure that there are no deflections. If there are deflections, we manually straighten the pipes by bending them. We open the windows and make hooks for them.

The advantages of greenhouses made of cellular polycarbonate will be described in one of our materials. We really hope that our tips for installing an arched greenhouse yourself will help you cope with the installation of your personal garden or country greenhouse. There is nothing difficult about this, the main thing is to have some time and 1-2 assistants. Happy harvest everyone!

Weaknesses of conveyor greenhouses

In any specialized store you will find many greenhouses, which differ in the material from which they are made, in size and price. But they all have common shortcomings that are not striking, but deserve special attention.

Most of the models presented in stores have an arched type of design. It is the easiest to make. The polycarbonate sheet is simply placed on a curved arch 1.9 meters high and 3.8 wide. At first glance, everything is ideally convenient, but in fact it is quite difficult to work in such structures, since the beds placed along the perimeter of the greenhouse are quite wide, making it inconvenient to water and tie up the plants.

There is a way out of this situation: before installing the frame of the structure, you need to make a kind of foundation, the height of which will be equal to the height of the beds. Plants are planted in ridges in a circle; to do this, make them about 40 cm each, and so on throughout the entire space.

Of course, with such markings it will not be possible to stretch the cart between the rows, but caring for vegetables and berries from the greenhouse will become much more convenient.

The frame, made of thin aluminum, is not at all an advantage, as it might seem at first glance. A strong gust of wind can easily pick up the greenhouse and move it to another place. If you have already purchased such a copy, then try to deepen the greenhouse into the ground as much as possible during installation.

Although within a few years it will become obvious that the service life of such a greenhouse is not as long as we would like. The foundation pipes begin to gradually deform and break, rotting. To extend the life of the greenhouse, we recommend installing it on a solid foundation.

Large reflective surface. Such a greenhouse is considered the best and has an appropriate price. The principle of its operation is that light does not penetrate directly onto the plants, but is refracted, becoming less hot.

Despite these negative aspects, factory greenhouses still have a number of advantages, the main one being ease of installation. The kit includes a certain number of parts that are machined down to the millimeter, all fastenings and instructions are provided, which clearly describes the sequence of actions that should be followed.

A greenhouse is not a greenhouse

The main fundamental difference between a greenhouse and a greenhouse is that the latter is always equipped with an external heating source to create the desired temperature. The greenhouse, as its name suggests, is heated exclusively by natural sources - sunlight, rotting manure or leaves. Its action is based on elementary physics, or more precisely, the “greenhouse effect” known to us from school lessons.

This is important to understand when choosing cellular polycarbonate for its construction. Polycarbonate sheets of rich dark colors or completely reflective ones are absolutely not suitable for you for a greenhouse.

It would be most correct to buy transparent polycarbonate or products in light shades - they transmit enough light, ultraviolet radiation, and perfectly diffuse it inside the structure.

Cellular polycarbonate of the thickness we recommend perfectly withstands mechanical loads, a possible large layer of snow, and hail impacts. Unlike glass, this is not a brittle material; it does not break from impacts and bends quite easily.

What tools are needed to install a greenhouse made of cellular polycarbonate

For work on the manufacture of elements and assembly of the greenhouse frame, you may need (depending on the working material):

- Hacksaw with blade for metal (or wood)

- Bulgarian

- Drill with speed control (screwdriver)

- Drill

- Hammer

- Screwdrivers

To mark on cellular polycarbonate, prepare a thin marker or felt-tip pen. A regular graphite pencil will leave a subtle mark and may be nearly invisible or scratch the polycarbonate surface. So, how to assemble a polycarbonate greenhouse?

Assembling the frame

The assembly of the frame is usually preceded by a detailed drawing of a drawing of a polycarbonate greenhouse or, at a minimum, a working sketch indicating the dimensions of the structural elements. This will help you not only when assembling the greenhouse itself, but also at the preparatory stage, when you will make its parts and cut cellular polycarbonate, as well as to calculate the need for the amount of material you need.

The greenhouse frame comes in two types, as do the greenhouses themselves - in-depth and above-ground. In any of the options, a greenhouse is a structure that is completely closed on all sides and has a bottom to retain heat inside. The shape of the upper part of the frame can be any - semicircular, straight, with a gable or pitched roof.

Drawing of a polycarbonate greenhouse

After assembling the frame (we deliberately omit the description of this type of work, assuming that you have skills in working with wood or metal), you will have to attach cellular polycarbonate to it.

The frame is assembled, sheets of cellular polycarbonate are cut to the required sizes. All that remains is to sheathe the frame with it, and you can use the greenhouse for its intended purpose. How to attach polycarbonate? To attach polycarbonate, you need to buy self-tapping screws with a flat bottom part of the head and rubber gaskets (washers). This is necessary to ensure a tight and airtight connection between the cellular polycarbonate sheets and the frame elements.

Work with a drill or screwdriver should be performed at slow speed. If the tool has a force limiter function, set it to the desired values. They can be determined by first experimenting with polycarbonate scraps and frame materials. Sheathing should begin from the bottom, after which you sheathe the walls and roof of the greenhouse.

Preparing to install a greenhouse made of cellular polycarbonate

Using a tape measure, you need to draw with a peg on the ground the approximate boundaries along which your greenhouse will be located. The design of metal tubes sometimes becomes covered with a coating of rust when stored in a warehouse. Therefore, such places can be cleaned with sandpaper and painted.

After this, you need to carefully count the carbonate sheets and figure out on the diagram how to cut it correctly.

To fasten the sheets to the metal frame and connect the structure itself, you need to purchase roofing screws for fastening to metal structures with a washer and a length of 35 mm in the amount of 250-300 pieces from a building materials store.

Features of the arched design

The basis of an arched-type greenhouse is metal arch frames; in the factory version they are most often galvanized to protect against corrosion. The arch is assembled from polycarbonate or durable film. Glazing cannot be used for it. Installation of the system is very simple and does not cause difficulties. The type of fasteners and their number may differ from one manufacturer to another. Sizes may also vary.

Instagram teplizaipolikarbonat

Instagram teplizaipolikarbonat

In any case, the arched greenhouse has many advantages, we will list them all.

pros

- Resistance to adverse weather conditions. The streamlined shape helps withstand strong gusts of wind. It prevents the snow from falling on the roof, it smoothly rolls down. True, if thaws occur, ice grows on the surface, which holds the snow cover. Then cleaning is required. It is also needed during heavy snowfalls.

- High strength. This applies to polycarbonate systems. During assembly, the strip of plastic is bent into an arch shape. Therefore, there are no joints or additional connections that reduce strength. In this case, polycarbonate acts as a coating and as a frame, giving additional rigidity.

- The arched configuration, even on a small base area, provides significant internal volume. Plants need enough air, however, a ventilation system is still needed.

- Good lighting. Light enters the building from all sides. Only arcs cover the light rays, but their area is small.

Inside such a greenhouse there is enough space for two or three beds located along the walls. Sometimes they make another end one.

- Country cottage area

Note for summer residents: how to assemble a greenhouse from plastic pipes with your own hands

The arched greenhouse also has disadvantages.

Minuses

- It will not be possible to plant tall crops under sloping walls. They will have to be placed closer to the center.

- It is inconvenient to care for plants planted near the walls and to arrange vertical beds.

- Difficulties in arranging ventilation. The basic configuration, at best, requires the presence of vents above the doors. This is too little for proper ventilation, so they also open the doors. This does not solve the problem, since plants in such conditions experience stress: too sharp a temperature difference between the cool lower part of the greenhouse and the hot upper part. In addition, a draft dries out the soil. The only way out is to install vents on the side walls. Installing them correctly is quite difficult.

Inexpensive models may not be sufficiently resistant to snow loads. Therefore, they may need to be modified. You can add stability by increasing the cross-section of the arcs or reducing the distance between them.

- Country cottage area

How to cool a greenhouse in the heat: 3 working methods