For owners of country houses or cottages not connected to central heating, maintaining a comfortable microclimate in the harsh Russian reality becomes a serious issue. A conventional boiler has to be constantly loaded with fuel, which burns quickly and requires a lot of space for storing coal or firewood. The solution could be the widespread use of a new product that has recently appeared on the market - a pellet boiler. The operation of this device is characterized by high efficiency, high efficiency up to 95%, good efficiency, and a long service life of over 20 years.

Now you can find many models that differ in size, shape, additional features and, of course, price. In the review you can get acquainted with such boilers, their structure, selection criteria, rating of the best products for the middle class and “premium class” devices.

What it is

A pellet boiler is a type of solid fuel heating device, where pellets are used as fuel - cylindrical granules from agricultural or woodworking waste, pressed on a granulator (special press).

Main types of pellets:

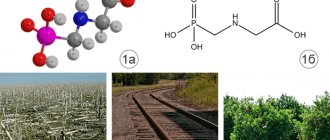

- white - made of high quality wood, low ash content up to 0.5%, but expensive;

- agropellets – agricultural waste (straw, sunflower husks) with a high ash content, as well as the need for regular cleaning of the boiler from slag;

- industrial - gray-brown in color with a high bark content, ash content greater than 0.7%, not recommended for domestic use.

Advantages of pellet boilers

- high degree of automation with programming of operating modes, as well as long-term operation without operator participation;

- equipping with remote sensors;

- simple maintenance;

- remote control from mobile applications or via GSM module;

- high efficiency;

- economical consumption of pellets compared to diesel fuel, liquefied gas or electricity;

- long service life;

- minimal emissions of harmful substances.

Flaws

- high cost of pellets;

- sensitivity to their quality;

- the need for dry storage;

- dependence on electricity supply;

- impressive dimensions.

Disadvantages of pellet heating

- High cost of equipment. A domestic boiler with a capacity of 20 kW will cost 170 - 200 thousand rubles; imported, from a manufacturer with a good reputation in the Russian market, will cost 200-250 thousand or more. It is important to understand that the chimney and its installation are not included in this amount.

- Large dimensions and weight. A 20 kW pellet boiler weighs from 200 to 400 or more kilograms, and is equipped with a hopper with a capacity of 150 - 300 liters. It is clear that the installation of such equipment can only be floor-mounted.

- Large combustion area for a pellet boiler. On average, one boiler requires at least 9 m2 of area, since according to safety requirements, the gap between the boiler and the wall (or other structures) must be at least 1 m on each side, and for a device with side service it is advisable to increase it to 1.5 m.

Pellet boiler in the boiler room

- The pellet boiler is absolutely dependent on electricity and cannot be used during a power outage.

- Loading pellets requires labor. The bunker is loaded manually; You can quite imagine how many kilograms of fuel you will have to carry on yourself if the capacity of the bunker is hundreds of liters.

- The boiler requires regular cleaning; with constant use, this should be done 2 times a month. Neglecting this rule can lead to damage to the fuel supply screw, and carbon deposits reduce the efficiency of the boiler.

- A separate large room is required to store pellets. If the house is used for permanent residence, then one heating season may require up to 10 tons of pellets - this is approximately 20 m3. You cannot store pellets in the open air or under a canopy: they are very hygroscopic (it’s not without reason that they are used to make inexpensive litter for cat litter boxes), and burning raw pellets leads to the accumulation of creosote in the boiler. Therefore, the main requirement for a room for storing them is good waterproofing, a more or less constant temperature and distance from sources of fire and strong heat.

Loading pellets into the boiler

Types and classification

By fuel

1. Pellet - only compressed granules are used.

2. Combined - the use of other raw materials as backup fuel (wood, coal).

By burner type

1. Retort - feeding pellets into a bowl “from the bottom up”, where air is pumped and where combustion occurs.

2. Flare - dosed supply into a horizontal tray, where the fire is inflated by injected air to form a powerful torch.

According to heat exchanger material

1. Cast iron - with a long service life and resistance to overheating, but heavy weight and poor impact resistance.

2. Steel - with a shorter service life, but more durable.

By download

- Automatic – pellet loading is regulated by programming by specialists;

- Semi-automatic – with manual adjustment;

- Mechanical – manual filling of the bunker.

By number of circuits

1. Single-circuit – only for operation in heating mode.

2. Double-circuit – the possibility of additional production of hot water.

Manually firing the stove with pellets

One of the simplest and cheapest formats for using such pellets involves manually adding fuel to the stove. For many people, this process seems unnecessarily complicated and incomprehensible, since the first time it is not possible to calculate the exact amount of fuel and the time of its addition.

After just a few times, you will be able to understand the features of the process and will easily control the flame power and the “operating” combustion temperature.

You can heat a stove with pellets in a conventional stove without significant modifications:

- The easiest way is to install a specialized basket in the oven. It has a fine-mesh structure, which prevents burnt pellets from falling into the ash pit. The cost of such products is extremely affordable, so every stove owner can afford it.

- If you want to do the work yourself without purchasing additional products, you should manually reduce the gaps between the grates. To do this, you need to re-weld the grate with a decrease in clearance or install a special mesh, which is made of thickened wire.

Using a pellet burner for a stove

Modernization of a wood-burning pellet stove by installing a burner device is optimally suited for heat generators operating using long-burning principles. After installing the burner, it is possible to achieve maximum heat transfer and economical consumption of pellets.

Converting the stove from wood to pellets is carried out by installing a mounted or built-in burner connected to a screw transmission and a fuel hopper. The design of the burner device consists of several important elements:

- The operation of an automatic pellet burner is controlled by a microprocessor chip. The controller selects the feed rate of granules and, in the event of an emergency, turns off the operation of the equipment.

- Transport feed – the equipment for organizing the supply of pellets includes: a screw feed, an electric motor. The nodes are connected to a controller that regulates their operation.

- Ignition and flame control system. Ignition is carried out as soon as the system starts. When the flame dies out, the pellets are re-ignited automatically.

A long-burning wood stove converted to pellets is economical. Given the availability of pressed pellets, heating costs are reduced by 30-40%.

The burner has a removable design. A long-burning heating stove operating on pellets and wood can be converted from one type of fuel to another within 10-15 minutes. For modification, there is no need for qualified assistance. It is enough to remove the burner and install the firebox door back.

Installing a pellet burner in a brick stove

Design Features

Main components:

- Combustion chamber - a combustion chamber with an installed burner, as well as two doors (inspection, cleaning).

- Convective - a built-in heat exchanger in the form of pipes or plates with a vertical, horizontal or combined arrangement for heating water (coolant) with hot air released during combustion.

- Ash pan is a container for collecting ash.

- Bunker – a container for storing pellets before feeding them into the firebox.

- Auger – for portion feeding into the firebox;

- Fan - to pump air in the absence of natural draft and maintain the combustion process.

- Control unit - for setting operating modes, combustion parameters, maintaining temperature.

Is it possible to burn a regular stove with pellets?

It was previously mentioned that pellets are extremely active in everyday life, but a special stove and burner system is required to ensure a normal flame and a uniform heat transfer process.

Despite a number of limitations, pellets can be burned without much difficulty in a conventional stove, however, the advantages of fuel in this format of use are often lost.

The main positive features of the material are:

- Long burning life;

- Low emission of smoke and toxic substances;

- High amount of thermal energy;

- Burnout uniformity.

Most often, minor modifications are required according to proven schemes. All of them differ from each other in their complexity, cost of implementation and the need for additional equipment. Despite all the difficulties, already in the first hours after the upgrade you will be able to forget about the difficulties that haunted you earlier.

Criterias of choice

Before purchasing, experts advise paying attention to:

- power - the simplest calculation is the ratio per 1 sq. meter 100 W, for example, for a room of 150 sq. meters, a floor-standing solid fuel pellet boiler with a power of 15 kW (100 W x 150 sq. m = 15,000 W) is suitable;

- Efficiency - as a rule, values are in the range of 85-95% with a direct dependence on the quality of the pellets;

- heat exchanger type – steel or cast iron;

- number of circuits - single-circuit or double-circuit if hot water supply is required;

- the volume of the bunker - depending on the needs of the user, as well as the characteristics of use;

- fuel supply - using a screw or vacuum with low noise level, but more expensive;

- additional functions: auto-ignition, self-cleaning, temperature sensors, GSM module.

Operating principle of a pellet stove

Pellet stoves are equipped with a special tank for a certain number of pellets. Pellets can be stacked on the side or on top. There are some differences: if pellet stoves are loaded from above, then their productivity is greater, but the quality of the pellets must be high. Side-loading pellet stoves require such a fastidious attitude to the quality of fuel.

The volume of the pellet loading tank may vary. The duration of operation of the furnace, as well as the frequency of loading fuel into the tank, depends on this. For most home and garden stoves, the standard period of operation without adding fuel is several days. The pellet stove has a control unit that regulates the intensity of the flame. You can use a thermostat that will be connected externally. During regular use, it will be necessary to clean the ash pan of the pellet stove at intervals of 1 week.

Where can I buy

It is better to buy popular models of pellet boilers in specialized stores of heating equipment for the home, as well as in representative offices of manufacturers of such equipment or their dealers. The best units offered by the best manufacturers, where you can not only visually inspect them, but also twirl them or listen to practical advice and recommendations - which company is better to buy, what they are, how much they cost, how to choose, what to pay attention to in order to avoid mistakes when choosing .

In addition, budget new items can be ordered online in an online store specializing in the sale of such products. In this case, help will be provided by popular aggregators, such as E-catalog or Yandex.Market, where product cards with the necessary information are posted - description, parameters and their comparison, photos.

Practical recommendations

Before you start assembling a pellet fireplace stove, you should decide what parts you need to purchase - we are talking about the burner and industrial automation. You should not experiment and assemble the burner yourself. Even if a lot of effort is put into it, its functionality may be very questionable.

It is best to purchase ready-made elements and use them later when assembling a pellet stove. If you make the boiler multifunctional, that is, provide it with a water circuit and the ability to work both on pellets for the fireplace, and on wood and coal, then in the future it can be modernized.

It is worth noting that heat exchange in these types of heating will differ only in the type of solid fuel and the method of its combustion.

The advantages of a universal boiler will be:

- If there are interruptions in the supply of pellets for the boiler, the boiler can still be used. To do this, remove one burner and put on another to heat the stove with prepared wood and coal.

- Alternatively, you can install a special burner in the boiler for burning natural gas or liquid fuel.

The combustion chamber is usually made of heat-resistant steel 5 mm thick. It is advisable to use ST20 carbon steel for these purposes, but the casing can be made of ST3 sheet steel with a thickness of 3 mm. The fire tubes and chamber doors are made of 6 mm steel, and the grate should be as much as 10 mm thick. In order not to bother with purchasing and assembling parts, sometimes it is much easier to purchase ready-made equipment.

If you make the boiler yourself, you will need a welding machine. The water grate must have very rigid walls. To do this, metal corners or pieces of reinforcement are sometimes welded onto them. At the end of the work, it is necessary to double-check the reliability of all welds. If flaws are found, they must be eliminated.

How to install

You can try to install a pellet boiler at home with your own hands if you have special knowledge or by using the Internet, where step-by-step instructions are provided. However, it is better to entrust the solution to this issue to professionals from a specialized organization that has a construction license, who will reliably install the unit during repair or construction.

Design must be completed before installation can begin.

Main stages

1. Preparatory:

- preparation of the premises;

- strengthening and leveling a fireproof base capable of supporting the unit;

- electrical wiring;

- installation of ventilation and chimney.

2. Installation and piping:

- installation on a hill, connection to the chimney of the gas-air duct;

- bunker installation, auger connection;

- control panel assembly;

- circulation pump piping;

- installation of an expansion tank;

- installation of automation for return control;

- wiring of backup power supply, installation of stabilizer;

- connecting the coolant and return circuits.

3. Commissioning activities:

- control of compliance with the project;

- leak testing;

- automation check;

- crimping;

- control start-up and parameter measurement;

- adjustment work.

4. First launch:

- filling the container with pellets;

- checking water pressure, replenishing it to the standard if necessary;

- opening the smoke damper;

- ignition - by control panel or manually;

- checking the compliance of the parameters with the project;

- stopping after burnout;

- control of coolant temperature to prevent condensation formation.

Common mistakes

- Lack of return temperature control.

- Unsatisfactory tightness of the gas circuit, decreased efficiency due to leakage of pyrolysis gas;

- Poor thermal insulation of the base, causing condensation and the release of harmful substances.

- The size of the boiler room does not comply with fire safety requirements, which does not allow servicing the bunker or auger.

Pellet boilers are characterized by efficiency, ease of operation, and long battery life. But optimal parameters can only be achieved if the equipment is correctly selected, installed and configured.

Enjoy the shopping! Take care of yourself and your loved ones!

Is there any point in doing this?

Often, a person who wants to install such a unit in his home is faced with the question of whether he needs to assemble a pellet stove with his own hands or whether it is best to purchase a ready-made option. It must be remembered that in the first case, a person will be able to create a unit that will fit the existing conditions in all respects, and in the second, he will have to use a structure that is ready for use, but does not take into account the individual characteristics of the room. If doubts are caused by the type of fuel used, then you need to know that pellets are a type of processed wood and agricultural waste, which makes the fuel efficient in terms of heat generation, but economical in cost. Such a homemade stove is environmentally friendly because:

- does not pollute the air;

- does not contain harmful components in vapors;

- do not require special fuel supplies, which eliminates the need to cut down trees.

It is important to remember: pellets must be stored in special conditions, as they ignite very easily, which can cause a fire in the room.

After weighing all the pros and cons, a person will be able to understand whether it makes sense for him to make such a boiler with his own hands or purchase one already ready for use.

Brands of automatic pellet aqua fireplaces

Aqua fireplaces are produced by leading manufacturers of solid fuel equipment. High-quality products are manufactured in Europe. Judging by customer reviews, the following models are worth purchasing:

- La Nordica Melinda Idro and La Nordica Graziosa Lux Plus are products of the Italian concern, characterized by the constant introduction of new technologies to increase heat transfer and automate the combustion process.

- EdilKamin Detroit and EdilKamin Boston are another example of the Italian approach to solving the problem of automation. Fireplaces operate in completely autonomous mode. The launch is carried out remotely.

- Palazzetti Martina IDRO LUX and Palazzetti Camilla IDRO - the manufacturer offers products made in modern and classic styles. Fireplaces have built-in and attached versions. If desired, cladding panels are supplied as an additional option.

- Klover Diva Plus is the difference between the series and its high thermal efficiency. The main purpose is to heat medium-sized houses.

- MCZ Ego Hydro and MCZ Club Hydro - a series of a German brand, are distinguished by high thermal efficiency and efficiency reaching 95.5%. The heat exchanger is made of gray cast iron.

- Hark ProAqua is a representative of the German school that produces solid fuel heating equipment. The models are distinguished by ease of setup and operation, and high operational reliability.

Best models

Fireplace installations Termal

Among the most popular lines of domestic and foreign manufacturers, one of the most inexpensive, high-quality and multifunctional, are termal pellet fireplaces. Today, the line includes about 20 different items.

Fireplace installations are produced in Russia, Italy and Macedonia. The production uses the latest and most innovative equipment.

The main advantages of the termal line include:

- The best and multifunctional equipment manufactured in European factories;

- Affordable cost, which is achieved through assembly work at factories in Macedonia;

- High-quality and high-strength materials ensuring easy use and durability of the structure;

- Possibility of fully autonomous operation in a given mode;

- high power and convenient connection;

- Uniform and efficient heating of the private sector;

- Possibility to use the installation as the main source of heating;

- Impeccable service, availability of all original parts, consumables and components.

Pellet fireplace Termal

Pellet fireplace for a small living room

Massive pellet construction

By choosing this type of heating, you get a lot of new opportunities:

- The design is completely ready for use. In order to connect such an installation it will take no more than one day;

- All work is fully automated. Some models can operate without refueling for up to four days. The newest models are controlled via a Wi-Fi Internet connection;

- Availability of a timer and several standard operating modes;

- Thanks to its small overall dimensions and universal design, such a heating structure can be installed in any room: living room, kitchen, bedroom, studio;

- A stationary system allows you to install your own individual chimney for such a unit;

- This line has fully automated control, which allows you to regulate the flow and level of heat, power, time, room temperature;

- The newest models are equipped with a digital interface that allows you to get maximum comfort when using.

Tip: after watching the video, pellet fireplaces, you can familiarize yourself with all the models in the termal line and choose the most suitable option for yourself. You can also learn more about all the most accurate, detailed characteristics and descriptions, as well as buy a fireplace at the lowest prices in our online store.