Quite often I hear from people that they cannot find a job or they always lack money. Once upon a time there were similar conversations in our family, but at one point I realized that something needed to change. A few weeks after realizing this, I came up with a brilliant idea - to start a business growing and selling tulips. Now this is the main source of our income. I’ll tell you in more detail later how all this happens.

Advantages

A fairly large number of types of greenhouses are produced in Russia, each of which finds its own consumer.

A wide variety of models are offered:

- glass, polyethylene and polycarbonate;

- frames made of all-welded steel pipes and similar ones made of collapsible ones; the frame is made of plastic, wood or metal;

- equipped with windows (most models), opening (“Delta”) or sliding doors (“Tulip”, “Botanist”);

- with a removable ("Convertible"), sliding to the ends ("Matryoshka"), sliding ("Botanist") or opening roof ("Umnitsa").

As for the “Tulip” greenhouse, this is a product patented in the Russian Federation and the Republic of Belarus. This type belongs to the new products of 2022, that is, a completely “fresh” design. Like any other thing, the Tulip greenhouse has both advantages and disadvantages.

The undoubted advantages include several characteristics.

- No snow load. The roof of the greenhouse can be easily moved during cold periods, which will prevent it from being damaged by the weight.

- Since the snow will fall directly into the greenhouse, it will cover the soil and prevent it from freezing. This, in turn, will allow the preservation of favorable soil microflora, which will have a positive effect on the growth and development of crops in spring and summer.

- The use of this type of greenhouse helps create a natural microclimate for plants, which leads to increased productivity.

- Ensure proper ventilation thanks to sliding roof sashes.

- Possibility of natural watering. If you move the roof flaps apart, natural irrigation will occur during rain.

- Polycarbonate is considered one of the most durable and easy-to-use materials.

- Ease of use due to design features. With careful use, the service life will be more than 10 years.

This type of greenhouse also has its disadvantages.

- The rapid loss of appearance of polycarbonate and its wear and tear compared to glass greenhouses, as well as the expensive replacement of failed areas.

- Supporters of traditional greenhouse designs do not approve of replacing the vents with sliding sides and moving them to the doors.

- There is also an inconvenience that polycarbonate is not included in the greenhouse kit and must be ordered separately. True, some summer residents, on the contrary, are happy about this, since you can choose the density of polycarbonate to your liking. Manufacturers explain the need to separately purchase polycarbonate by the fact that there is currently no representative office of the company in Russia, and supplies from Belarus are expensive and unreliable in terms of the possibility of damage to the material.

- The main disadvantage of this type is its price, which varies from 25,000 rubles. up to 46,000 rubles, which can be quite a significant amount for most gardeners.

If we compare the “Tulip” with the “Delta” greenhouse, which at first glance has a similar type of device, we can highlight the main difference: in the first version the roof and sides move, and in the second they rise. Accordingly, “Delta” and other similar structures require additional space when its doors are open. This is not required for Tulip.

Greenhouse "Flora-Cabriolet"

, Vladimir region. Factory website: https://7teplic.ru The frame is galvanized or painted. Profile 20 mm. The roof is removable. A foundation is required. The frame costs 28,000 rubles. + foundation for 4500 rubles = 32500 rubles.

Advantages: Straight walls – more usable area. You can order a galvanized frame.

Disadvantages: The painted frame will rust over time. Welded, welding seams rust. High walls have greater windage. Bulky, inconvenient to transport in a car. Not convenient to use. The edges of the removable roof are located at a height of 2 meters, making it difficult for short people to use. Before winter, it is necessary to completely remove the roof and put it away, and in the spring, insert a long three-meter sheet into the guides in place; this requires two tall people and a free space of 2-3 meters on one side. The length of the polycarbonate sheet on the roof is 3 meters; you need to have a free space of 2-3 meters on one side to use it. In summer, the sheets cannot be extended more than 20 cm, otherwise the wind will fray the free ends and may even tear them out of the guides or break them. There are no seals, the heat will escape through the cracks. The kit does not include high-quality, durable polycarbonate. Greenhouses “Flora Cabriolet” are equipped only with cheap polycarbonate from the KS Profplast plant without UV protection on the surface in the form of a film, but only “in bulk”. Such polycarbonate can be destroyed by the sun within 5 years. The walls are covered with weak, “lightweight” polycarbonate with a reduced density. Difficulty in self-assembly.

Tulip greenhouse with sliding roof and sides - a leader in comfort

Traditional greenhouses with closed sides, making it difficult to approach plants, and welded prefabricated arches, reducing resistance to loads, are being replaced by more reliable structures. Summer residents prefer durable products. The Tulip greenhouse with an opening roof and sides does not collapse under the weight of snow, allows you to conveniently approach the plants and get a rich harvest.

Accessories and additional equipment

The basic kit contains all the parts needed to build the basic model. It includes arches for 3 arches, connecting elements, screws, screws, nuts and everything for fastening the covering. For the basic kit, 2 sheets of cellular polycarbonate, the thickness of which is 4 mm, and 3 polycarbonate H-shaped profiles 6 m long are sufficient.

The basic model has dimensions: height - 2.1 m, width - 3 m, length - 2 m, but the manufacturer provides for expansion, or rather extension, of the greenhouse. If necessary, you can purchase additional packages with inserts, each of which extends the structure by 2 m.

The Orion greenhouse is already equipped with a ventilation system. It includes sliding roof sashes, as well as two windows and doors. If it will function in winter, then the room needs to be additionally equipped:

- lighting to extend daylight hours in winter and autumn;

- heating (electric or gas);

- irrigation system (the best option is drip irrigation).

You can also provide racks for boxes with seedlings and shelves for household tools inside the greenhouse. Important! In the instructions, screws, screws and studs are shown in actual length. In order to take screws of the required sizes for fastenings, they can be checked according to the drawn template.

Features of the Tulip greenhouse

The new design of the Tulip greenhouse with a sliding roof and sides has a number of advantages along with the traditional ones:

- reinforced “anti-storm” guide arc system;

- simplified assembly using a four-bolt “crab” system;

- reliable frame made of all-welded arcs;

- Attached is a video instruction for assembling the Tulip greenhouse;

- sheets do not stick when condensation accumulates;

- the opening mechanism of the roof and sides is equipped with rubber seals;

- polycarbonate is mounted in guide arcs;

- no foundation required;

- the opening roof and sides are resistant to wind and snow loads;

- Warranty period up to 15 years.

Types of pop-up greenhouses

For home cultivation of garden crops, greenhouses of standard dimensions are usually installed: 2x4 meters. Depending on the type of structure, the following types of structures are distinguished.

- Convertible . The frame resembles a bread box. The roof is not removable, but folds back or slides down along built-in grooves. If necessary, you can open not the entire roof, but only sections of it.

- Butterfly . It looks like an arch. The roof consists of several parts that rise when it is opened upward. If you plan to install a large structure, it is recommended to divide it into separate segments - this will protect the crop from hypothermia.

- Matryoshka . Greenhouses of this type are similar to the “butterfly” one, however, in this case, the roof parts are moved to the side, which allows both to completely open the space and to ventilate individual areas. No foundation installation is required, and the entire structure is easy to assemble and transport if necessary.

Advantages and disadvantages

Advantages of the Tulip greenhouse with opening top:

- galvanized solid-bent arches increase the reliability of the structure;

- the opening roof mechanism eliminates snow loads;

- natural microclimate increases productivity;

- the opening roof and sides allow the greenhouse to be watered with rain, which enriches the earth with minerals;

- the opening mechanism of the sides promotes natural air exchange - plants receive the necessary dose of oxygen every day without drafts;

- opening sides allow you to conveniently approach each plant;

- the opening top will help fill the greenhouse with snow, this protects the soil from freezing and preserves its microflora;

- the guides are made of galvanized profile and equipped with a rubber seal at the points of contact with polycarbonate;

- opening sides and roof promote natural pollination of crops;

- The warranty period has been extended to 15 years.

- when installed without a foundation, severe distortion of the structure is possible;

- it is difficult to mount the opening element of the sides and roof to the arches;

- plastic parts lose elasticity in the cold, forming gaps between the frame and the guides of the opening mechanism;

- the manufacturer is located in Belarus, which complicates the supply of spare parts, since Russian distributors do not sell them;

- The crab system becomes loose during operation.

How does it differ from analogues

The differences between the Tulip greenhouse and similar greenhouses are presented in the table:

Collapsible arches are susceptible to destruction in winter and in very windy weather. The structure is unstable.

Solid bent arches increase the rigidity of the structure. Increases stability.

Products are made from profiles with a cross section of 20*20 mm. The thin pipe cannot withstand harsh weather conditions.

The production uses galvanized all-welded pipe with a cross-section of 20*40 mm. This increases the reliability of the structure under loads.

Cheap H-shaped guides made of plastic cannot cope with the load. In winter, when exposed to snow, polycarbonate swells and is squeezed out.

The innovative guide system is equipped with a rubber seal. This improves the ergonomic properties of the design.

Complex assembly. Lots of fasteners.

Welded parts greatly simplify the installation of the greenhouse. The greenhouse remains to be assembled like a construction set.

An open roof does not provide adequate ventilation. When the door and roof are open, a draft occurs, which reduces the immunity of plants. The sides are equipped with expensive windows. There is no opening mechanism.

The sliding system raises the sides and lowers the roof, which allows you to ventilate the greenhouse in 2 minutes in natural conditions without drafts. There is an opening mechanism.

What can be grown in a Tulip greenhouse

One of the advantages of greenhouses with opening tops and sides is their versatility. Such greenhouses are perfect for growing fruits, vegetables and flowers. Often, a greenhouse is used to force tulips in early spring.

The structure is suitable for breeders. The innovative design allows you to freely approach plants and carry out the necessary experiments on them.

Correct calculation of the tulip growing scheme is the key to success

For the first time, we decided to organize our business so that the flowers would bloom right by March 8th - the day when they will become most in demand. To get the desired result by this date, we purchased the bulbs in mid-August, after which we ensured their storage at a temperature of +2-5 degrees until December.

In December, the male half of our close-knit team began preparing boxes with soil (I’ll say right away that sandy soil is ideal for forcing tulips). The prepared soil was laid out in boxes, and then the bulbs were planted in it. The ideal time to plant bulbs is mid-December.

Using the “anchor effect” will help you get the desired salary

Attitudes from childhood: how to change your money thinking and become richer

Banal laziness: 5 habits that can cause you to be considered incompetent at work

After planting, the boxes should be removed to a dark place where the temperature does not rise above +9-11 degrees. Here they should be kept for several weeks, until the first shoots begin to appear.

As soon as the emerging leaves reach 8-10 cm in height, you can transfer the boxes with bulbs to a prepared greenhouse, heated to a temperature of +15 degrees. In such conditions they need to be grown until the buds appear.

Design characteristics

New for 2022, the Tulip greenhouse with opening sides and a sliding roof is made from a closed galvanized pipe 40*20 mm. The ends of the structure are equipped with wide doors with built-in windows. A 1 m wide door connector allows you to bring a wheelbarrow into the greenhouse.

Dimensions

The manufacturer produces a product with a width of 3 m, a height of 2.1 m, and a length of 4, 6, 8, 10 m. The length of the greenhouse can be increased at the customer’s request in increments of 2 m.

The opening side element allows free access to plants from all sides, so it can be installed closely between beds.

The size of the Tulip mini-greenhouse with opening sides is 2000*1100*1000 mm. At the request of the summer resident, the mini greenhouse can be equipped with a galvanized bed, in which case its height will increase by 200 mm. The modular system allows you to increase the length to 4, 6, 8, 10 m, in multiples of 2 m.

Materials

The frame of the greenhouse is made of galvanized pipes with a cross section of 40*20 mm. The innovative four-bolt crab fasteners are made from UV-resistant plastic or galvanized iron. If you have a choice, it is better to choose iron elements.

The roof is covered with Standard or reinforced Premium polycarbonate with a UV filter. The guides are made of profile and plastic with a UV filter and sealing rubber bands along the contour.

Equipment

The polycarbonate greenhouse set Tulip is equipped with:

- supports;

- guides that open the sides and roof;

- arcs;

- installation diagram;

- polycarbonate;

- bolts, hardware, self-tapping screws and screws;

- crab fasteners.

Greenhouse “Nurse-Clever – Standard”

Manufactured by Metal Service, Novosibirsk. – the plant closed in 2019. Profile 20 mm. The roof can be opened with a winch. Foundation required, not included. Frame price from 19,400 rubles. + the cost of your foundation + lugs 1 pc. – 250 rub. (for reliable fastening of a frame 6 meters long, a minimum of 8 hooks are required)

Pros: The roof opens and closes quickly. Galvanized.

Disadvantages: Requires the purchase of a foundation. There are no dealers in the regions; frames are sent throughout Russia by a transport company. Difficult self-assembly. It is impossible to open part of the roof, for example, in the middle or along the edges, you can only open the entire roof at once. The winch may break.

Choosing a location for installation

The manufacturer guarantees that the greenhouse can be installed on any flat area. However, the structure is a reinforced structure, so assembly experts recommend building a foundation. It will be enough to build a log base from 100*100 mm timber.

The site on which the structure will be located must be in an open, sunny and windless place. A hard and level soil surface will protect the greenhouse from distortions.

The location of the greenhouse close to the house or barn will increase ease of use. Since there is always a need to carry buckets, boxes, and a fertilizer sprayer into it. But it is also necessary to take into account the proximity of the water supply point.

If the size of the plot allows you to squeeze the greenhouse only between the beds, you should leave space under the path for convenient passage.

Assembly and installation

Orion should be installed in an open area, at a distance of at least 2 m from buildings and trees. This is necessary so that in winter large snowdrifts do not fall from the roof of the house and the crowns of trees onto the greenhouse and damage it.

Important! Press washers are used to attach polycarbonate to metal so as not to damage the fragile material. Do not tighten the screws too tightly to allow room for thermal expansion. The assembly of the greenhouse structure must be carried out strictly according to the instructions, which are provided by the manufacturer complete with all the parts.

According to the manufacturer's manual, assembly is carried out in stages:

- Assembly of arched ends, the design of which includes door frames and base profiles. All pipes are connected using special screws and fasteners.

- The central arcs are assembled.

- The arcs and ends are connected by purlins 2, 2-1.

- T-shaped pegs are attached to the base.

- The diagonals of the finished frame are measured, and if necessary, the greenhouse is leveled.

- The pegs are buried in the ground to the ground.

- Doors and windows are assembled and hinges are attached to them.

- Polycarbonate sheets are cut into the required pieces and inserted into frames and screwed. Open honeycombs are sealed with tape. A door seal is also attached, which eliminates the risk of drafts.

- Door leaves (top and bottom) with screwed handles are attached to the frames.

- For printed sheets, the open honeycombs are immediately sealed with tape.

- The uncut material is applied to the end frame, screwed to the pipes, and then the excess part is carefully cut off with a sharp knife.

- The sliding roof panels are assembled. Pieces of polycarbonate are cut off, and the sections with open honeycombs are sealed with tape. Special metal corners are attached to the upper and lower edges of the polycarbonate, to which handles are pre-attached.

- The walls of the greenhouse are covered with polycarbonate as usual.

- Special H-shaped profiles are attached to the arches on top, along which the roof sashes will move. Prepared roof panels are inserted into these profiles. They should move freely in both directions all the way to the ground.

- The corners of the ends are sewn up with a special rubber seal.

Video: assembly and installation of a greenhouse with a sliding roof “Orion”

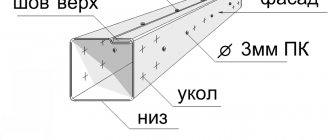

Assembling the Tulip greenhouse

To assemble the greenhouse, you will need the following set of tools:

- screwdriver with a cross and an 8 mm hexagon;

- 10 mm wrench;

- construction knife with a retractable blade;

- roulette;

- level.

It is recommended to install the Tulip greenhouse wearing cotton gloves with anti-slip rubber coating. In the selected area, it is necessary to level the ground and, if necessary, cover it with geotextile fabric.

If the owner decides to build a foundation for the greenhouse, it is necessary to lay a beam measuring 10 * 10 m according to the dimensions of the greenhouse on a flat, prepared surface.

The set is equipped with lugs. If the foundation is not being constructed, it is necessary to install these supports around the perimeter. The lugs are leveled to avoid further distortion of the Tulip polycarbonate greenhouse.

The base is mounted level on the lugs or foundation. Using the “crab system” all elements of the structure are secured.

After installing the base, it is necessary to check the level of the future greenhouse diagonally. Arcs are attached to the base in 1 m increments.

The ends are sheathed with polycarbonate. The remaining material is cut end to end with a construction knife with a retractable blade.

The ends are installed on the base.

The arches installed on the base are securely fixed with guides using the Crab system. This element gives stability and rigidity to the structure.

The erected structure is checked by level.

Polycarbonate is cut out according to the dimensions of the sidewalls and roof elements.

Guides for the opening system are attached to the arches.

The covering material is tightened into the grooves for polycarbonate and a rubber seal is laid.

Strengthen the connecting elements of the retractable polycarbonate structure with forks.

Check the operation of the installed greenhouse elements.

How to assemble a Tulip greenhouse on video:

Treatment of polycarbonate greenhouses in spring and autumn from pests and diseases

In a humid and warm climate, favorable conditions are created inside the greenhouse for the development of pathogenic fungi and bacteria, as well as the proliferation of harmful insects. Therefore, the greenhouse frame and soil should be disinfected. It is advisable to carry out such treatment in the fall, after harvesting, and in the spring, before planting new seedlings.

Autumn work includes:

- cleaning of all plant debris, supports and garters;

- processing of the frame and coating: wash the internal and external surfaces with warm water and laundry soap or liquid detergent, using a soft brush, sponge or cloth, then rinse with clean cold water; Do not use hard materials or abrasives;

- soil treatment: uncontaminated soil can simply be dug up and fertilized, contaminated soil must be treated with preparations containing copper, and in case of severe contamination, the top layer of soil must be removed and replaced with new fertilized soil.

In the event of a disease outbreak in a greenhouse, the soil and equipment should also be treated with special chemical or biological agents. In the spring, all stages of autumn treatment are repeated, but the use of chemicals should be avoided.

Don't compromise. Your garden deserves the best!

7 ADVANTAGES of a greenhouse with a removable top

1. Living soil

I think there is no need to explain the benefits of snow cover for the earth. In closed greenhouses, the soil freezes, beneficial microorganisms die, the soil becomes desalted and dries out - the soil has to be completely changed every 2-3 years.

In greenhouses with a removable roof, snow falls directly onto the beds all winter, covering our dear soil. This not only retains moisture in the soil and prevents it from drying out and turning into dust, but also protects against desalination. Natural snow cover also protects beneficial microorganisms in the soil from freezing. If you deprive greenhouse beds of it, the soil in them will quickly deplete. As experienced greenhouse growers are convinced, it is better to keep the soil in the greenhouse alive than to completely change it every two years, introducing new infections and parasites with the new soil.

As a result, we save time (no need to throw snow inside the greenhouse) and money (soil is expensive these days)

2. Frame strength

The most obvious one is that you don’t need to choose the most durable greenhouse that can withstand snowfalls in winter. Everything is simple here - no roof, no problem. Let's forget about supports, about weekend trips to the dacha to dump snow - we save time and nerves.

. If, due to inexperience, it seems that the snow is not so heavy, you are mistaken. In one winter, it will accumulate in the greenhouse as much as a whole company of soldiers would stand on it at the same time, and not just two people happily hanging, as is usually depicted on advertising brochures. It's tons and tons, and wet snow is especially dangerous. Unfortunately, even the most advertised “powerful” greenhouses have the ability to completely collapse in snowy winters. Also, you yourself may have noticed more than once in photographs and in life how the polycarbonate walls of the arched greenhouse bend inward - from the snow. This is no wonder, because the snow puts pressure not only on the roof. And this is a significant reduction in the life of the entire structure. There is only one solution - so that the snow falls easily and without obstacles inside the greenhouse and also accumulates near its walls, as well as outside. This equalizes the pressure.

3. Overheat protection

A removable greenhouse roof is also good for the summer. Even with vents, the temperature inside the greenhouse can reach as much as 45°C, and this is a direct path to pollen sterilization, the absence of ovaries and, as one would expect, not a single fruit. This is popularly called “overheating” the plants, which can be much more dangerous than letting them through. And it happens that even open doors at the ends of the greenhouse are not enough to save the plants from overheating, and the ventilation holes are even made small. It is easy to ventilate such greenhouses by opening one of the removable roof elements or all of them at once. In addition, such ventilation is uniform and draft-free, which is also very valuable.

4. Excellent illumination

You know very well how much light the plants in a greenhouse need. And the same quantity as in open ground cannot be found in closed ground. Even the highest quality polycarbonate absorbs some spectra - why not make the roof removable? Let the sun's rays caress the leaves of a tomato or pepper directly, and not with the help of artificial and dubious phytolamps.

5. Normalization of the microclimate

After all, it is under the top of the greenhouse that the hottest air collects. Such a roof is the most effective ventilation, while ordinary side vents often only chill the plants. Something similar was once implemented by Jacob Mittleider, and a removable roof is the next stage. But then you ask: why do most industrial greenhouses have windows either in the doors or above the doors? In fact, this is the simplest design solution and saving of metal, and not at all an exact calculation.

6. Saving on strength

And the most important advantage is that such a greenhouse can be built with a lightweight design and completely forget about supports. You can safely build even from the cheapest plasterboard profiles and no longer worry that they will not withstand snow loads. Why, then, with all the advantages, such a greenhouse is no longer located on every site? The fact is that many are still afraid of such a new product - they say that after a thunderstorm they will have to look for a roof in neighboring areas. That's why it's important to choose a good and stable design, agree. Those. We are talking about the so-called “windage” of the greenhouse, namely its resistance to wind. Although, we note, the owners of such unusual structures claim that none have flown away yet. And everything new is always met with hostility - over time, all those who have ever known the happiness of straightening a greenhouse that has collapsed from snow will definitely implement such know-how.

7. Simple design

Agree, a removable roof for a greenhouse is only needed when it can be removed easily, in a maximum of 10 minutes. Therefore, let's take a closer look at the proposed design option - these are meter-long polycarbonate sheets that slide down. Height 2 meters, two vents at the ends and two doors. There are trusses on the roof every meter, and a special profile with grooves is attached to each of them. Polycarbonate is inserted into them, which can be moved down with a slight movement of the hand. There is also a special clamp on the side, which is used when the roof is closed so that it does not move out.

Parameters and equipment

Width 2.8 m, height 2.2 m, two doors, two windows

Distance between arches: 1 m, 9 rows of ties + base

All-welded trusses and ends, made of prof. pipes 20x20mm.

Connection of parts - pipe to pipe (father - mother)

Painting color: white (powder painting made in Italy).

The base is 4 meters. professional pipe 30*20.