In modern construction conditions, polycarbonate can easily be called a universal material used in various fields. It is actively used in the construction of greenhouses, shopping malls, stadiums and train stations, as well as in private construction. It is significantly lighter and at the same time much stronger than glass, has transparency and is quite easy to install. However, the question often arises of how to join polycarbonate, what should be used for this, what points to consider and observe. This is exactly what today's conversation will be about.

general information

Polycarbonate is a polymer plastic in its structure. Its undoubted advantage is the high level of protection against temperature changes and exposure to ultraviolet radiation. Thanks to this, it is actively used in a variety of climatic zones and conditions, but the strengths of the material are fully revealed only if the installation technology is followed. First of all, this concerns the joining and fastening of sheets to each other; moreover, this will make it possible to carry out repairs to the building without any problems or complications in the future, if the need arises.

Preparing polycarbonate for joining

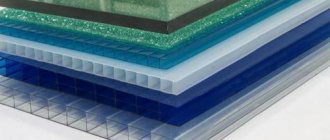

Polycarbonate is a solid, transparent, two-layer polymer material.

Both cellular and monolithic polycarbonate are used for outbuildings. The second is a solid slab and does not require preparation for installation.

Cellular - 2 thin sheets of polycarbonate, fastened together by numerous thin partitions. They form cavities that resemble honeycombs. This option is lighter than a monolithic one, bends easier, but can withstand fairly high loads.

However, panels with a honeycomb structure need protection. The ends of the sheets are open; moisture or even insects can get into the cavities inside the material. This happens if the sheets are installed at a slope. The ends should be closed. To do this, determine which edge of the slab is considered top and which bottom. The top one is sealed with a solid sealing tape to prevent water from leaking in. The bottom edge is sealed with perforated tape to allow condensation or rainwater to drain out.

If the sheets are secured with an arch, the ends do not need to be pasted over. This joining method for cellular polycarbonate does not allow leakage inside.

Advantages of polycarbonate

Among the many advantages of this material, there are several that play a particularly important role, namely:

- transparency, according to this criterion polycarbonate is practically in no way inferior to glass and can successfully replace it;

- in terms of strength, it is approximately 50 times lighter than glass, accordingly, the installation process becomes easier and more convenient;

- polycarbonate weighs little, in this regard it is much more profitable than glass;

- the material has excellent resistance to chemical influences;

- serves for a long time, maintaining proper aesthetic appearance;

- protects well from ultraviolet radiation;

- resistant to high and low temperatures, can be used in any climatic conditions;

- Polycarbonate has excellent thermal insulation properties and is also waterproof.

Polycarbonate, its types and advantages

Polycarbonate is a modern material that is often used instead of iron, glass or plastic. The material is made from polycarbonate granules, from which slabs are smelted. The latter, depending on their properties, are used in construction, medicine, and in the production of household appliances and electronics. In home construction, greenhouses and greenhouses are often made from it, for which polycarbonate is connected to each other.

There are several types of polycarbonate:

- According to the “honeycomb” shape (rectangular, triangular, honeycomb, cruciform);

- By color (colorless and colored);

- By the number of layers (two-layer, three-layer, multi-layer);

- According to the presence of ultraviolet protection (without protection, with protection on one or both sides of the sheet).

Polycarbonate has several important advantages. It is durable (10 times stronger than acrylic and 100 times stronger than glass), but flexible and bends easily. It can withstand temperatures from -40 to +120 degrees, but does not burn well. It is impact-resistant and lightweight, transmits light well and retains heat, and does not fade over time. The material itself is environmentally friendly, not afraid of water and rust.

Cellular polycarbonate Source domteplic.by

Before deciding how to join polycarbonate together, it is worth understanding its disadvantages. The last few:

- Polycarbonate is easy to scratch;

- It is destroyed by exposure to UV rays if protection is not provided;

- When exposed to heat, the material expands and contracts when cold.

When using polycarbonate outdoors, these features must be taken into account, for example, leaving a thermal gap between the sheets.

What methods of joining sheets can be used?

There are three main methods of attaching polycarbonate sheets to each other. The first option, based on thermal connection, is the most complex and can only be used if you have some experience in this field. The other two, which involve gluing sheets and fastening them with a profile, are much simpler and not so demanding of practical construction skills.

Fastening polycarbonate using gluing method

This method makes it possible to “hide” the connection point from the eyes of others. In this case, a special glue is used, applied with a gun; the manual method in this case is undesirable. For super-strong bonding, silicone adhesive specially developed for this purpose is used. It is also possible to use other options, for example, solvents with methyl chloride or ethyl chloride, as well as mixtures thereof. Any of the methods described above will allow, provided that the gluing technology is followed, to achieve not only an attractive appearance of the structure, but also to create excellent water resistance and thermal insulation.

Thermal fastening and joining of sheets using a profile

Accurate adherence to instructions and compliance with temperature conditions is the main requirement in this case. With this method, the connection of polycarbonate sheets is carried out as follows: two sheets are brought to a docking lock preheated to the required temperature, then, after it is lowered, the sheets are automatically placed in the place intended for them. If the design involves contact with water, for example, with precipitation, then care should be taken to create a small gap during the fastening process.

Initially, the panels have a standard size, so they need to be cut before starting joining work. This procedure is no different; it is performed using a regular hacksaw or circular saw.

The profile connection of polycarbonate sheets to each other also has its own characteristics. Here, in addition to the saw, you will also need profile fasteners, which have a standard size, which facilitates the installation procedure. The only difficulty, and even then, which is rather relative, will be to correctly calculate the number of such fasteners. Here it is important to consider in advance how many and where there will be bends and angles so that the result of the fastening is as reliable as possible.

The joining procedure should be carried out on an open and level surface; for example, a carpenter's table is perfect for this. For separate profiles, you need to take care of making a special strip, preferably made of wood and always flat. If you are building a greenhouse, then it is advisable to use the point fastening method using thermal washers and self-tapping screws. It is simple and easy to use; for example, it makes sense to use it when creating any arched structure.

Final stage

Upon completion of the installation of the sheets, the protruding, aligned ends are covered with a special profile, which will add rigidity to the structure and give it an aesthetically finished look. A transparent or end profile matched to the color of the material is also placed on the free ends of monolithic panels. In this case, it plays only an aesthetic function. Finally, a film is removed from the polycarbonate, which protects the material from accidental damage during installation work.

Aesthetic end profile made of aluminum

By following the installation rules, you can reliably connect two polycarbonate sheets together, creating a durable and aesthetic protective coating.

What tools and materials will be needed?

An undoubted advantage of polycarbonate is the absence of the need to use any special professional tools. To cut sheets of the required size, a regular hacksaw or circular saw will be sufficient. To connect the profiles to each other, factory fasteners are used, the number of which depends on the scale of the work.

Various operations related to joining polycarbonate sheets can also be performed with ordinary tools, for example, a drill, a screwdriver or a hammer with a screwdriver. It is advisable to carry out all work only on a flat surface, otherwise there is a risk of damage to the material during its connection.

How to connect polycarbonate to each other?

Polycarbonate is a universal building material, widely used in agriculture, construction and other fields. This material is not afraid of chemical influences, which increases its reliability and does not deteriorate its presentability. Polycarbonate does not deteriorate due to high temperatures, so it is widely used in areas with hot climates. The article will discuss how to connect sheets together, which is sometimes required when working with this material.

Linear profiles of detachable and one-piece type

Linear profiles come in detachable and non-detachable types; the first is the more complex option. In this case, the profile base is attached to wooden planks using screws, after which the polycarbonate panels are placed in the recesses and both halves are connected to each other using a special lock. To give the structure its final appearance, an external profile is used. Its use makes it possible to connect all the panels into one surface, as well as decorate the edges of the polycarbonate.

How to connect with a one-piece profile? In this case, polycarbonate is inserted into the grooves and after that the fastening system with panels is strengthened through and through with self-tapping screws. Here it is important to take into account the fact that it is advisable to take self-tapping screws that are equipped with either thermal protection washers or special gaskets with similar properties.

Material characteristics

Polycarbonate is a polymer based on ester compounds of carbonic acid. Using various methods, raw materials can be used to make building panels, various containers, medical equipment, ceilings and lenses for microscopes. The material is used very widely.

For the consumer, the following properties are of greatest importance:

- strength – much superior to both silicate and acrylic glass;

- light transmittance – quite comparable to that of glass – 75–86%;

Fastening accessories

- fire safety - unlike its acrylic “brother”, polycarbonate is a non-flammable substance;

- thermal insulation is much superior to glass, especially when it comes to cellular panels. In greenhouses and greenhouses, the use of polycarbonate can reduce heating costs by up to 30%;

- lightness - low density ensures low weight of the product with high strength. Installation of structures, as well as joining of slabs, is a job that can be done independently;

- flexibility - it is quite easy to give the panels a curved shape directly at the installation site.

Special and angular profile fasteners for joining

Since we are not always talking about flat surfaces and we have to deal with complex terrain, it is necessary to use corner fasteners. From an installation point of view, they do not differ in any way from linear ones and are also produced industrially. Usually one-piece corner profiles are used, which make it possible to decorate those areas where the joint is at an angle.

Quite often, certain difficulties arise with joining profiles at the ridge girders in the places where the slopes on the roofs are connected. A special corner profile is used here - “ridge”; its scope of application is usually greenhouses with hotbeds, as well as terraces of various types.

Important to know: During the installation process, you must leave a small gap between the profile and the panel, from two to five millimeters. This is due to the fact that polycarbonate panels expand under the influence of temperature and without this space the material will be subject to deformation.

Tips and tricks

To prevent polycarbonate sheets from deforming under the influence of temperature changes, it is necessary to leave a gap between them and the profile wall of at least 4 mm. The quality of the entire constructed structure is especially affected not only by the choice of connection method, but also by the implementation of preparatory measures. Also, if it is necessary to cut plastic, you should use a circular saw with a stop and fine teeth - this way you will be able to achieve an even cut. Chips must be removed without fail, otherwise the quality of the connection between the plates will suffer.

We join the material on the roof

To carry out such a process, you must first make a selection of rafters, which will subsequently serve as support beams. Rafters are usually chosen wooden, with sufficient thickness, about 0.4 centimeters, no less. The choice in favor of wood is justified in the sense that it is initially treated with special means that protect it from the harmful effects of the external environment.

The installation of the rafters must be carried out taking into account the dimensions of the polycarbonate sheet, otherwise the masonry pattern will turn out to be asymmetrical. Installation of polycarbonate begins with cutting out sheets of the required size; it is better to do this using a grinder so that the number of microcracks is as minimal as possible.

Installation of sheets on slings is carried out using self-tapping screws and sealed protective washers. Their task is not only to securely attach polycarbonate to wood, but also to protect the profile from deformation and subsequent destruction. The ultraviolet layer should be located on top; it can be recognized either due to special markings, or due to the presence of a dark film, which will then be removed. Fastening of honeycomb sheets is carried out with connections placed on top. In this case, the relevant question is how to seal the joints that have formed; in this case, the optimal solution would be to use a sealant that will provide reliable protection against moisture and leakage.

What it is?

First, let's figure out what it is - a docking or connecting profile. It's simple - this element is a long plastic strip with a certain structure inside (most often H-shaped). Intended for joining or connecting two sheets of cellular polycarbonate both in greenhouses and on various roofs, partitions, etc.

Docking profile for polycarbonate

The purposes of using a profile for polycarbonate are given below.

- Aesthetics . The joints between two polycarbonate sheets look neater and more beautiful if covered with a profile. In addition, if you pay attention to a polycarbonate roof that was joined without using a profile, you can see debris and dirt right inside the honeycombs - hollow channels that form in the structure of the material. And this, you see, significantly spoils the appearance. And if the dirt from the outside is easy to wash off with plain water, then from the inside it is no longer so easy to remove. The connecting (as well as the end) profile will help keep the inside of the polycarbonate clean.

Consequences of neglecting the docking profile

- Better sealing . The joining profile allows you to connect two sheets of polycarbonate without gaps or cracks. At the same time, it will hold them securely and firmly. With the help of this element, the sheets become like a single roof or wall. At the same time, there are types of profiles that will allow you to join corner parts.

- Easy to install . Usually, no one encounters any difficulties during the installation of this element.

- Easy dismantling . If necessary, the connecting profile can be quickly untwisted and removed. It will also make it easier to replace one of the polycarbonate sheets if necessary.

- Tightness . Due to the tight fit of the profile to the polycarbonate sheets, a roof mounted in this way will not leak.

- Beautiful appearance . A roof or wall using a joining profile looks much nicer and neater than without it.

Creating an optimal microclimate in a polycarbonate greenhouse

The joining profile is usually made of a transparent material - polycarbonate, which allows it to be used for both transparent and translucent structures that must be well lit from the inside. This element allows the roof or wall to retain its ability to transmit light as much as possible. It can also be made of aluminum.

Profile for polycarbonate clamping/docking, aluminum, AD 53-10

On a note! The joining profile can be made in various color variations - exactly the same as the polycarbonate itself. Most often in stores you can see yellow, green, transparent profiles.

You also don't have to worry about UV protection. The joining profiles are protected against harmful radiation - exactly the same as on polycarbonate sheets. They are convenient to use not only for double- and single-slope greenhouses, but also for arched and lancet ones. The fact is that the joining profiles bend perfectly within the permissible radius and they can be used to join two pieces of material on these types of structures.

Profiles for fastening cellular polycarbonate

Let us list the main advantages of using joining profiles.

One-piece polycarbonate profile

Covering the canopy with polycarbonate using a joining profile

Prices for connecting profiles for polycarbonate

connection profile for polycarbonate

Working with a canopy

At first glance, working with polycarbonate canopies is difficult, because you have to deal with different shapes, types and types of these structures. In reality, there are no particular difficulties, because this material has excellent ductility. It is not difficult to bend polycarbonate in the desired way, the main thing is to preheat it. A cold sheet should not be bent; it can easily become deformed and break.

The first step is to build a metal frame that will serve as a support and foundation for the entire structure. There is no fundamental difference whether this frame is assembled from component parts or purchased ready-made; in the latter case, the preparatory stage is even more simplified.

To directly install the canopy, wooden support slings are required. They are laid at the same distance from each other to create a symmetrical pattern. The sheets are fastened to the slings using self-tapping screws, after which the joints are placed and secured, for which complete parts are used.

As you can see, the installation of polycarbonate sheets is not particularly difficult; the main thing is to adhere to the manufacturer’s recommendations and carry out the installation in accordance with all existing rules.